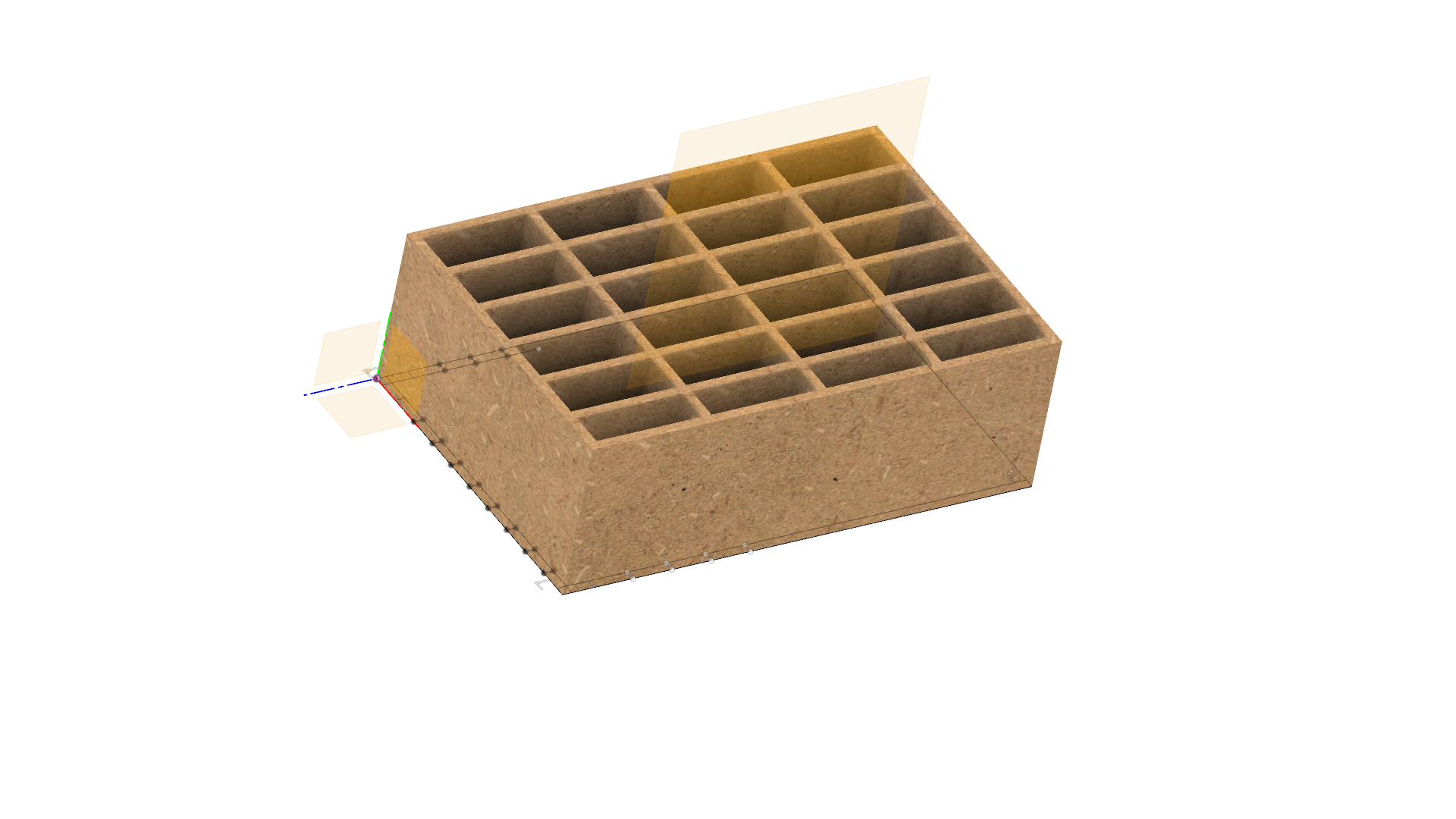

At the anorg kit sprint on 24. and 25th of February 2018 I used the time to 3D Model a pencil holder in Fusion 360 I downloaded in 2014 and adapted to 3mm plywood. I even laser cuttet it back then and sold it at the first Maker Faire in Paris 2014.

I always wondered how this mdf pencil cube was designed and I finally managed to do it with Fusion 360 this weekend. It was quite a challenge but I tought me a couple of new tricks of fusion. Many od

Thats like it looks like if you change the sides.

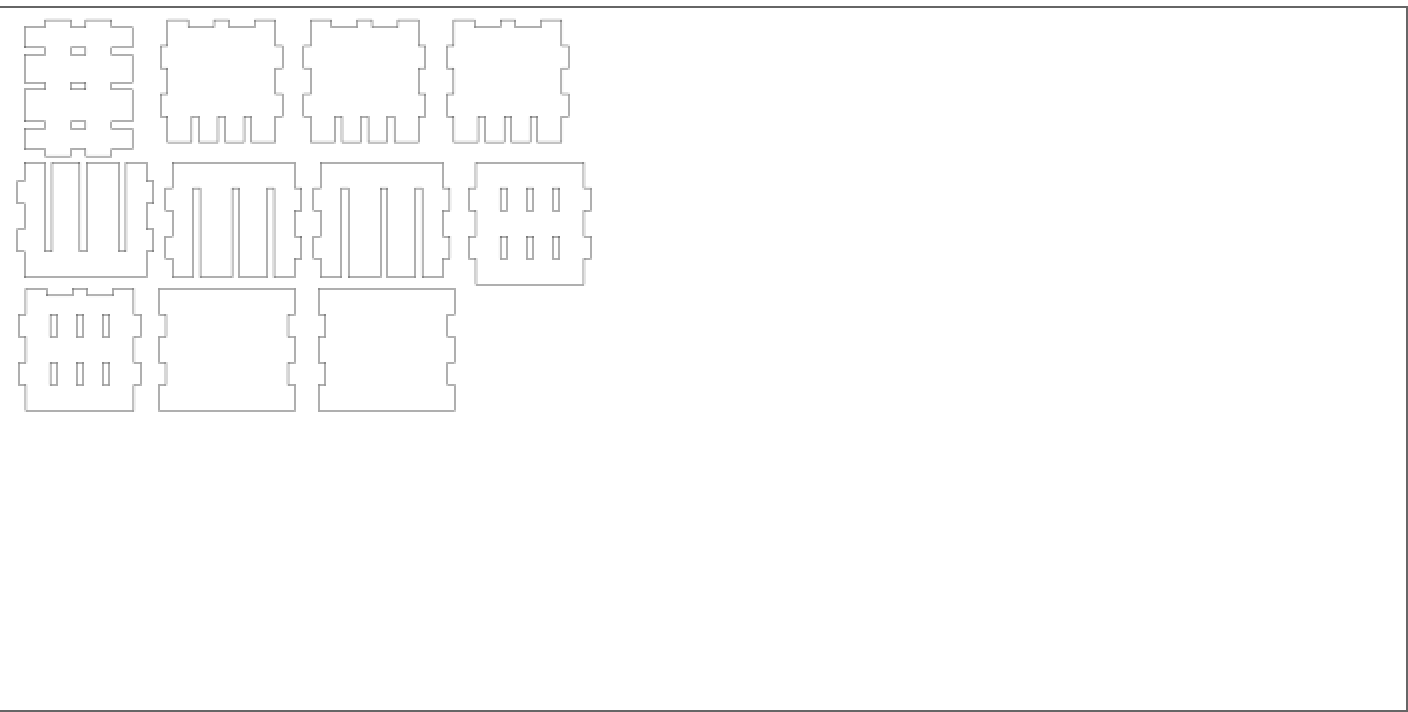

You can lay down the file flat with a Nesting tool and projecting all the sides on a sketch.

The pencil holder is paremetric in the length, witdh and the thickness of the material but I have not figured out how to make the number of holding spots. I want to also code this holder in openSCAD soon.

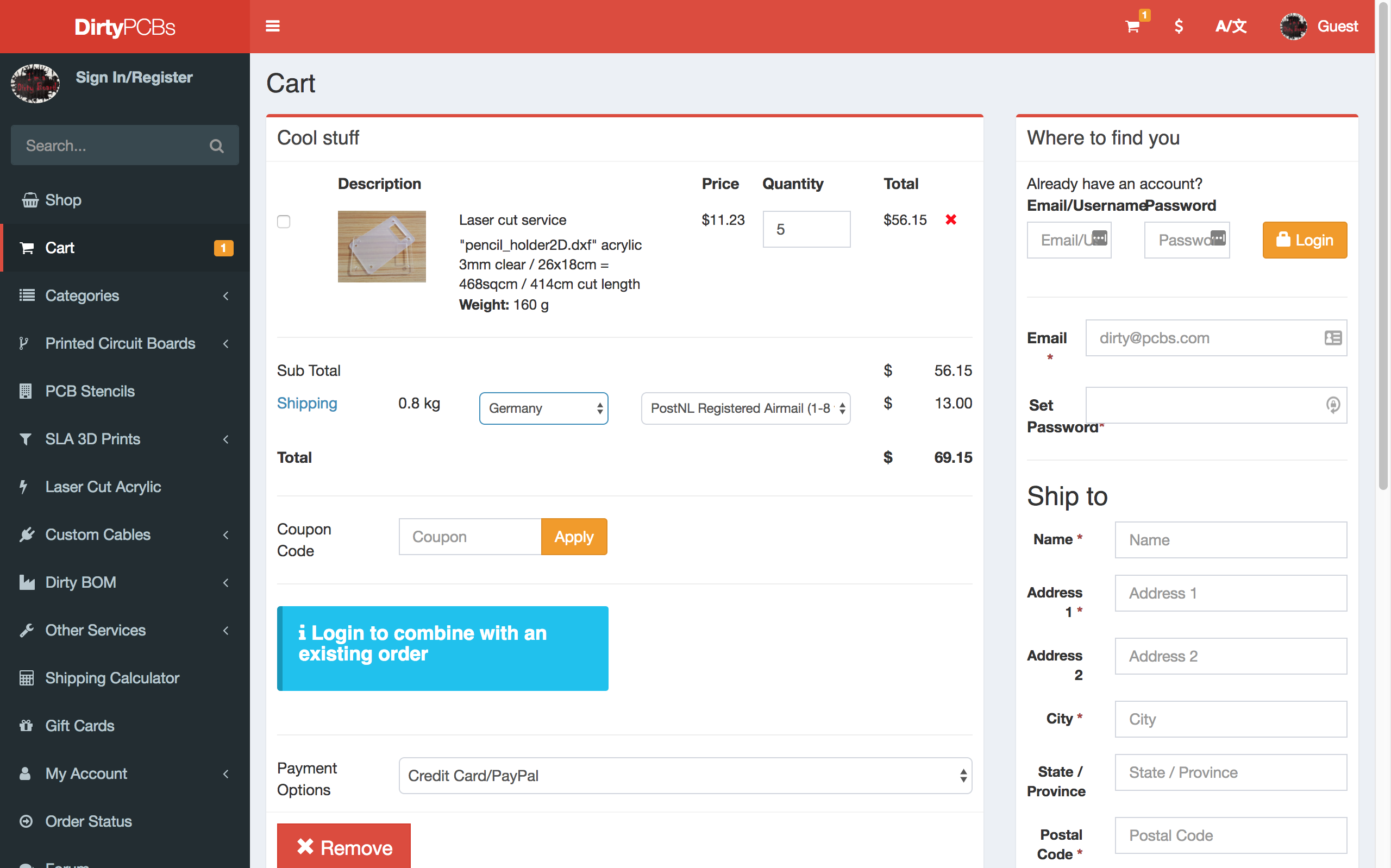

I also checked out Dirty PCB to find out if they provide laser services and found out that they cut 3mm plexi.

- get Fusion360: its free for students and hobbyists

- Nesting tool

- download the model, I continue working on it --> http://a360.co/2oGIFyE

- open Fusion and upload to your projects

- adjust paremeters

- mdf or other material + lasercutter

- laser cutting service (see below)

Sure you can go on and lasercut this box yourself but I wanted to explore if there is a way that somebody is doing it for you. Also there might be many people that do not have access to a laser cutter.

5 pieces will cost me with shipping $ 69.15 from dirtypcbs.

Then I also checked as a reference the lasercutting service formulor.de in Germany.

They also have great guide on how to prepare your file for lasercutting in inkscape, illustrator and corel draw.

I checked and one box would be 19,62 € plus shipping.

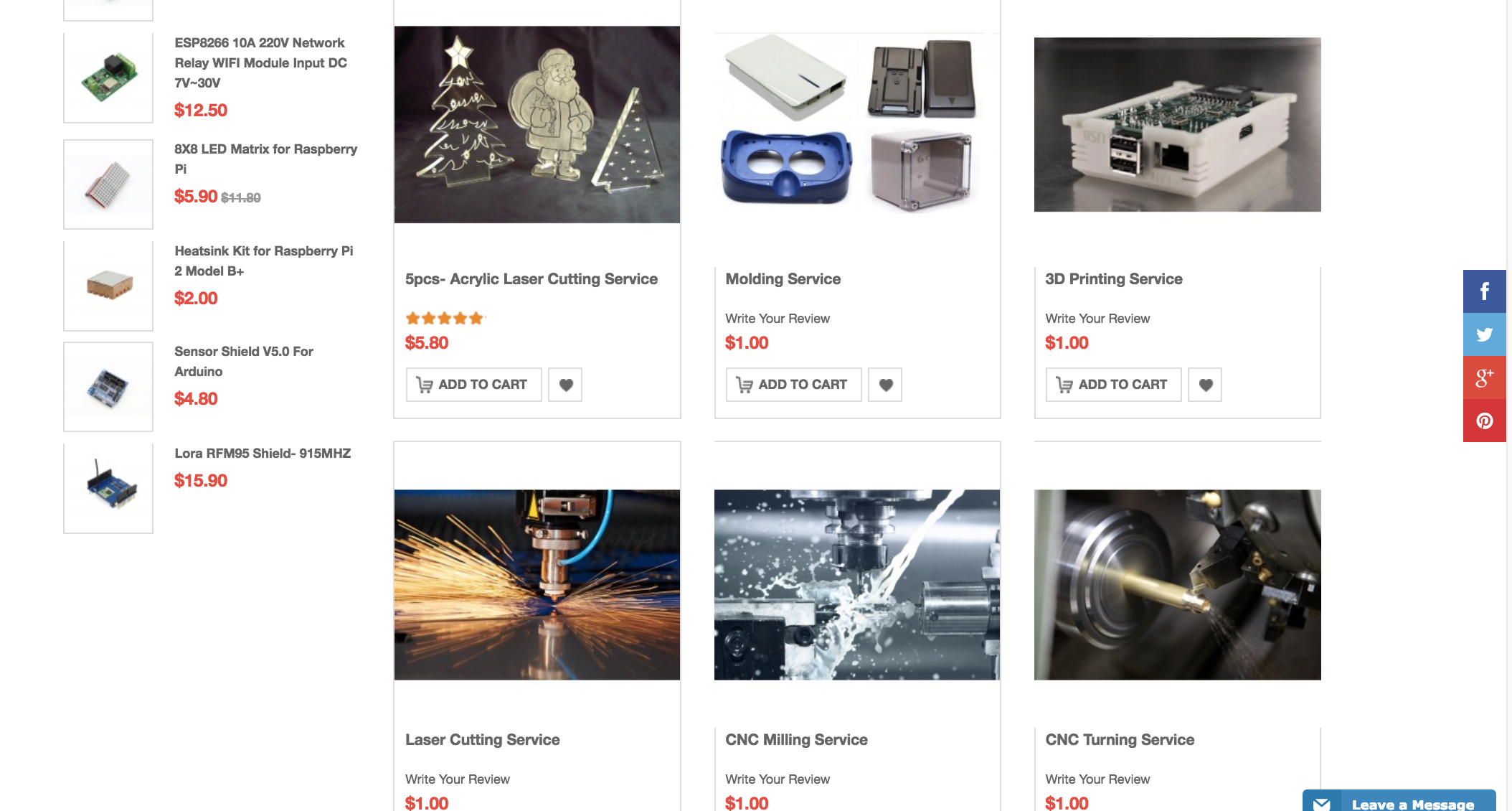

Then Radomir suggested a chinese services called elecrow were you can have your pcbs made but also they will lasercut, make a mold for you or cnc.

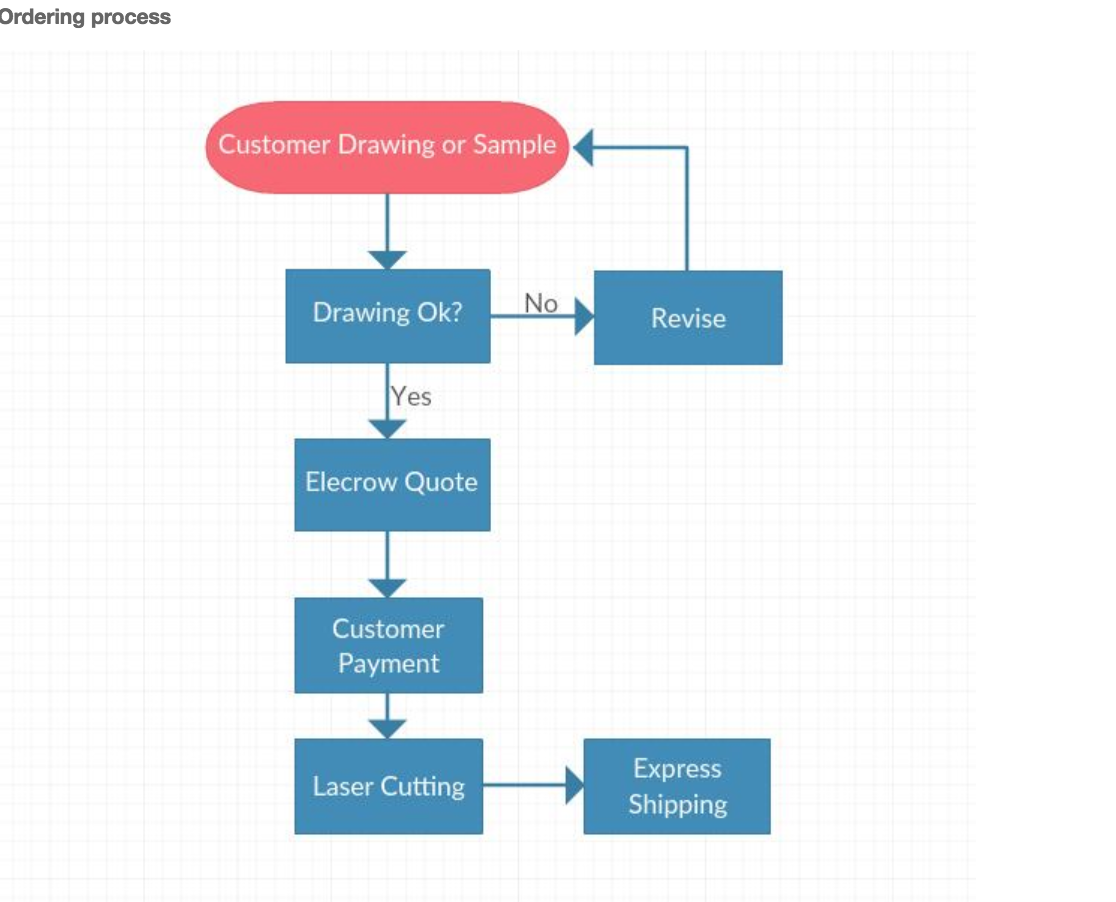

I also send the design to service@elecrow.com and they will come back with a offer. This is the process.

#How you can help?

- make the model in an opensource software like openscad, FreeCad, antimony, blender

- design the model in onshape

- design the model in solidworks

- I still have some problems that one extrude is not selecting the whole profil

#Contact

Andreas Kopp

#Credits

This design inspired me 2014 to get into laser cutting. The design was from YamashitaKen which I adapted in 2014 to be flat.

#Licence

This project is Public Domain (CC0 1.0 Universal (CC0 1.0). Nobody cares what you do with this stuff.

For more information, see license.