This robot is for use in RBE 3001 as a teaching platform for robot kinematics and trajectory planning and image recognition.

You need to follow all instructions in this guide in order, doing steps out of order means you may need to take apart the robot or risk breaking a component.

Read through each section completely and then do the actions in the guide. Doing this will make sure you have an understanding of why and what you are doing.

You need to install Ubuntu 18.04 on your personal computer.

The rest of the guide assumes you have a base familiarity with the linux terminal and Ubuntu.

If you do not, here are resources to help you get familiar

Once you have Linux open a terminal (Ctrl+Alt+t) and run the following commands

sudo apt-key adv --keyserver hkp://keyserver.ubuntu.com:80 --recv-keys 71EA898B

sudo apt-get install software-properties-common

sudo add-apt-repository "deb http://ppa.launchpad.net/mad-hephaestus/commonwealthrobotics/ubuntu bionic main" -y

sudo apt-get update

sudo apt-get install bowlerstudio curl git putty zip unzip lightdm

sudo adduser $(whoami) dialout

After running the commands above a menu should pop up allowing you to choose between lightdm and gdm3.Choose the lightdm option

If the menu does not pop up run.

sudo dpkg-reconfigure lightdm

Restart your computer and you should see a slightly different login screen when you boot into Ubuntu.

Doing so will install some programs that you need for later steps, as well as configure your login manager to avoid a known bug with the default one.

The programs installed are

- BowlerStudio

- Used for design modeling of the robot arm, install drivers, and unit-test hardware, this is for 3d display of the robot

- curl (allows you to get files from the internet)

- git (allows you to access and work with code repositories)

- zip/unzip (allows you to zip and unzip files)

- lightdm (an alternative login manager)

Tools in this section you will need to complete the build. If you are missing any of the required tools contact an SA and they may be able to provide workarounds.

Items that start with 🔧 are found in the Bookstore Tool Kit.

Items that start with 🔧 are found in the Bookstore Tool Kit.

Tools in this section you might need to complete the build.

Feel free to source these tools from wherever is nearby and cheap, this is just the first amazon link or what was included in the tools kit.

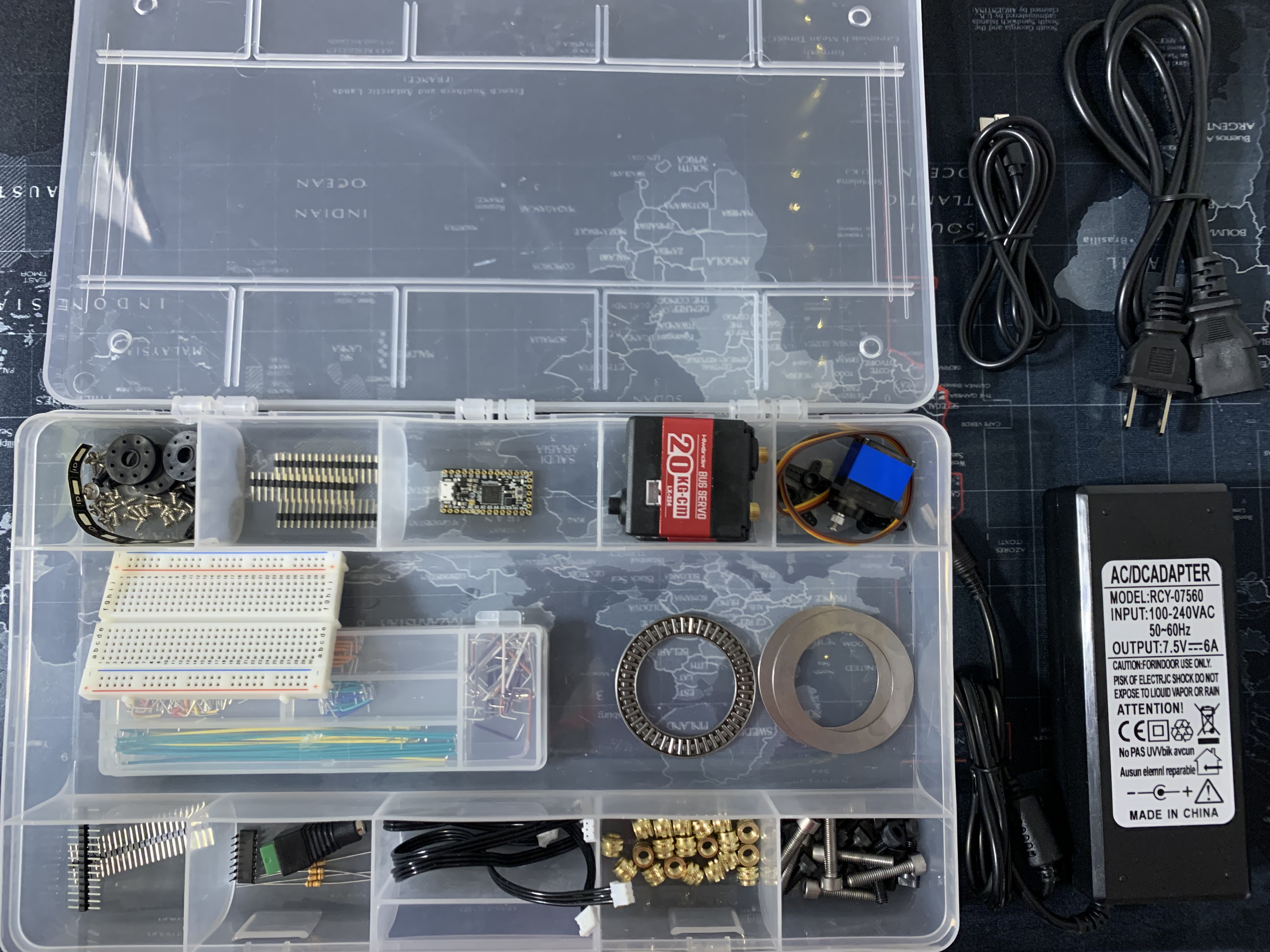

The goal of this section is to give you an understanding of your kit and the parts in it. This section assumes you have purchased the RBE 3001 Main kit and the RBE 3001 Camera kit.

*Note the box in the image is not included get your own.

3x - Smart Servo Kit: Servo Motor that drives the main 3 joints of the arm,along with a cord and servo horns.

1x - Power Supply: Provides power to arm, via a DC jack.

1x - Adafruit ItsyBitsy : The microcontroller for the arm.

1x - USB Cable : A wire to connect the ItsyBitsy to their computer.

1x - Double Header Pins : Pins to connect wires and the ItsyBitsy to the breadboard.

1x - Thrust Bearing : A ring of bearings for the base joint.

2x - Thrust Bearing Surface : A metal ring to support the thrust bearing.

20x - Heat-Set Inserts : Threaded inserts for the 3D printed parts (sold in packs of 50).

7x - M5x25 : Long bolts to assemble arm (sold in packs of 50).

13x - M5x12 : Short bolts to assemble arm (sold in pack of 100).

1x - Gripper Servo : A servo to operate the gripper.

1x - Power cord : Used to power the arm.

3x Metal horn sold in packs of 5

12x M3x10 bolts

1x Barrel_Jack Digikey PN: CP-102AH-ND

2x Conn_01x03_Male Digikey PN: PPPC031LFBN-RC

3x Conn_01x03_Male Digikey PN: 455-1705-ND

1x SW_SPDT Digikey PN: OS102011MS2QS1

2x SW_SPST Digikey PN: 486-3460-ND

1x 74126 Digikey PN: 296-8221-5-ND

2x 1x14 header https://www.digikey.com/en/products/detail/sullins-connector-solutions/PPTC141LFBN-RC

*Note if you did not purchace the camera kit you will need to buy a button to assemble the robot. Or if you are approved to go on campus you can get one from the Foisie lab.

-

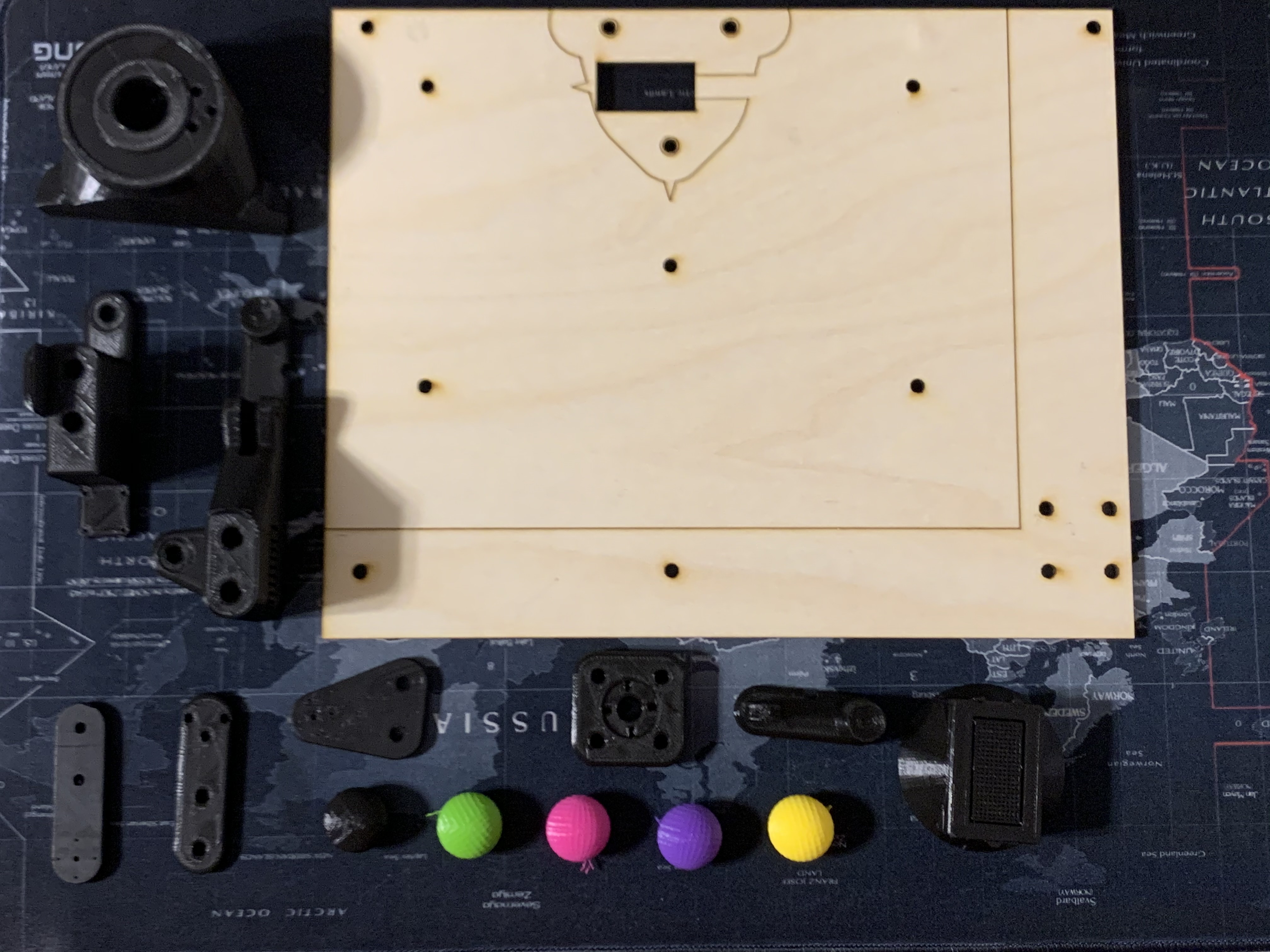

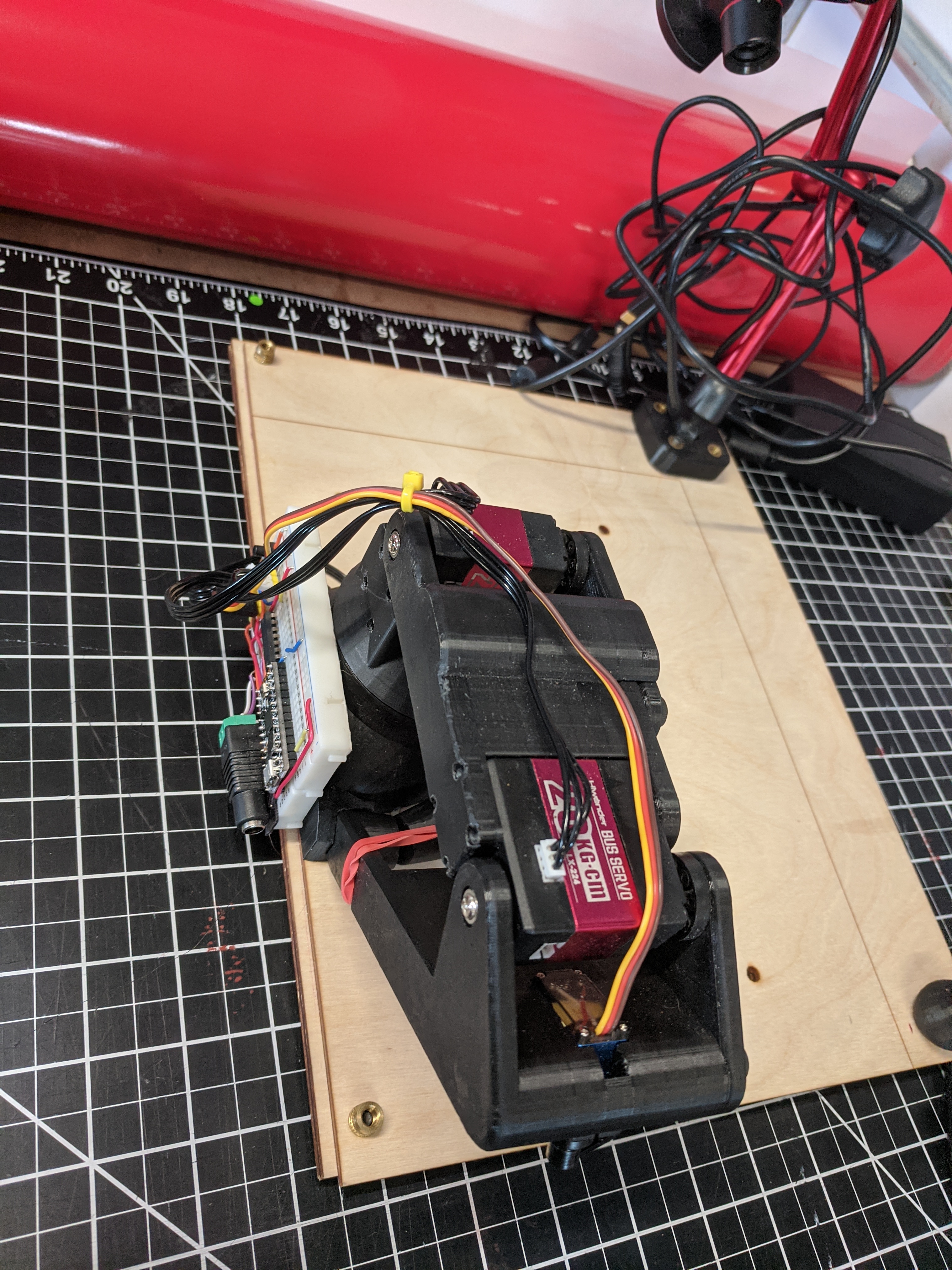

1x - Base: The arm's base

-

1x - Link 3 Bracket: The middle link of the arm

-

1x - Main Gripper Body: The main part of the gripper mechanism

-

1x - Gripper Claw: The mobile part of the gripper

-

1x - Link 1 Output Bracket: The part of the base joint that will rotate

-

1x - Link 3 Output Bracket: The panel to hold the smart servo at the gripper's base

-

1x - Camera Stand Base: A part to mount a threaded stand to the board

-

1x - Board: A wooden board to mount the arm

-

1x - Link 2 Output Bracket: A bar with five holes to mount a servo horn

-

1x - 3 Hole Bar: A bar with three holes for holding a servo

-

5x - Orb: Pink, yellow, purple, green, and black colored orbs

(Not the camera kit provided to students for A20)

- 1x Camera

This next step of instructions will guide you in assembeling the elctronics for the arm and then calibrating the servos.

From now on, all you need to do to calibrate the arm is move the robot to the calibrate pose and hit the calibration button on the breadboard. You will need to calibrate the robot every time the ItsyBitsy is power cycled.

Setup Matlab and begin working

Open BowlerStudio, in the menu

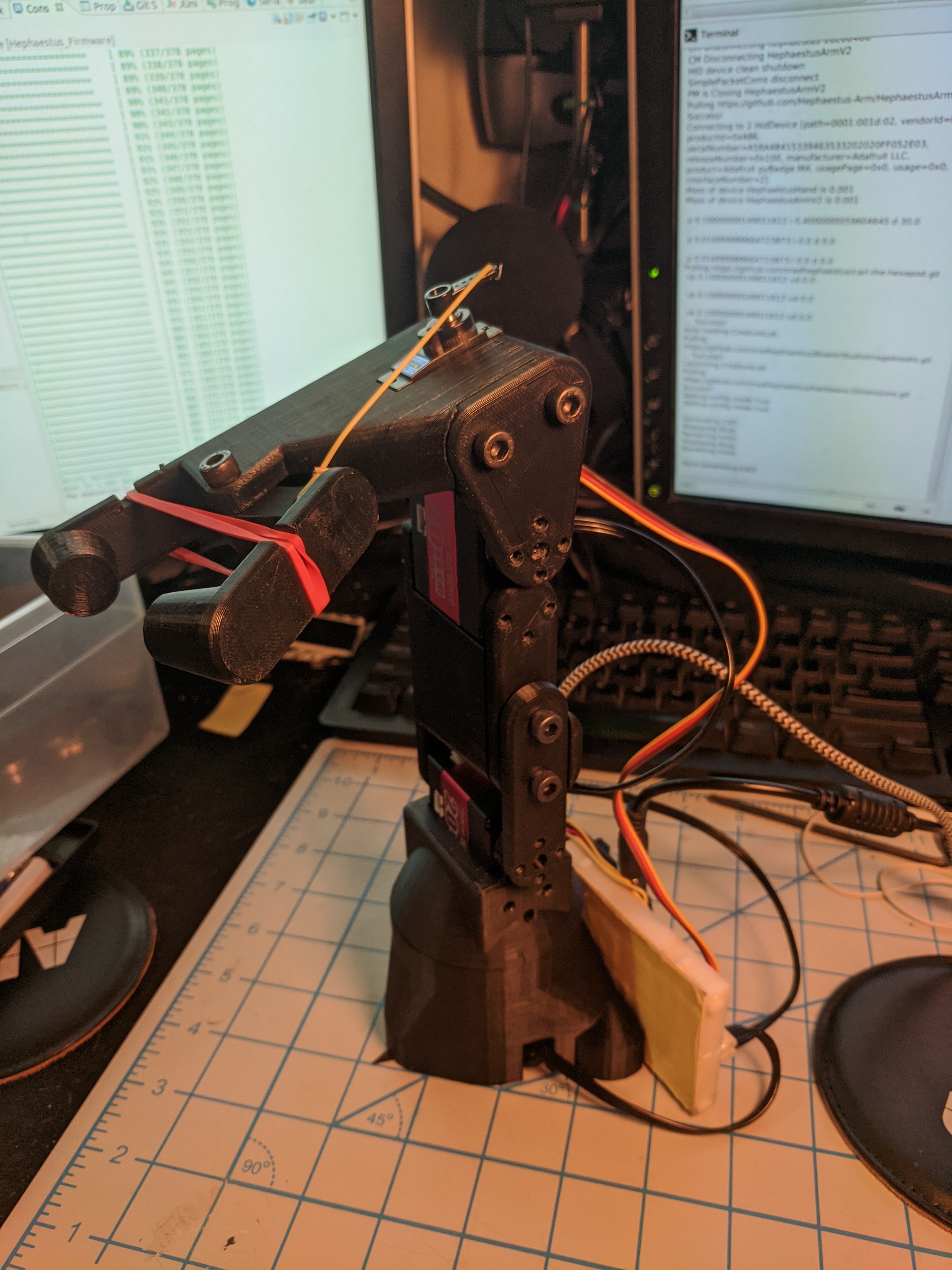

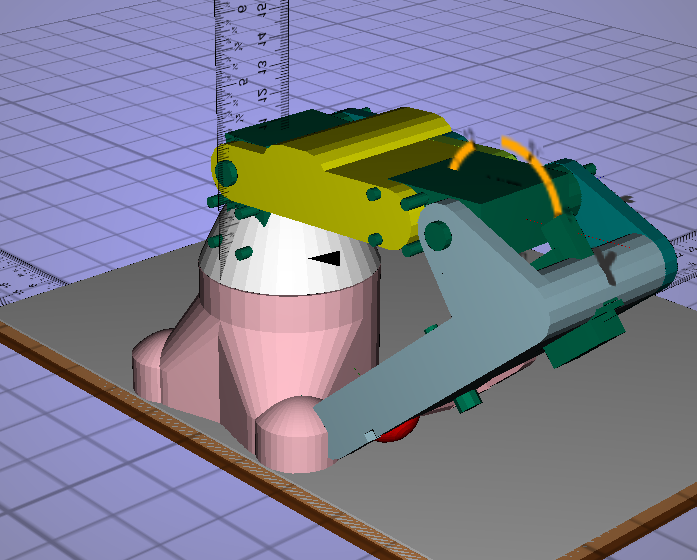

Add device -> creatures -> Hephaestus Arm V2

This will generate the CAD and run the simulation.

Current Release Printable STL's

Print these with supports everywhere, do not reorent the parts. They are printed in this orientation to increase operating strength.