Listed below are the key requirements for the inventory management and order processing system:

- Manage an inventory of products

- Keep track of which items have been stocked

- Transforming incoming orders into outgoing shipments as appropriate

Edge cases to consider

- Max package size is 1.8kg, therefore breaking order into mulitple packages

- Out of inventory, in which case we ship what we can, and then wait until a restock happens

- When a restock happens, ship out pending items that weren't fulfilled immediately

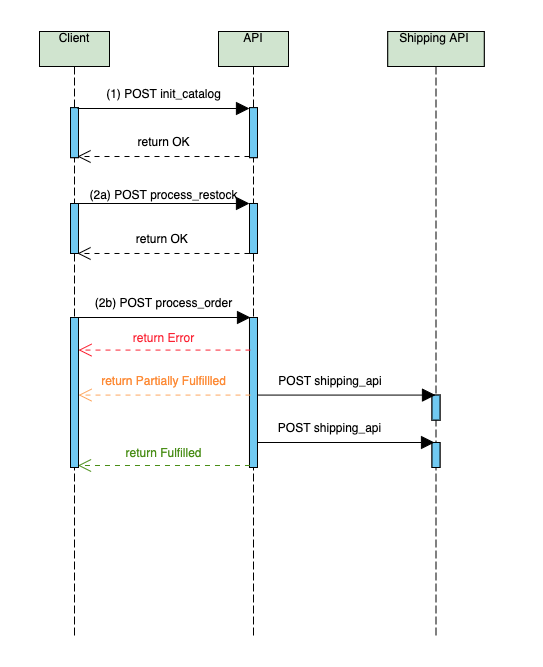

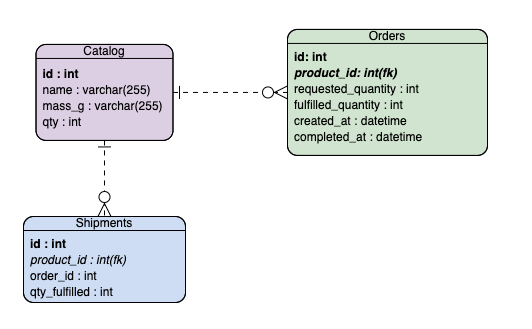

Init_catalog - will initially populate (product-info) to the catalog table with the initial quantity of 0 for each product type

Process_order - will primarily do the following key things

-

Checks to see if the order received is a new or existing pending order * If new order, saves to orders table before querying * If existing order, queries table * I'm only pulling orders that have

outstanding qtyof products that needs to be fulfilled -

Go through the order 1 qty at a time

-

Check if we have stock for 1 qty of the product and if we do

- If adding 1 qty of the item doesn't exceed 1800g shipment package, then we add

- Else if adding the 1 qty of the item to the shipment package > 1800g, then we ship out the package we have

-

We invoke ShipAPI as many times as we need - continously updating the

outstanding qtyfield of our orders table

Connected to DB - Both of the routes mentioned above have a fully functional PostgresSQL DB hosted on ElephantSQL

Init_catalog - I did not have time to finish coding this out, but have included my pseudo code as to how I might have approached it with more time

Typescript - Added types where I could but not fully exhaustive

-

Where possible - I considered doing a bulk add of information to the DB to minimize hitting the DB frequently, I implemented this in init catalog

-

Because I'm iterating through 1 quantity of each product during process_order at a time and making multiple requests to the DB, this could lead to a heavy load on the DB and not the most optimal. I took a very brute force solution to the problem

-

I'm aware that this could be a relevant knapsack algorithm which I could have approached to further optimize the system. Rather than hitting the DB with each iteration, I can decide what products go in my package, how my packages are most optimally split, and then invoke the shipAPI.

- Hosted my DB on ElephantSQL, you can connect in your terminal using the command

psql postgres:ekwmfpwq:cnGh7BO3pHq6XaPX_Zh1b5yyUlglaNV3@raja.db.elephantsql.com:5432/ekwmfpwq;-

The catalog DB has already initially been populated with the data with Qty 0

-

If you would like to run through the process, please manually add

qtyto the product_id of the catalog. Ideally, process_restock would have adding the qty to the catalog table. -

Send an order in and you should see the shipments table populate based on the packages that get sent