Water boiler automation with a Fronius pv inverter on a Raspberry Pi.

The objective was to harness the surplus generated by the PV system and enhance daytime self-consumption through water heating. This approach not only reduces the energy fed back to the grid but also curtails the need for heating resources like pellets, oil, or other fuels.

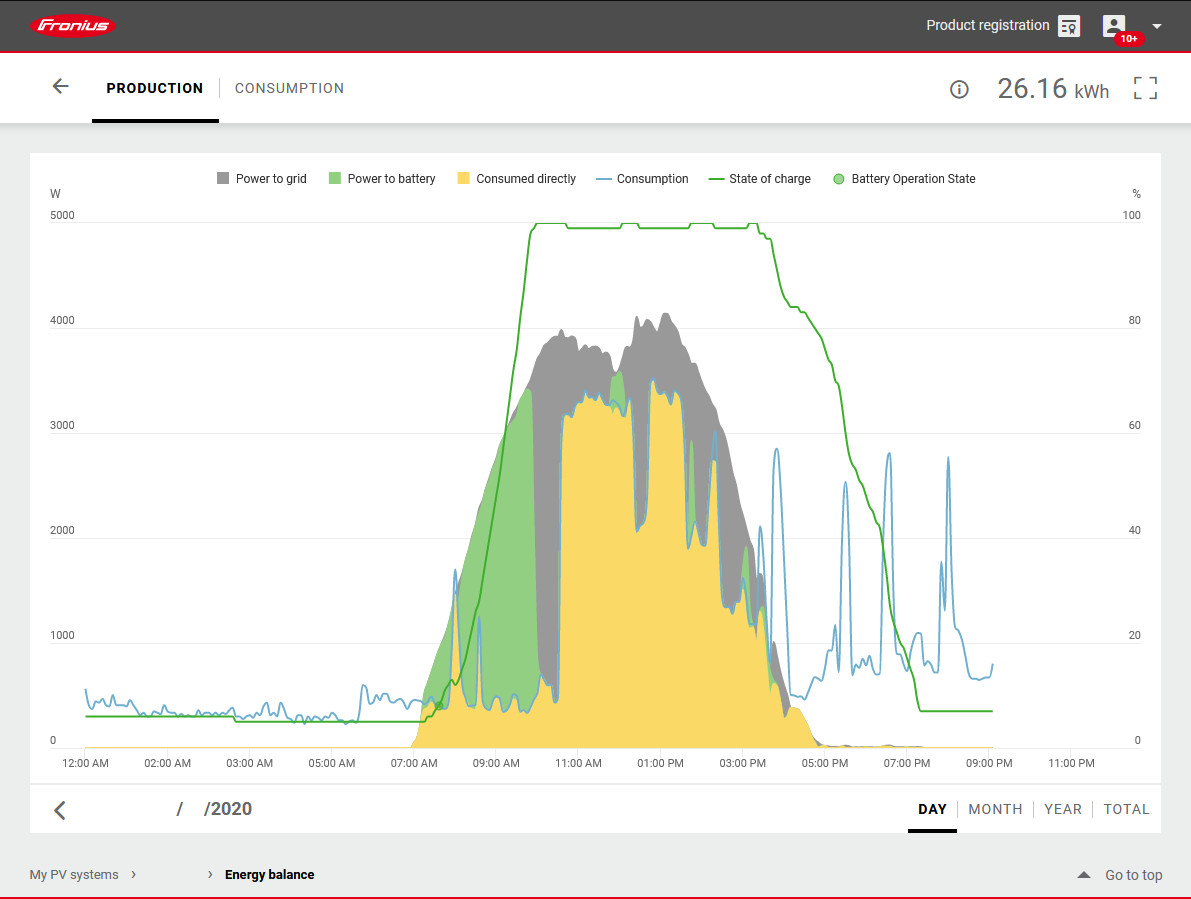

The yellow area illustrates the self-consumed energy after using Boilr (this program) to increase self-sufficiency. The blue line is the overall energy consumption. The gray region represents the surplus energy directed into the grid. The green line corresponds to the battery charge level, depicted as a percentage, while the green segment represents the surplus energy channeled into the battery.

The yellow area illustrates the self-consumed energy after using Boilr (this program) to increase self-sufficiency. The blue line is the overall energy consumption. The gray region represents the surplus energy directed into the grid. The green line corresponds to the battery charge level, depicted as a percentage, while the green segment represents the surplus energy channeled into the battery.

Here, it's evident that all the energy generated by the PV system serves either to charge the battery or for direct consumption (inclusive of electrical devices and the water heater's heating element).

Here, it's evident that all the energy generated by the PV system serves either to charge the battery or for direct consumption (inclusive of electrical devices and the water heater's heating element).

If dealing with the electrical aspect isn't within your comfort zone, it's advisable to seek assistance from an electrician, as mishandling it can pose serious risks.

- Fronius official API documentation: Documentation - Fronius Solar API V1

- Postman request collection: Postman Collection - Fronius Solar API V1

- Build image (on Raspberry Pi)

docker-compose build

- Run app in container

docker-compose up -d

In order to install and use Docker on a Raspberry Pi 1 Model B I had to set sysctl vm.overcommit_memory=1 and restart after the installation.

- Install python3

sudo apt install python3 python3-venv

- Clone the repo

git clone https://github.com/PeterBrain/boilr.git boilrcd boilr

- Create a virtual environment (not not... it's up to you) & activate it

python3 -m venv venvsource venv/bin/activate

- Install all requirements

pip install -r requirements.txt

- Create boilr folder in /var/log

mkdir /var/log/boilr

- Create boilr.log file in /var/log/boilr

touch /var/log/boilr/boilr.log

- Edit configfile to your needs

vi boilr/config.py

Starting:

python3 -m boilr startStopping:

python3 -m boilr stopOthers:

python3 -m boilr [-h] [-v] {start,stop,status,restart,run,manual {0,1}}Complete guide (boilr -h):

usage: boilr [-h] [-v] {start,stop,status,restart,run,manual} ...

Water boiler automation with a Fronius pv inverter on a Raspberry Pi.

optional arguments:

-h, --help show this help message and exit

-v, --verbose log extra information

commands:

{start,stop,status,restart,run,manual}

start Starts boilr daemon

stop Stops boilr daemon

status Show the status of boilr daemon

restart Restarts boilr daemon

run Starts boilr in command-line

manual Manually override gpio channel (contactor)

Additional hardware required. Please check:

https://github.com/PeterBrain/boilr- Raspberry Pi with operating system (for me it is model 1B with headless Raspbian)

- Python 3 (tested with 3.10)

- some python packages

- Docker

Here is a list of all parts I used (2020):

- Contactor to switch the three phases AC (~20€)

- 5x1.5mm2 copper stranded cable (~10€)

- Ferrules (for stranded wires)

- circuit breaker (I had one available, but it would cost around 20€)

- Distribution box (~20€)

- Raspberry Pi 1B (used for about 5€) + an sd card for the os

- Relay for the pi (5pcs for 8€, only one necessary)

- Ethernet cable (I had an old one at home (Cat5 - not even Cat5e))

- Network switch (used, gigabit (overkill) around 5-10€, or an old router with a builtin switch for free)

I had the option to use a WiFi dongle instead of an Ethernet cable, but due to the weak signal strength in my cellar (where the water boiler is located), WiFi connectivity wasn't viable. Additionally, the PV inverter, which is already connected via LAN, is situated in the same area.

| Inside | Outside |

|---|---|

Regarding the second Schuko socket, I made an oversight and didn't consider the distribution box lid. Unfortunately, the lid cannot be closed when there's something plugged into the Schuko socket on the hut rail.

The existing design exhibits a significant limitation: in contrast to Ohmpilot, a comparable Fronius product that boasts notably higher efficiency due to its use of PWM (Pulse Width Modulation), my setup operates solely in two states. It's either fully activated, providing maximum power to the heating coil, or completely deactivated. The optimal efficiency advantage is sacrificed on days when PV production falls just short of meeting both the household's current consumption and the water heating requirements.