This project solves the problem of long reverse bowden tube friction in 3D printers, specially as it pertains to MMUs (such as ERCF).The purpose of the filament buffer is to add a small amount of pressure to the filament path between the extruder and the spool via a stepper motor.

This mechanism is used to lift the filament up to the extruder, and to pull the filament down from the spool. The stepper motor is controlled by a PID loop, which is tuned to maintain a constant pressure on the filament. This pressure is measured by the HES sensor on the PCB. The stepper motor is driven by a TMC2209 stepper driver, which is controlled by an STM32 MCU.

Here you can find all of the files needed to build your own OpenAMS filament buffer, filament sensor, and stepper follower.

This is a work in progress, so please check back often for updates.

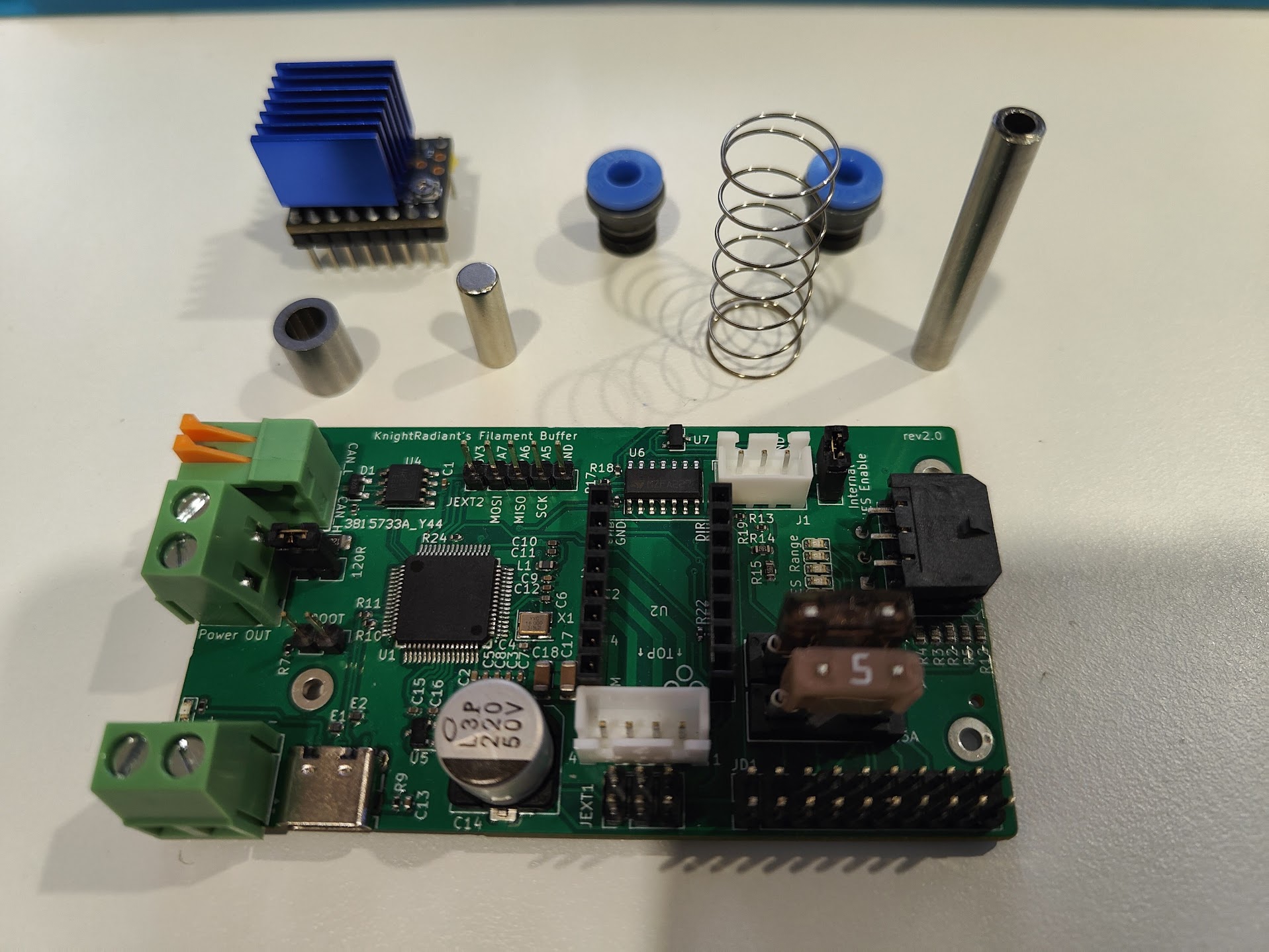

| Item | Quantity |

|---|---|

| ECAS04 | 2 |

| 8mm OD x 5mm ID x 10mm length oiless bearing | 1 |

| 5mm Diameter x 15mm length magent | 1 |

| 5mm OD x 3mm ID x 37mm length stainless steel tube | 1 |

| 13mm OD x 0.6mm wire size x 30mm length spring | 1 |

| TMC2209 stepper stick | 1 |

| ACE FPS PCB | 1 |

Print the following STLs:

Buffer Slider

Buffer Slider Base

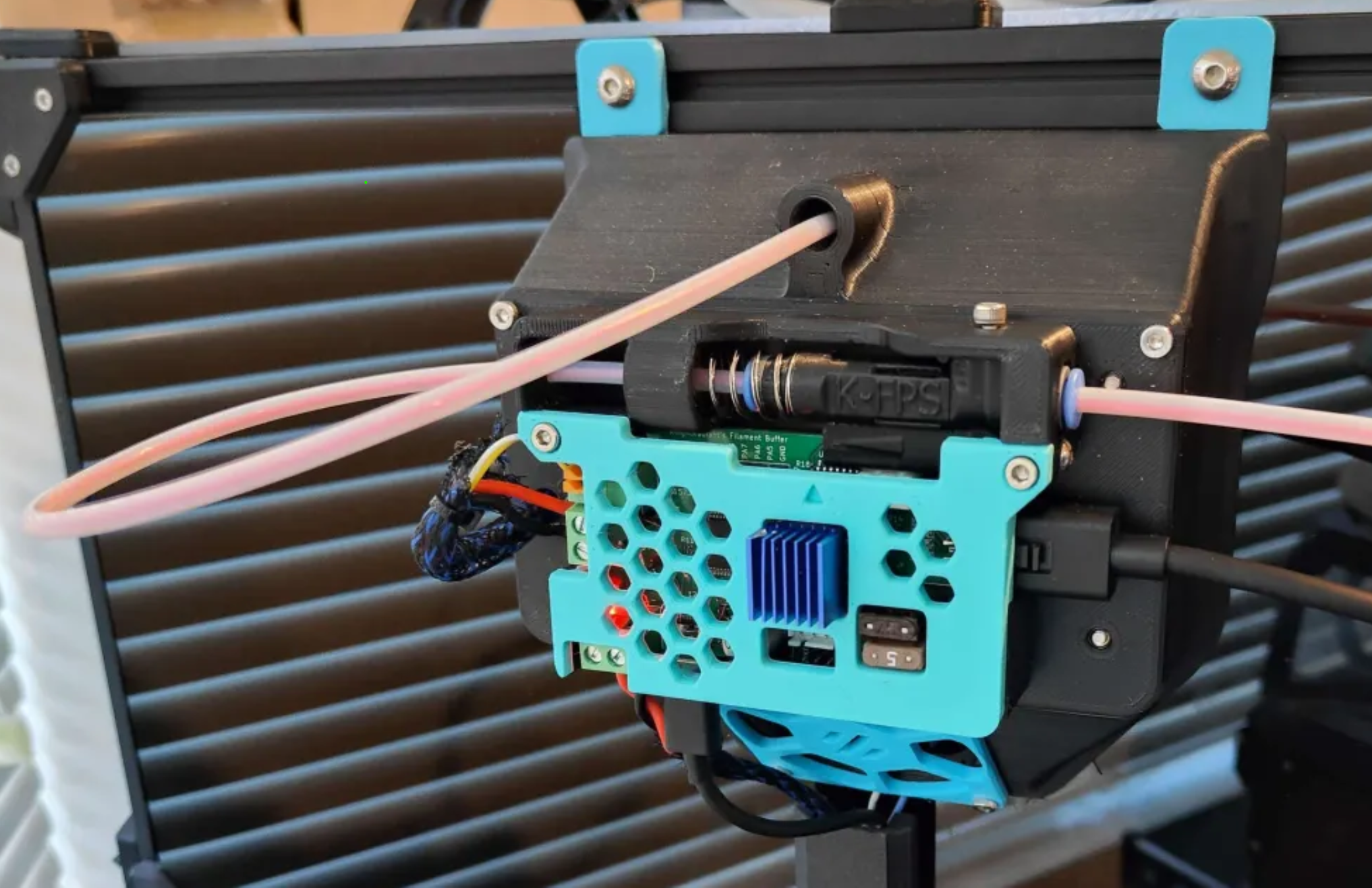

If installing standalone, print the following STLs:

If installing in the rear of a Voron Trident or 2.4, print the following STLs:

Font Case

Rear Case

Front Cover

Please add the contents of klipper/klippy/extras under the same folder of your klipper source code. Also the config file needs to be added to your klipper config folder and included at the top of your printer.cfg file.

The following GCODE commands are enabled, please include these on PRINT_START and PRINT_END, and PRINT_PAUSE and PRINT_RESUME macros:

ENABLE_STEPPER_FOLLOWER

DISABLE_STEPPER_FOLLOWER

It is recommended that during manual filament changes and filament loading, the stepper follower is disabled and the stepper follower extruder is unlached, as to allow the filament to move freely without the stepper follower attempting to maintain pressure on the filament.

For testing, the PID control loop for the follower can be set on the fly using the following command:

SET_STEPPER_FOLLOWER_PID KP=<value> KI=<value> KD=<value>

The config file contains a set of values that seems to work well for most printers, but you can tweak them to your specific needs.