! The ZYNQ-IPMC Software Framework resides here.

ZYNQ-IPMC Official Hardware Repository

Department of Physics, University of Wisconsin-Madison, USA

1. Overview

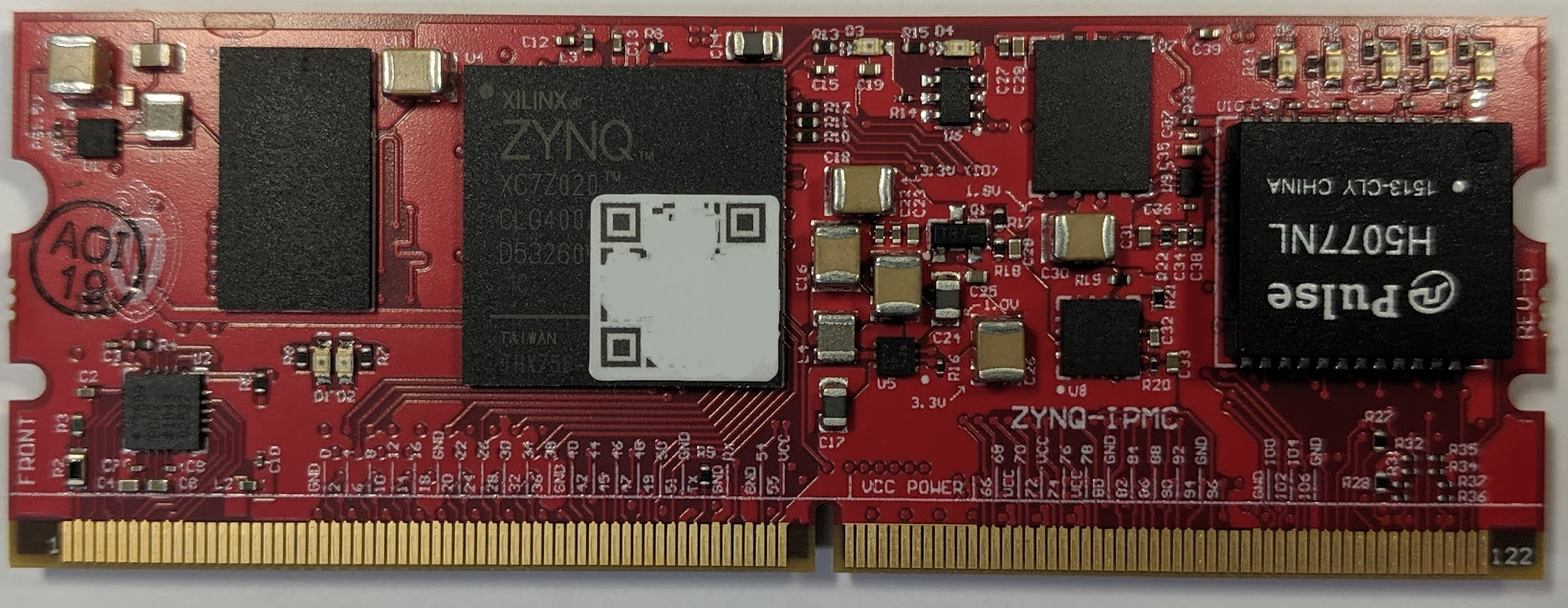

ZYNQ-IPMC is a high versatile open-source self-contained Intelligent Platform Management Controller (IPMC) in a miniDIMM-244 mezzanine form factor with extended monitoring features targeted for Advance Telecommunications Computing Architecture (ATCA) applications in accordance with the PICMG 3.x standard.

A Xilinx Zynq-7000 System-on-Chip (SoC) powers the ZYNQ-IPMC. Coupled with 256Mbytes of DDR3, fast ADCs and a large number of GPIOs that can take any standard protocol natively, forms an ideal solution to monitor and log voltages, currents, temperatures and others metrics in ATCA applications.

For detailed information of the hardware check the PDF datasheet here.

2. Altium Symbol and Footprint Library

The Altium project with the ZYNQ-IPMC symbol and footprint can be found here.

3. Picking between Zynq-7014S and Zynq-7020

Both Zynq-7014S and Zynq-7020 are pin-compatible and can be assembled in the ZYNQ-IPMC. The primary different is that the Zynq-7014S is a single core and has roughly 20% less resources than the Zynq-7020. The Zynq-7014S is also cheaper.

ZYNQ-IPMC framework only uses a single-core and won't benefit from an additional core nor FPGA resources. Therefore, the Zynq-7014S is recommended for most applications.

From tests and experimentation a medium to high populated ZYNQ-IPMC solution requires around 25% of resources from a Zynq-7020.

4. Bring-up and Testing

Standard electrical checks for hardware bring-up should be followed (e.g. visual inspection, ohm-meter tests, voltage levels, etc.) before inserting the IPMC on a carrier.

The ZYNQ-IPMC Test Board can be used for these tests and additional connectivity tests.

5. Fabrication and Assembly

All files required to fabrication and assembly are included in this repository. They can be found at here.

Recommendations on how to prepare packages for each fabrication step is below.

5.1. Fabrication Package

The following folders and files are recommended to be sent the PCB fabrication house:

- Gerbers (either Gerber or GerberX2)

- NC Drill

- Test Points

- PCB drawings (ZYNQ_IPMC-PCB.PDF)

- Drill drawings (ZYNQ-IPMC-DrillDrawing.PDF)

5.2. Assembly Package

The following folders and files are recommended to be sent the assembly house:

- Gerbers (either Gerber or GerberX2)

- Bill of Materials (BOM)

- Pick and Place

- Assembly drawings (ZYNQ_IPMC-Assembly.PDF)

6. Disclaimer and Licensing

The project is distributed as-in under the MIT license agreement as seen here.