Team qed∎ consisted of Daniel Linke, Dirk Legler and Sascha Peukert.

ThyssenKrupp already uses data like elevator cable runtime to predict maintenance needs. We gather additional data from inside and outside the elevator to improve both customer experience and maintenance handling. For now, we collect temperature and humidity data, brightness and loudness. This allows the elevator to choose a certain floor with the right climate to ventilate during standby time or dim the elevator music if people are talking to each other. Additinally, events like a sudden increase in humidity inside the elevator can indicate a spill that needs to be cleaned.

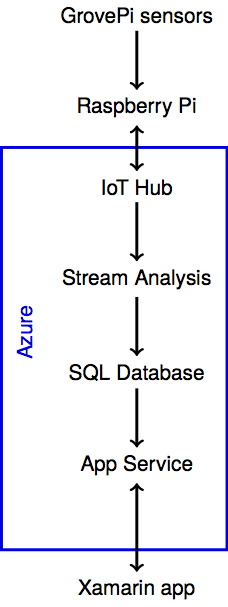

The project consists of three parts: The measuring device (a Raspberry Pi 2 with GrovePi sensors running Windows 10 IoT), the cloud data handling (IoT Hub, Database,…) and a smartphone app for the maintenance personell (Xamarin based).