Arduino Nano firmware for my home-brewery

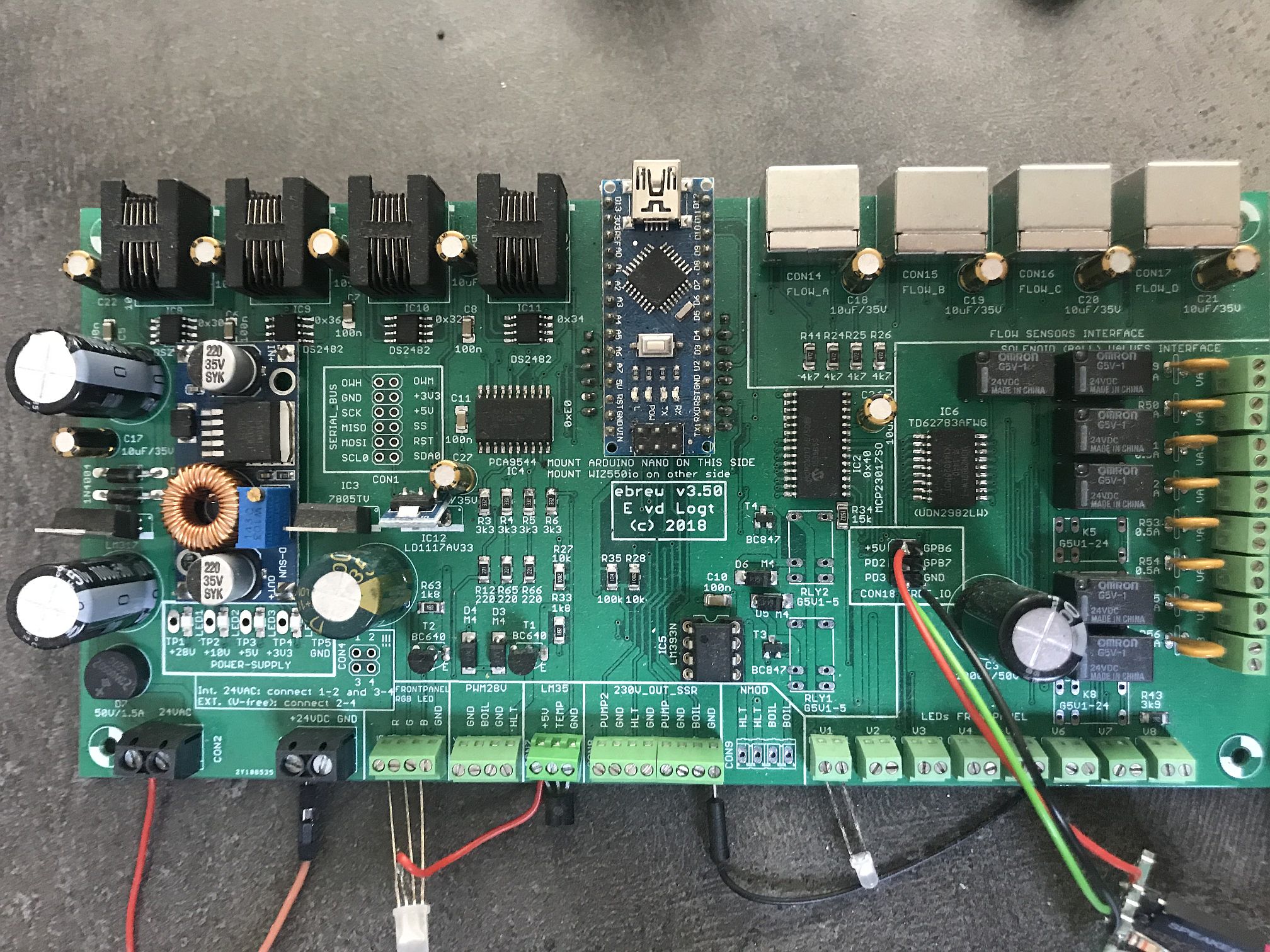

Top view of v3.50 of the main-PCB

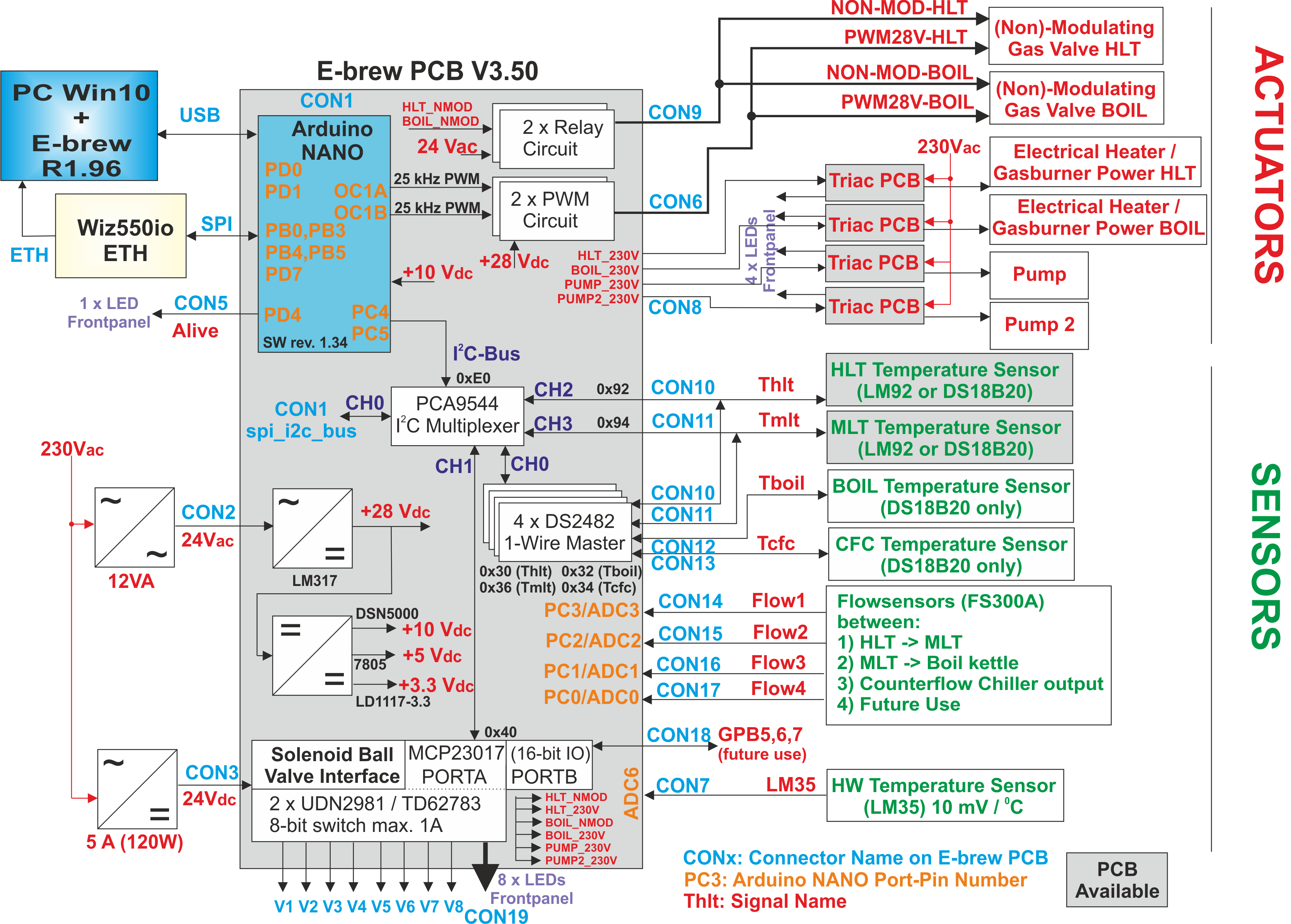

The current PCB and firmware have the following features:

- Reading a maximum of 6 x temperature sensors: one each for the three brewing-kettles, one at the output of the counterflow-chiller, one at the entry of the MLT return-manifold and a spare one that can be used as a backup for the HLT or MLT sensor. Both one-wire (4) and I2C sensors (2) are supported.

- Reading of the hardware temperature: this is to protect the Solid State Relays (SSR).

- Reading a maximum of 4 x flowsensors: between HLT and MLT, between MLT and boil-kettle, one at the output of the counterflow-chiller and one at the entry of the MLT return-manifold.

- Control of 8 x solenoid ball-valves at 24 V DC.

- Control of 4 x SSR at 230 V AC: the pump, a second pump (for the HLT counterflow-chiller), 230 V on/off for the HLT and the boil-kettle gasburners.

- 2 x PWM signals (25 kHz, 28 VDC) for the modulating gasburners (HLT and boil-kettle burners).

- 2 x SSR outputs for two HLT heating-elements. With this, heating of the HLT is possible with a gas-burner, with 1 or 2 heating-elements of with a combination of these.

- Ethernet and USB connection to PC: USB-connection is used for debugging, main connection between PC-program and the firmware is Ethernet.

Hardware architecture of PCB v3.50

More hardware and firmware design details: see my website: http://www.vandelogt.nl/uk_hardware.php

Use with Atmel Studio v6 or higher.

The Arduino-Nano uses a network cable as its main-connection to the PC. This is powered through a WIZ550IO module. It uses DHCP to obtain an IP address automatically. The standard port number for the firmware is set to 8888.

The Arduino-Nano also uses a virtual COM port as a backup connection to the PC. This virtual COM port uses the USB port of the Arduino-Nano. At the PC side, the Arduino Nano is recognised by Windows (if the standard drivers for the Arduino-Nano have been installed). Virtual COM port settings are (38400,N,8,1).

Typically the PC-program sends commands to the Arduino-Nano, like P0 (Pump Off) or P1 (Pump On). These commands are then executed by the Arduino-Nano. Although you can type in the commands manually, it is more efficient to use a dedicated PC-program for it, with a nice Graphical User Interface.

If you install the Arduino Nano PCB for the first time, it is best to use a terminal program that can handle a virtual COM port (I had good results with Realterm). At initial power-up, you can type S0 to retrieve the version number of the firmware (and to check that everything is working). The E1 command enabled the Ethernet module, if everything goes well, the IP address of the Arduino Nano PCB is returned.

More information about the PC-Interface can be found at my website: http://www.vandelogt.nl/uk_hardware.php#PC_INTF