The psen_scan_v2 package is a ROS integration driver for the PSENscan safety laser scanner product. It lets you integrate the laser scanner data into your ROS Environment easily. Using the standard sensor_msgs/LaserScan message format ensures compatibility with other laserscan-post-processing nodes such as gmapping. For a general overview, link collection and tutorials we refer to the ROS wiki page.

PSENscan firmware >= 3.1.0 is supported on the following models:

| Type | Features | Order number |

|---|---|---|

Common features:

|

||

| Light versions Additional features: Muting, EDM, Override | ||

| PSEN sc L 3.0 08-12 3.0 m | safety zone, 8 or 12-pin exchangeable memory module | 6D000012 |

| PSEN sc L 5.5 08-12 5.5 m | safety zone, 8 or 12-pin exchangeable memory module | 6D000013 |

| Master versions Additional features: Muting, EDM, Override, restart in accordance with EN ISO 61496-3, vertical applications | ||

| PSEN sc M 3.0 08-12 3.0 m | safety zone, 8 or 12-pin exchangeable memory module | 6D000016 |

| PSEN sc M 5.5 08-12 5.5 m | safety zone, 8 or 12-pin exchangeable memory module | 6D000017 |

If you are interested in using the PSENscan safety laser scanner without ROS, please take a look at our C++ standalone library. You can read more about it in the standalone folder

Needed Equipment:

- PSENscan safety laser scanner

- ROS Machine

To use the package, you can install prebuilt packages with

sudo apt install ros-$ROS_DISTRO-psen-scan-v2

To start reading data from the safety laser scanner and publishing scans execute roslaunch psen_scan_v2 psen_scan_v2.launch in a command line. This will launch the ROS Node with the default configuration.

If you wish to set parameters from the command line, add them to the end of the command as parameter:=value, separated by spaces.

roslaunch psen_scan_v2 psen_scan_v2.launch sensor_ip:=192.168.0.10 host_ip:=192.168.0.20 host_udp_port_data:=3050This example configures the safety laser scanner at 192.168.0.10 to send it´s frames to 192.168.0.20:3050.

The tutorials describe how to create an application package with your own launch file, where you can easily adjust the configuration parameters.

host_ip (string, default: "192.168.0.50")

IP-Address of host machine.

sensor_ip (string, default: "192.168.0.10")

IP-Address of safety laser scanner.

host_udp_port_data (int, default: 55115)

UDP Port on which monitoring frames (scans) should be received.

host_udp_port_control (int, default: 55116)

UDP Port used to send commands (start/stop) and receive the corresponding replies.

prefix (string, default: "laser_1")

Name of this scanner that can be changed to differentiate between multiple units.

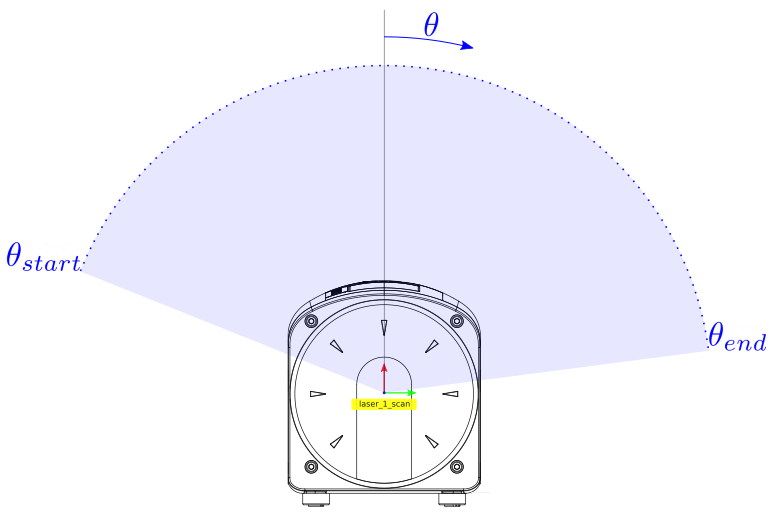

angle_start (double, default: -2.40 (= -137.5 deg))

Start angle of measurement. (Radian)

angle_end (double, default: 2.40 (= 137.5 deg))

End angle of measurement. (Radian)

/laser_scanner/scan (sensor_msgs/LaserScan)

Publishes a complete scan from the PSENscan safety laser scanner. Scan fragments that contain no measurement data are not published. This can happen with smaller scan ranges.

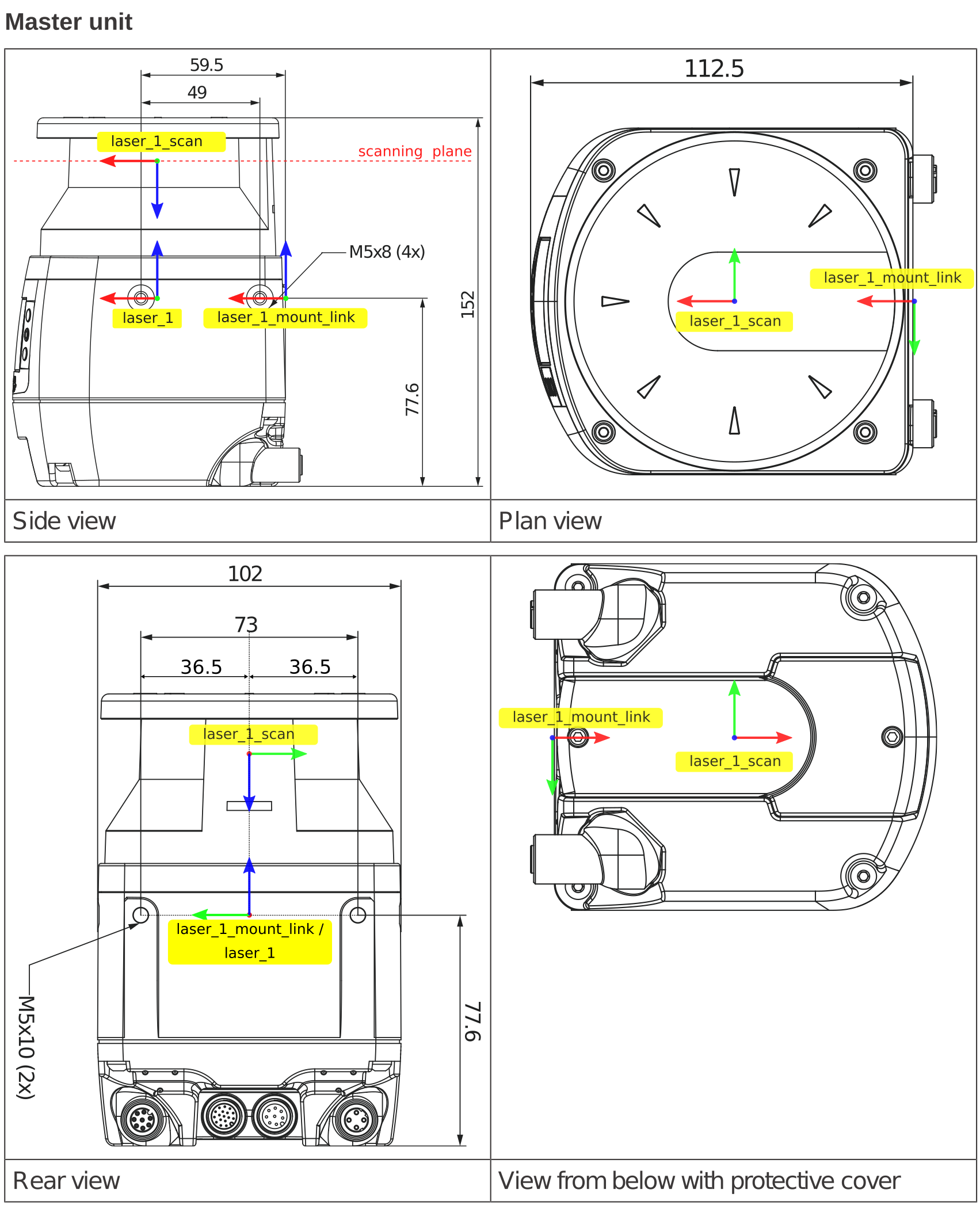

The location of the TF frames is shown in the image below.

These names are defined by the aforementioned launchfile parameter prefix.

Changing them is necessary for instance when running multiple scanners.

You can adjust the scan field to your needs by changing angle_start and angle_end. The published (sensor_msgs/LaserScan) will only contain data within the given angle limits. Both limits are defined within the laser_1_scan frame as shown in the image below.

| Platform | Melodic | Noetic |

|---|---|---|

| CI | ||

| Buildfarm src | ||

| Buildfarm bin |

main is considered to be the active development branch, it targets the ROS distributions melodic and noetic.

To update your ROS environment from the former psen_scan package (which supported firmware versions up to 3.0), please execute the following steps:

- Update scanner firmware using PSENscan Configurator (unless the device has firmware 3.1 already)

- Install the new ROS package

sudo apt install ros-$ROS_DISTRO-psen-scan-v2 - Replace the launch file arguments:

passwordandx_axis_rotationare obsolete and should be droppedangle_startandangle_endare now in radians, in direction of the x axis of the scanner tf frame

- In your application launch file / roslaunch command: replace all occurrences of

psen_scanwithpsen_scan_v2

Our international hotline staff will support you individually about our ROS packages at ros@pilz.de

Find more information about the PILZ safety laser scanner on the product website.

Visit us at pilz.com

PILZ is an international-scale, innovative automation technology company. PILZ uses its solutions to create safety for man, machine and the environment. In addition to head office in Ostfildern near Stuttgart, the family business is represented over 2,400 employees at 42 subsidiaries and branches on all continents.

The company’s products include sensor technology, electronic monitoring relays, safety relays, configurable and programmable control systems, automation solutions with motion control, systems for industrial communication as well as visualization solutions and operator terminals.

PILZ solutions can be used in all areas of mechanical engineering, including the packaging and automotive sector, plus the railway technology, press and wind energy sectors. These solutions ensure that baggage handling systems run safely at airports and funiculars or roller coasters travel safely; they also guarantee fire protection and energy supply in buildings.