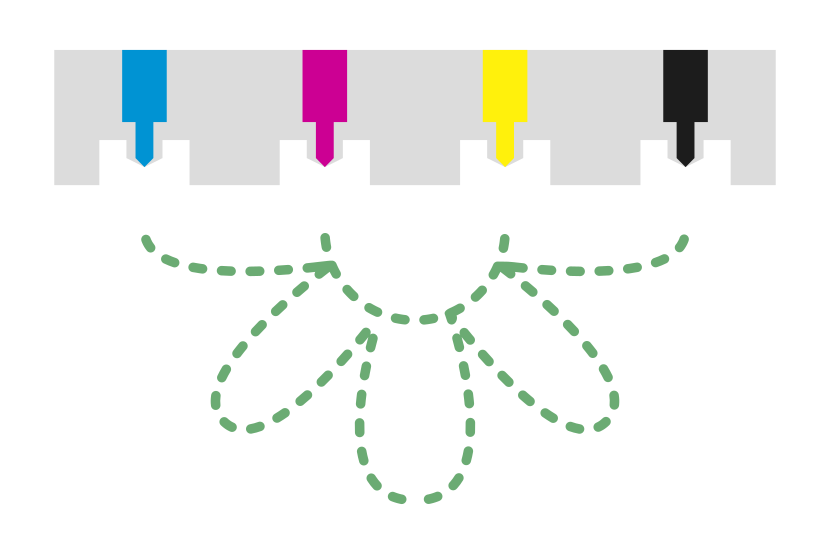

Possible ways to print with toolhead.

The printhead could be used as an add-on for

have to be carefully chosen if you want them to be food grade.

This is my attempt to build an open source inkjet printer by myself.

I started this project because I wanted to build a binder jetting 3D

printer but couldn't find any open source inkjet printer designs.

Back in 2019 after reading through the build logs

of the Oasis 3D printer I was scouring the internet

for anyone's attempt to build an inkjet printer:

-

Without access to industrial production

-

With simple electronics

-

From scratch

-

At home

After I successfully built some projects I found on the

Reprap Forum & Wiki I started to work on my own.

The first working prototype I built had a PMMA printhead

and was able to print - if everything was aligned perfectly -

with black ink made from thinned out paint.

Afterwards I designed a printhead with internal channels

that could flush out the air through the inbuilt nozzles and

printed it using a SLA 3D printer.

After some testing and creating single / multi printhead

builds I wanted to try printing in four colors, that is

While I designed all the required parts, I never got around

to assembling or even trying them out until I attempted to

write the Hackaday building instructions.

At the time I decided to redesigned the project to fit on

an Ender 3, this however also made me realize that the

machine was far too unreliable.

To remedy this, I changed the following:

-

Designed SLA 3D printed piezo pumps

to replace the piezo printheads -

Used MOSFETs + higher voltage for

switching the piezos instead of H-Bridges -

Used a vacuum duct to carry away excess

ink that would otherwise block the nozzle

with large ink drops.

With these changes the printer should be ready to do hour

long prints without failing due to design based problems.