CAN bus interfacing with the Thomson Linear Electrak HD smart actuator.

Note, this code is a first prototype for experimentation and has not been extensively tested.

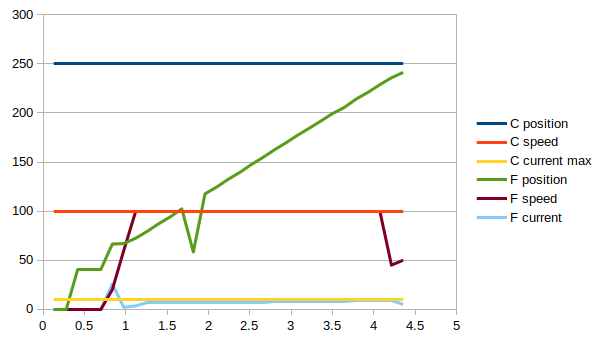

Command actuator to move to 250 mm at 100% speed:

$ python3 python/gotoposition.py -p /dev/ttyACM10 -s 100 -l 250The following plot shows data from a run like this:

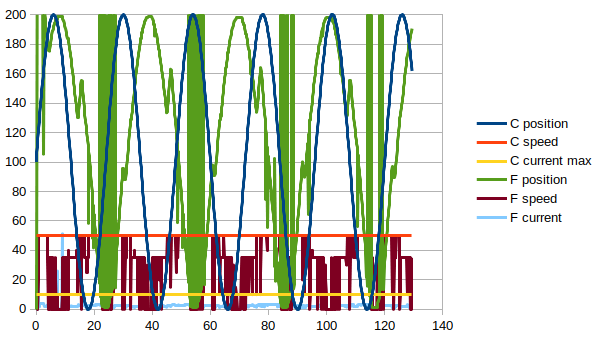

Move the actuator from limit to limit repetitiously at 50% speed.

$ python3 python/sinusiodal.py -p /dev/ttyACM10 -s 50 There is no closed-loop control implemented. As can be seen, the position signal is very noisy, and no filtering is used at this point.

The core functionality of this library is to move the software interface with the Electrak HD actuator up one abstraction by handling both the J1939 protocol and the data format specified by the manufacturer, Thomson Linear. The logging will consist of two levels:

- Logging of the address and data fields sent (before encoding) and received (after decoding)

- Logging of the address and data raw bits sent (after encoding) and received (before decoding)

These two categories are logged in two different CSV files, both in the log/ directory which is created at the root of the repository if it does not exist. Timestamps are logged with each entry in both files, and will exactly correspond for correlating entries between the files.

Notes:

- Data values from the sent commands (ACM's) have column headings starting with a "C" character

- Data values from the sent commands (AFM's) have column headings starting with a "F" character

This section describes the interface with the Electrak HD and provides sources.

Here is a list of the sources used:

- Actuator Manual

- A Comprehensible Guide to J1939

- "the book"

- Linux Kernel J1939 Documentation, Socketcan

-

Page 22 of the actuator manual specifies the use of the Proprietary A2 PGN, and on page 24 defines its use for feedback messages.

- The book provides a specification of this PGN on page 67.

- It is a peer-to-peer message, or PDU1 format

-

Decoding the 29-bit ID

-

Field Priority PGN R DP PDU Format PDU Specific Source Addr. Right Shift Amount 26 8 25 24 16 8 Mask 0x3FF00 1 1 0xFF 0xFF 0xFF Value 6 126720 0 1 239 255 19

-

-

Decoding the Data Bytes

-

The bits we are extracting each of the below values from may be 1 or two bytes, depending on data item length, specified at page 24 of the manual.

-

Each byte must be reversed before usage.

-

Each value's bit-order is reversed before it is scaled and used.

-

Field Pos Current Speed Volt. Err. Temp. Err. Motion Ovrld Backdrv Param Sat. Fatal Right Shift Amnt 2 1 4 2 0 7 6 5 4 3 2 Mask 0x3FFF 0x1FF 0x1F 0x3 0x3 1 1 1 1 1 1

-

-

Page 22 of the manual specifies the use of the Proprietary A PGN, and on page 23 defines its use for control messages.

- See page 66 of the book

-

Encoding 29-bit ID

-

We will need to reverse all the values to be least significant first

-

Field Priority PGN R DP PDU Format PDU Specific Source Addr. Value 6 61184 0 0 239 19 Anything? -

Reverse the packed bytes before they are sent out

-

The PDU specific is the destination address in peer-to-peer communication.

- Same as the source address from the AFM

-