ROBOTICS ENGINEERING

Presented by:

SOLÈNE GUILLAUME

ZAIN BASHIR

YAMID ESPINEL

1. INTRODUCTION:

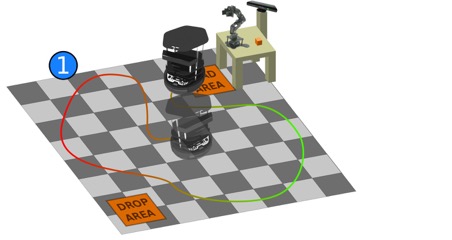

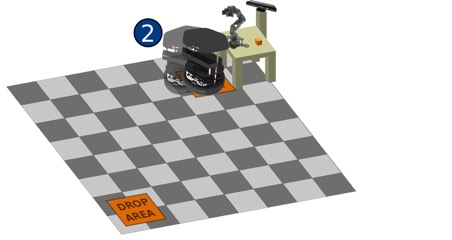

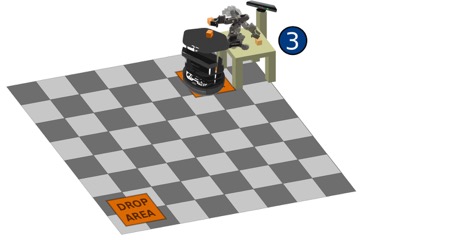

The scenario is split in six parts. The first part is Mapping & Localization: the robot has to move to a goal point using a map. The goal point is set to be in front of a first table. This first position of the robot will be not precise.

The second part is Fine positioning: with the help of visual servoing, the robot has to be in a very precise position in the world, to adjust the current position of the robot, so that we can perform pick and place. A kinect on the robot is used to perform these two parts.

The third part, our part, is pick and place: with the robotic arm placed

on the first table, we have to pick a small cube from the table and

place it on the turtlebot. To do so, we are using a fixed kinect that

‘sees’ the arm, the table and the turtlebot.

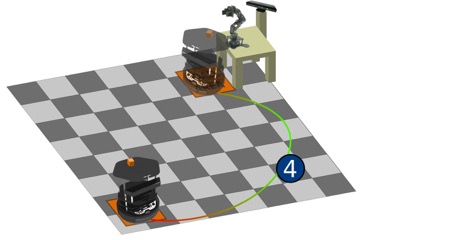

The fourth part is Mapping & Localization again: the robot has to go in

another goal point of the map, which is in front of a second table.

The fifth part is Fine positioning to put the robot precisely near the second table. The sixth and last part is Pick & Place to put back the cube to the second table using a second robotic arm and a second fixed kinect.

As mentioned before, we have worked on pick and place. The arm that we used was a PhantomX Pincher robot. It was previously assembled and tested by the students from BSCV. We split our project into three parts:

-

Kinect calibration: the calibration will help us to know the position of the camera in the 3D space, locating all the objects in the workspace and consequently giving the possibility to perform precise control of the robotic arm.

-

Control of the robot arm: in a first time we will control the arm by controlling manually each joint of the arm. In a second time we will control the arm by planning a trajectory so that the arm will move to a goal position autonomously.

-

Pick and place: we will detect the cube and plan a trajectory to pick and place it. This has to be completely autonomous and efficient.

2. ARM SETUP:

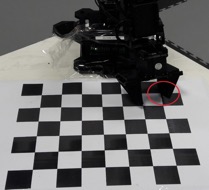

To perform the pick and place task we first setup our PincherX arm and the Kinect. As shown in figure 1, our Kinect is fixed to one corner of the table while the arm is positioned exactly opposite, along the diagonal.

|

|

| (a) | (b) |

|

|

| (c) | (d) |

Figure 1: Kinect and arm setup. (a) Left view (b) Front view (c) Right view (d) Top view

3. ARM CALIBRATION:

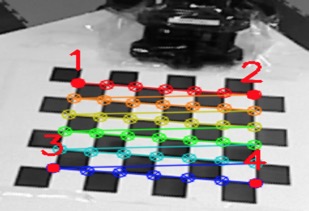

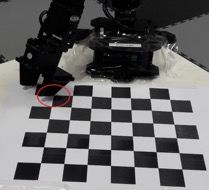

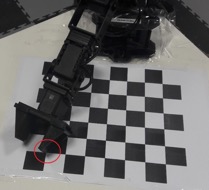

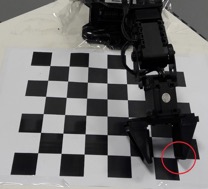

Arm calibration with reference to our task exclusively refers to getting the position of our arm base inside the Kinect camera frame. To do this we first place a checker board pattern of size 8x7 with each square of size 27mm on the table. We then run the launch file named calibrate.launch in the ROS terminal. This launch file contains the code to detect the checker board pattern and give an image (figure 2) which has four corner points labelled.

Figure 2: Labelled corner points

Once we have this image (figure 2) displayed on the screen, we place the pincher on each point, in order, one at a time and press enter. The placement of the pincher on these points is shown in the following figure.

|

|

| (a) | (b) |

|

|

| (c) | (d) |

Figure 3: Placement of pincher on four corner points. (a) Point 1 (b) Point 2 (c) Point 3 (d) Point 4

As soon as the pincher is placed on the last corner point (point 4), the position of the arm base with respect to the camera is published. A line similar to the one given below will be seen in the terminal which gives the calibration parameters.

rosrun tf static_transform_publisher 0.644927 -0.0369269 0.924532 -0.454811 -0.0169744 0.8893334 -0.0440946 /base_link/camera_link 100.

To check the accuracy of the calibration we can run the command given above in a separate terminal and check if the virtual arm is superimposed to the real one as seen by the camera.

4. THE ALGORITHM:

In this stage of the experiment, we have to find a way to detect any block on the table and make the robotic arm to grab it and put it on top of the robot. The selected solution makes use of the “turtlebot_block_manipulation” package [x], which is a set of launch files and C++ programs that perform scene management, detection of the blocks on the table, and movement of the arm; once executed, the user can select one block in rviz and drag it to the desired position, making the arm to pick the object and carry it to the final location.

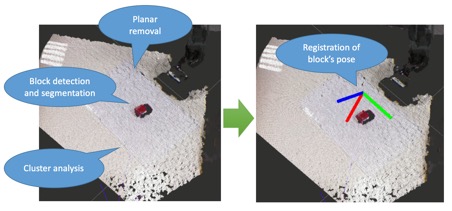

4.1. Block detection:

This section of the program is done by the BlockDetectionServer class (in the block_detection_action_server.cpp file), which receives a depth map and an execution order, and returns a list of the detected blocks in the scene (see figure (x)). The block detection algorithm contained there works by taking the depth map generated by the Kinect camera and filtering it by height to leave only the points present between the table height and the predetermined block size value, with the help of a pcl::PassThrough object.

Once filtered, the largest planar object present in the remaining pointcloud is segmented out by using a pcl::SACSegmentation object, which will return the point indices that make part of the planar object (table). By using these points, a pcl::ExtractIndices object lets us to select and extract the points that are not part of the planar object so in the end we obtain only the elements that are on top of the table.

Now, it’s the moment to check if the extracted elements correspond to the desired blocks. First, the point cloud is divided in clusters of 25,000 points thanks to a pcl::EuclideanClusterExtraction object. For each cluster, the external points are detected and so the maximum cluster size is computed; the cluster will correspond to a block if it fulfils all the following conditions:

(sb - t) < lx < (sb*sqrt(2) + t)

(sb - t) < ly < (sb*sqrt(2) + t)

t < lz < (sb + t)

where lx, ly, lz are the cluster’s dimensions in every axis, sb is the size of the block to be detected and t is a size tolerance set to 1 cm.

If the cluster contains a block then its center position is computed as:

xc = xmin + lx/2

yc = ymin + ly/2

zc = max - sb/2

where xc, yc, zc are the center coordinates of the cluster/block, and xmin, ymin, zmin are the extreme points of the block for each axis. These coordinates are then added into the list of detected blocks, taking the arm’s frame as reference. One example of the detection results can be seen in the following figure:

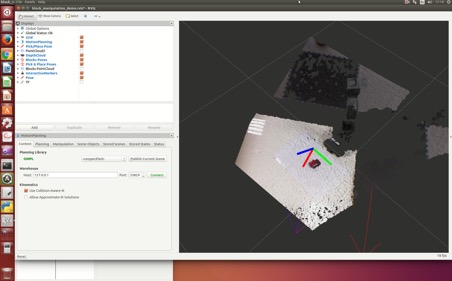

Figure 4: Block detection as seen in RViz

We have seen that sometimes the arm itself can be detected as a block, as some of its components may resemble a cube. To fix this, we make the robot go up so that there are no interferences between the camera and the workspace, leaving just the blocks as the elements on top of the table. This is done by adding a hard-coded final goal with a command that makes the robot move straight-up in the “block_manipulation_demo.cpp” file.

4.2. Interactive visualization and manipulation:

Once the BlockDetectionServer class has detected the desired blocks, these are sent to the InteractiveManipulationServer class which will show some 3D representations of the detected blocks in RViz and then it will receive mouse inputs from the user, who has to click and grab one of the blocks so that the arm takes and moves the block to the desired position.

The algorithm starts by creating virtual 3D cubes for representing the detected blocks in the table (using the addBlock method); these will be located at the same positions as the real ones and will have a size according to the predefined value (which should approximately math the real block size), as shown in the figure (x).

Once these markers are inserted into memory and displayed, a callback function InteractiveManipulationServer::feedbackCb is registered. This function is activated whenever the user presses or releases the left button and it performs different actions for each of these actions: if the button is pressed down, this usually means the user has selected one of the blocks so this initial position is stored in memory as an old_pose variable; once it has finished dragging the object and releases it, the callback function will call the moveBlock method, which will first correct the position of the block in Z by compensating the arm’s bumper height and then will a message to a /pick_and_place topic with the initial and final positions of the arm.

For our case, we have modified the code in such a way that as soon as one block is detected, the arm will go and perform pick and place. To achieve this, in the addBlock we have added some lines to set the detected block as the pick position, while the drop position is hard coded in such a way that the block is put on top of the Turtlebot; then the moveBlock function is called and the arm starts performing the pick and place.

4.3. Pick and place:

In order to make the robotic arm to take the block and put it on top of the Turtlebot, the PickAndPlaceServer class will divide this task into several steps so that the control of the arm is done more efficiently. The arm’s movements are planned using the MoveIt! interface, for which the arm are the gripper are initialized as objects of type moveit::planning_interface::MoveGroup, letting us to set a target pose and making the interface to compute the best trajectory to reach it:

-

Open gripper: The gripper servo is set to a position in such a way that the block can fit into it.

-

Rotate arm towards block’s position: The arm is moved at the xy position where the block is located, but keeping a predetermined z position (not taking the arm down to avoid collisions with the block).

-

Move arm down to block’s z position: The arm is moved down until the position of the block in z, so that the gripper is able to enclose it.

-

Close gripper: Make the gripper tightly grab the block.

-

Lift arm up: Move the arm up to a predefined height while holding the block.

-

Rotate arm towards final position: Arm is moved to a final predefined xy position where the block is going to be dropped. This position is supposed to be the location where the Turtlebot is right now.

-

Move arm down to final z’s position: The arm takes the block down approximately to the same height as where the block was before.

-

Open gripper: Move the gripper’s servo such that the block is released.

-

Lift arm up: Move the arm up to a predefined height, so that the Turtlebot can take the block away without problems.

Once all the pick and place process is completed, a warning is sent to the main process indicating the successful operation; like this, the system will send a message to the robot to let it know that it can go to the second table.

5. COMMUNICATION WITH TURTLEBOT:

Taking into account that the pick and place algorithm will start working once the Navigation and the Visual Servoing tasks are done, there must be a way for this last module to tell our system that its process has finished. Once this notification arrives, the block detection and pick and place tasks should be executed so that the block is finally put on top of the robot.

We could opt for running our application in the Turtlebot along with the other applications. But if we do that way, there will be some conflicts with the topics being used by elements of the same type. For our case, we are using a Kinect camera for the depth map generation, a type of resource also used by the other two processes. If our code is run on the same Turtlebot, the stream given by our Kinect camera will override those from the cameras of the other groups, making their algorithms to fail.

We look then for a method to send and receive messages between two different roscores, finding that the Multimaster algorithm [] is one of the easiest approaches to broadcast messages to a roscore that is not sharing the same topics. In this Multimaster algorithm there are two files to be modified: the config.yaml file which contains the list of topics to be broadcasted, and the multimaster.launch file, in which we have to specify the IP address of the computer where the chosen topics are going to be sent.

Before the algorithm starts, it waits for a notification from the Visual Servoing module which is running in the Turtlebot. Because it is the robot the one who is going to send the message, the Multimaster package is configured and compiled directly on it. Then, the servoing module will send a finish notification through the “/robot_status” topic, which is remapped as “/relay/robot_status” by Multimaster, making us to listen through this last topic.

After all the pick and place process is done, the robot is also waiting for a completion signal so that the second part of the Navigation algorithm can take the robot to the second table. This makes us to also install the Multimaster package in our workstation, configuring the foreign IP to be that of the robot. Then, once our algorithm is completed, it will send a signal through the “/arm_status” topic, which in the robot will be seen as “/relay/arm_status”.

6. INTEGRATION AND EXECUTION:

All the modules that conform the project are automatically initialized from a single .launch file, avoiding the necessity of running separate files in order to get all the processes up and running. Among the nodes and configuration parameters that are initialized in the “block_manip_complete.launch” file, we find the following ones:

-

Loading of transformation parameters after calibration.

-

Turtlebot arm bringup files.

-

Arbotix GUI.

-

Robot description and configuration files (URDF, SRDF, .yaml, …)

-

MoveIt! framework to provide path planning.

-

Kinect camera drivers.

-

Block detection base services.

-

And finally, our block manipulation program.

In order to run the program, the user must be sure of having all the devices connected (Kinect camera, robotic arm). Sometimes the robotic arm might need special access permissions, so we can run the following command to give the necessary authorizations:

$ sudo chmod a+rw /dev/ttyUSB0

Once everything is set up, the program can be compiled using the Catkin compiler by running catkin_make from the Catkin workspace. The project will be compiled under the name “turtlebot_arm_block_manipulation”. Once correctly compiled, it can be started by running the command:

$ roslaunch turtlebot_arm_block_manipulation block_manip_complete.launch

Once executed, an RViz window should appear with the scene on the screen:

Figure 5: RViz showing the scene with the robotic arm and a detected block

Then the program will wait for the completion message from the Visual Servoing task and begin the block detection.

7. MULTIMEDIA:

"Pick and place" video:

https://www.youtube.com/watch?v=dZAcbrz18cU

8. REFERENCES:

- "Turtlebot Arm": http://wiki.ros.org/turtlebot_arm

- "PhantomX Pincher Robot Arm": http://www.trossenrobotics.com/p/PhantomX-Pincher-Robot-Arm.aspx

- "Turtlebot Arm by Nathan Crombez": https://github.com/NathanCrombez/turtlebot_arm

- "ROS by Example", Patrick Goebel - ISBN: 5-800085-311092