TL;DR This guide shows the process for engineering, fabrication, and operating of the OTB (Open Temperature Block). The OTB is a bench tool for controlling the temperature of DIY biological experiments to include and is not limited to PCR, heat shock, hibernation, and incubation.

1. Define the Problem:

The goal is to create a DIY, open-source, heating and cooling device for use in biological experiments. The DIY portion of this device will be assembled using basic tools. Being open-source allows for revision, evolution, and free dissemination. The heating control will allow for PCR reactions, heat shock experiments, incubation, and hibernation.

2. Identify Constraints:

| Name | Parameters |

|---|---|

| Size | Microplate footprint (127.76 mm x 85.48 mm) |

| Weight | For shipping lighter is better |

| Cost | < $1000 USD (Competitor range: $900 <-> $20K, Average $5k ) |

| Power | 120VAC and 240VAC input |

| Temperature Range | ≤ 3°C to ≥ 100°C for a duration of < 30 Minutes |

| Componets | Readily sourced; electronics, hardware, microcontroller |

| Decibels | 60 decibels |

| Water Tight | Does not leak |

| Geometry | Rectangular |

| Cleanability | Allows for cleaning. |

| Assembly | Uses standard hex screws. |

3. Brainstorm:

| Idea | Pro | Con |

|---|---|---|

| Peltier (TEC) | Cost-effective, heats and cools, small size | Uses a lot of power to remove heat. |

| Heat Element | Cost-effective, any size filament | Doesn't cool |

| Compressor heat exchanger | Power Efficient | Expensive, Slow, not DIY. |

4. Select promising solution:

The engineered solution will use a Thermal Electric Cooler (TEC) and a heat exchanger. To create the OTB there will be three systems; power, data, and water-heat.

The OTB is powered by a 12V 17AMP power supply. This will power the Peltier, fans, pump, and a voltage regulator will step down the 12V to 5V for the microcontroller.

The OTB data system is broken into device logic and external control. Device logic describes the microcontroller interaction with the Peltier, Temperature Probes, input devices. To accurately control the Peltier the microcontroller supplies a PWM signal to the high-power motor controller. This will change the electrical duty cycle allowing for precise Peltier control. The microcontroller samples temperatures from two thermistors. One thermistor is located on the heat block and the other is attached to the heat exchanger. These values will provide the logic needed to safely control the heat and cooling operations. External control consists of an I2C slave data line, display with buttons, and Wifi. The I2C data line allows for sending and receiving data from a Master I2C device. The display consists of an OLED display and four buttons. The OLED in conjunction with the buttons allows the user to navigate through menus, and execute functions. Lastly, the Wifi provides a wireless gateway to Communicate with the OTB via a web page and RESTapi.

The water-heat system consists of a water block, pump, fan, and radiator. In the heating phase, the microcontroller sends positive voltage to the Peltier. In the cooling phase, the microcontroller sends a negative voltage to the Peltier. Durning all heating and cooling operations the pump is moving water through the water block, through the tubing, to the radiator, and back to the water block. The radiator uses an electric fan to blow air over the fins and exchange heat to the environment.

Sketch (Free Body Diagram):

MATH:

5. Prototype

Parametric Model.

Version 1

Version 1

Version 1

6. Test

7. Iterate

8. Communicate Results.

| QTY | Name | Quantity | Cost | Item Cost | Total Cost | URL |

|---|---|---|---|---|---|---|

| 6 | Peltier | 10 | 28.99 | 2.899 | 17.394 | https://amzn.to/3pDVF7H |

| 2 | 120x40 Water Cooling Block | 2 | 18.99 | 9.495 | 18.99 | https://amzn.to/3pyl8zk |

| 1 | 96 Well Aluminum Block | 1 | 169.13 | 169.13 | 169.13 | https://amzn.to/3DyzIvE |

| 1 | 24 Well Aluminum Block | 1 | 71.89 | 71.89 | 71.89 | https://amzn.to/3dthdhx |

| 1 | 384 Well Aluminum Block | 1 | 0 | 0 | 0 | |

| 3 | Thermistors | 10 | 13.99 | 1.399 | 4.197 | https://amzn.to/3IsNvaJ |

| 1 | Wifi Microcontroller | 1 | 44.61 | 44.61 | 44.61 | https://amzn.to/3lIX8YV |

| 1 | 240x360 Radator | 1 | 29.99 | 29.99 | 29.99 | https://amzn.to/3duD08s |

| 3 | 120 Fan | 4 | 17.99 | 4.4975 | 13.4925 | https://amzn.to/2LkDNhD |

| 1 | 2 Relay Module | 4 | 8.99 | 2.2475 | 2.2475 | https://amzn.to/3rHmMkP |

| 6 | Vinyl Tubbing | 50 | 26.99 | 0.5398 | 3.24 | https://amzn.to/3pyTouq |

| 8 | Hose clamps | 25 | 10 | 0.4 | 3.2 | https://amzn.to/3lLbY14 |

| 1 | Pump | 1 | 37.79 | 37.79 | 37.79 | https://amzn.to/3y0tPpT |

| 1 | Power Supply | 1 | 28.99 | 28.99 | 28.99 | https://amzn.to/3dsQ0LN |

| 0 | Stand Offs | 1 | 0 | 0 | 0 | |

| 1 | Case | 1 | 60 | 60 | 60 | |

| 6 | 12G Copper wire | 25 | 36.66 | 1.4664 | 8.80 | https://amzn.to/3lL9YpA |

| 4 | G1/4 Thread Soft Tube Barb | 6 | 11.15 | 1.86 | 7.43 | https://amzn.to/3pxsC5G |

| 1 | Ardunio PCB Board | 1 | 10.99 | 10.99 | 10.99 | https://amzn.to/3pyTouq |

| 1 | Real Time Clock (RTC) | 5 | 17.49 | 3.50 | 3.50 | https://amzn.to/3IfnBqF |

| 1 | DC-DC Buck | 1 | 30 | 30 | 30 | https://amzn.to/3Gn74iR |

Total $565.88

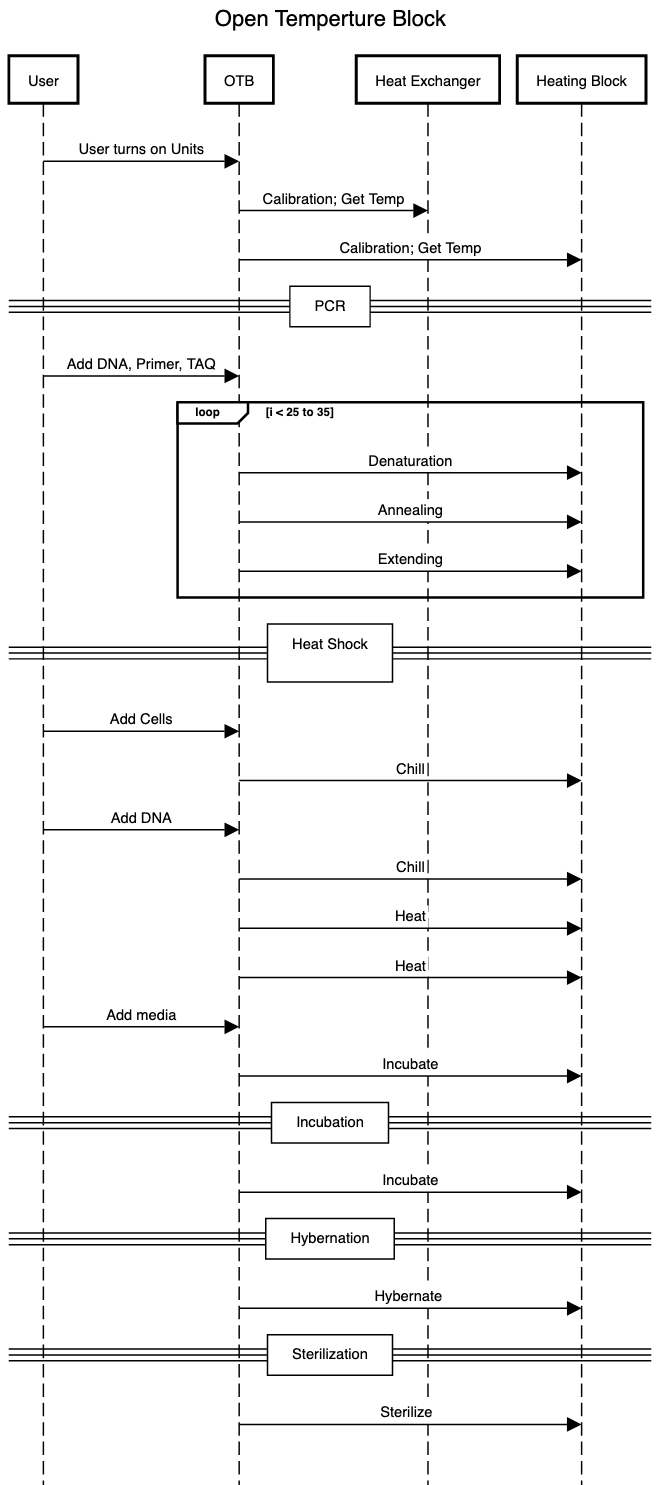

This Sequence Diagram outlines the functions needed for the OTB.

- Download Arduino IDE

- Download this Zip File to your computer

- Navigate to the

Open_Temperture_Block Codefolder - Upload Open_Temperture_Block.ino Code to Arduino

- Solder wires and components onto Arduino Sheild PCB

- Solder OLED, (4) Buttons, Wires, and JST-XHP connector to PCB

- Affix fan to the radiator.

...

...

...

...

This project is licensed under the MIT License - see the LICENSE.md file for details