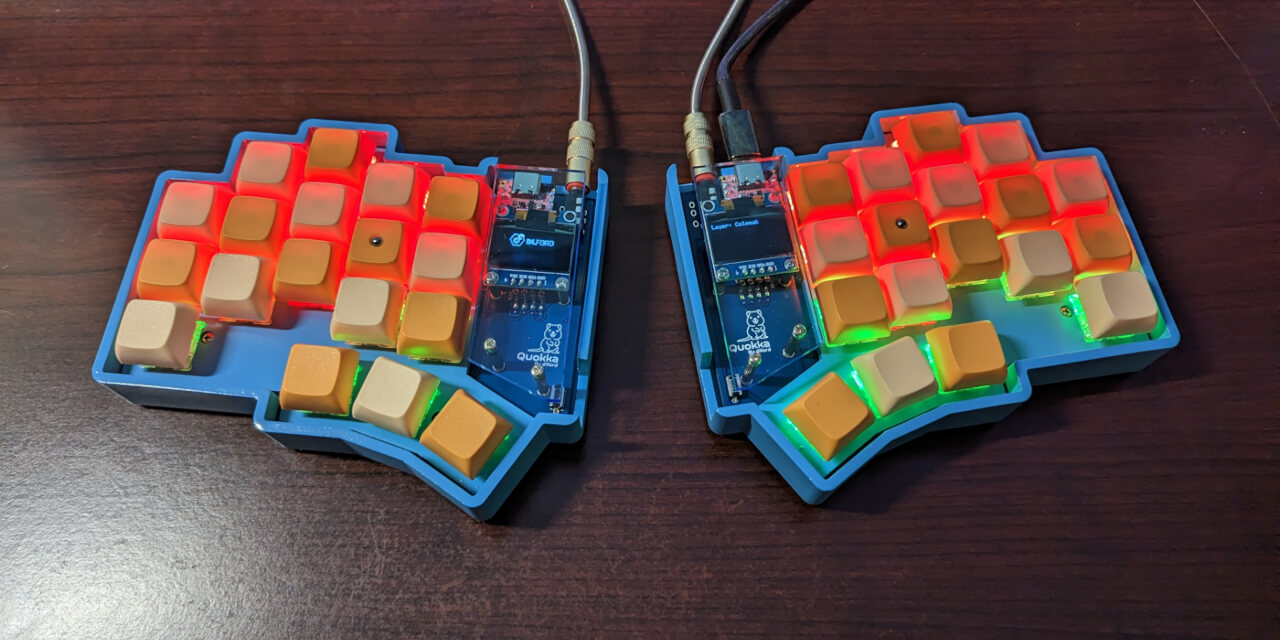

- Designed for smaller handed folks

- Steep columnar stagger

- Slightly tucked in thumb cluster

- Per-key RGB Matrix using the easier to solder SK6812-MINI-E LEDs

- Piezo speakers

- 128x64 OLED displays

- TRRS jack faces back to keep your cables out of the way

- Full duplex serial connection between halves

* Affiliate Links

- 36x MX keys

- 36x Kailh MX Hot Swap Sockets*

- 36x D_0805 1N4148 Diodes*

- 2x PJ-320A TRRS Jacks*

- 2x Adafruit KB2040 MCU

- 8x Stick-on Rubber Feet*

- 2x PTS636 SP43 LFS Reset Buttons (Optional)

- 36x SK6812-MINI-E RGB LEDs (Optional)

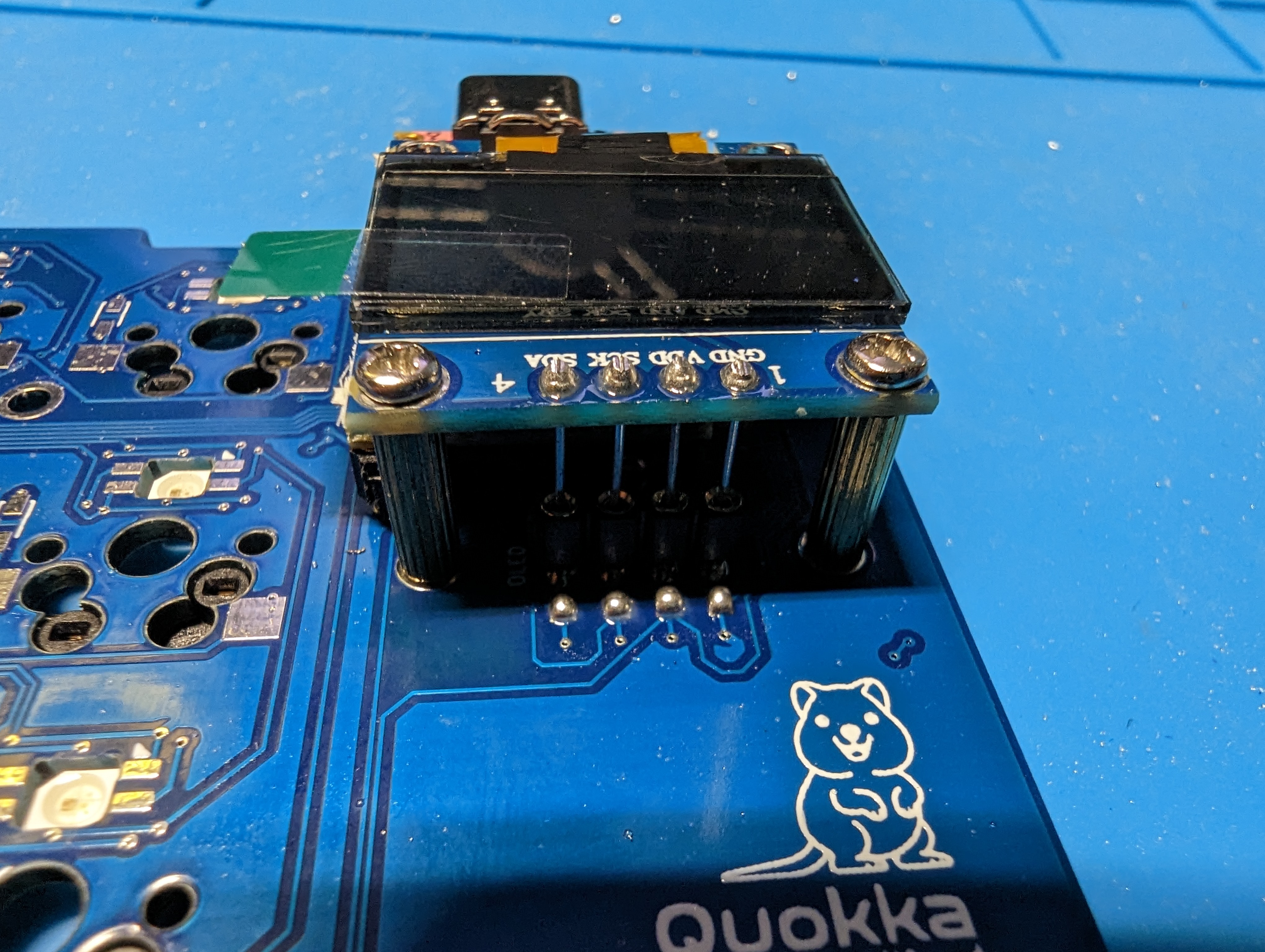

- 2x GME12864-49 OLED Displays (Optional)

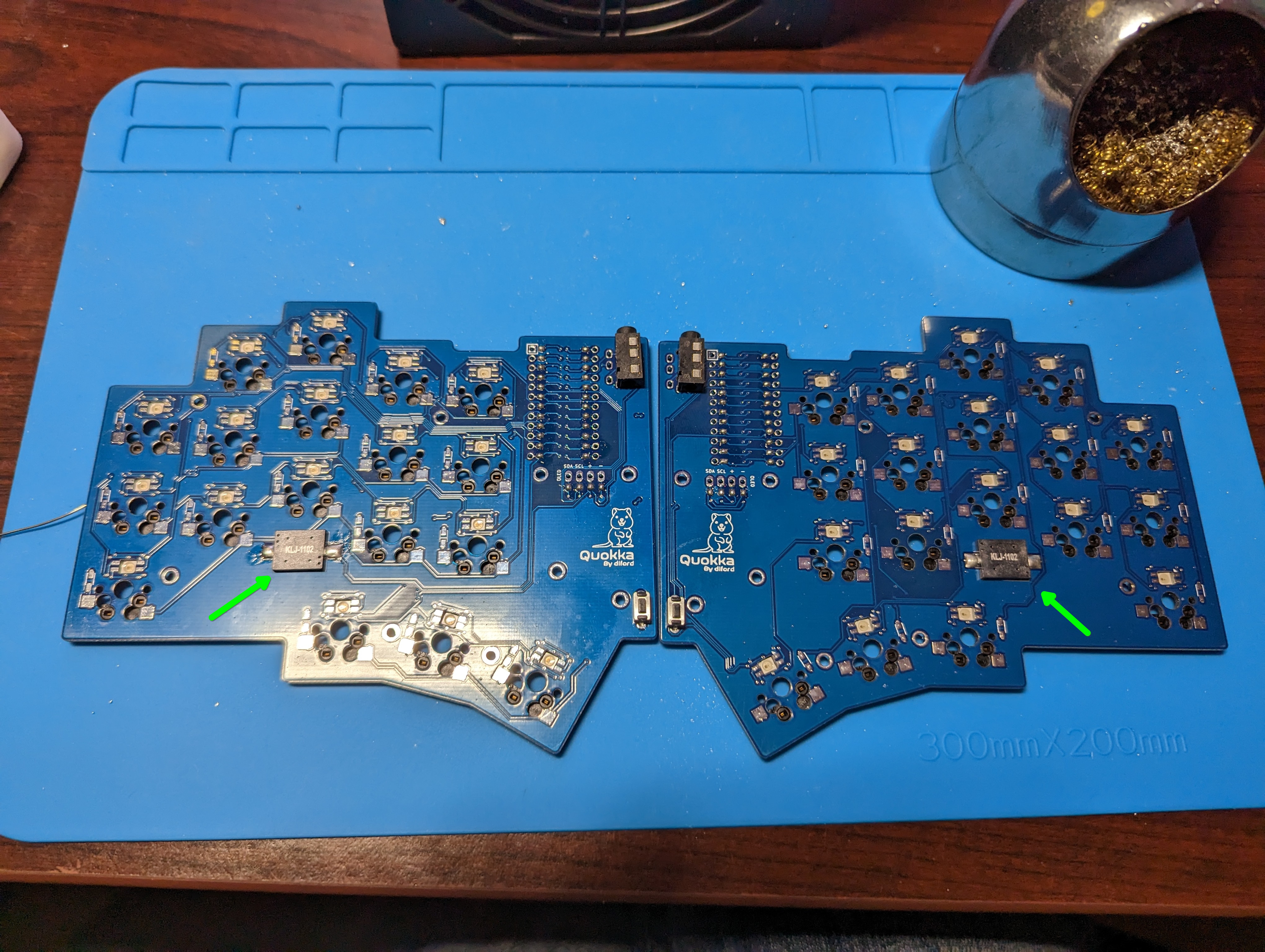

- 2x KLJ-1102 Piezo Speakers (Optional)

- Pin header strip sockets* (Recommended, for hot swapping MCUs/OLEDs)

- Through hole resistors or diodes to sacrifice legs for pin header strip sockets (if using)

- OLED hardware

- 16x M2x4mm screws

- 4x M2x10mm stand-offs for OLED mounting

- 4x M2x15mm stand-offs for OLED covers

- 3D Printed Case hardware

- 10x M2x9mm screws

- 10x M2x3mm heat set inserts

- Plated Case hardware

- 20x M2x4mm screws

- 10x M2x8mm round stand-offs for plate cases (these stand-offs* fit in a 1/8" hole, don't forget a drill and 1/8" drill bit)

Download the necessary assets from the releases page, you will find instructions on producing parts there as well.

-

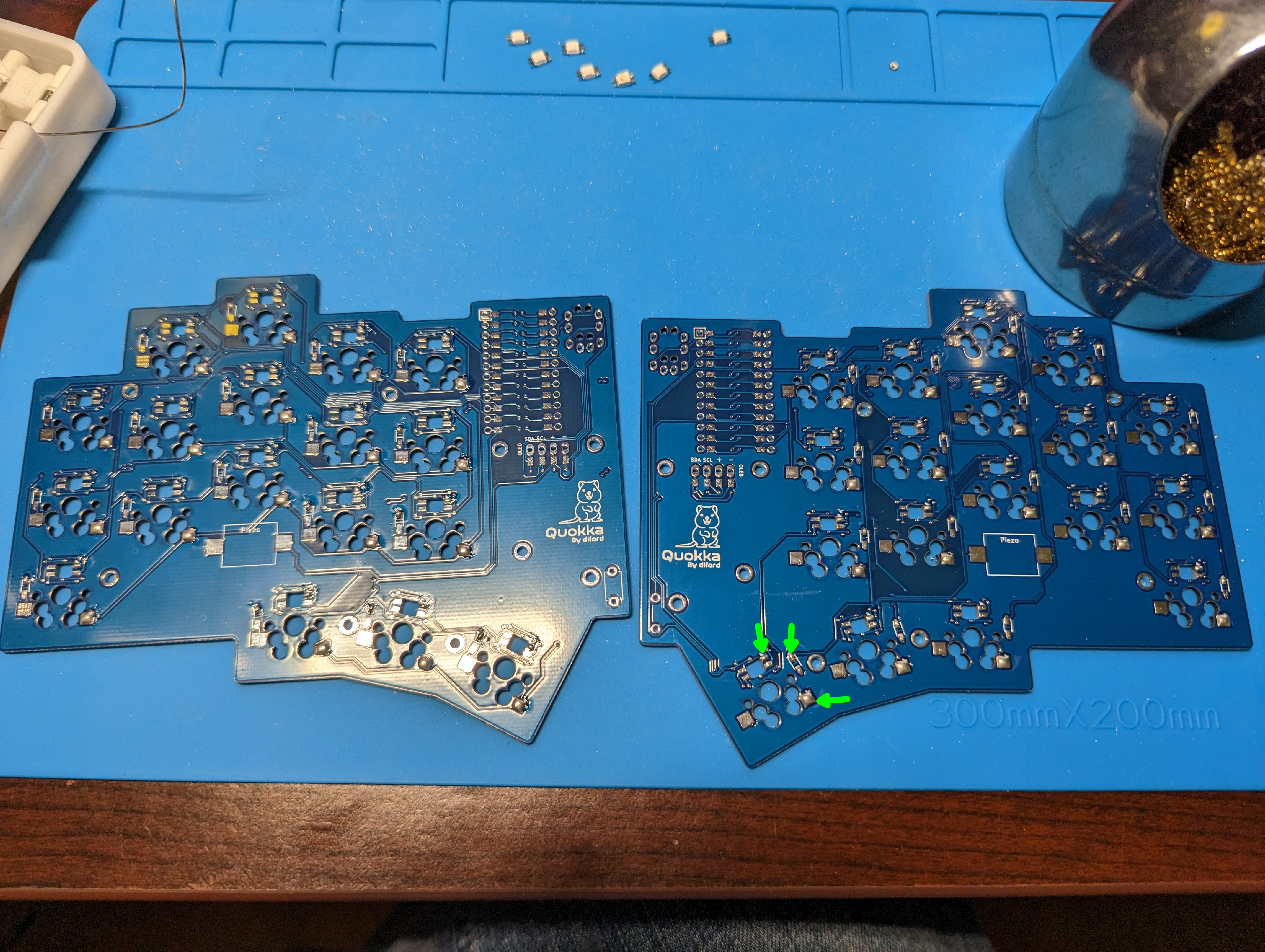

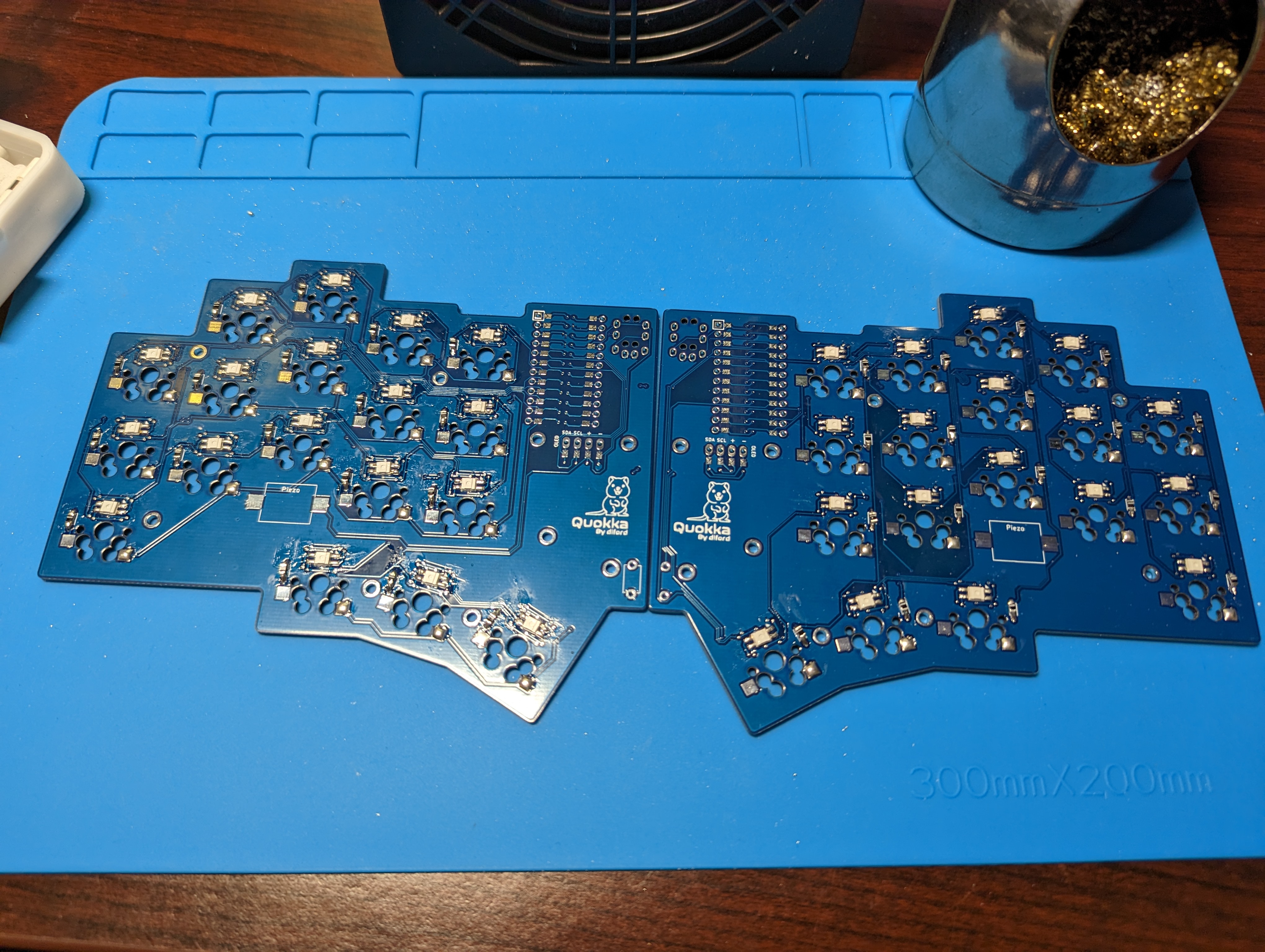

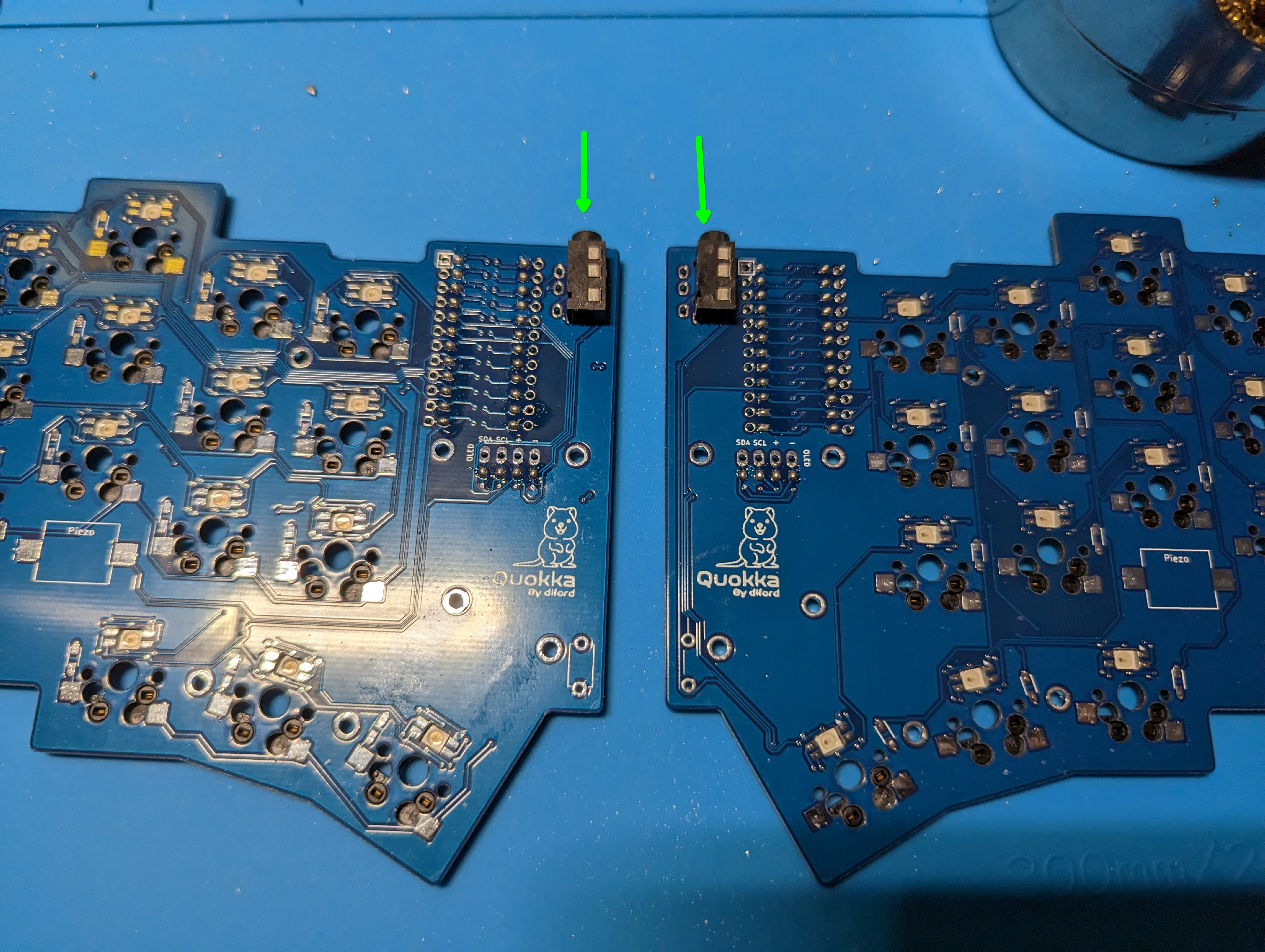

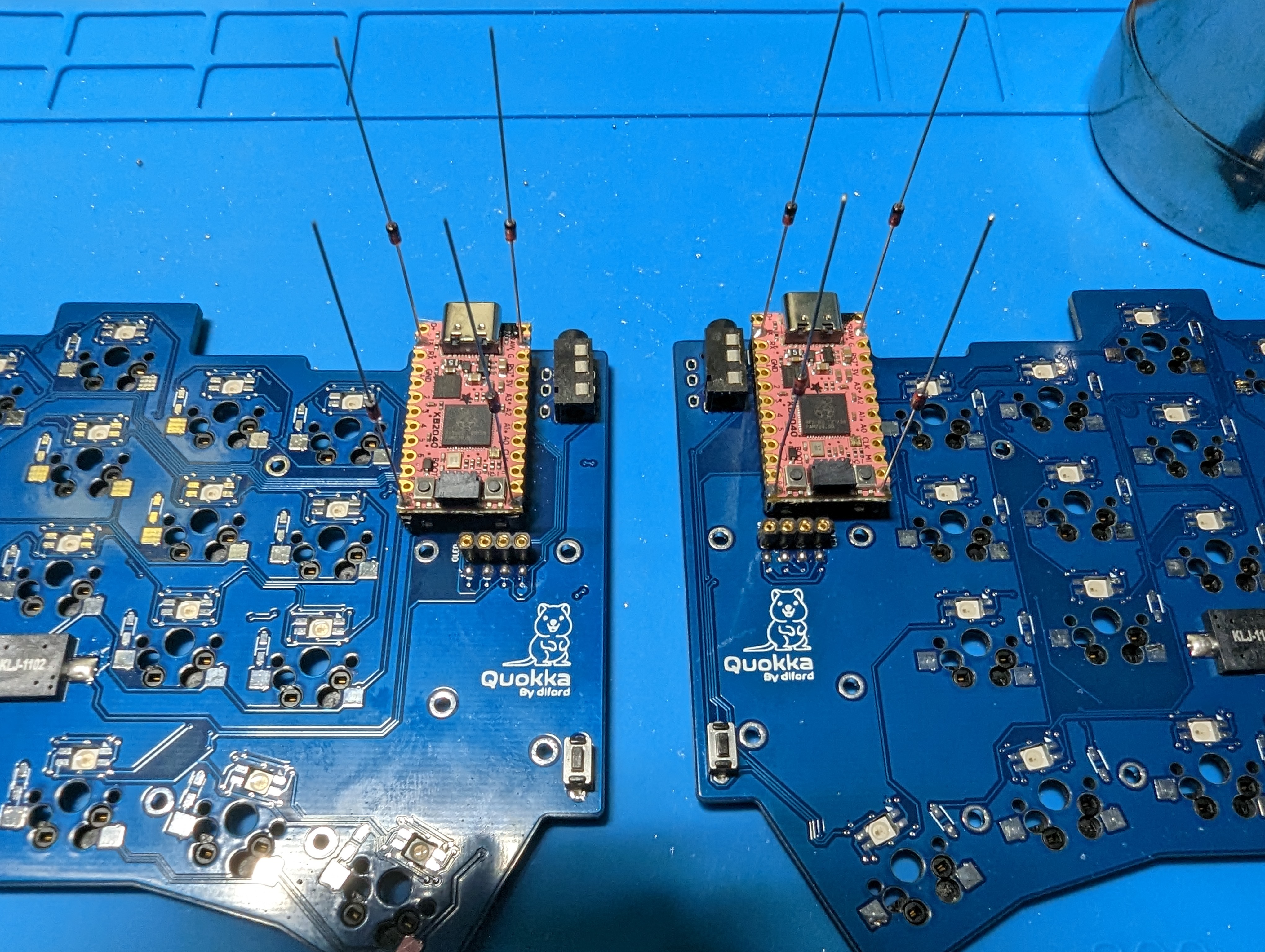

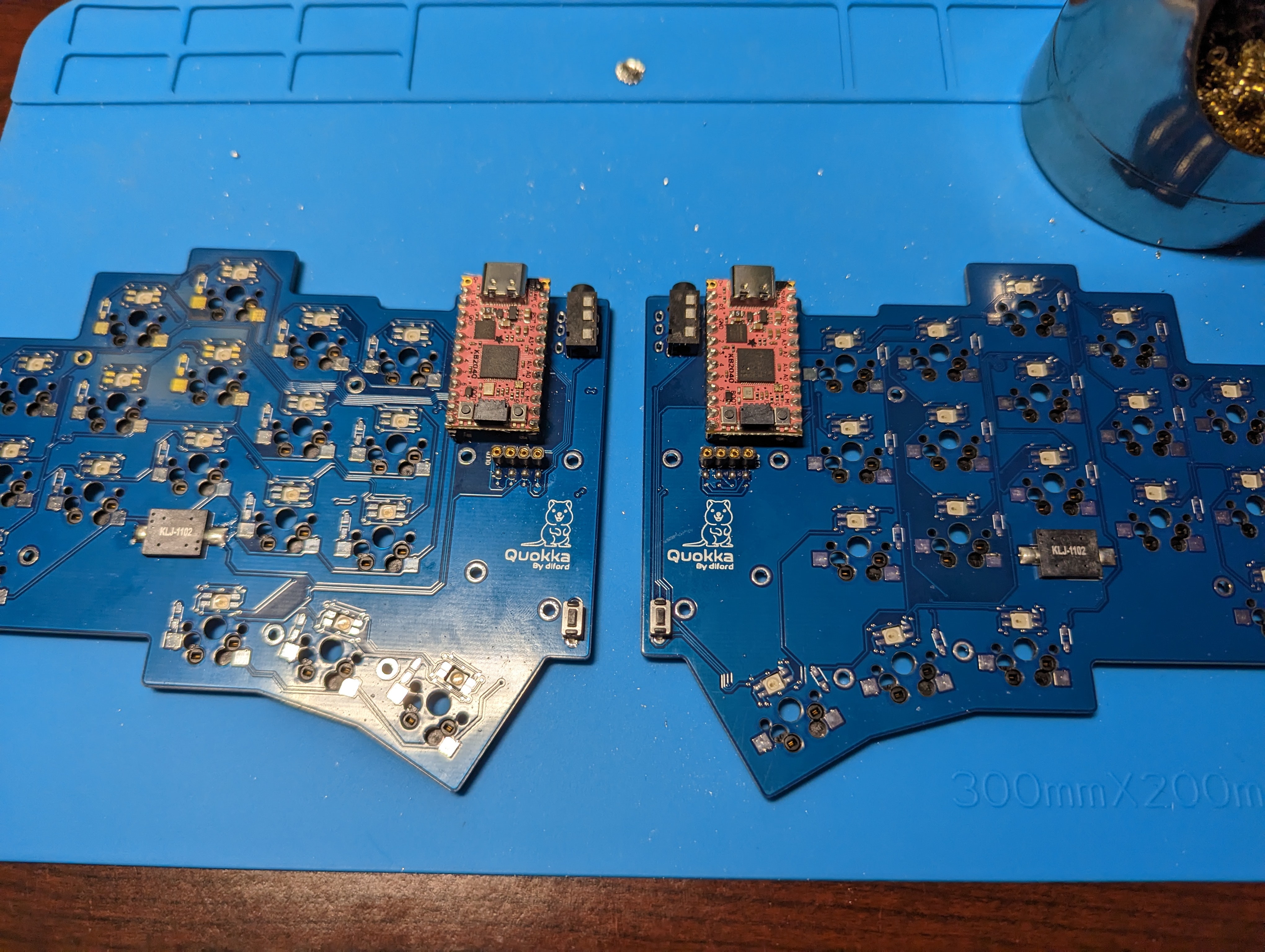

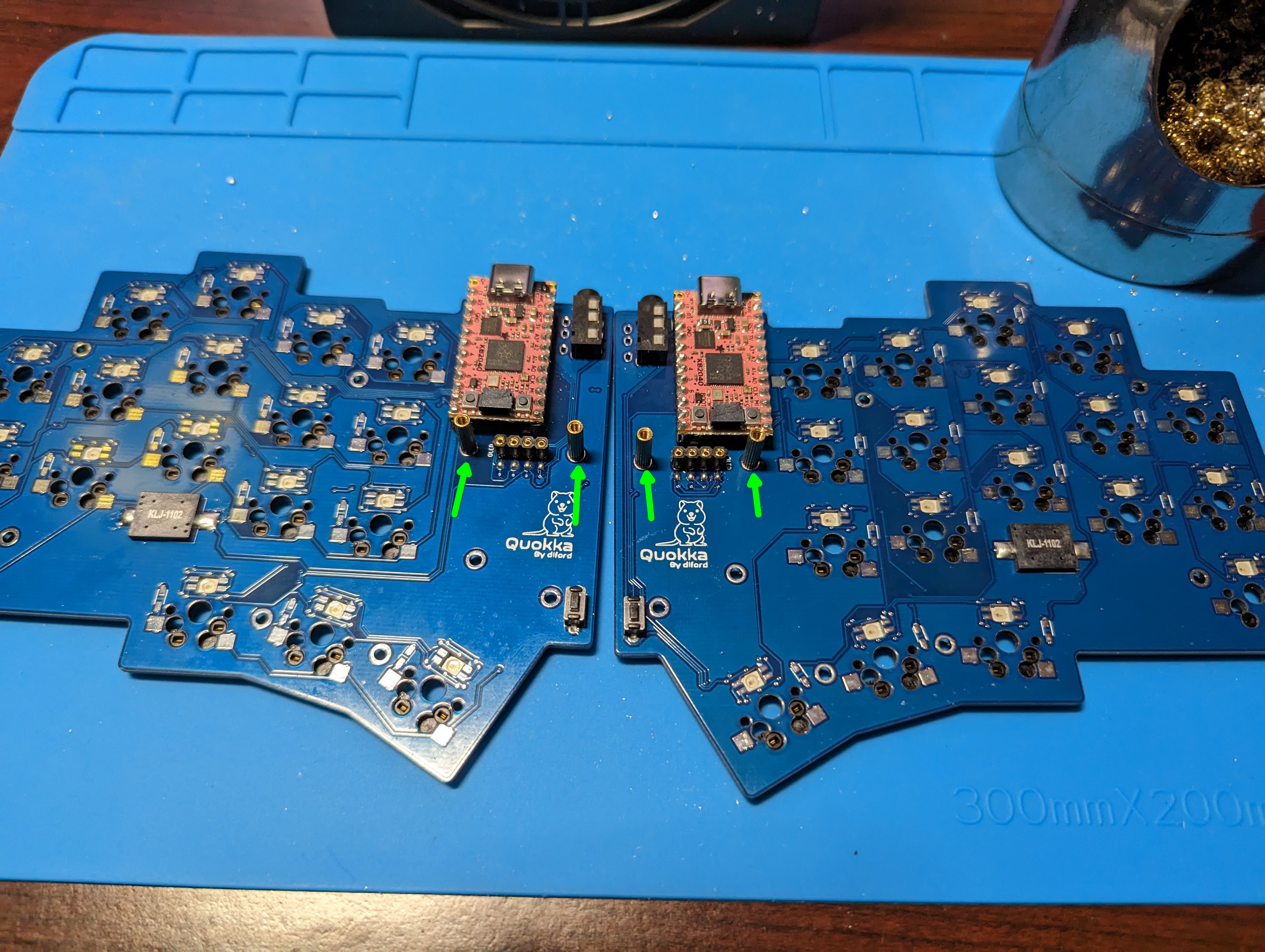

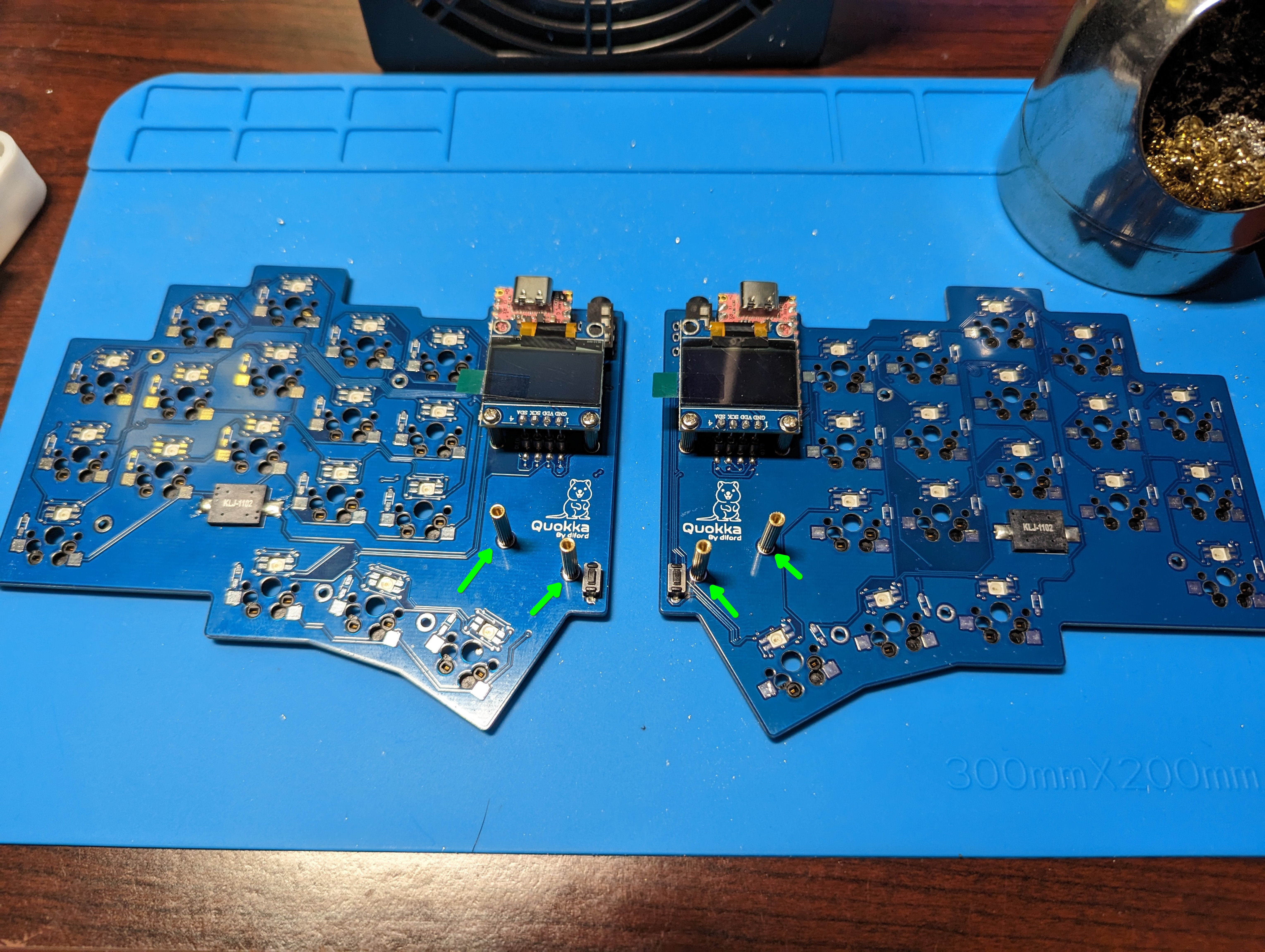

Lay out two PCBs, make sure one is flipped, as if you were to type on the keyboard.

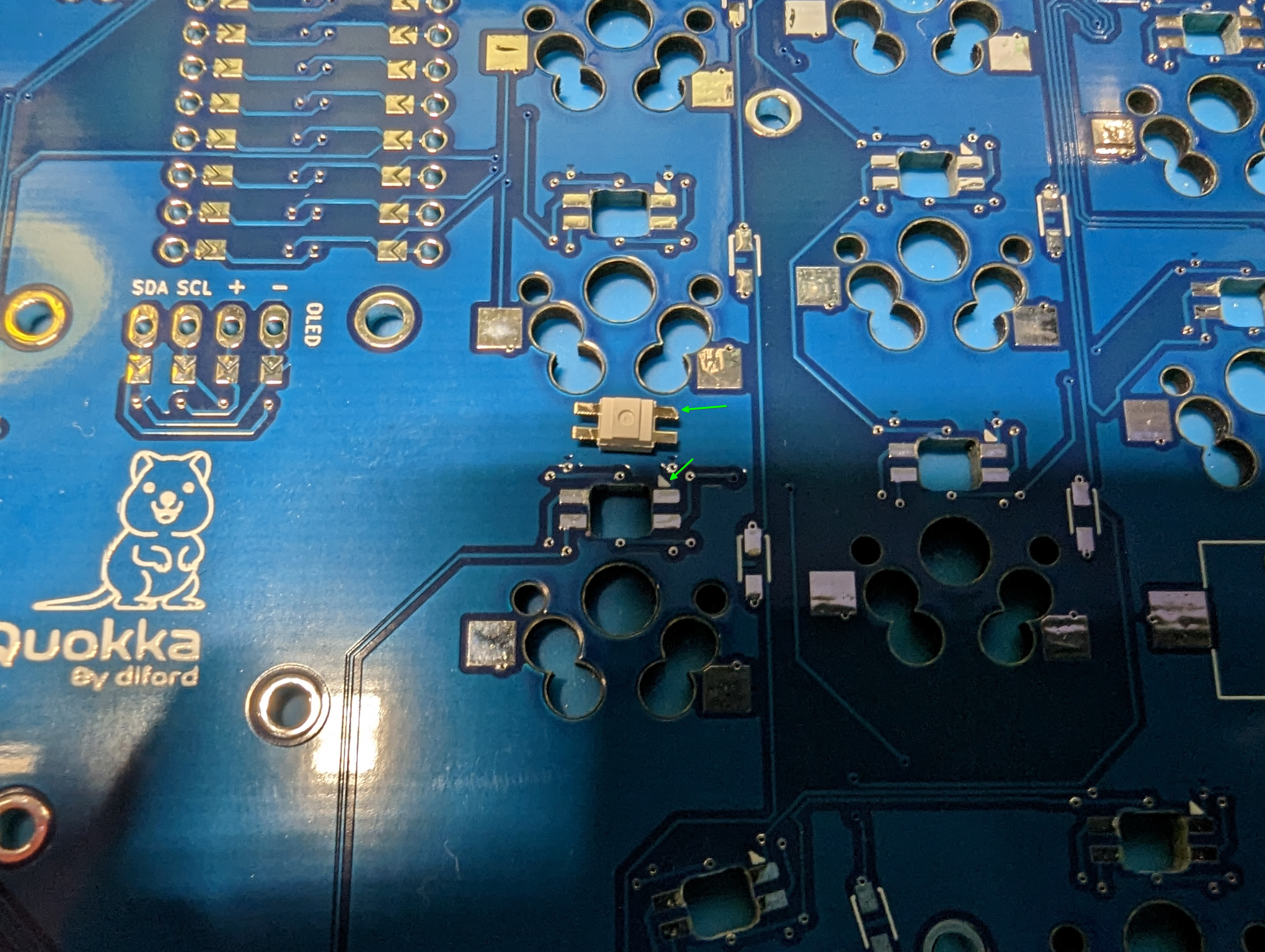

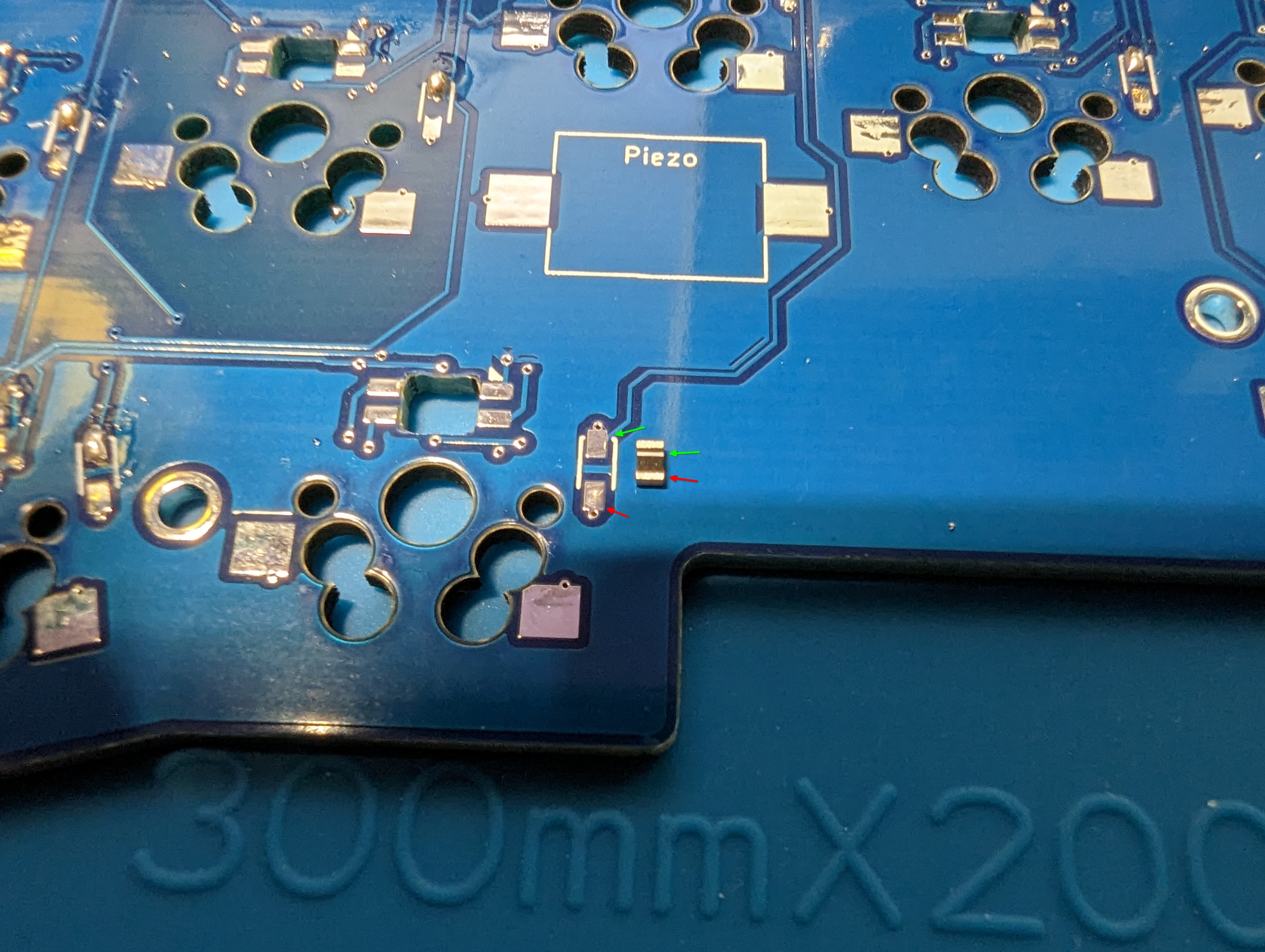

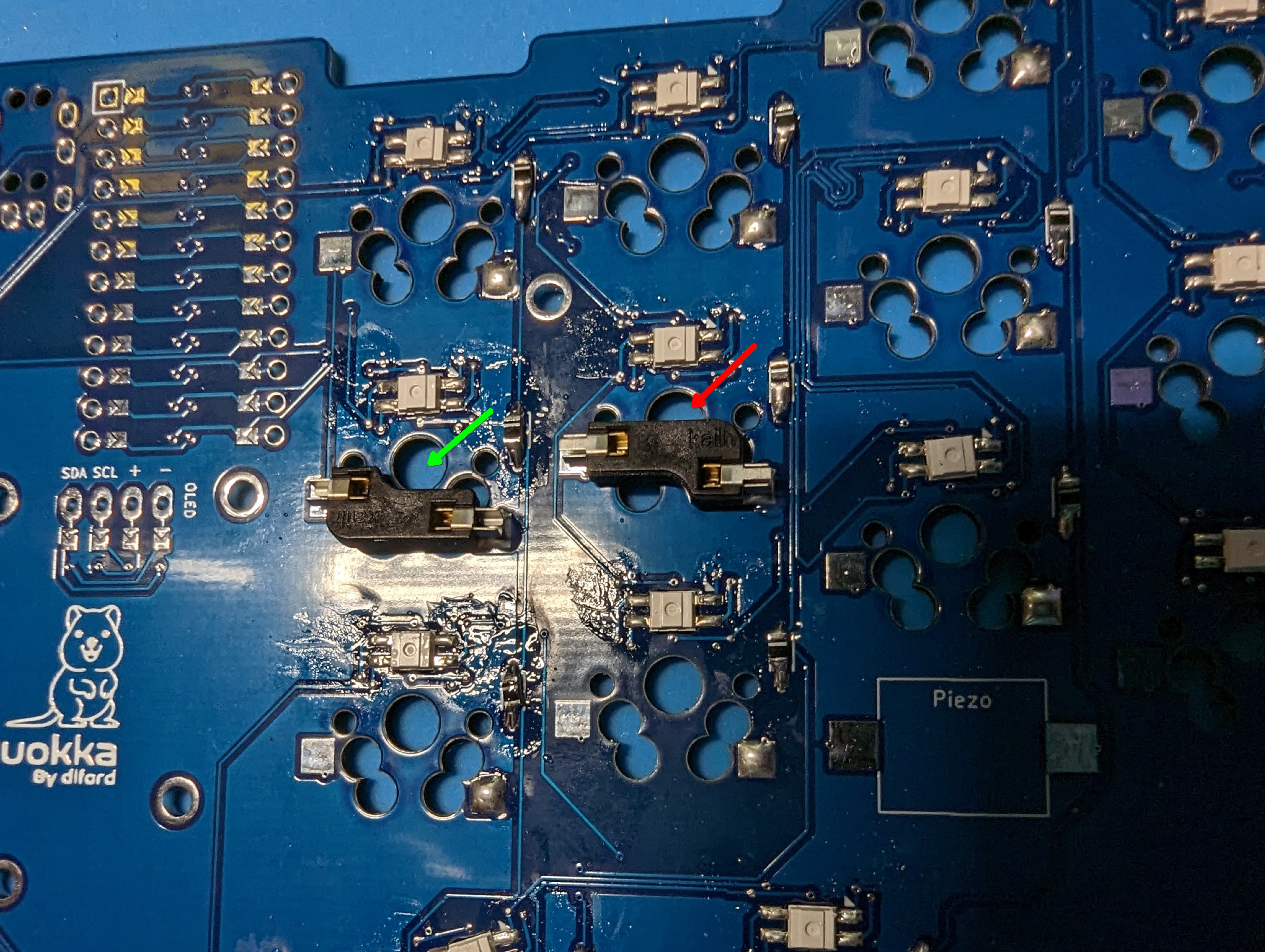

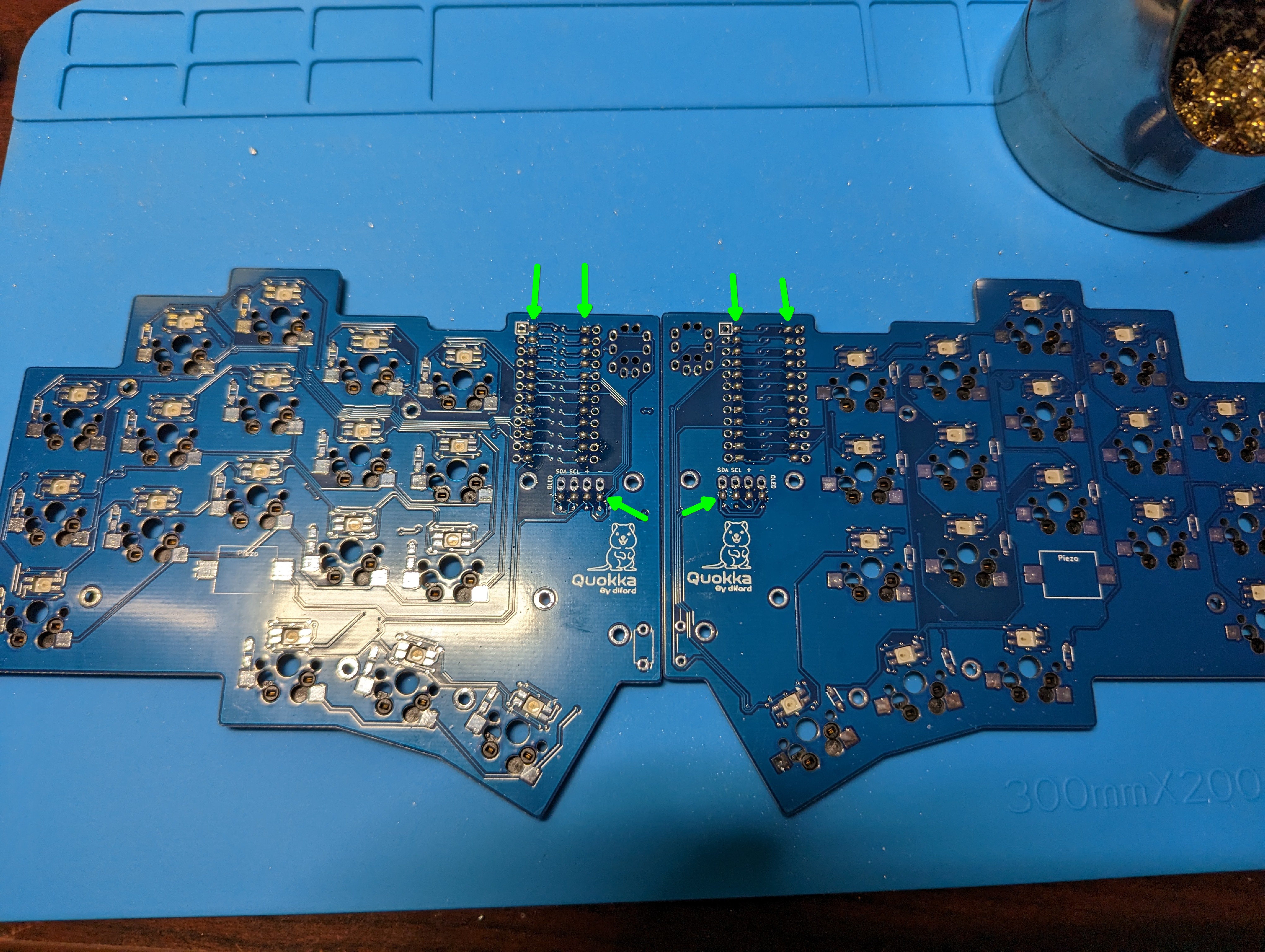

*Note: if you intend to use plates for the case, you will need to carefully drill out the 5 mounting holes on each PCB (marked in green) with a 1/8" drill bit so the stand-offs can fit through the holes (do not drill out the OLED or OLED cover mounting holes marked in red).

-

Tin SMD Pads

Add a bit of solder to on leg of the diodes, switches, and LEDs (if using)

When soldering SMD components, line up the part close to it's mounting place, heat up the solder on the pre-tinned pad, then slide the part in place, hold it there until after solder is cooled (tweezers will help with smaller parts), then solder the remaining legs, and go back over the first leg to ensure a good connection.

-

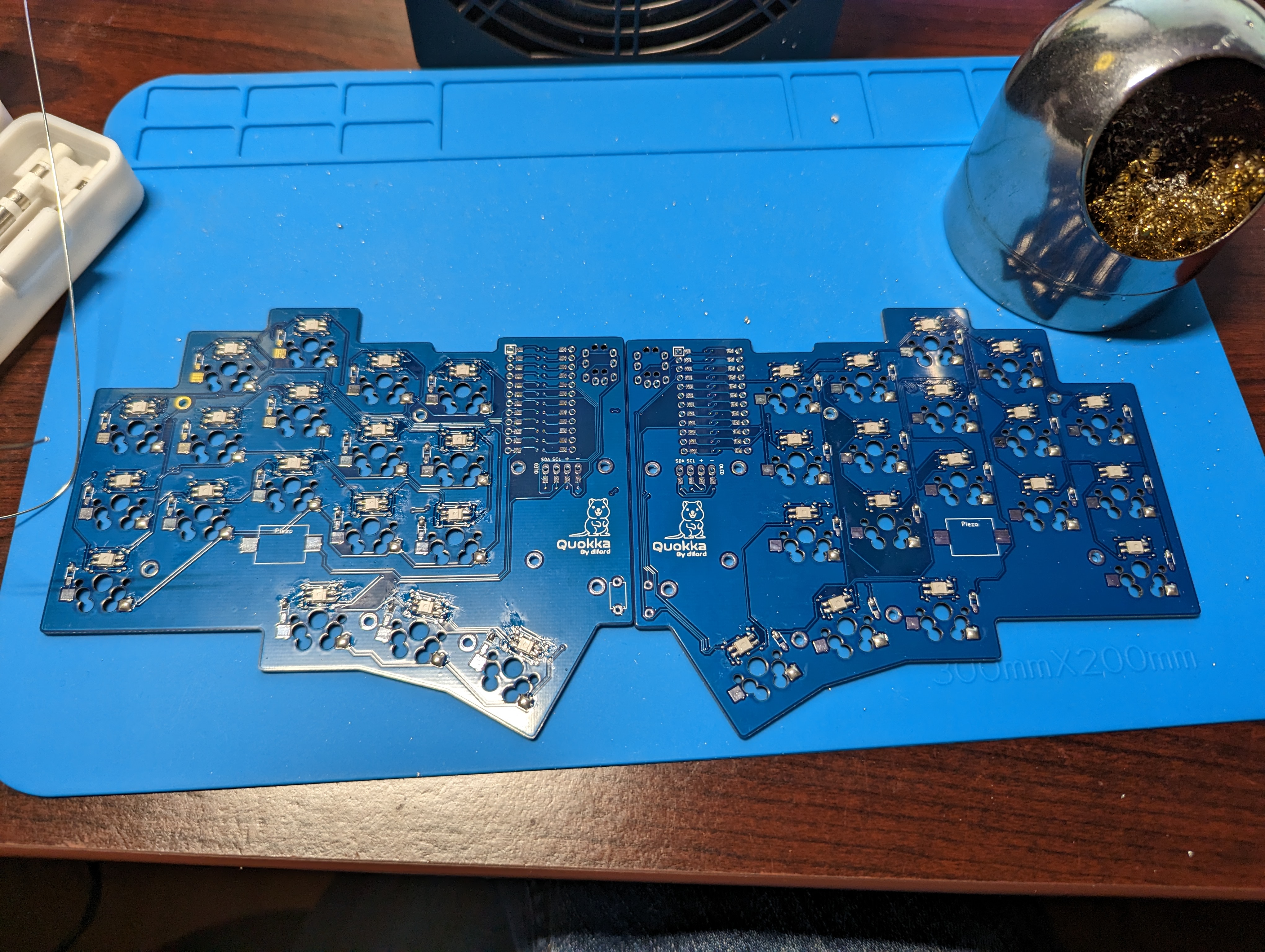

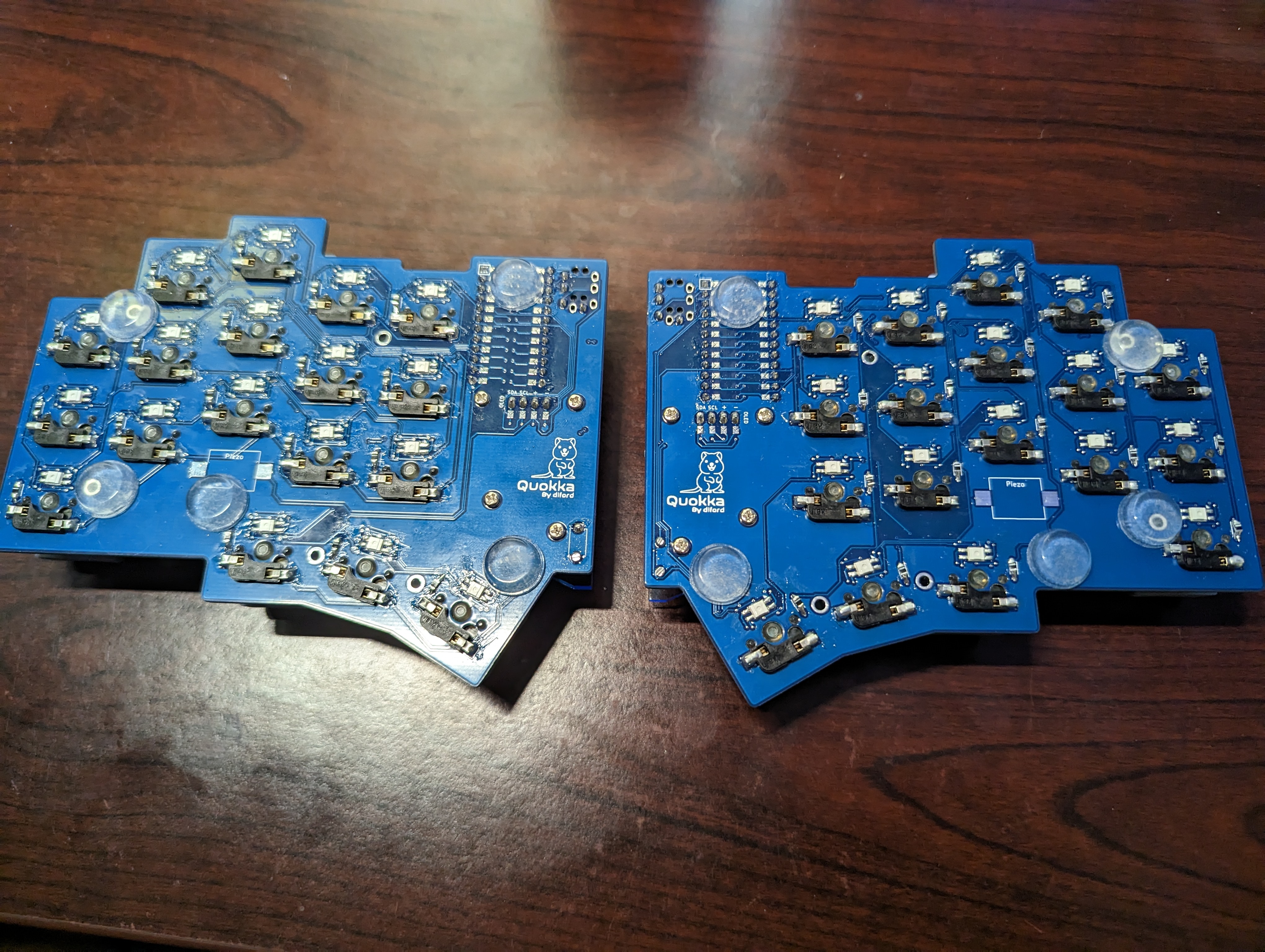

Solder LEDs (if using)

Place the LEDs face down in the square holes, match the leg with a notch in it to the white triangle on the PCB

-

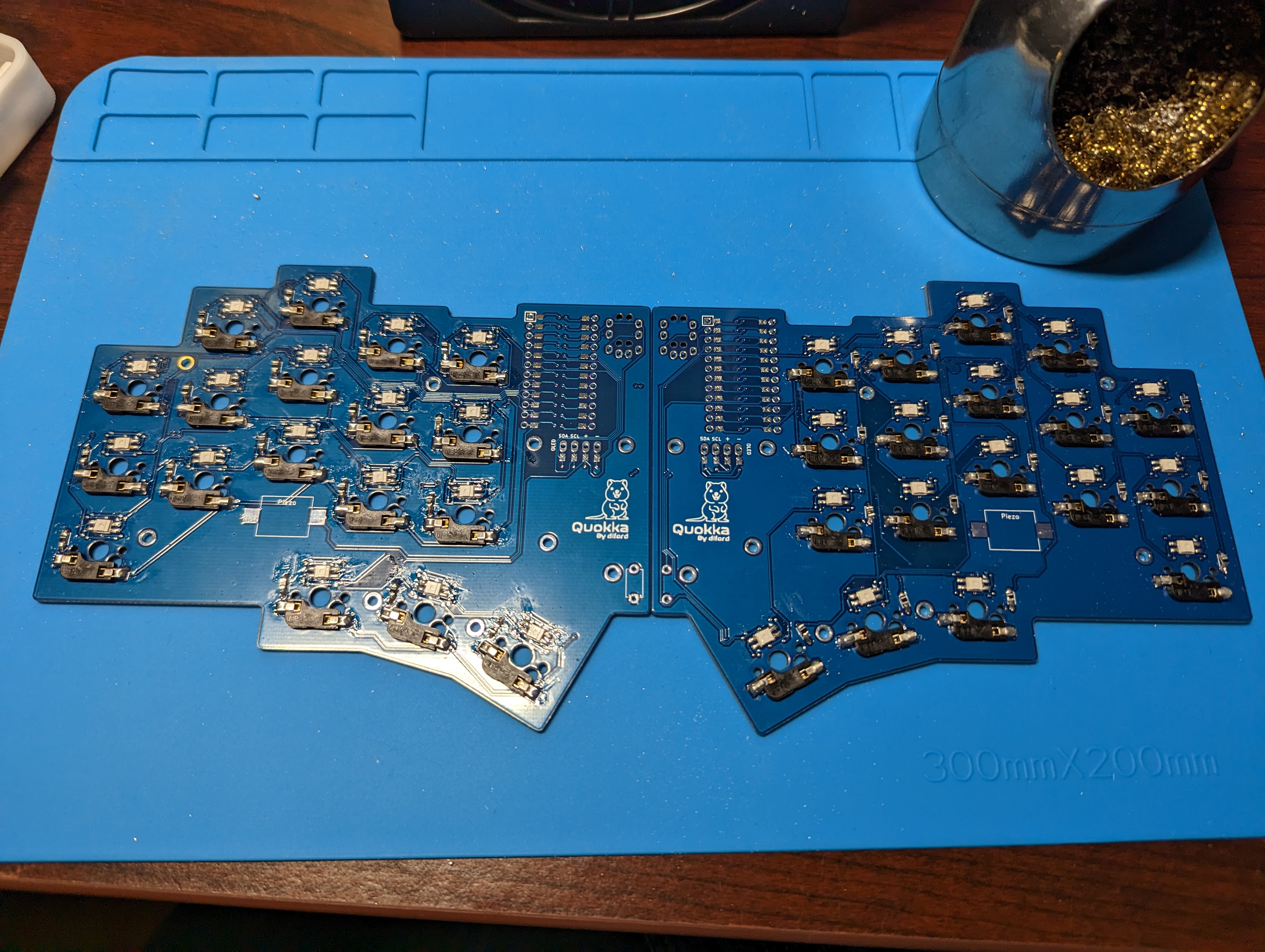

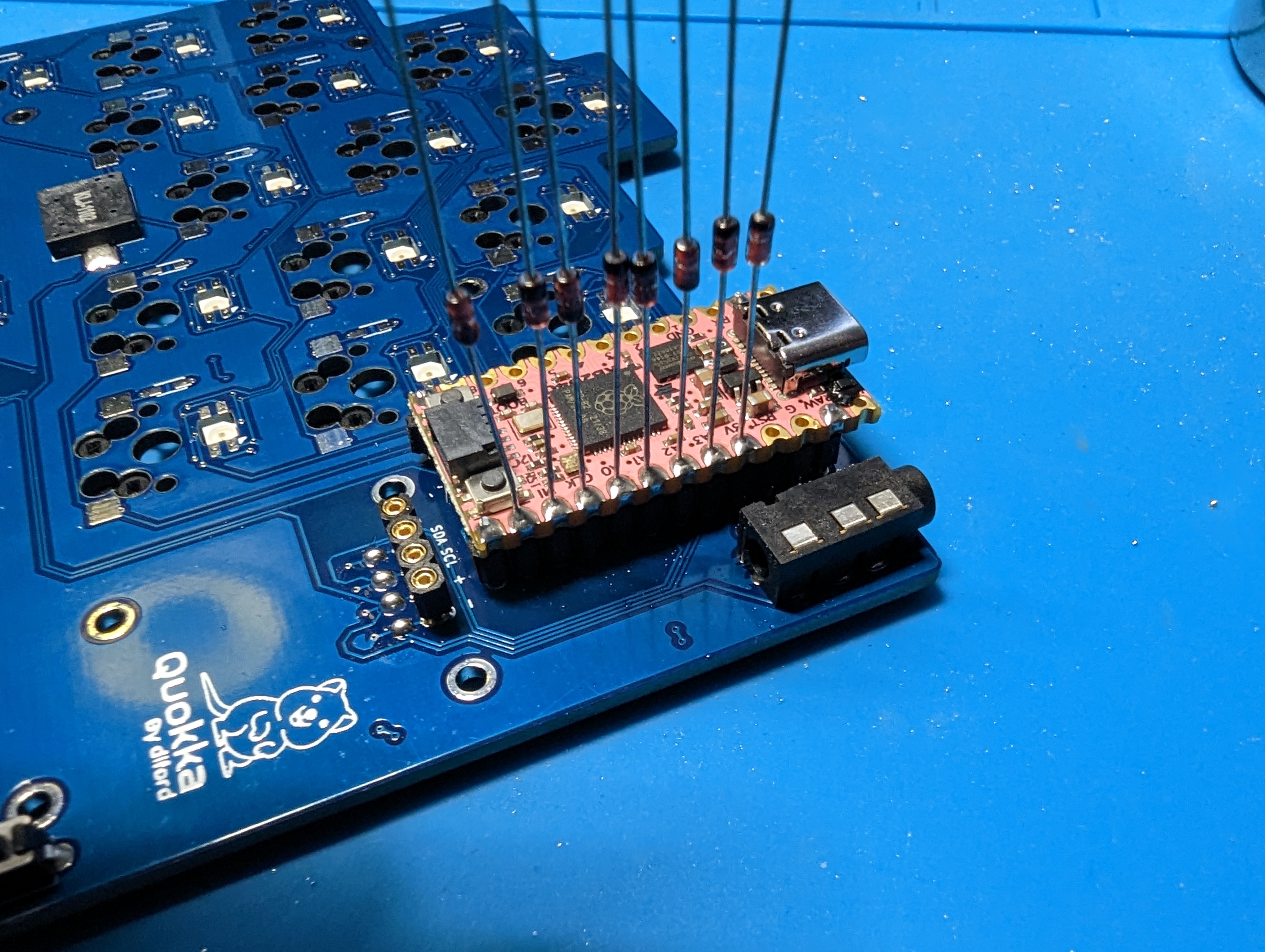

Solder Diodes

Place the diodes with the stripe facing the top of the keyboard (opposite the thumb keys)

-

Solder Hot Swap Sockets

Place the sockets so the curved portion is on the left, so as not to cover the center hole for the switch pin

-

Flip the PCBs over, so everything you just soldered on is on the back, facing the table

-

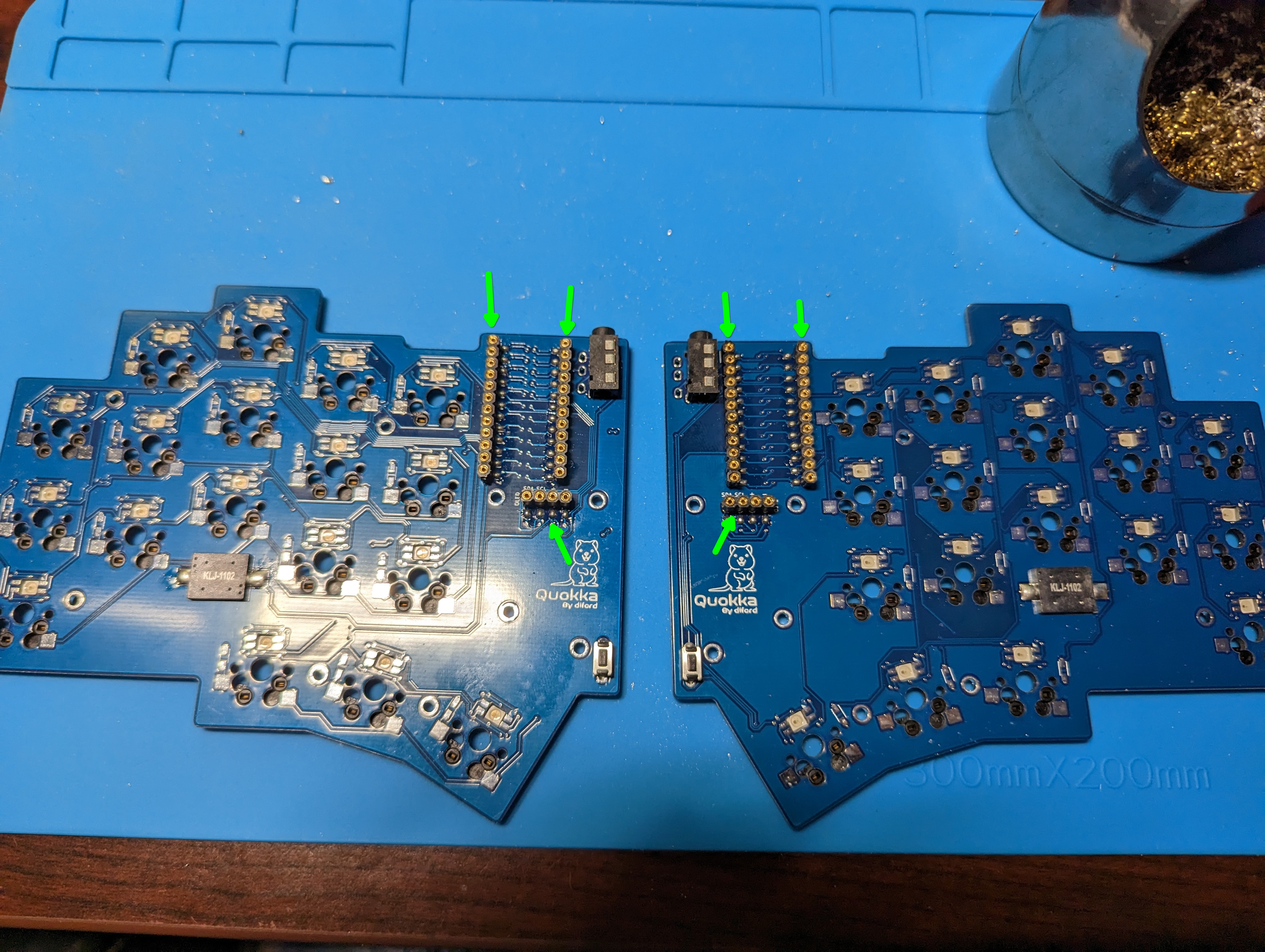

Solder the jumpers for the MCU and OLED (if using)

-

Solder the TRRS jacks

-

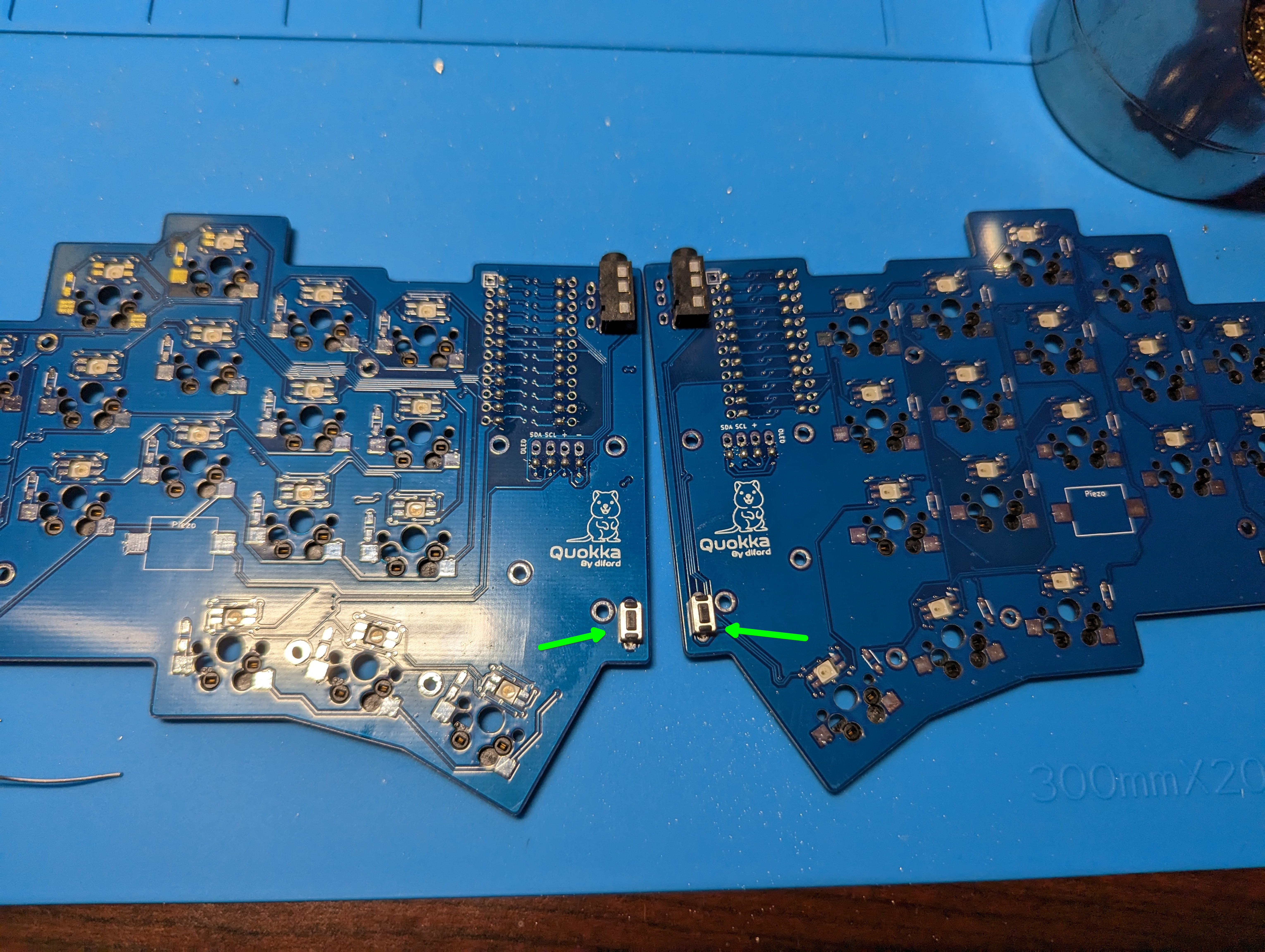

Solder the reset switches

-

Solder the piezo elements (if using)

The orientation of piezo elements does not matter

-

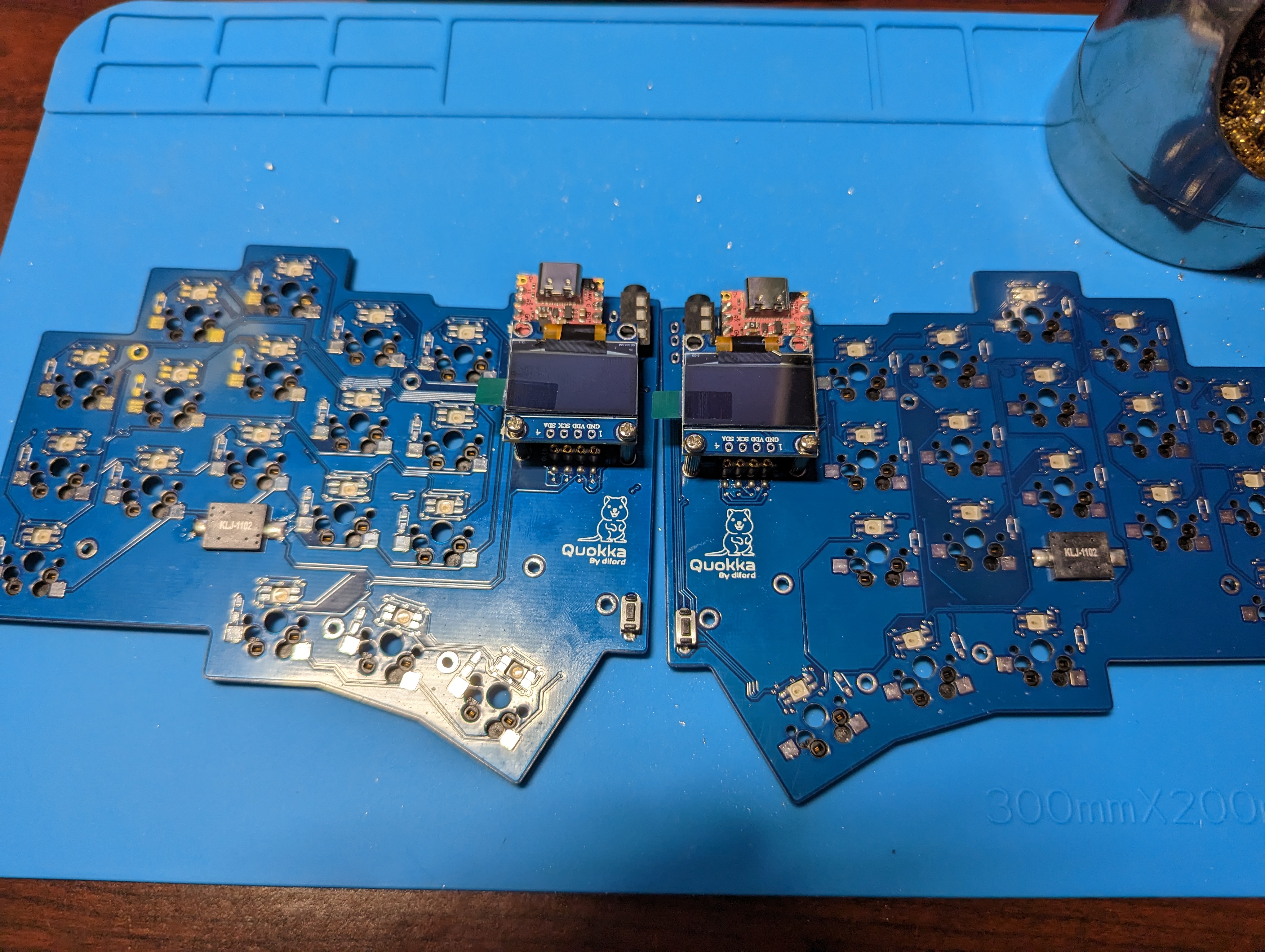

Solder the header strip sockets for the MCU and OLED (if using)

After soldering the first leg, heat it back up and adjust the angle of the strip to be as close to vertical as possible

-

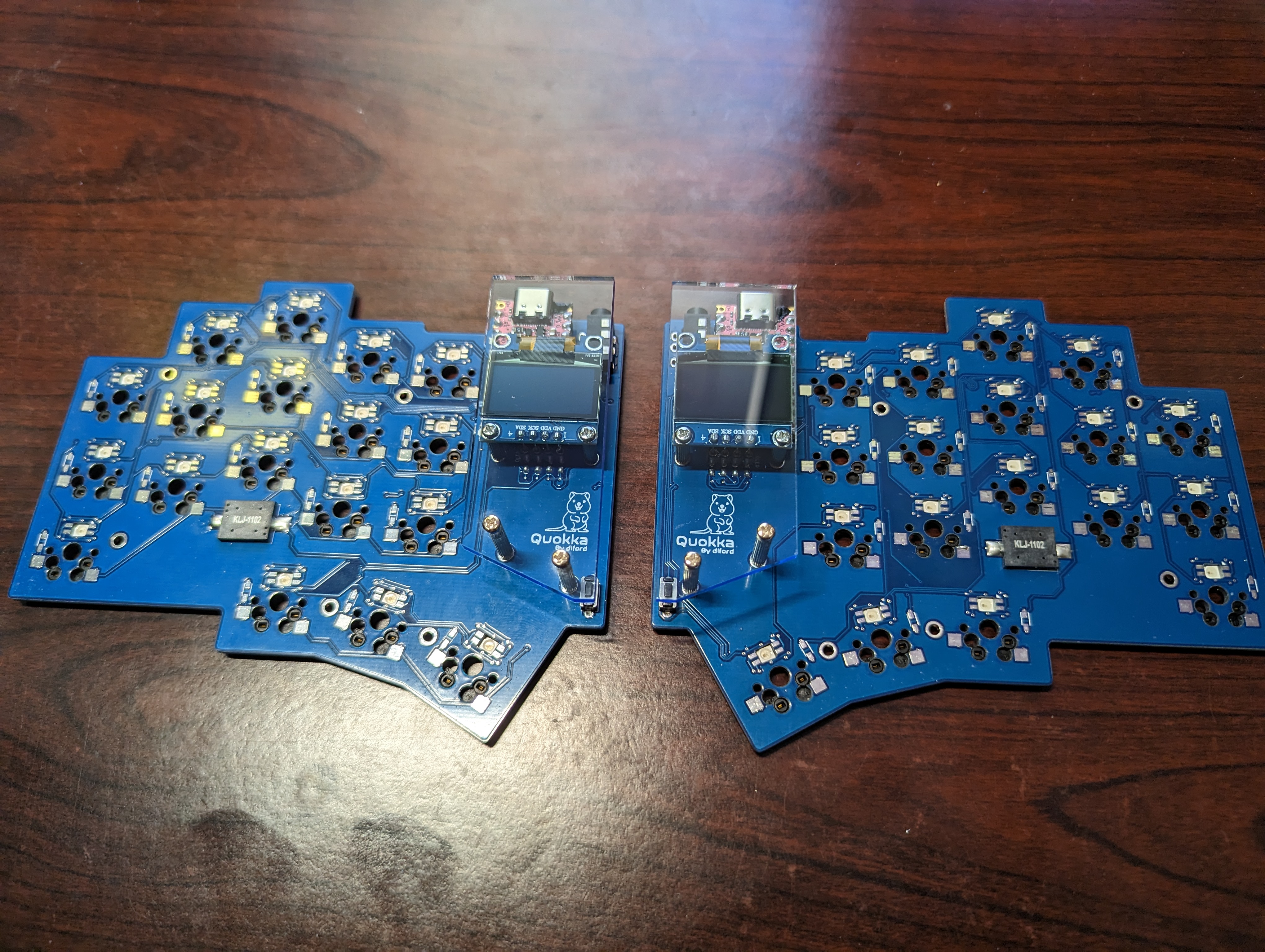

Place the MCUs

Orient the MCUs so they are face up, with the USB-C port facing the back of the keyboard (opposite the thumb keys)

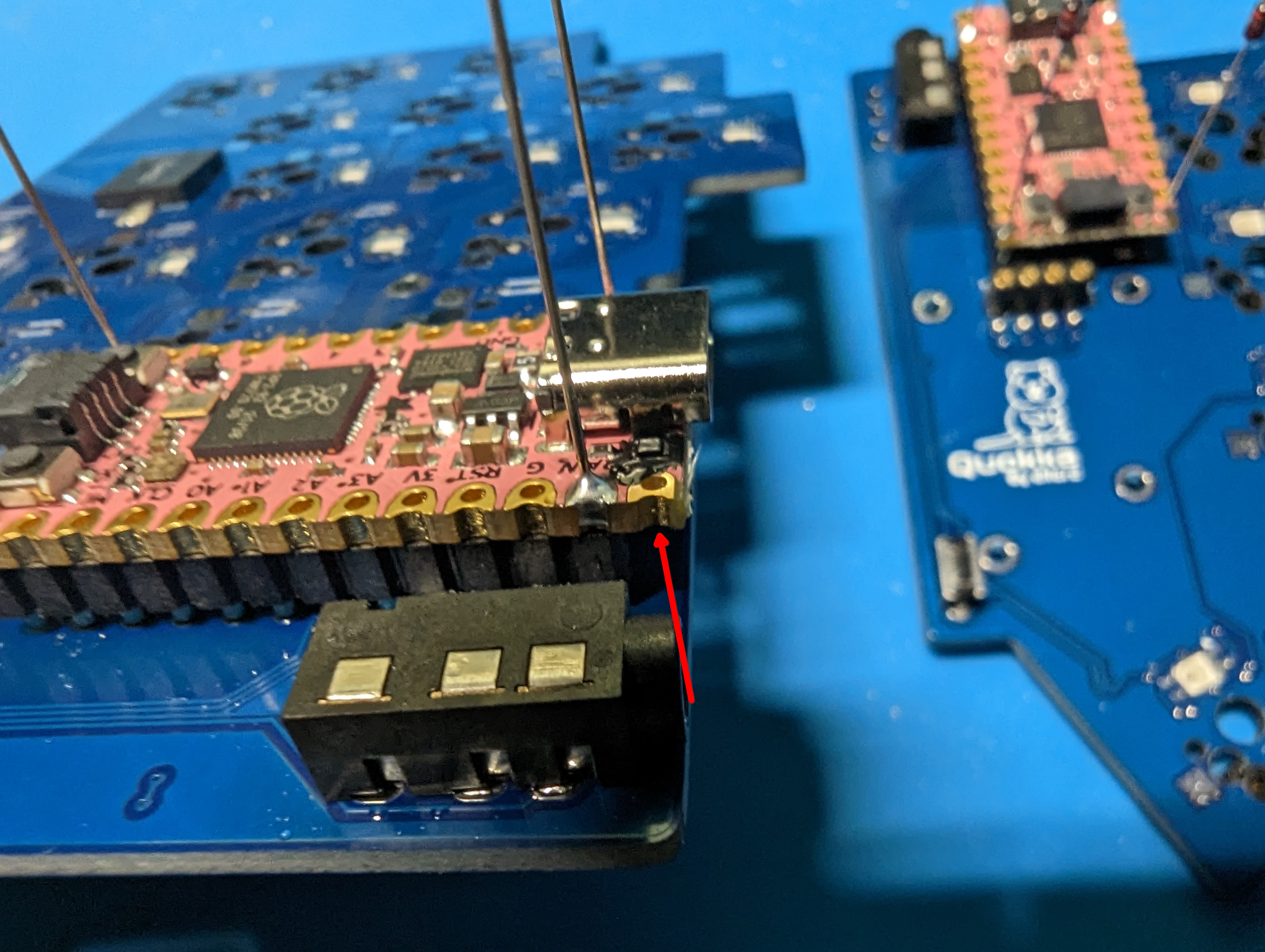

Use through hole diode or resistor legs to pin down the four corners of each MCU, you should feel some resistance before they drop into the socket, then they will feel snug. Solder down the four corners first.

Note that the two contacts closest to the USB-C port on the KB2040 are not used here (also, you may paint black over the power LEDs like I did here, they are quite bright)

Cut the diode or resistor legs above the solder joint, and continue soldering each leg the same way

-

Now is a good time to flash your MCUs, since the boot button will be covered by the OLEDs later on. After the initial flash, they can be put into bootloader mode by double clicking the reset switch (configured by the QMK options

RP2040_BOOTLOADER_DOUBLE_TAP_RESETandRP2040_BOOTLOADER_DOUBLE_TAP_RESET_TIMEOUTinconfig.h) -

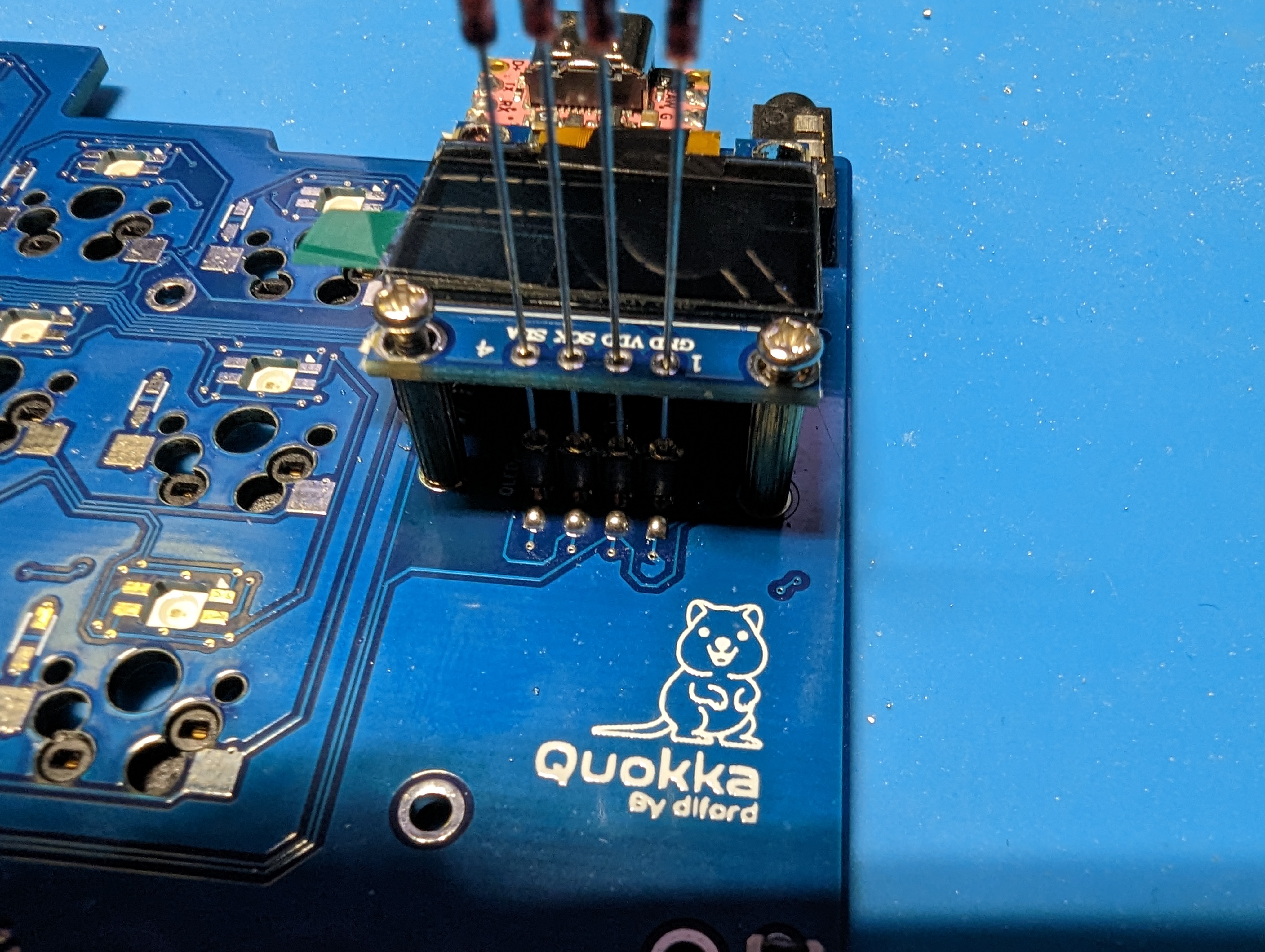

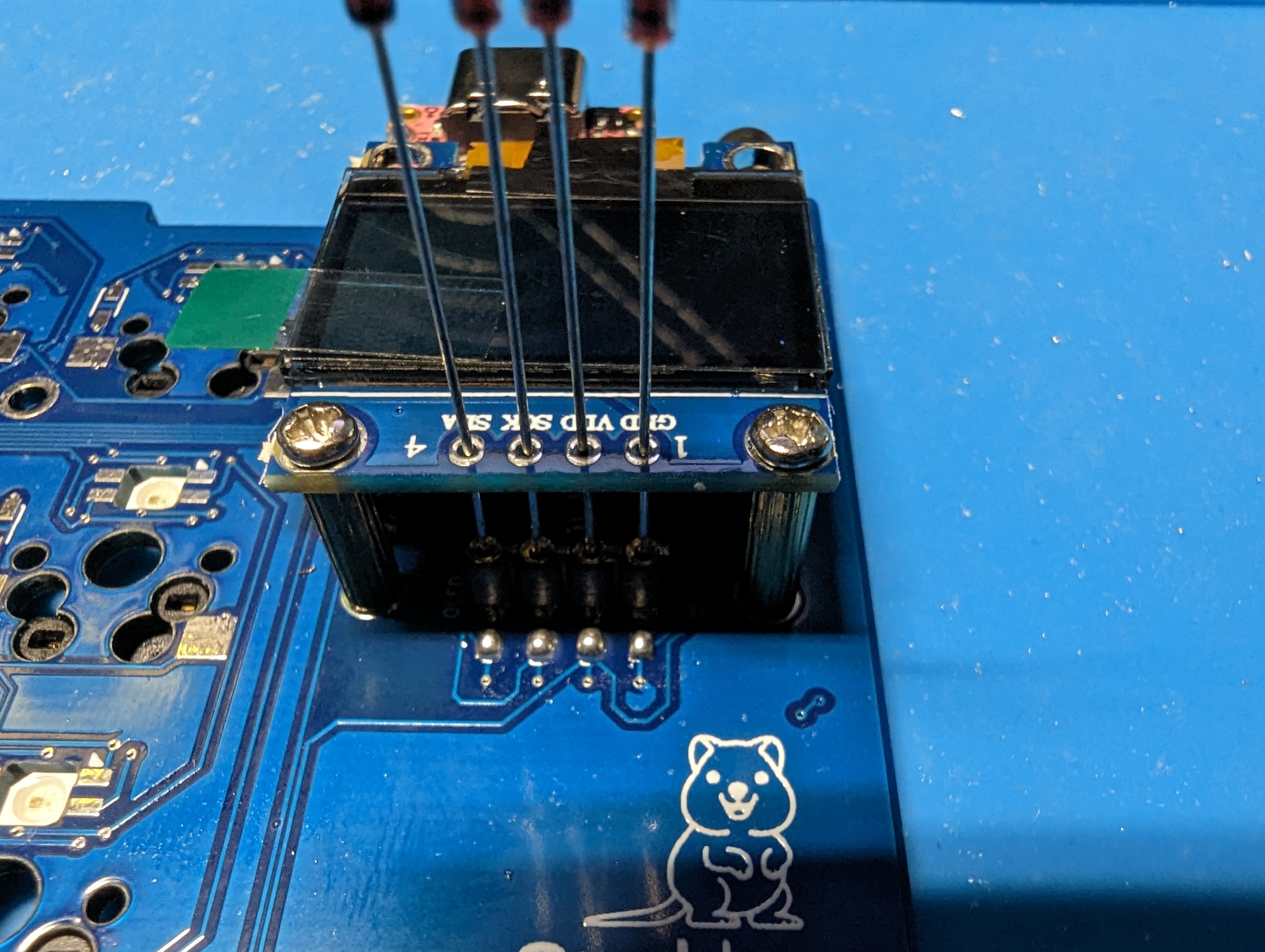

Install OLEDs (if using)

Install M2x10mm stand-offs in the two holes in line with the OLED header strip sockets

Screw the OLEDs to the stand-offs but leave them loose for now

Push more diode or resistor legs into the OLED header strip sockets

Now tighten the OLED mounting screws, keeping it as straight as possible

Solder and cut the pins

-

Install OLED covers

Install M2x15mm stand-offs into the OLED cover mounting holes

Install the OLED covers onto the standoffs

-

Case options

-

No Case

The easiest option, just stick some rubber feet to the bottom of the PCBs and call it a day

-

3D Printed Case

-

Print or order the parts

-

Install the heat set inserts into the bottom of the case body parts, careful not to push too deep as they will go right through the case.

-

Sand and paint the case, if desired

-

Place the PCB into the case body

-

Place an M2x9mm screw into each of the holes in the plate, then push a spacer on the the screw from the bottom of the plate

-

Place the plate over the PCB and tighten each screw

-

Install your switches

-

Stick some rubber feet on the bottom of the case

-

-

Plated Case

Note: If using the 3D printed plate spacers, assemble without switches and install them last, using the bottom spacer with the wide end against the bottom plate, and the top spacer with the wide end against the PCB.

-

Install M2x8mm stand-offs on the bottom of the plates in the mounting holes

-

Install a switch into each corner of the plates

-

Install the PCB onto the switches in the plate

-

Install the remaining switches

-

Install the bottom plate on the stand-offs

-

Stick some rubber feet on the bottom plate

Shown here using Aluminum plates from Ponoko, though I would recommend using FR4 plates, or deburred and anodized aluminum plates from sendcutsend.com for less money

-

-