Initial release of the Better Solar User Interface for American Made Solar Prize Round 5: Software Track SET! stage.

- Automate image interpretation and provide valuable statistics.

- Create a user-friendly experience for a historically time-consuming image processing practice.

- Provide an all-in-one system that can be tailored to fit a consumer's needs.

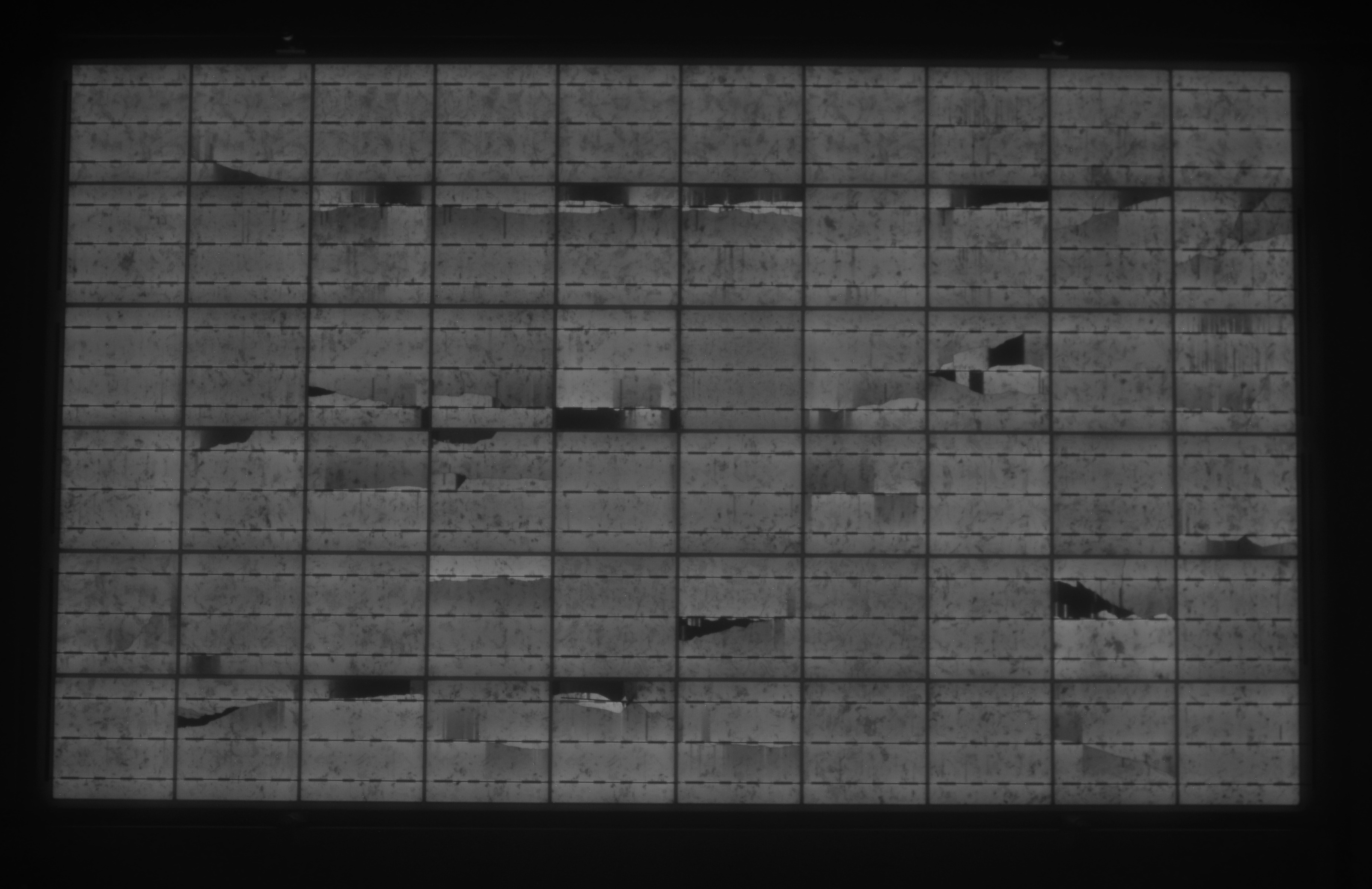

In the solar industry there is a consistent influx of valuable Electroluminescence (EL) images, which become overwhelming and unmanagable. Inspecting these images easily becomes a tedious and monotonous process.

The Better Solar approach relies on a supervised Machine Learning (ML) approach that has been proven to effectively detect, localize, and classify numerous defects that can originate in manufacturing, during accelerated aging tests, or following field exposure.

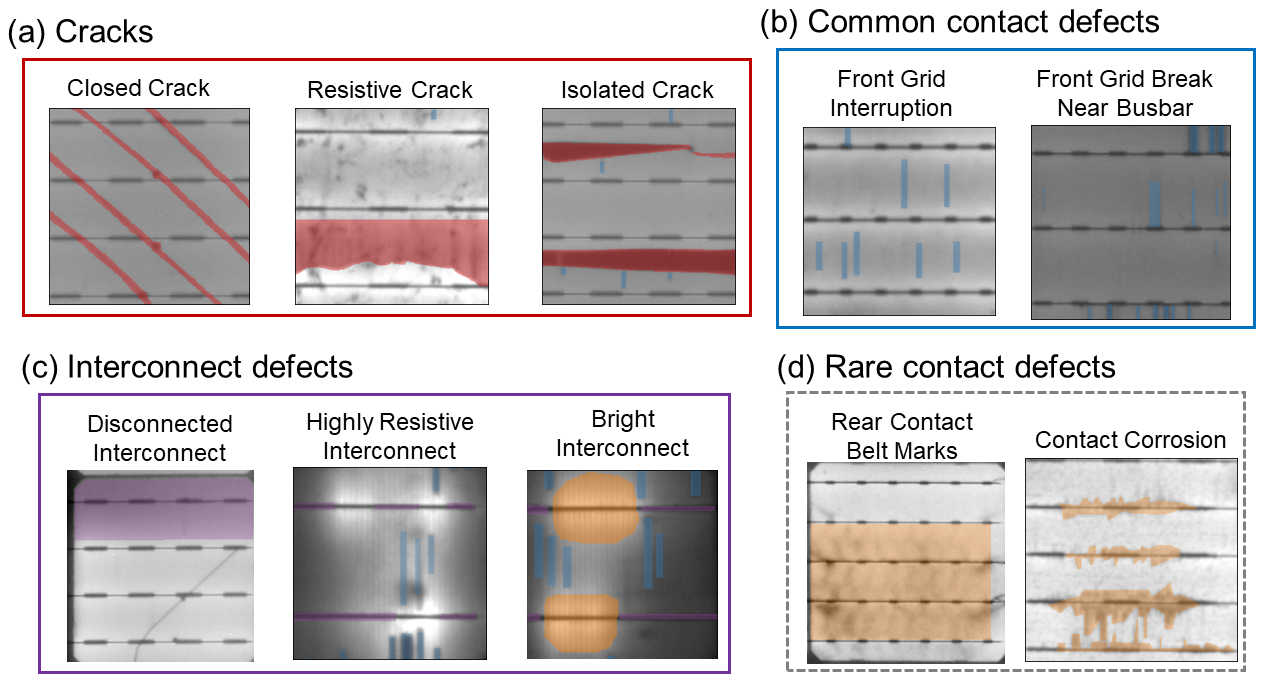

At this point, the software can effectively provide granular output with defect detection and localization of the various defects shown below. This output allows for further analysis on defect impact on module outputs, valuable to the customer. Eventually, our solution will provide this feedback on the magnitude of the problem (e.g., its impact on energy yield) and provide suggested corrective actions both in a manufacturing or a field-based setting.

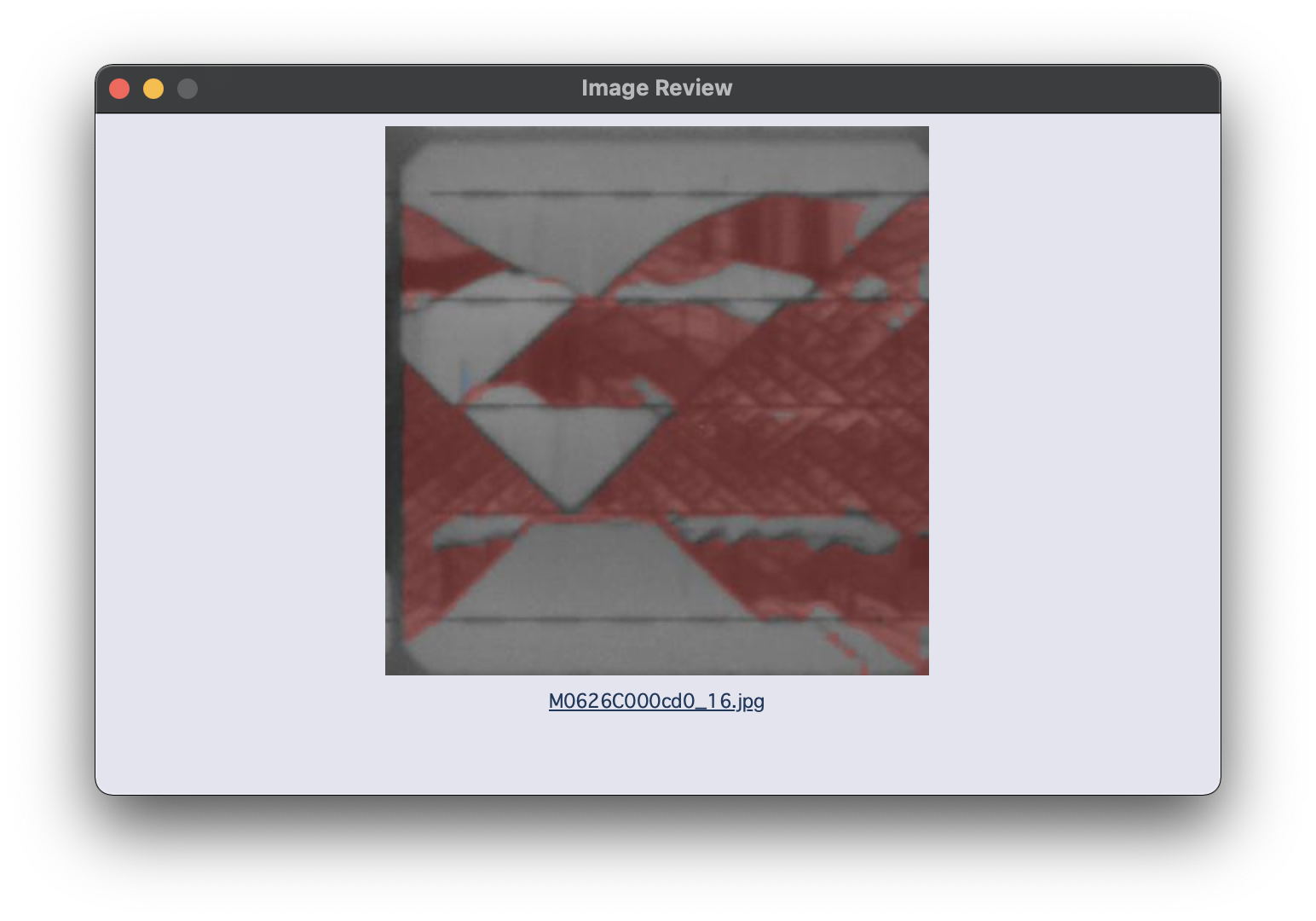

* The colors and groupings of defects in the application are consistent with this figure. Cracks are grouped into

a red category, contact defects are labeled blue, interconnect failures are purple, and the brightspots and corrosion

are both in yellow (shown in different model selections)

* The colors and groupings of defects in the application are consistent with this figure. Cracks are grouped into

a red category, contact defects are labeled blue, interconnect failures are purple, and the brightspots and corrosion

are both in yellow (shown in different model selections)

- Basic System Workflow

- Interface Screenshots

- User Guide

- Release History

- Notable Future Plans

- Contact Us

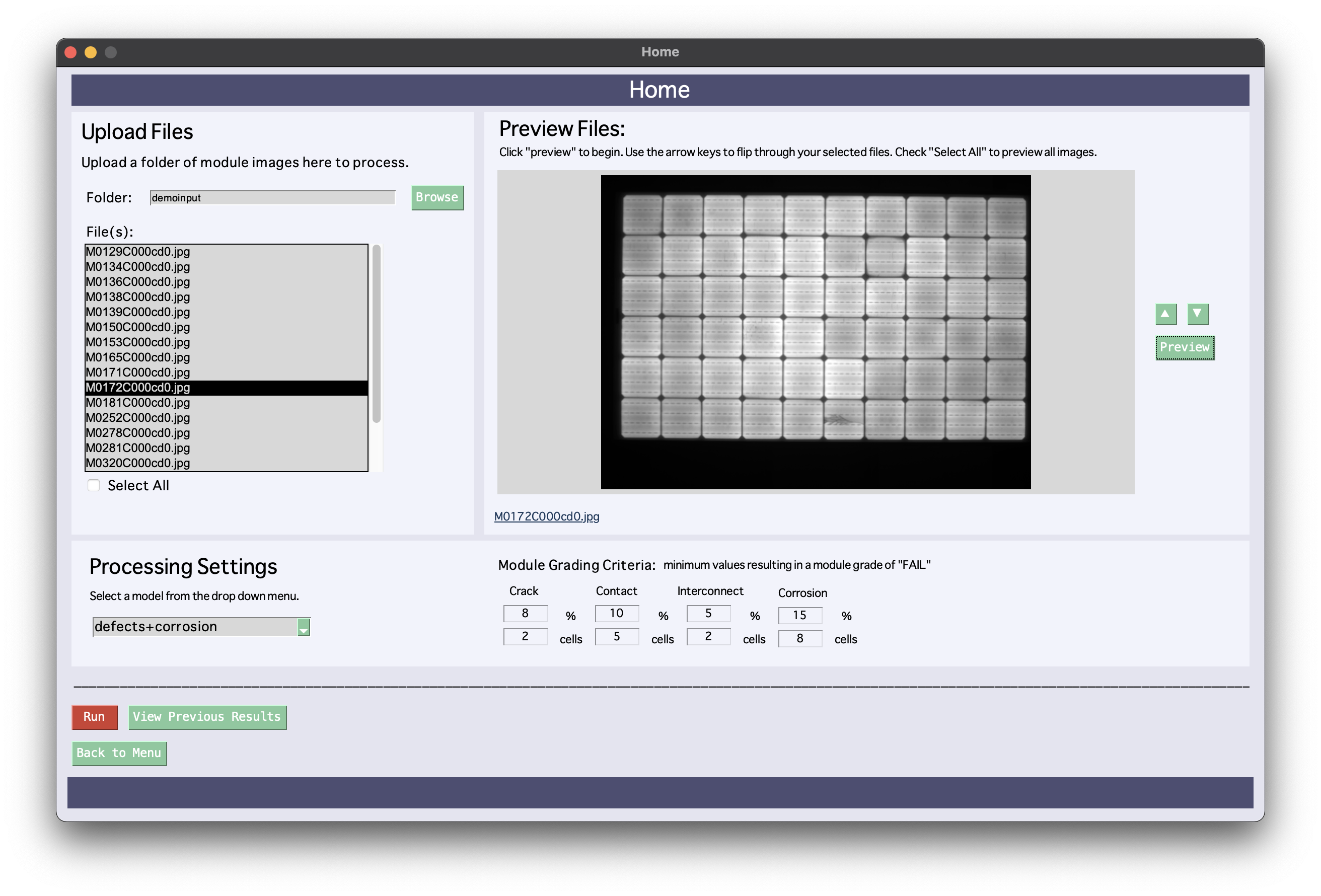

- Upload module files and select custom processing settings on UI. (See: 'Screenshots: Home Page Window')

- Module files are fed into image preprocessing algorithm. Modules are split into individual cells.

- Cell files processed with our ML cell level analysis and defect detection algorithms.

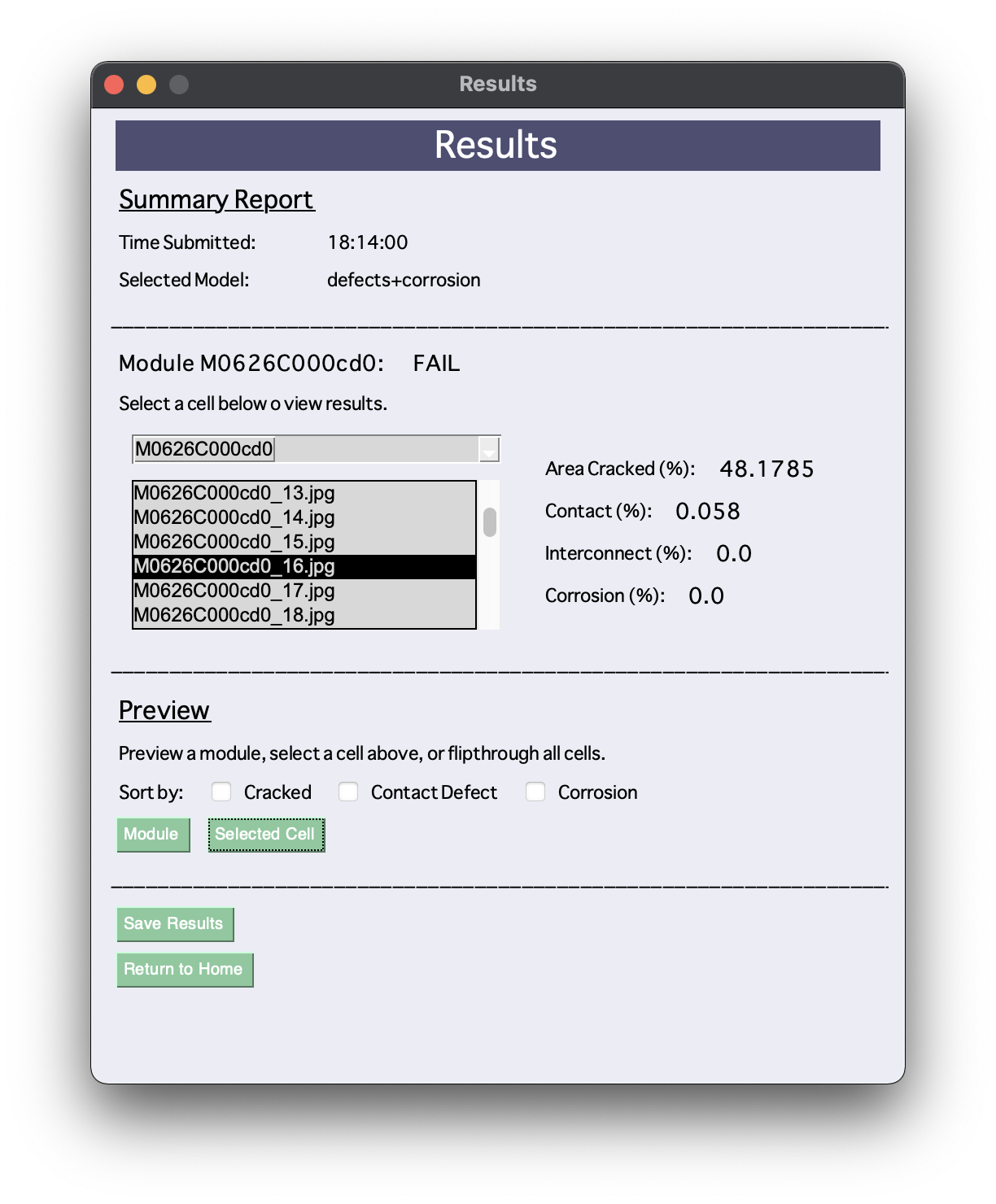

- Analysis and defect detection results collected and outputted, allowed for display and viewing. (See: 'Screenshots: Results Window')

(For initial 0.1.0 Release of BetterSolarUI)

* (installation has been tested on Python 3.7 and up on Windows, Linux, and MacOSX)

To run this project, install it locally on your machine. Use:

- Using GitHub CLI:

gh repo clone bettersolar/BetterSolarUI- Using git in terminal/command line:

git clone https://github.com/bettersolar/BetterSolarUI.git- Using python IDE w/ integrated source control/git support:

- Find git clone support, paste

https://github.com/bettersolar/BetterSolarUI.git

- Find git clone support, paste

Requires python environment to run. Example environment setup instructions: https://docs.anaconda.com/anaconda/install/index.html

IMPORTANT NOTE: if using an Anaconda environment, this must be ran before the requirements.txt file (dependency issues):

conda install -c conda-forge pyhull* there still seems to be an issue with this package using Anaconda on Windows. Please reach out if you have trouble getting an environment set up

Using the included requirements.txt file, use terminal to easily install dependencies onto your dedicated environment with:

pip install -r requirements.txtpython3 interface.pyFolder Structure:

BetterSolarUI

- demoinput\

- demoout\

- models\

- images\

...

[ interface.py, process_cells.py, etc]

- Input files placed in:

demoinput - Cell-cut modules outputted in:

images- Pre-cut cell images may be used, just place them in

images\{module_name}\, they will not get overwritten

- Pre-cut cell images may be used, just place them in

- Processed files outputted in

demoout - Defect Detection models placed in

models- Currently two models are avaliable for selection via the UI:

defect+brightspot.pth: cracks, contact interruptions, resistive interconnect defects and highlights interconnect brightspots.defect+corrosion.pth: cracks, contact interruptions, resistive interconnect defects and contact corrosion.

- Currently two models are avaliable for selection via the UI:

- 0.1.0

- Initial Release for SET! Submission of American Made Solar Prize Round 5: Software Track SET!

- Automated Detection of Module Size (e.g. 6x10, 60 cell)

- Various Bit Depth Imagery Accomodation

- Include Additional Defect Types and Grading Criteria

- Expand Image Preprocessing to include:

- Lens distortion (e.g. Fisheye Distortion)

- Intensity Normalization

- Background corrections

Email us at contact@bettersolargroup.com.