This is a mod of the original, gorgeous Horizon. Changelog:

- Removed 2 columns

- Fully wireless: added battery connector & power switch

- Replaced Horizon logos with Tool (band) heptagram graphics

Horizon is a 44 key (4x12) ortholinear keyboard, powered by an Arduino Pro Micro.

This keyboard is a grid of 1U keys with no special features: no hotswap, no RGB, no OLED screen, no knobs.

gerbers: Gerber files for PCB manufacturinggraphics: Source assets for PCB silkscreenkicad: KiCad project files (schematics and PCB designs)kicad-libraries: KiCad components and footprintskicad-plugins: KiCad Pcbnew Python pluginsimages: Images for project documentation

Two separate PCB designs are available for MX and Choc keyswitches, with their respective footprints and key spacing (MX: 19mm x 19mm, Choc: 18mm x 17mm).

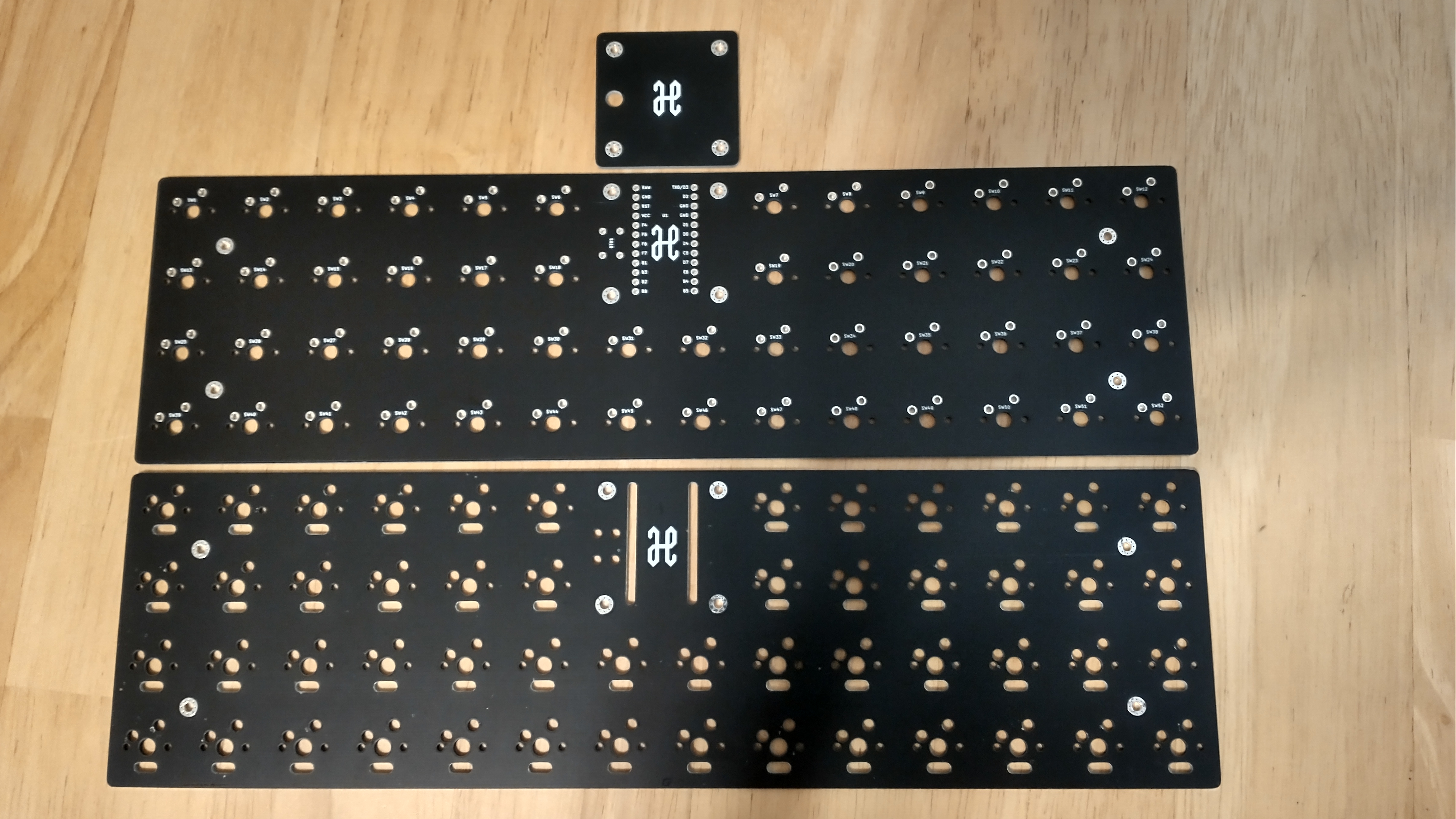

Each design consists of a main PCB, a top plate to protect the microcontroller, and a bottom plate to protect the bottom components:

The bottom plate is a cutout of all the components exposed through the bottom of the main PCB, and screws directly against the main PCB. This nicely guards you and your desk surface from all the pointy through-hole bits, while retaining a low keyboard height:

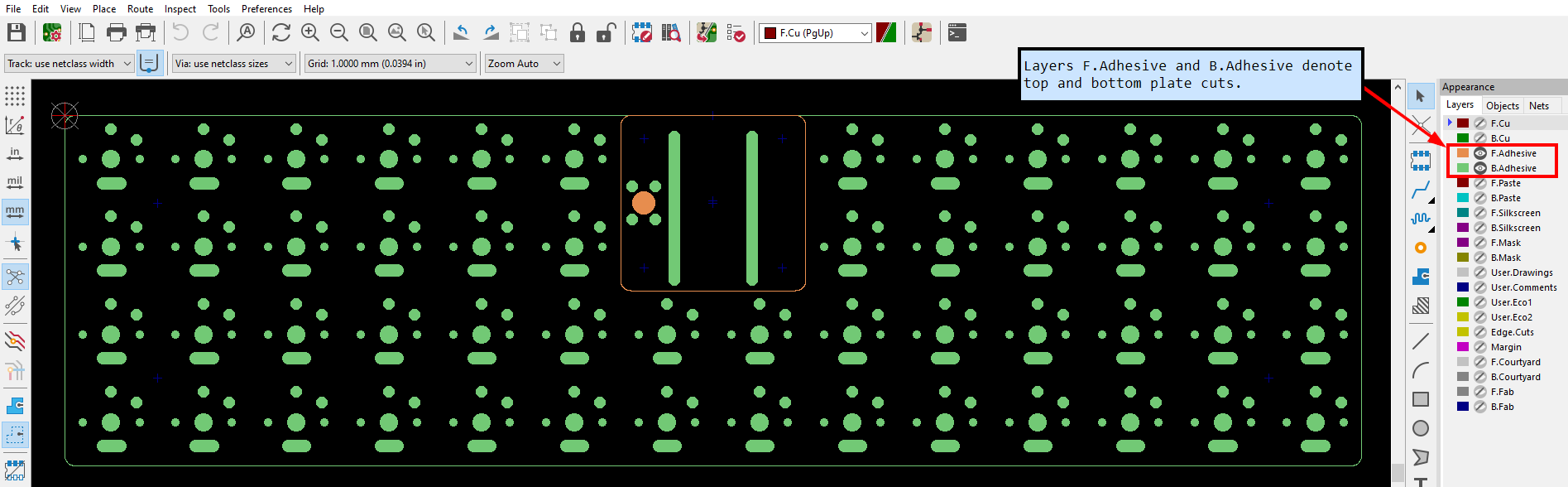

The bottom and top plates are generated via a custom KiCad 7 Python SWIG plugin Horizon Board Producer.

For the plugin to generate these plate boards, the PCB and its footprints use the following layer convention:

F.Adhesivedesignates top plate holes and edge cuts.B.Adhesivedesignates bottom plate holes and edge cuts.

When the board producer runs, these layers are used as follows:

- On the board and footprints:

- Graphics on the plate's designated layer will be moved to

Edge.Cutswhen producing that plate. - As with all edge cuts, please make sure your graphics are non-overlapping closed shapes.

- Graphics on the plate's designated layer will be moved to

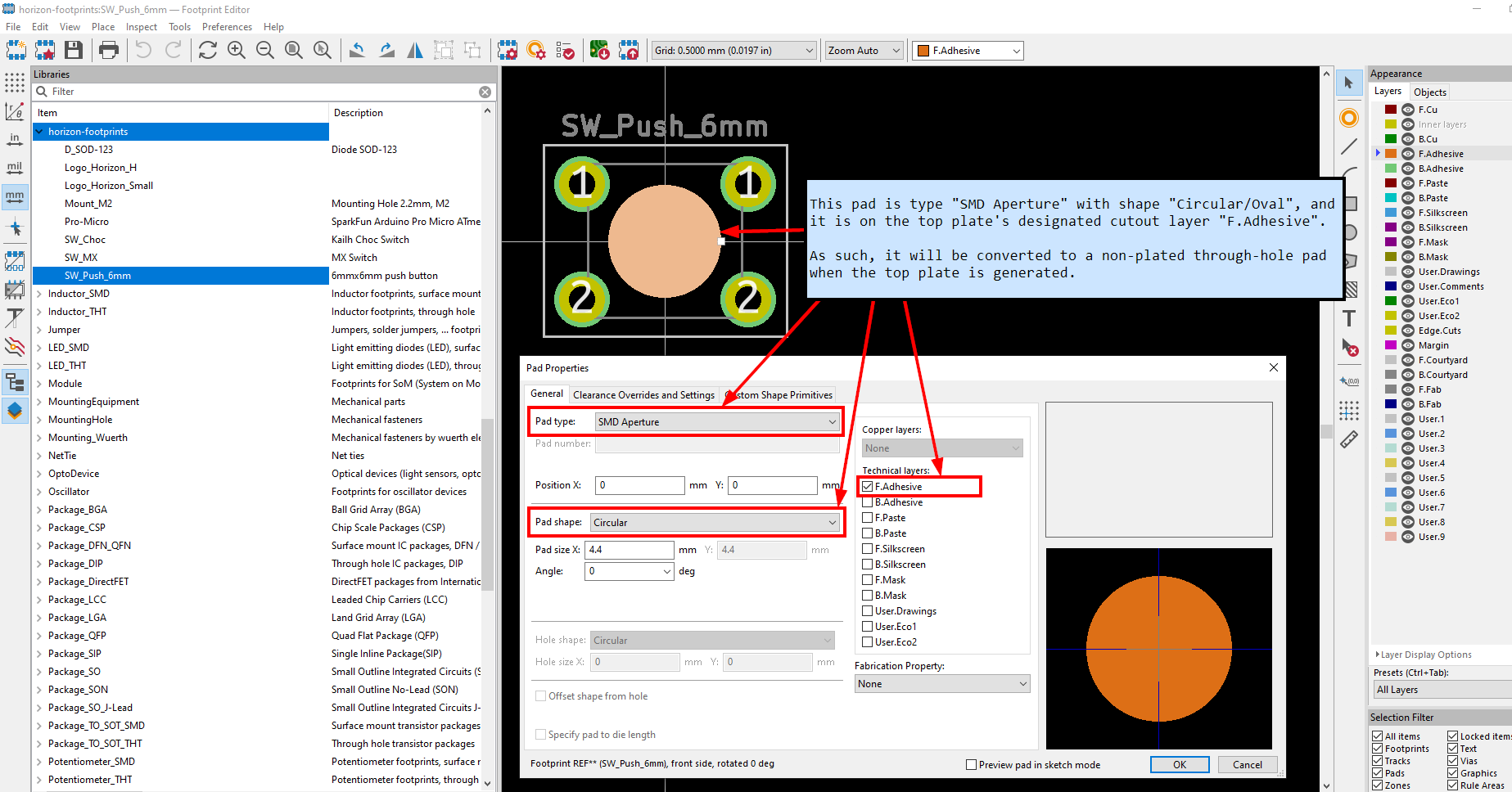

- On footprints only:

- Pads of type "SMD Aperture" and shape "Circular/Oval" on the plate's designated layer will be converted to proper NPTH pads.

- Note only circular/oval shapes are supported for these pads, because they are the only available hole/drill shapes. If you need a fancy plate cutout shape on your footprint, then draw graphics lines on the designated layer.

- IMPORTANT: When adding pads solely for plate cutout purposes, set the technical layer to just the designated plate cutout layers. Leave all other technical layers unchecked.

Additionally, the board producer plugin will preserve any in-bounds "H" footprint pads (mounting holes), "LOGO" footprint graphics (custom silkscreen art), and board silkscreen on the plates. Other items which are not needed for plates (e.g., copper tracks and zones) are removed from the plates.

The board producer plugin also generates all the Gerber files for production.

Please note the board producer plugin expects the following folder structure:

- The KiCad PCB file is two folders deep from the project root, e.g.,

kicad/[board-version]/[board-name].kicad_pcb - When the plugin executes, a folder called

tempis created in the project root to store any temporary files created.- Each time the board producer runs, any existing files in this temporary folder are deleted.

IMPORTANT: If you would like to use this plugin and plate edge cuts convention for you own project, please make sure you carefully examine the output Gerber files! The plugin ultimately worked well for my case, but you might need to make adjustments to the plugin to suit your project. And to reduce the chance of being charged extra money by PCB manufacturers, use footprint plate holes instead of edge cuts whenever reasonable to do so.

IMPORTANT: This plugin uses pcbnew.LoadBoard() to load copies of the PCB, which is not safely supported in a running instance of KiCad. To avoid project integrity problems this may cause to the running KiCad instance, the plugin forcefully exits KiCad upon execution completion.

- ZMK only. Horizon Mini's shield definition is in Pe8er's zmk-config.

For PCBs, keyswitches, and keycaps, get parts depending on your desired keyswitch type.

| Part | Purpose | Quantity | Notes | Vendor URL |

|---|---|---|---|---|

| Main PCB | circuit board | 1 | Send Gerber zip files to JLCPCB. | |

| Top plate PCB | protects microcontroller | 1 | ||

| Bottom plate PCB | protects bottom pins and components | 1 | ||

| Arduino Pro Micro | Microcontroller board | 1 | Or use another Pro Micro compatible board with same dimensions (confirmed Elite-C V4, nice!nano 2.0, and Adafruit KB2040 fit) | AliExpress (TENSTAR ROBOT) - Micro USB 3-18V |

| Sockets | so you don't need to solder the MCU itself | 1 | Aliexpress | |

| MSK-12C02 | Power switch | 1 | Aliexpress | |

| 6x6mm DIP 4-pin tactile switch | Reset button | 1 | AliExpress (xin cheng electronic)- 6x6x10mm | |

| 1N4148 SOD-123 | Diodes for keyboard row-column matrix | 52 | AliExpress (DSSRQI) - 1N4148 SOD-123 | |

| Battery | to eliminate wires | 1 | ||

| Battery socket | to plug into the PCB | 1 | ||

| Keyswitches | 44 | PCB mount (5 pin) switches recommended | MX: AliExpress (KPrepublic) - Gateron Switch RGB 5pin Clear, Choc: MKUltra Corporation - Kailh Low Profile Choc Switches | |

| Keycaps | 44 | MX: AliExpress (Cool Jazz)- DSA 1U Keycaps, Choc: MKUltra Corporation - MBK Choc Keycaps / wrk. Legend | ||

| M2 6mm screws | Secure main PCB and plate PCBs | 8 | AliExpress (wuhushiyu) - 200PCS-M2 Mix - Black | |

| M2 nuts | Secure main PCB and plate PCBs | 8 | See M2 set above | |

| M2 8mm male-female standoffs | Raise top plate PCB above microcontroller | 4 | See M2 set above | |

| 2mm tall rubber bumpons | Raise board above desk surface and provide skid resitance | 6 | Shop around - you can get cheaper alternatives if you don't need 96 of them! | Amazon - 3M SJ5302 Clear Bumpon Blister Pack (96 Bumpons) / Aliexpress / Aliexpress |

M2 standoff height requirements are dependent on the seated microcontroller height. An M2 spacer set should give you enough options. I recommend getting a reset button ~2mm taller than the M2 standoffs so the button is level with the top plate.

If using a LiPo battery and a bluetooth Pro Micro compatible board, then use battery size 301230. Just make sure the microcontroller socket height provides clearance for the battery to fit underneath (standard SIP sockets are a common choice).

These are the manufacturing settings I used when ordering from JLCPCB:

- Base Material: FR4

- Layers: 2

- Dimensions: (whatever the gerber file specifies)

- PCB Qty: 5

- Different Design: 1

- Delivery Format: Single PCB

- PCB Thickness: 1.6

- PCB Color: Black

- Silkscreen: White

- Surface Finish: LeadFree HASL-RoHS

- Outer Copper Weight: 1 oz

- Gold Fingers: No

- Confirm Production File: No

- Flying Probe Test: Fully Test

- Castellated Holes: No

- Remove Order Number: Specify a location

IMPORTANT: All PCBs have "JLCJLCJLCJLC" silkscreen text underneath the Pro Micro footprint. If you want to remove the order number from the boards or you want to print the PCBs with another manufacturer, then I recommend removing this silkscreen text from the .kicad_pcb file, and then re-run the Horizon Board Producer plugin to create the updated Gerber files.

- The main PCB uses a ground plane, so ground pads are more stubborn to solder. Make sure your soldering tip has good surface area coverage across the pad and component leg. If your soldering iron supports it, turning up the temperature a bit can help too.

- Before soldering the keyswitches, make sure they are perfectly straight and fully inserted into the PCB. Put the keycaps on the inserted keyswitches, and give a thorough visual inspection for any spacing or height irregularities between the keycaps. For MX builds, Gateron switches in particular have thicker PCB-mount pins - push these keyswitches in hard to make sure they are fully inserted!

- To get a perfect fit between the main PCB and bottom plate, keep your soldering tidy! Clean any excess solder/flux which falls outside the bounds of the bottom plate cutouts.

- Attaching the main PCB and the bottom plate requires a very steady hand. The approach that worked best for me was using narrow tweezers to grip the edges of the hex nut against the main PCB, while driving in the screw from the bottom plate.

- The top plate is a very tight fit. If the inner keycaps rub against it, first ensure the top plate is perfectly centered. To center it, slide a thin piece of cardstock in-and-out between the inner keycaps and the top plate on all sides. If that does not resolve the keycaps rubbing, then remove the top plate, sand its edges a bit, and try again.

- Rev1 (2021-07-30 - not publicly released):

- PCB: Experimental prototype of MX board.

- Schematic: Wire as 42 key 7x6 matrix (original release only had 6 keys on bottom row).

- Rev2 (2021-09-26)

- PCB: Create MX and Choc boards with bottom and top plates.

- Schematic: Wire as 52 key 4x14 matrix.

- Rev2.1 (2021-10-24)

- PCB: Slightly improve thermal relief clearance to make soldering ground pads easier.

- Rev2.2 (2021-10-25)

- Horizon Board Producer plugin: Now supports converting designated placeholder pads to NPTH pads during plate generation.

- Footprints: Replace graphics which indicate plate cutouts with placeholder pads which indicate plate NPTH pads.

- PCB: Gerber files regenerated using updated board producer plugin.

- Rev2.3 (2022-03-21)

- Horizon Board Producer plugin: Upgrade to KiCad 6

- PCB, Schematic: No physical changes. Files upgraded to KiCad 6, and Gerber files regenerated using updated files.

- Rev2.4 (2023-11-09)

- Horizon Board Producer plugin: Upgrade to KiCad 7

- PCB, Schematic: No physical changes. Files upgraded to KiCad 7, and Gerber files regenerated using updated files.