We are group from NCKU CASLab undergraduate students. We are dedicate to solve the problem of solder joint detecting problem. Since inspecting solder joint defect by human eye is time consuming and low efficiency, we proposed a detection system combine with edge AI and computer. Our device could also work only with power supply and need no computer or laptop connect to it. Hope this AIoT device could solve the problem people long encountered.

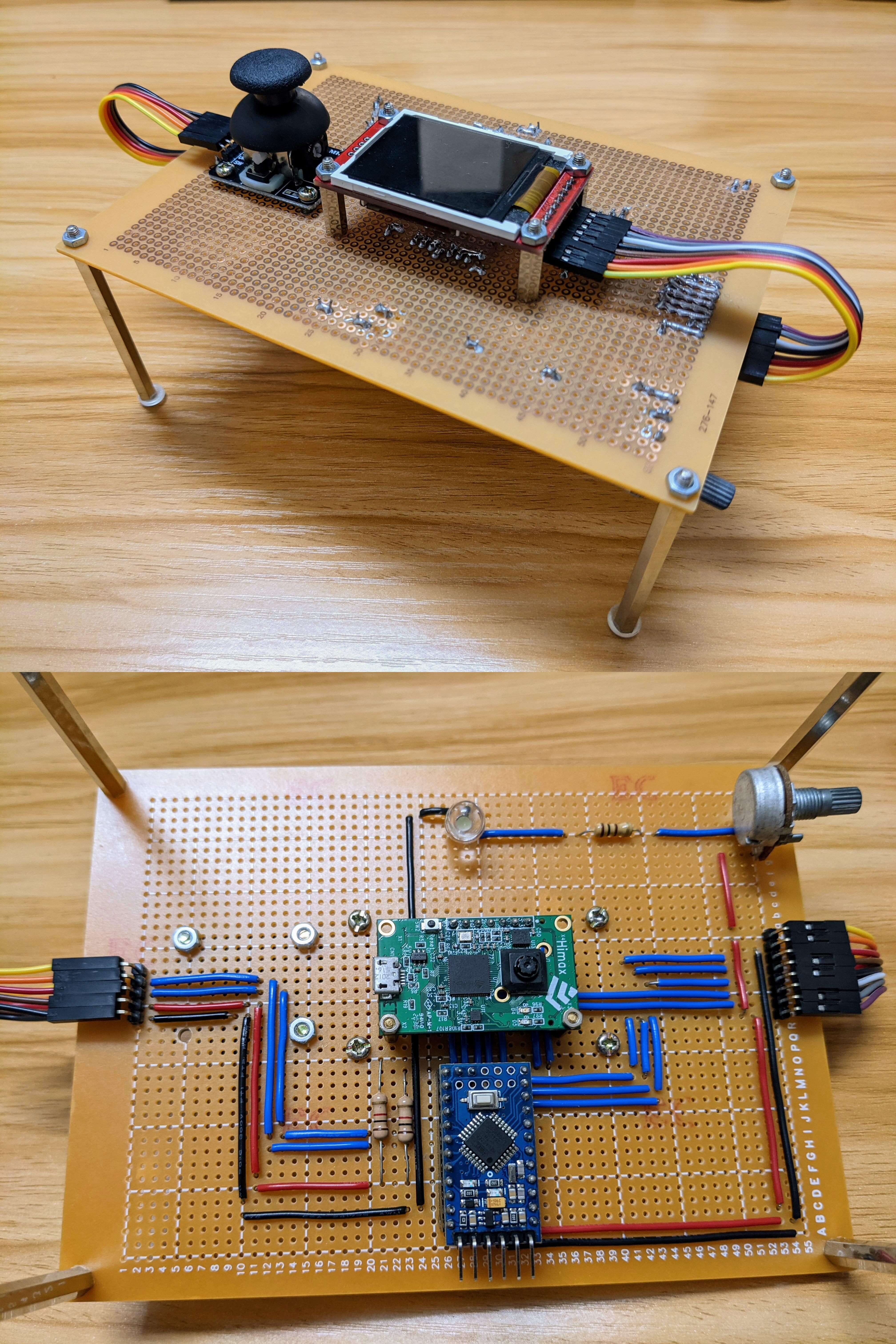

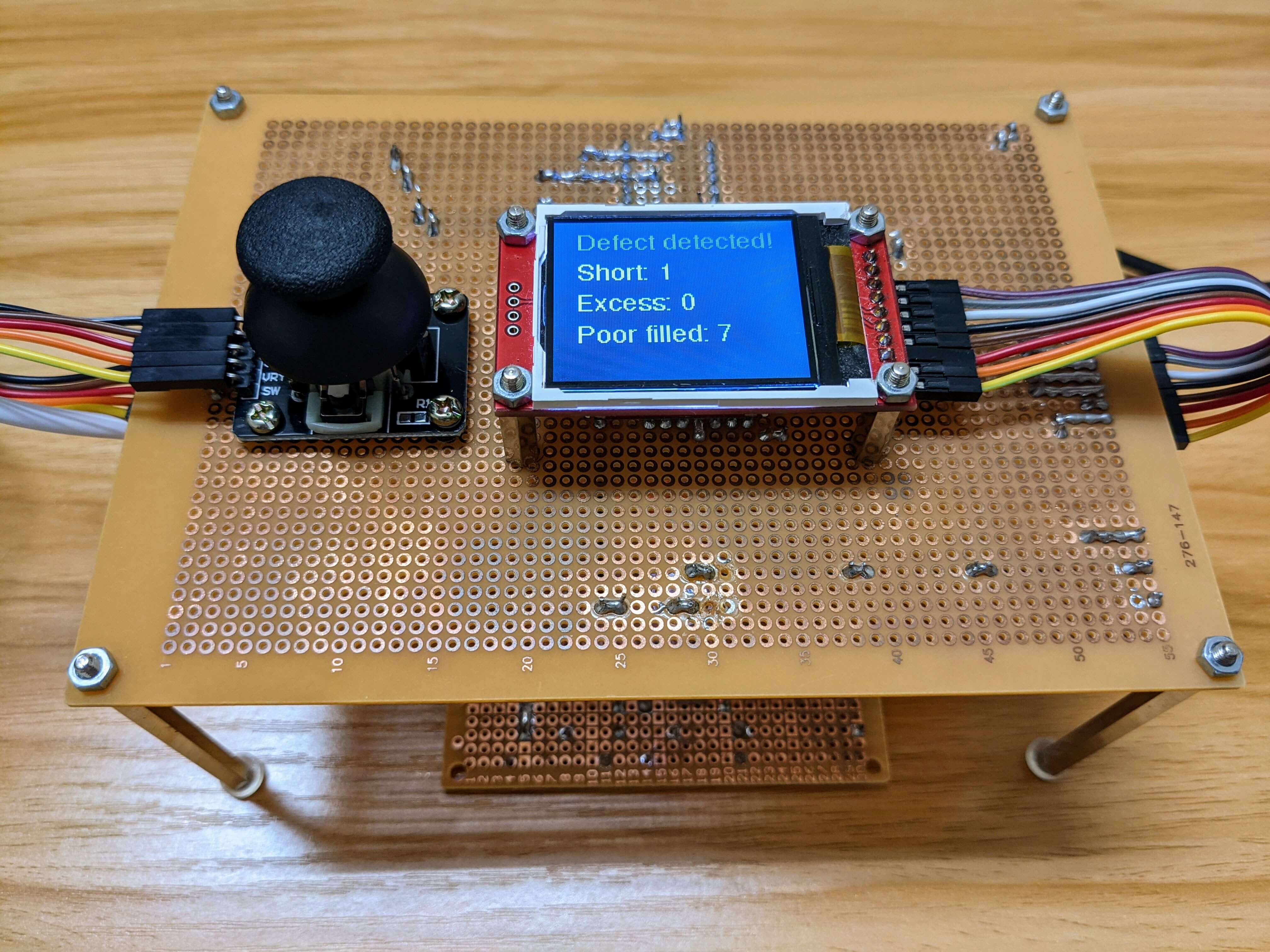

Device Image

-

Compile and generate image file for uploading to Himax WE-I Plus EVB

Before started, make sure that

lrzszandtkinter(often named aspython3-tkin most disto) is installed in your computer$ cd himax_tflm && make downloads # download himax sdk $ cd ARC_SDK $ make clean $ make && make flash

You should see

output_gnu.imgin this folder after this step. -

Deploy image to Himax WE-I Plus EVB, we use

minicomandxmodemhere, connect Himax WE-I Plus EVB to your device first$ sudo minicom -s # configure minicom baud rate to 115200(minicom) press 1 on keyboard and reset on WE-I Plus (minicom) press 1 to upload image (minicom) select xmodem and choose the image file (minicom) after uploading image file, press reset on WE-I Plus -

Deploy Arduino pro mini

- open

tft_display/tft_display.ino - plug in Arduino pro mini and upload the program

- open

-

Computer library settings

-

requirement: Python 3.9.6, pip 20.3.4

-

install pip libraries with

$ sudo pip install -r requirements.txt

-

-

With computer / laptop

-

Make sure Himax WE-I Plus EVB has been connected to computer through micro USB cable (should be able to transfer data), Arduino is optionally powered

-

Use

pyserialto receive messages from Himax$ sudo python SerialGui.py usage: SerialOut.py [-h] [-p PORT] [-b BAUD] [-t THRESH] [-i IOU_THRESH] optional arguments: -h, --help show this help message and exit -p PORT, --port PORT specify the port of WE-1 Plus -b BAUD, --baud BAUD specify the baud rate of transferring image and predictions -t THRESH, --thresh THRESH specify the thresh of detecting -i IOU_THRESH, --iou_thresh IOU_THRESH specify the iou thresh of detecting

-

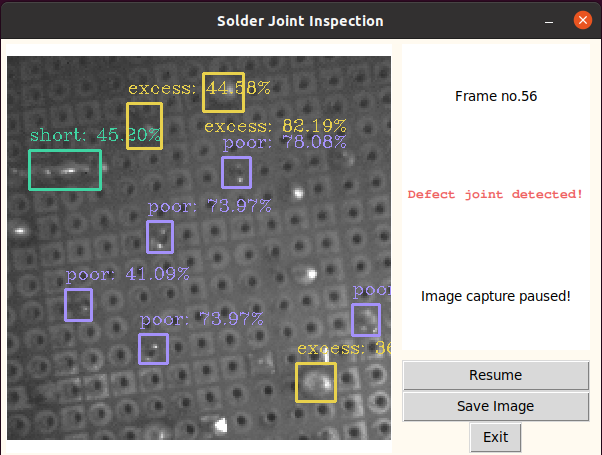

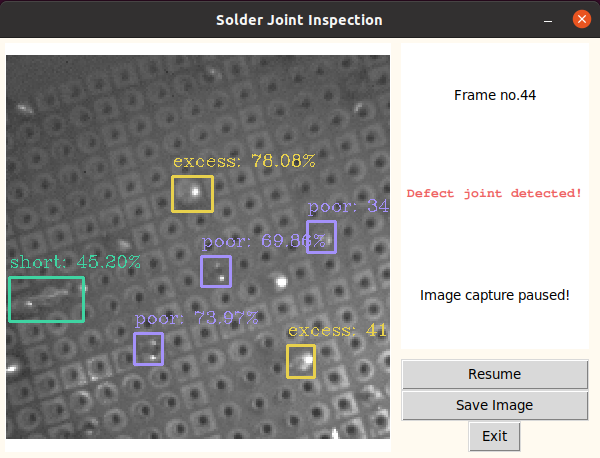

After start signals were sent from WE-I Plus, one can see the detection result from the screen

-

To save current inference picture, press

SPACEto capture; to exit from the program, pressESC -

GUI buttons are available to use, here are functions provided

- Pause: pause image capturing, after the button is clicked, it will become Resume button

- Save: save current inference result picture

- Exit: exit program

-

-

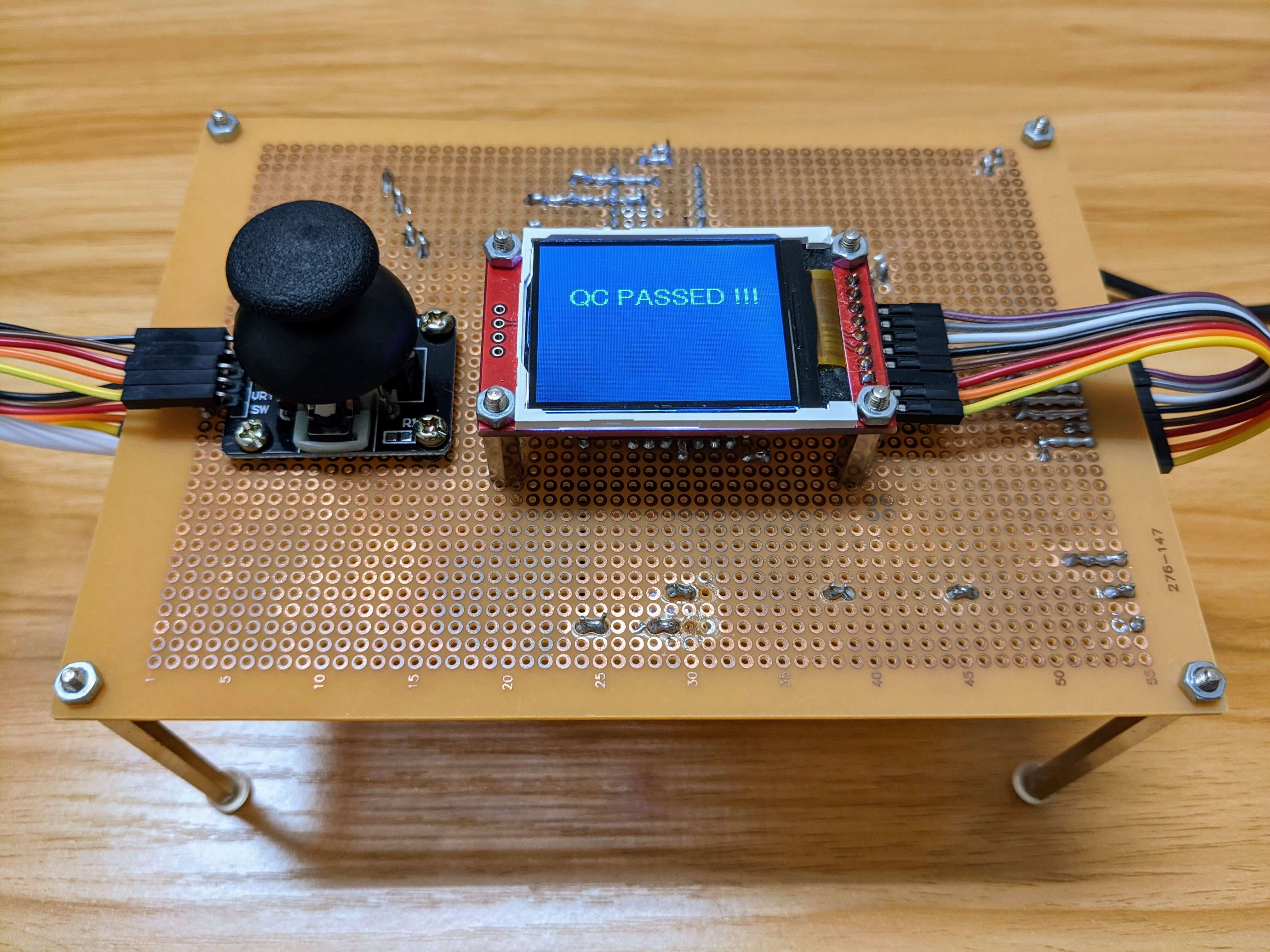

Without computer / laptop

- Power up WE-I Plus and Arduino, one should see the QC test result from the TFT display, there were two results:

- QC PASSED! - indicates that there were no defected joint detected on the current frame

- Defect detected! - indicates that there might have some specification problems on the current frame, the amount of defected joints of each classes would also been shown

- Power up WE-I Plus and Arduino, one should see the QC test result from the TFT display, there were two results:

-

Note

- If the scene is too dark for you, you could alway adjust the variable resistor on the board to adjust the light for better inferencing environment

- You could adjust the image region by controlling the joystick, the supported direction is up, down, left, right, with high threshold to glitch

-

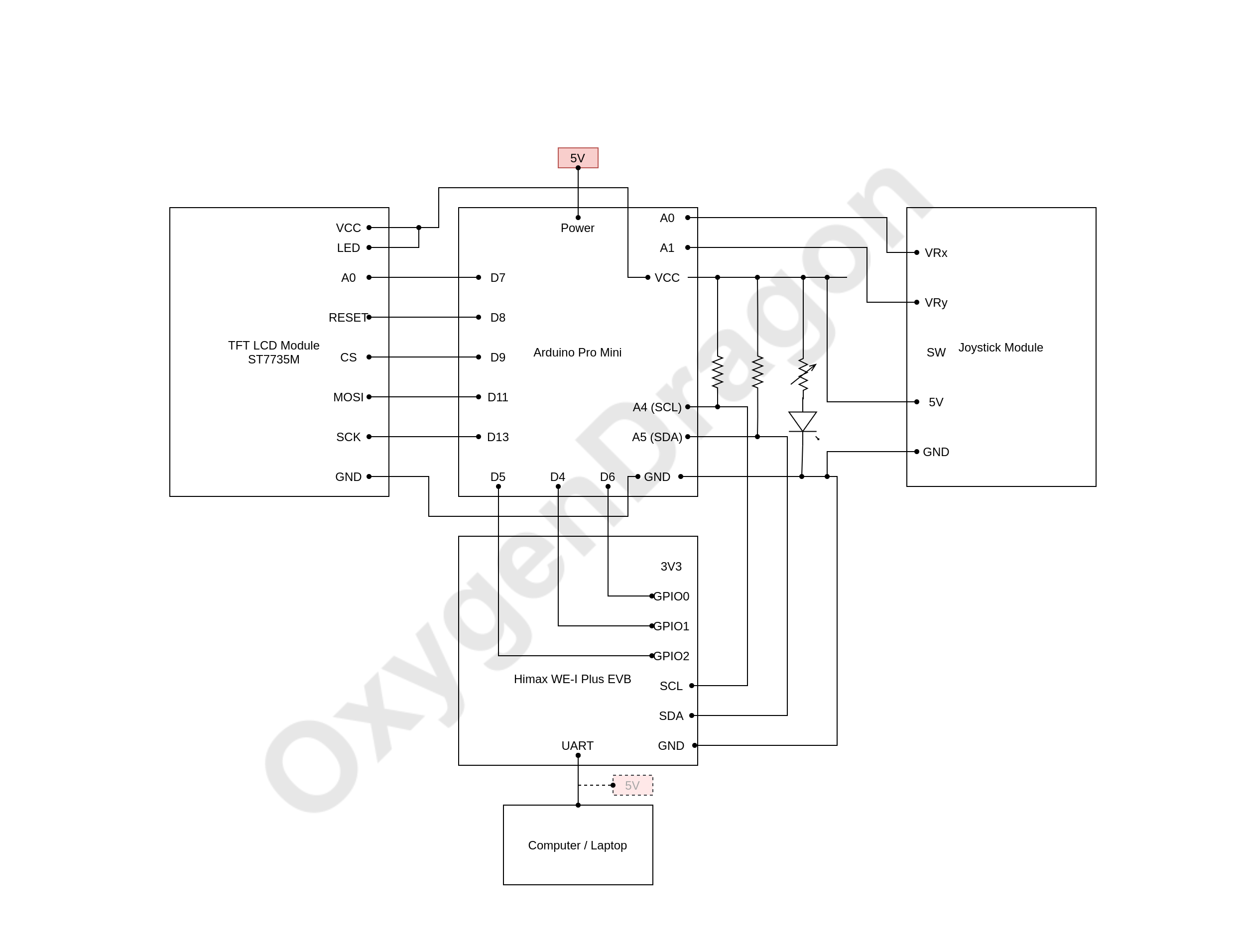

Develop board / modules

- Himax WE-I Plus EVB - edge AI inference development board

- Arduino Pro Mini - development board for decoding output from WE-I Plus and send to display

- ST7735 - 1.8 inch TFT display for displaying basic information of current captured frame

- Joystick - Joystick module for controlling the position of interest image region

-

Schematic Diagram

Schematic Diagram

-

Model on WE-I Plus

-

TensorFlow Lite for Microcontroller

-

Converted and pruned from yolov3-tiny

-

Dataset: captured from self-soldered boards, total number of 921 pictures

-

Input: (1, 384, 384, 1)

-

Output: (1, 24, 24, 24)

-

Performance:

- mAP: 80.52%

- Poor joints AP: 70.73%

- Short joints AP: 87.90%

- Excess joints AP: 82.91%

-

Implementations

Since the original yolov3-tiny model was too large to fit into the microcontroller, we have made some improvement on it to make it suitable for our project. Since the height of our device is fixed, the size of joints would be mostly the same, thus, we decided to prune off one of the branch of the model that is used for detecting larger objects. And in order to make further improvement on the model size, we have make some of the filters smaller, the comparison with original yolov3-tiny is as the following table

yolov3-tiny optimized yolov3-tiny original .weight size 604 KB 34.7 MB mAP 80.52% 81.41% output number 1 2 activation function relu6 leaky relu for further model details, you could use

netronto checkARC_SDK/src/model.tflite -

Quantization

To further decrease the model size and make it more suitable for hardware device, we have do

int8quantization to our model, the tflite model size has decrease from 591 KB to 164 KB with slightly accuracy loss.

-

-

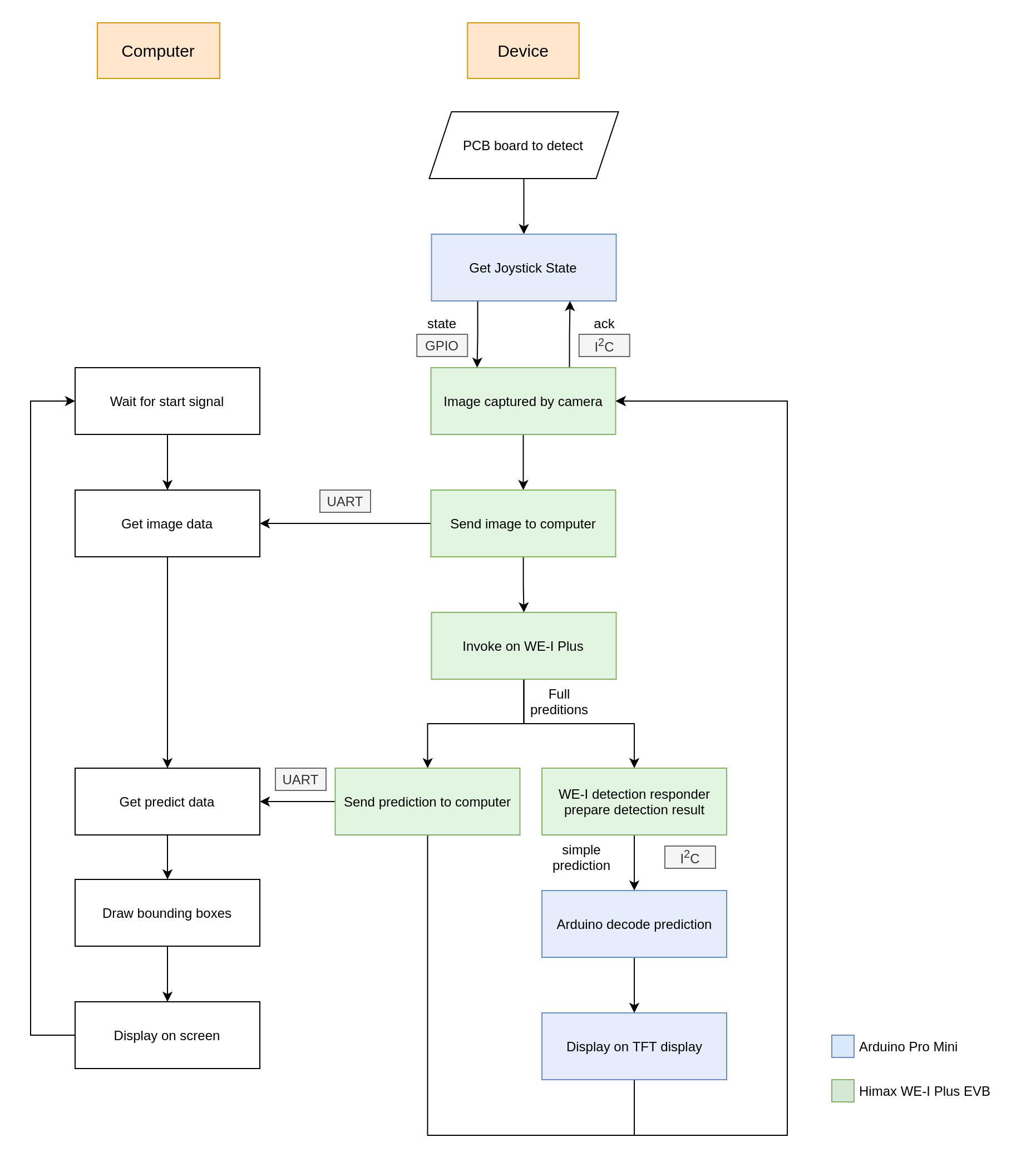

Flow chart

Flow chart

-

Explanation

Our system is able to operate with/without computer connection. With computer connection, the required data, such as image, predictions, would be sent to the serial through UART protocol. After gathering sufficient requirements, our program would draw the bounding box on the image received by the prediction. Though this may consume some time to decode the predictions to bounding boxes, we have reduce lots of calculation time with substituting the output sigmoid function with relu1, which need not to have lots of exponential calculations.

On the other hand, the TFT display would also shows the texts indicating the amount of each classes of defected joints if the Arduino is powered up. It provides the fastest way to have the user interact with the device, so the device could work even if the computer is not in present!

| QC passed condition | Defect detected condition |

|---|---|

|

|

| Result 1 | Result 2 |

|---|---|

|

|

- Get Joystick state: 0.081 sec

- Get image (including transfer data to computer): 0.536 sec

- Invoke model: 0.575 sec

- Predict results (including transfer data to computer): 0.749 sec

- Frames per minutes: 30.9 frames