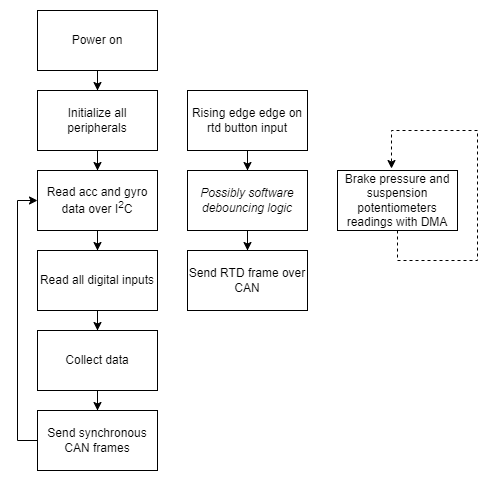

It's main task is to receive signals from sensors mounted on the car and analyze them and send to CAN-bus.

The hardware part of the project is the PCB board which is connected to the sensors and CAN-bus. The microcontroller which is used is STM32L4P5RET6. The PCB is supply by 5VDC.

It receive signals from :

inductive sensors - there are used to measure wheels rotation speed- brake pressure sensors - which measure the pressure in the brake system

- shutdown circuit sense:

- BSPD

- Overtravel switch

- Driver's kill switch

- Left and right kill switches

- acceleration - from MPU on board

The program is required to collect and relay data @ 100 ms. Two adc peripherals are used to collect data from 3 analog sensors each.

ADC clock frequency:

Sampling time:

Oversampling: by 256

Sample conversion time:

With oversampling:

Timer synchronization to avoid unnecessary measurements?