Aug 31st, 2024: The sander is now finished and works successfully for me. I will add more documentation in the future.

In this project I am designing and building an edge belt sander. Design constraints:

-

Using only 3D printed components + widely available off-the-shelf hardware (as far as possible) to make it fast and easy to reproduce.

-

For belt size 915 x 100 mm (but may offer other configurations in the final release).

-

Speed controllable brushless motor.

-

Belt change

and alignment adjustmentwith no tools. I had to compromise, because after adding the electronics there was not enough space for a large belt alignment screw - belt alignment now does require a hex key driver -

Low profile form factor of less than 14cm - the sander should fit into a drawer when not in use.

-

Modular design to allow for customization and faster/cheapter iteration during development.

-

Ideally: Option to power from two 18V batteries.

-

Prototype a rough full model to ensure the dimensions fit

-

Design, test, and refine the lever mechanism for the belt tightener

-

Done after testing more than 20 different prototypes: type 1, type 2, type 3

-

Latest iteration, successfully printed and tested

-

-

Choose a motor

-

Dismissed: 997 motor, mostly due to ventilation requirements.

-

Dismissed: Skateboard motor type 1. Doesn't fit into desired envelope (see design constraints above). It is too long with the shaft included.

-

Dismissed: 6384 motor. Just about fits, but with no space left for routing the cable securely and more expensive because it requires large bearings.

-

Chosen: 90 mm skateboard motor type 2

/motor.jpg)

-

-

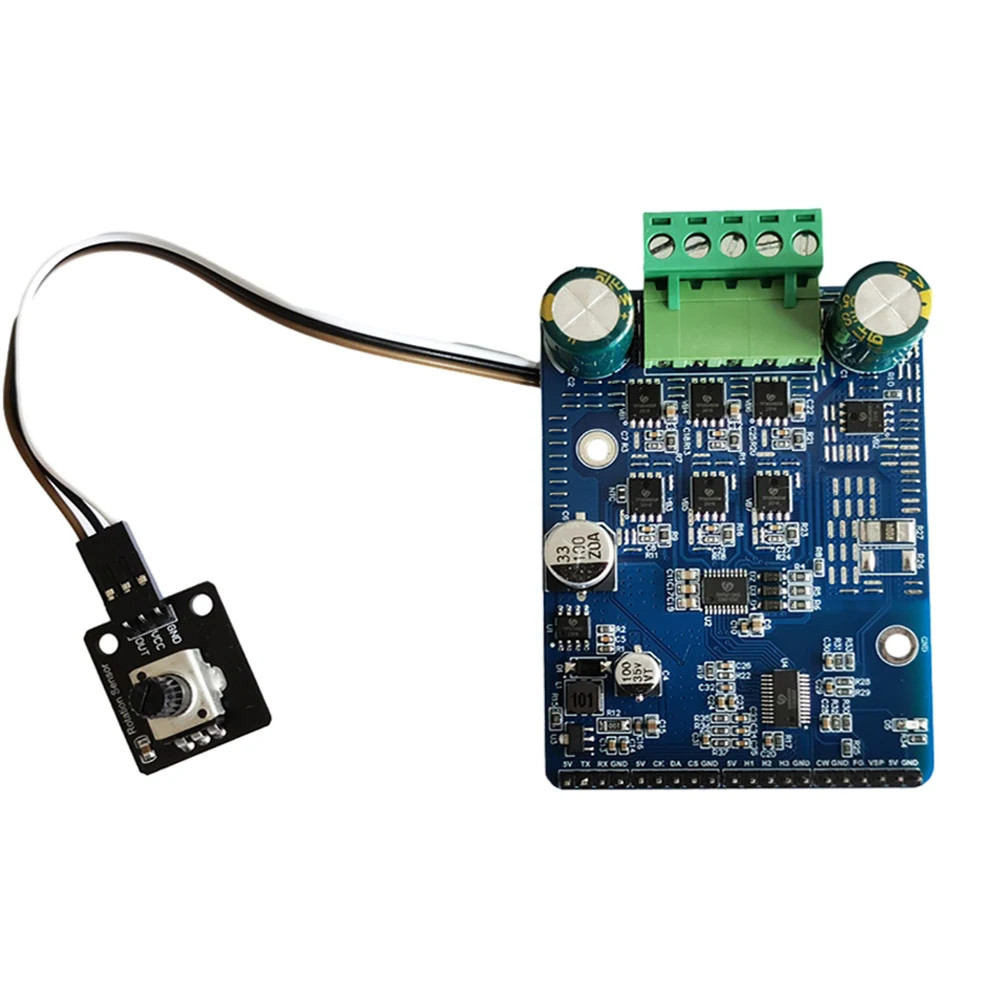

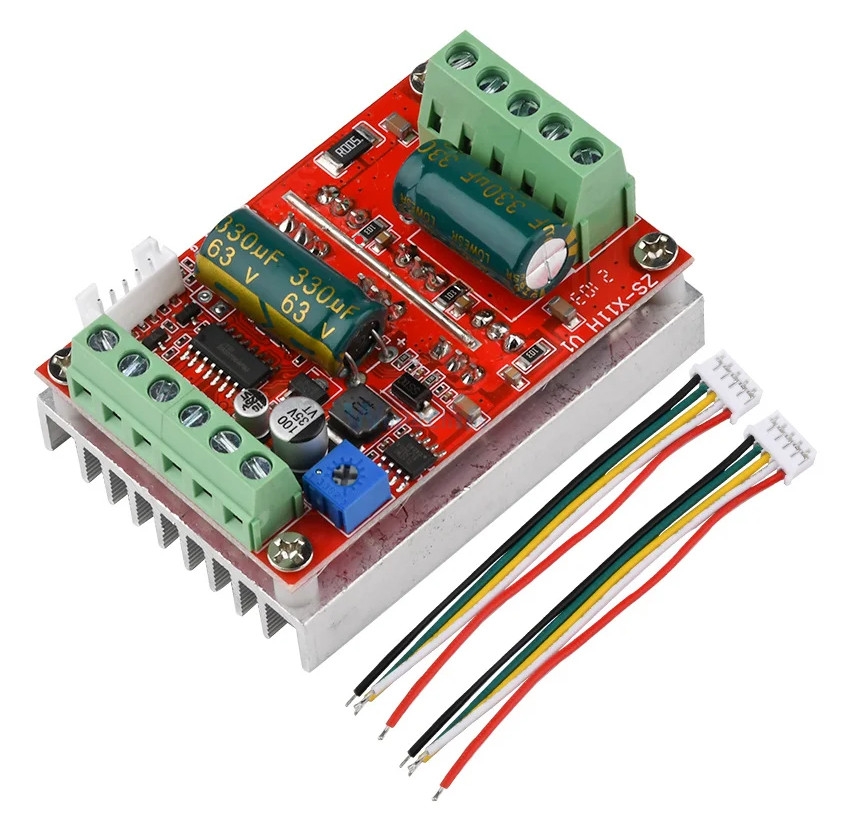

Choose a BLDC controller

-

Choose a microcontroller

- Dismissed: NodeMCU ESP8266 with 0.96 display. Large form factor made panel dimensions too large.

- Chosen ESP32 S2 Mini with separate display.

-

Create CAD models for all electronic components

-

Brake resistor (3rd party model found)

-

10k Potentiometer (3rd party model found)

-

Power switch (3rd party model found)

-

Microcontroller (3rd party model found)

-

Build and test the electronics

-

Order parts

-

Double check polarity of xdrive connectors, they use red for GND in some cases! (GPIO-connector seems wrong in photos)

The connector is indeed wrong - red is GND. Be careful.

-

Figure out maximum power draw of VCC pins of ODrive. (Sufficient for microcontroller+display? Otherwise need a separate step down module)

Should suffice: The XDrive uses an STM32F405RG, which according to its data sheet can provide a maximum of 240mA at 3.3v on Vdd. The OLED display draws 0.08W = 24.2mA, the ESP8266 has a maximum draw of 170mA and much lower with WiFi disabled. To be safe I'll keep WiFi disabled on the controller.

-

Install Logic Level Converter between ODrive and microcontroller

-

Install Hall sensor filter capacitors

-

Assemble the whole setup

-

Install and test the thermistor

-

-

Software

-

Potentiometer to set velocity

-

Resolve "ENCODER_ERROR_ILLEGAL_HALL_STATE" issue by adding filter capacitors: Encoder error ERROR_ILLEGAL_HALL_STATE

-

Figure out microcontroller / ODrive communication. Details of the investigation documented here

-

Retrieve and display actual speed from ODrive

-

Actually send the set speed to the controller.

-

-

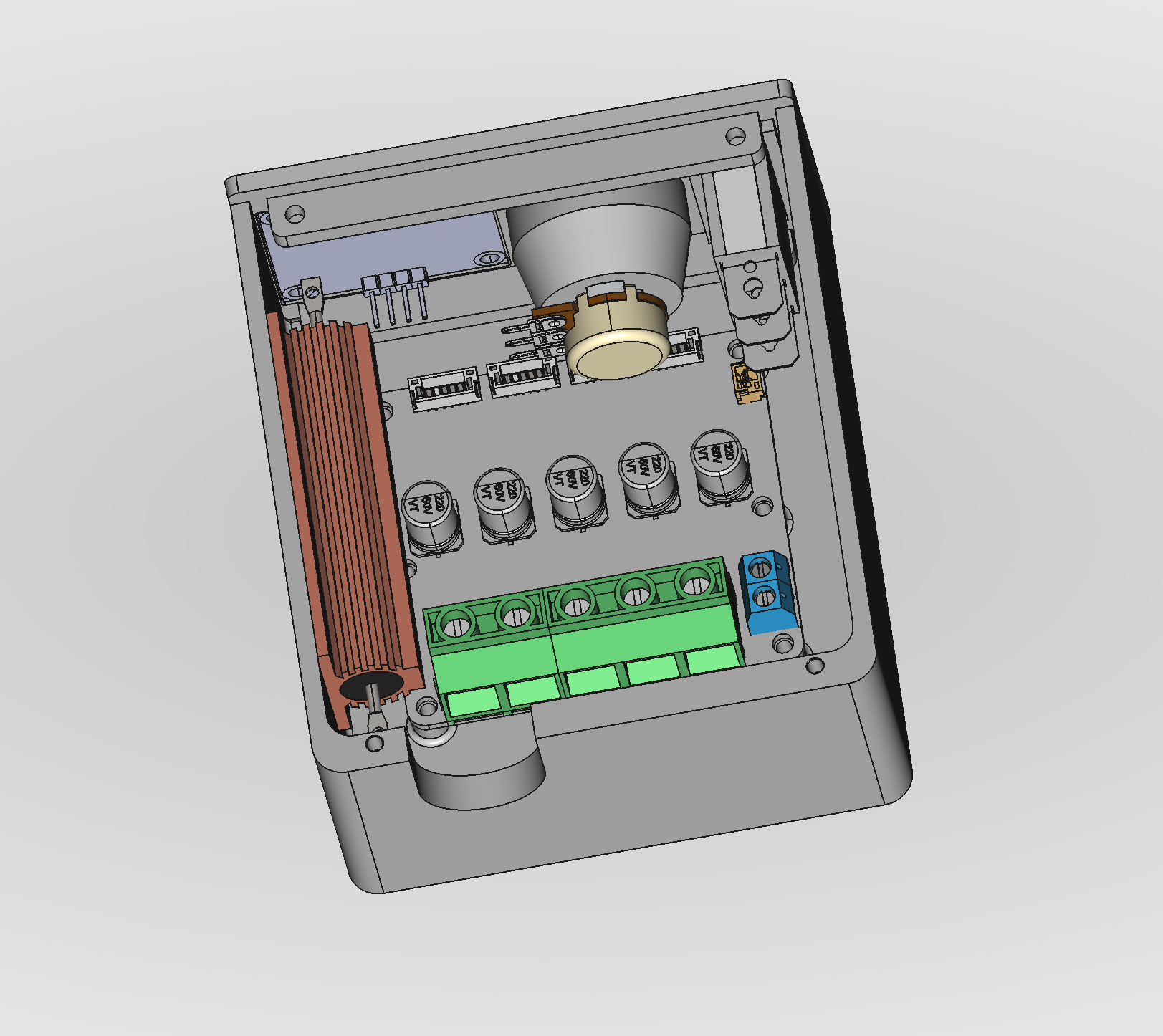

Design and refine an electronics enclosure module to fit into the sander

-

Potentiometer knob

-

Panel for display and speed knob.

-

Enclosure with mount plate for ODrive Mini and brake resistor.

-

Final assembly

-

-

Design and refine hub driven roller with the skateboard motor.

-

Create the new overall assembly tying everything together.

-

Fully model the design: Draft done

-

Create new belt aligner.

-

Go through every feature (screws, bearings, etc.) to try and reduce the amount of different hardware needed.

-

Check and refine all models.

-

Print, test, refine, iterate

-

-

Make a backing plate from steel or aluminium.

-

Design and build the final base plate.

-

Provide more clearance (1.5mm on each side?) between rollers and housing, to fit washers on both sides.

-

Make left carriage bearing cutouts larger - 23mm probably. It doesn't need tight clearance, as it is pulled to the right anyway.

-

Separate the carriage arm from the bracket, make them connectable using screws. For better printability/modularity.

-

Make the arm shorter, to make more space for electronics in the unit.

-

Recess the tightener knob into the unit. Knob became obsolete with new lever design

-

Bottom could be 2mm slimmer because it will be seated in a base plate anyway. Not slimmed down because space was needed for routing the cable in it.

-

Dust extraction

-

Oscillating unit

-

Reduce velocity based on proximity sensor