ABWProfileMaker Is a Windows based tool used to create ICC Profiles that can be used to accurately print black and white images using programs that impliment ICC color management like Photoshop. It is unique in comparison to other tools in that it creates a fully functional B&W profile for use in Black and White workflows. It is used in the same manner as regular color managed printing. For instance, letting Photoshop manage "colors" and selecting Relative Intent with/without BPC. It produces accurate soft proofs including things like the subtle tones when printing B&W sepia.

A big reason to use the printer's B&W mode is that prints are more stable and blacks are printed more smoothly. The printer uses only small amounts of CYM inks in black and white mode. One can see the measured difference as smaller variations in patch colors in the comparison here.

Photoshop sometimes disables showing non OEM profiles when you select B&W in the printer's dialog. This is a problem with Canon, among other, printers. Fortunately, there is a workaround that will not only show the custom profiles, but put them in the top selection area. This is also handy for putting regular, color, custom profiles that you have made at the top for rapid access.

Open Windows Color Management dialog. Then select use profile checkbox then push the ADD button. This displays the installed profiles. Select your custom profile. Now it will show up in Photoshop's print dialog and you can select it to both soft proof and Photoshop's color managed printing.

Windows x64 vers 7,8,10,11. Spectrophotometer and software than can read printed patches and produce a CGATs file. I1Profiler can be used without a license to create, print, and scan charts w/o a license. Software than creates ICC profiles from CGATs files. Tested with Argyll and I1Profiler. Argyll is recommended but I1Profiler, which requires a license to make profiles, can be used. However, I1Profiler requires an additional manual step since it doesn't have a command line batch processing mode.

The program reads a CGATs measurement file of black and white patches. It then creates two new CGATs file with synthesized colors added. The first tosses out the color info (Lab's a* and b*) and adds synthesized colors so that an accurate printing profile can be constructed. The second CGATs file retains the (a* and b*) of the neutral patches and then adds synthesized colors around them. The profile created from this file is not accurate for printing but it is accurate for the reverse lookup that soft proofing uses. Then the program splices in the soft proof lookup tables from the second profile into the first profile creating a profile that can be used for both printing and soft proofing.

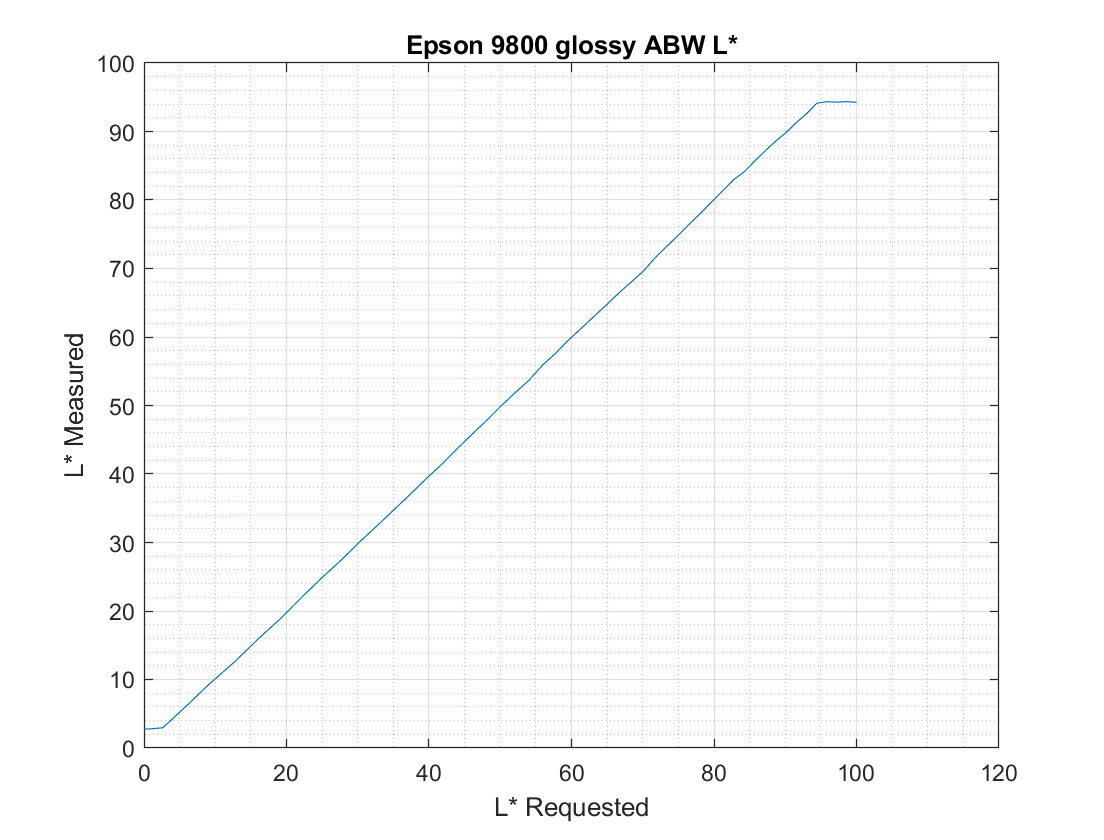

This is the tone curve (L*) from my Epson 9800 using Absolute Col. Intent. It's from actual measurements of neutral patches from L*=0 to 100. It's correctly shows clipping at the paper's darkest black and white of unprinted paper. Elsewhere, the match between requested L* and actual printed L* is nearly perfect. If printed with Relative and BPC the line goes straight from L=0 to 100 since the L* is expanded to 0 and 100.

To minimize configuration errors I highly recommend B&W images be in sRGB colorspace. The sRGB tone curve, while suboptimal for color, is actually better than other working spaces for black and white. This is because the deltaE between RGB steps is almost always lower than that of other spaces like Adobe RGB or ProPhoto RGB as a result of the lead in ramp sRGB has. sRGB more effectively spreads out the change in L* over the full RGB range while its smaller overall color gamut isn't relevant to black and white images.

Standard ICC profiles are those made from patches printed w/o "color" management. They can be used for soft proofing and printing B&W using Relative or Absolute colorimetric intents using the same process as color printing with "Photoshop Manages Colors." Some printers (Epson with ABW) will show all installed profiles when the driver is in B&W mode. Others won't automatically but are easily added using Microsoft's "Color Management" Control panel. This is also convenient for regular color printing since the profiles will show up at the top of the profile list in Photoshop. Open up the Color Management Control Panel. Select the B&W printer, and set the "use my settings for this device" then select your custom B&W profile from the list of installed profiles. Now it will show up in Photoshop's print dialog.

This operates in Photoshop just like regular printing letting Photoshop manage color printing - but with a B&W profile! It does require that the image be in RGB but with no color. Thus each value of R,G, and B are equal to each other. And only the L* is controlled by the profile. a* and b* are determined entirely by the settings in the printer driver's B&W mode such as setting the tone to "warm" Printing should be normally be done with Relative Colorimetric Intent. BPC is optional. Precision grays of known L* can be printed using Absolute Colorimetric.

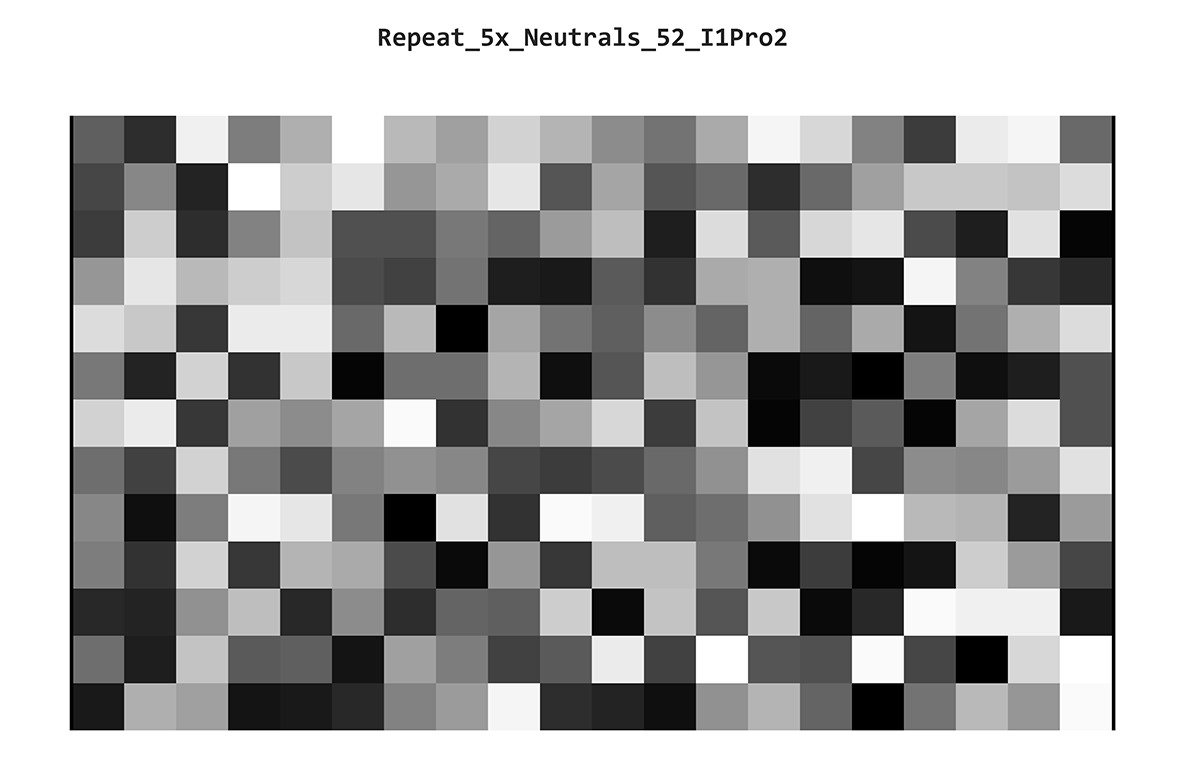

To create a standard B&W profile print the chart in the misc directory that matches your instrument (I1Pro, I1Pro2, or i1iSis). Here is an image of the i!Pro 2 260 patch chart included in the misc directory.

Make sure you save your black and white printer settings in the printer driver so you can load the same settings when you print in the future. It's a good idea to name the profile you make and saved settings the same. Use Adobe ACPU or other program that bypasses color management. Alternately, you can use I1Profiler to print the provided chart file. Load the appropriate chart .txf, also in directory misc. For instance: Repeat_5x_Neutrals_52_I1Pro2.txf. The charts provided contain 260 patches which are the RGB sequence (0,0,0), (5,5,5), ... to (255,255,255) repeated 5 times and scrambled. Scan the print with a spectrophotometer using I1Profiler and save the measurement data as a CGATs text file by selecting "Save" then entering a file name and selecting "i1Profiler CGATS CIELab (*.txt)".

If you suspect the patches are not printing consistently, you can run the prgrogram with the special option "EVAL" and it will de-randomize and sort the patches. It will also print the Lab values of each patch, error differences from the mean when multiple patches with the same RGB are in the CGATs file, and location of each patch. This option can also be used on regular color CGATs files and doesn't require the patches all be B&W.

ABWProfileMaker EVAL measurementfile.txt

ABWProfileMaker\misc>abwprofilemaker EVAL 9800_Y_ABW52x5Matte_M2.txt

-----ABWProfileMaker V2.2-----

52 unique patches

R G B L* a* b* Diff from ave Patch#

Patch: 0 0 0 24.3 0.4 -0.0

24.2 0.3 0.0 -0.1 -0.0 0.0 87

24.4 0.4 -0.0 0.1 0.0 0.0 96

24.3 0.4 0.0 0.0 -0.0 0.0 201

24.3 0.3 -0.1 -0.0 -0.0 -0.1 208

24.3 0.4 -0.0 -0.0 0.1 0.0 233

Patch: 5 5 5 24.8 0.5 0.1

24.8 0.5 0.1 0.0 0.0 -0.0 71

24.8 0.5 0.1 0.1 -0.0 -0.0 176

24.8 0.5 0.2 0.1 -0.0 0.1 205

24.5 0.5 0.1 -0.2 0.0 0.0 215

24.8 0.4 0.1 0.0 -0.0 0.0 250

...............

Patch: 250 250 250 91.0 1.3 -0.1

91.0 1.4 -0.2 -0.0 0.0 -0.2 85

91.1 1.4 -0.1 0.1 0.0 -0.0 126

90.9 1.4 -0.0 -0.1 0.0 0.0 207

91.1 1.3 -0.0 0.1 -0.0 0.0 219

91.0 1.3 0.0 -0.0 -0.1 0.1 260

Patch: 255 255 255 92.9 1.0 -0.9

92.9 1.0 -1.0 0.0 0.1 -0.1 41

92.8 0.9 -0.9 -0.1 -0.0 -0.0 66

92.8 0.9 -0.8 -0.0 -0.0 0.0 168

93.1 1.0 -0.9 0.2 0.0 0.0 204

92.8 0.9 -0.8 -0.1 -0.0 0.0 259

Now just execute ABWProfilerMaker with the name of the measurement file and the desired profile name. This will make the two special CGATs files as well as print metrics and statistical information.

ABWProfileMaker measurementfile.txt desiredprofilename

The last step is to execute the batch file that calls Argyll utilities to create the profile:

make_argyll_abw_profile

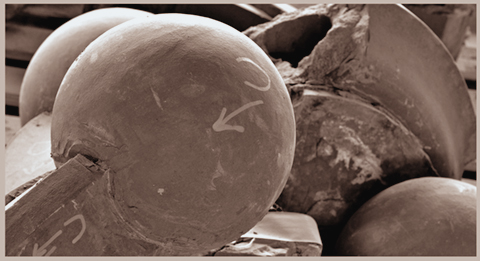

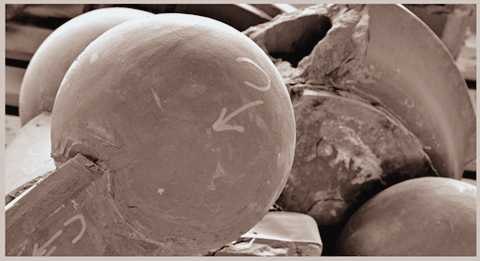

That's it! You now have a B&W profile suitable for use in printing and soft proofing. Be sure to install it or just copy it into C:\Windows\System32\spool\drivers\color Note that the profile is for use only when printing B&W images using the printer's B&W mode. You must use B&W RGB images where all the RGB values are the same (ie: B&W) for accurate results. And here's what the print and image softproof looks like when printed letting the printer manage color. The first was with the 9800 set for "darkest" tone and the second with "lighter."

Often, black and white printing, when done with profiles will, at best, not show in Photoshop the tint or deviation from neutral of the actual print. This is problematic because prints are not perfectly neutral even when no tint is selected. Additionally, subtle tints can provide an artistic touch to black and white prints. It's desirable for soft proofing to show this tint. For example the Sepia or Cold settings in Epson ABW printers.

Tools for making ICC profiles, such as those from X-Rite and the open source Argyll assume RGB color and require data sets that contain a range of RGB values and corresponding Lab (more formally L*a*b*) values that result from measuring the printed colors. ABWProfileMaker provides a process for creating ICC compliant profiles for use in Photoshop and other programs that use ICC profiles to accurately display (aka softproof) and print black and white images using black and white printing modes.

Black and White modes are available on most printers designed to reproduce high quality prints. Examples are Epson's "Advanced Black and White" mode and Canon's Black and White Photo Print modes which are selectable in the driver.

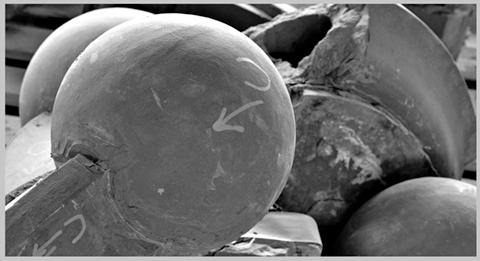

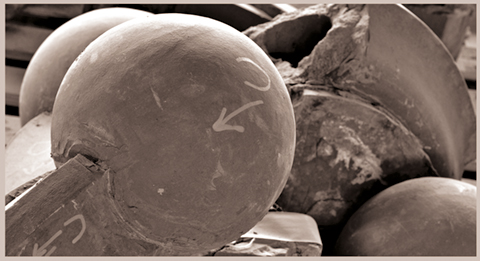

For example, this image from a B&W crop from one of Keith Copper's (North Light Images).

When printed on Matte paper on an Epson 9800 using ABW mode, PK ink, with a maximum yellow-orange tint prints like this using Relative Colorimetric Intent without using BPC (Black Point Compression):

Using BPC lightens the overall image to bring out features in darker areas that are otherwise not printable. This is especially noticeable on matte prints with low DMax (high black L*).

The ABWProfileMaker program accomplishes this in conjunction with regular tools for making ICC profiles by taking B&W patch measurements, including any tints, and making two sets of RGBLAB values in CGATs (an industry interchange format). The a* and b* values are zeroed for the first created RGBLAB set while the second set uses measured a* and b*. Profiles are made from each of these. The first set is zeroed because we want the profile to map neutral RGB values to neutrals to send to the printer. This provides accurate L* for the B&W print. The second profile keeps the a* and b* values. This provides accurate data for soft proofing. Since this data is in the AtoB profile tables, this table is then copied into the first profile replacing its AtoB tables. Both CGATs files contain additional, synthesized, non-neutral RGB and Lab values. The synthesized colors are needed so that the profile software works correctly since it expects a color gamut, not black and white data.

Note that the profile is for use only when printing B&W images using the printer's B&W mode.

Several steps are required to create a Black and White profile. First a set of neutral steps is generated and printed. Second, the printed chart is scanned with a spectrophotometer like an XRite I1 Pro 2 or i1iSis and the CGATs measurements including RGB and Lab* values are saved. Third, the measurement file is read by ABWProfileMaker which creates 2 CGATs files as well as a batch file which uses Argyll to create 2 profiles and ABWProfileMaker then splices the AtoB tables of the second profile into the first.

Target charts for printing and/or loading into I1Profiler are provided in the misc directory for the supported spectrophotometers. These were made from the command: ABWProfileMaker -S 5, which creates a 260 CGATs patch set. Also provided are measurement files and the created profiles in neutral, cool, and sepia ABW settings for the Epson 9800 using glossy paper. You can use the measurement files to test out your Argyll installation.

Here is how ABWProfileMaker was used to create the profile used for the images above printed on an Epson 9800 with ABW.

Spectro measured CGATs files are provided in the "misc" directory. These files are from a set of 260 patches which are (0,0,0), (5,5,5), ...(255,255,255) repeated 5 times then scrambled to minimize spectro reading errors when creating the profile. The following command reads in the black and white CGATs file and creates 2 synthetic CGATs files containing RGB and Lab info. Synthetic colors are added where RGB are non neutral so that profiling software can create profiles but accurate info for the RGB/Lab neutrals are retained. Part of the process prints out statistical information, including paper white and black ink L*, that is useful for looking at the "lumpiness" and random variation of the measured patches. See B&W statistics

ABWProfileMaker 9800_Y_ABW52x5Matte_M2.txt 9800_ABW_Y_Matte

Then you run the newly created batch file. It generates 2 profiles using Argyll profiling tools then splices the AtoB table from the second profile into the first to enable soft proofing. Temporary files are removed. This executes the batch file and creates the profile: "9800_ABW_Y_Matte.icm".

make_argyll_abw_profile

Alternately, if you have a licensed I1Profiler you don't need Argyll tools and can make profiles manually from the two created CGATs files then execute ABWProfileMaker with the profile name in the same order as the batch command file does it. Results are effectively identical. I prefer Argyll since I1Profiler doesn't offer batch processing.

Install the profile or copy to your computer's profile directory: "C:\Windows\System32\spool\drivers\color"

You can also run the program in steps that create the patch set, process spectro measurements, and splice reverse lookup color into the printing profile. Here's the instructions you get just running the program with no arguments:

-----ABWProfileMaker V2.2-----

---------- Step 1 -----------

ABWProfilePatches S|L [n]

Creates RGB CGATS file Where "S" generates 52 RGB patches 0:5:255,

"L" generates 256 RGB patches 0:1:255 and the optional [n] is number

of pattern repeats. Use this to print and read a B&W profile chart using

i1profiler in B&W mode.

---------- Step 1.5 -----------

ABWProfilePatches EVAL MeasurementFilename.txt

When "EVAL" is the first argument, the CGATs file is read, identical

RGB patches are aggregated, average printed out for each

patch's L*a*b* values, patch diffs from ave. and location# are printed.

This can be used with regular, non-neutral patch sets

---------- Step 2 -----------

ABWProfilePatches MeasurementFilename.txt ProfileName

Reads a ABW CGATS measurement file of neutral patches and creates

synthetic RGBLAB CGATs files named "ProfileName.txt" and "ProfileName_adj.txt"

from which one creates ICC profiles. Then make profiles from these two files

using an automatically created batch file "make_argyll_abw_profile.bat"

if you have Argyll's software installed or manually with a program like

I1Profiler

If only the MeasurementFilename is given, just display statistics,

and extended tracking accuracy. This can be used to compare how close

the intrinsic neutral tones are to sRGB. This mode can also be used to

compare how well a B&W profile tracks ReLCol, RelCol/BPC, or AbsCol.

See readme file in github for examples.

---------- Step 3 -----------

ABWProfilePatches Profile

Manual mode: Where profile is the name of base profile with a suffix of ".icm"

Use i1profiler to create two ICM profiles from the two output CGATs files from

step 2. The second profile has the

same name with "_adj" added. The A2B1 tables inside the Profile_adj.icm

replace the A2B1 table inside Profile.icm. Discard the "_adj" profile.

and install the first in your system's profile directory.

A Windows x64 (64 bit) executable is provided as a "Release".

For those that wish to use Linux or iOS, there is standard source code.

The provided C++20 code is portable and requires no libraries.

A Visual Studio 2022 project is provided but one can also just load the

.h and .cpp files in the same directory, compile the source files,

and link into an executable.

The second step in making the synthesized patch sets has an additional feature. It prints out a distribution that shows how much dE20000 variation occurs between steps of 5 and 15. This provides information on how smooth the neutral tone transitions are.

One easy way to see how much better Black and White mode over just using standard color printing to print black and white images is to compare Black and White against printing the neutral patches using standard color settings. I see over a 2 to 1 reduction in L* errors using Black and White.

Here is a comparison of the statistics for Glossy (PK Ink) on the Epson 9800 using ABW and using the same, device neutral patch set with full color selected.

First, these are the statistics in color mode. This shows that adding CYM inks, even with device neutral patches (R=G=B), which is required for color printing, produces much higher measurement variations.

-----ABWProfilePatches V2.2 in color printing mode-----

Statistics for: 9800Neutrals52x5_dev_M2.txt

White Point L*a*b*: 94.89 -1.54 -2.00

Black Point L*a*b*: 3.59 -0.29 -0.91

At RGB130 L*a*b*: 32.14 -1.07 0.55

---Patch deltaE2000 variations B&W printed using full color mode---

These are deltaE2000 variations from the averages of RGB patches

comparing patch values with those of adjacent patches either 5 RGB

steps or 15 RGB steps away. Also shown are the deltaE200 variations

but with a* and b* ignored (eg, 5z, 15z). This is useful to evaluate

Luminance without color shifts from neutral. These variations are much

smaller since a* and b* contribute heavily to deltaE2000 calculations.

Note: L* a* and b* are standard deviations of individual patches, not

dE2000, and are only printed when the charts have duplicated RGB patches

Steps (with ab zeroed) 5 15 5z 15z L* a* b*

50 Percent of dE00s <= 0.11 0.67 0.03 0.31 0.13 0.08 0.10

75 Percent of dE00s <= 0.18 0.82 0.08 0.38 0.18 0.12 0.12

90 Percent of dE00s <= 0.23 0.96 0.11 0.54 0.24 0.16 0.14

95 Percent of dE00s <= 0.33 1.22 0.14 0.72 0.25 0.21 0.15

98 Percent of dE00s <= 0.38 1.65 0.17 0.80 0.34 0.25 0.18

100 Percent of dE00s <= 0.52 2.12 0.19 0.96 0.37 0.27 0.26

This shows that B&W mode printing produces more consistent L*, a* and b*.

-----ABWProfilePatches V2.2 in ABW mode -----

Statistics for: 9800Neutrals52x5_ABWy_M2.txt

White Point L*a*b*: 94.89 -1.53 -2.10

Black Point L*a*b*: 2.87 0.27 -0.26

At RGB130 L*a*b*: 54.54 6.06 11.52

---Patch deltaE2000 variations B&W printed using ABW---

Steps (with ab zeroed) 5 15 5z 15z L* a* b*

50 Percent of dE00s <= 0.04 0.26 0.02 0.11 0.10 0.05 0.08

75 Percent of dE00s <= 0.05 0.32 0.03 0.20 0.13 0.07 0.10

90 Percent of dE00s <= 0.08 0.43 0.05 0.24 0.15 0.08 0.13

95 Percent of dE00s <= 0.23 0.81 0.11 0.27 0.16 0.08 0.14

98 Percent of dE00s <= 0.30 0.94 0.11 0.30 0.20 0.10 0.16

100 Percent of dE00s <= 0.30 1.12 0.15 0.64 0.20 0.11 0.17

Example of Epson 9800 on Matte using PK inks (high black point L*). Files are in the misc directory. PK ink has quite a high L* minimum (darkest black) but better shows soft proofing. Here's the statistics.

ABWProfileMaker 9800_Y_ABW52x5Matte_M2.txt 9800_ABW_Y_Matte

-----ABWProfileMaker V2.2-----

Creating synthetic patch sets

From: 9800_Y_ABW52x5Matte_M2.txt

To: 9800_ABW_Y_Matte.txt

And: 9800_ABW_Y_Matte_adj.txt

And a batch file to make Argyll profiles: make_argyll_abw_profile.bat

White Point L*a*b*: 92.89 0.95 -0.90

Black Point L*a*b*: 24.32 0.36 -0.02

These are deltaE2000 variations from the averages of RGB patches

comparing patch values with those of adjacent patches either

5 RGB steps or 15 RGB steps away. Also shown are the deltaE200

variations but with a* and b* ignored (z cols). This is useful to evaluate

Luminance without color shifts from neutral. These variations are much

smaller since a* and b* contribute heavily to deltaE2000 calculations.

Note: L* a* and b* are standard deviations of individual patches, not

dE2000, and are only printed when the charts have duplicated RGB patches

Steps (with ab zeroed) 5 15 5z 15z L* a* b*

50 Percent of dE00s <= 0.03 0.20 0.02 0.10 0.10 0.03 0.07

75 Percent of dE00s <= 0.04 0.25 0.03 0.20 0.12 0.04 0.08

90 Percent of dE00s <= 0.06 0.33 0.04 0.24 0.14 0.05 0.10

95 Percent of dE00s <= 0.07 0.45 0.04 0.25 0.15 0.06 0.10

98 Percent of dE00s <= 0.07 0.52 0.05 0.29 0.16 0.07 0.11

100 Percent of dE00s <= 0.08 0.55 0.05 0.30 0.17 0.08 0.15

make_argyll_abw_profile runs the batch file which synthesizes two CGATs file, creates two ICC profiles, and merges the relevant tables from one to the other. Then removes the "_adj" temporary files.

set ARGYLL_CREATE_WRONG_VON_KRIES_OUTPUT_CLASS_REL_WP=1

txt2ti3 9800_ABW_Y_Matte.txt 9800_ABW_Y_Matte

colprof -r .1 -qh -D 9800_ABW_Y_Matte.icm -O 9800_ABW_Y_Matte.icm 9800_ABW_Y_Matte

txt2ti3 9800_ABW_Y_Matte_adj.txt 9800_ABW_Y_Matte_adj

colprof -r .1 -qh -D 9800_ABW_Y_Matte_adj.icm -O 9800_ABW_Y_Matte_adj.icm 9800_ABW_Y_Matte_adj

erase 9800_ABW_Y_Matte.ti3

erase 9800_ABW_Y_Matte_adj.ti3

erase 9800_ABW_Y_Matte.txt

erase 9800_ABW_Y_Matte_adj.txt

ABWProfileMaker 9800_ABW_Y_Matte.icm

erase 9800_ABW_Y_Matte_adj.icm

rem Install 9800_ABW_Y_Matte.icm in "C:\Windows\System32\spool\drivers\color"

ABWProfileMaker can also evaluate the accuracy of a B&W profile or color profile when printing black and white. This is done by assigning the B&W chart to sRGB. Then using Protoshop to print the chart in one of three modes: Relative Colorimetric with BPC, Relative Colorimetric without BPC, or Absolute Colorimetric. All three modes are, unlike Perceptual, deterministic and the printed patch, Lab values are colorimetric. Absolute mode should track the chart's sRGB for measurements that are in gamut. That is, when the printed patches are above the paper's black ink and below the paper's unprinted (white). Relative Colorimetric mode expands the upper range such that sRGB's white corresponds the measured paper white. In addition, the XYZ values are shifted so that paper white corresponds to Lab=(100,0,0). Relative Colorimetric mode with BPC is further altered by shifting the paper's black point to Lab=(0,0,0). So while the paper's blackest black might be L*=4 and the whitest white is L*=94. the image Lab values are smoothly mapped all the way from L*=0 to L*=100. This prevents blocking in light and dark areas that exceed the paper's capability.

When ABWProfileMaker is executed with only one argument and that argument is a text file (ends with ".txt"), the measurement file will be evaluated as if the chart image was in sRGB. The print mode, be it Abs., Rel. or Rel. with BPC is detected automatically. The sRGB, sRGB L*, Projected L* values, measured Lab values and differences with the projected sRGB L* printed.

Here's the result when the chart is printed with BPC on glossy with my 9800. The first few lines show RGB values of 0,0,0 and 5,5,5 with an L* of 0.0 and 1.4. The projected L* values, (2.8 and 4.0), are the ideal, calculated values. The measured L*a*b* values are next. The last column is the difference between the projected (ideal) L* and the measured L*. The set can be considered deltaE's showing the quality of the profile at each point. Black and white profiles have no control over a* and b*.

The measured Lab, scaled for white and black point is (0,0,0) and (1.1, .1, .1) and the "Diff" column shows that the printed L* is .3 less than the ideal, scaled value.

Continuous slope, may be Relative Colorimetric with BPC

RGB L*(sRGB) L*(proj) L*a*b* (Measured) Diff

0 0.0 2.8 2.8 -0.2 -0.6 0.0

5 1.4 4.0 3.7 -0.2 -0.5 -0.3

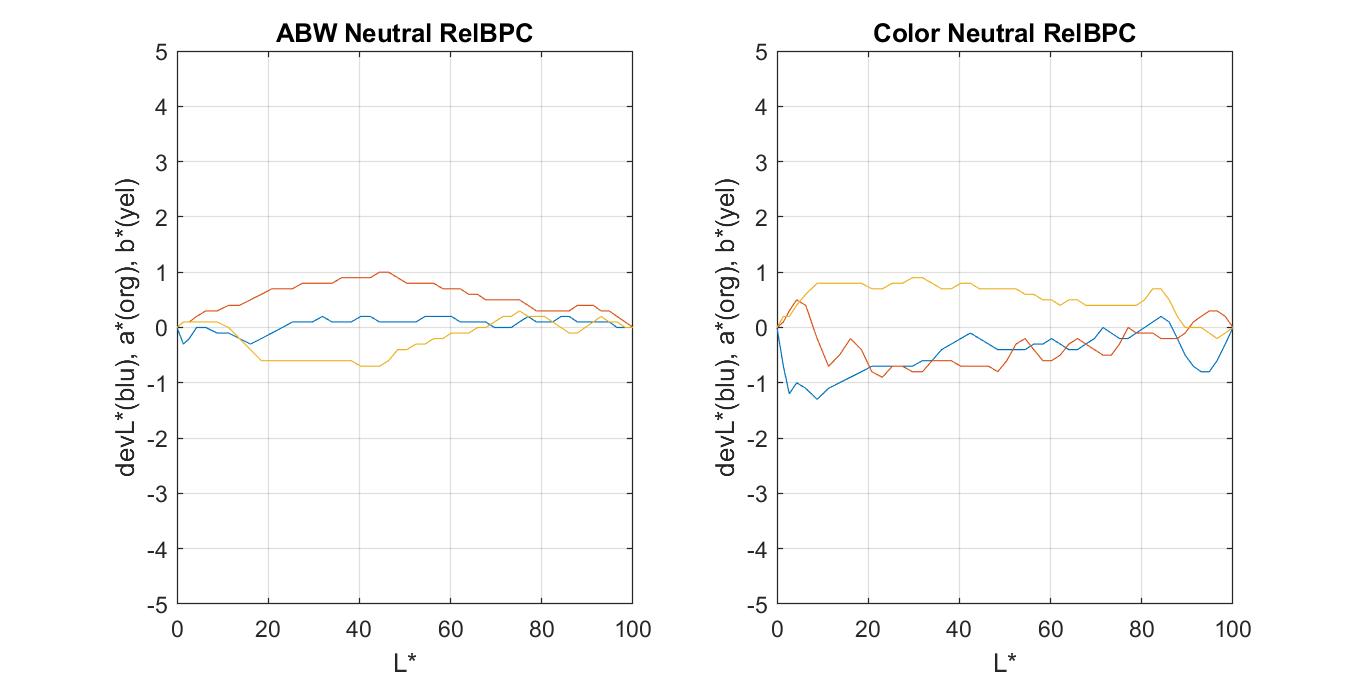

Here's a chart showing the measured, scaled Lab values comparing Black and White (default neutral) and standard, full color mode. Black and White printing provides smoother transitions over the RGB steps as much less CYM ink is used and the 9800 has 3 gray/black inks. Full color printing, even of pure neutrals, uses a lot of CMY inks to facilitate smooth transitions to color. These introduce more low level variation in the printed measurements. Another point is that Black and White printing can not adjust a* or b*. What you see is what you get. It can only be changed by altering the driver settings. For instance selecting Sepia or Cold for a B&W print.

This shows the 52 chart steps when assigned sRGB and printed using Photoshop Manages Color and selecting the custom B&W profile. Options were Rel. Col. with BPC. This has the effect of scaling the Lab values from the sRGB patches between the paper's black and white points. Executing the program with one argument that is the text file of spectrophotometer measurements produces two groups of data. The first group shows various stats that are useful for detecting abrupt changes as well as variations between patches that have the same RGB values.

Command: ABWProfileMaker Repeat_5x_Neutrals_52_9800_Costco_Def_sRGB_M2.txt

-----ABWProfileMaker V2.2-----

Statistics for: Repeat_5x_Neutrals_52_9800_Costco_Def_sRGB_M2.txt

White Point L*a*b*: 94.81 -1.52 -1.82

Black Point L*a*b*: 2.80 -0.18 -0.55

---Patch deltaE2000 variations---

These are deltaE2000 variations from the averages of RGB patches

comparing patch values with those of adjacent patches either

5 RGB steps or 15 RGB steps away. Also shown are the deltaE200

variations but with a* and b* ignored (z cols). This is useful to evaluate

Luminance without color shifts from neutral. These variations are much

smaller since a* and b* contribute heavily to deltaE2000 calculations.

Note: L* a* and b* are standard deviations of individual patches, not

dE2000, and are only printed when the charts have duplicated RGB patches

Steps (with ab zeroed) 5 15 5z 15z L* a* b*

50 Percent of dE00s <= 0.03 0.14 0.02 0.06 0.09 0.04 0.06

75 Percent of dE00s <= 0.05 0.19 0.02 0.10 0.13 0.05 0.08

90 Percent of dE00s <= 0.05 0.23 0.04 0.13 0.16 0.06 0.10

95 Percent of dE00s <= 0.06 0.27 0.05 0.23 0.18 0.07 0.11

98 Percent of dE00s <= 0.10 0.39 0.09 0.38 0.20 0.08 0.11

100 Percent of dE00s <= 0.10 0.55 0.10 0.55 0.22 0.10 0.13

The second part shows the accuracy of the profile. L*(sRGB) is the luminance of the sRGB values and goes from 0 to 100. L*(proj) is the scaled sRGB luminance and is calculated based on the intent of the printed image. In this case Relative Coloriemtric with BPC.

Continuous slope, may be Relative Colorimetric with BPC

RGB L*(sRGB) L*(proj) L*a*b* (Measured) Diff

0 0.0 2.8 2.8 -0.2 -0.6 0.0

5 1.4 4.0 3.7 -0.2 -0.5 -0.3

10 2.7 5.2 5.0 -0.2 -0.5 -0.2

15 4.3 6.6 6.6 -0.1 -0.6 0.0

20 6.3 8.3 8.3 -0.2 -0.7 0.0

25 8.8 10.2 10.2 -0.2 -0.7 -0.1

30 11.3 12.2 12.1 -0.1 -0.8 -0.1

35 13.7 14.2 14.1 -0.1 -0.9 -0.1

40 16.1 16.3 16.0 -0.1 -1.1 -0.2

45 18.5 18.3 18.1 0.0 -1.2 -0.2

50 20.8 20.4 20.3 0.1 -1.3 -0.1

55 23.1 22.4 22.4 0.1 -1.3 0.0

60 25.3 24.4 24.5 0.1 -1.3 0.1

65 27.5 26.5 26.6 0.1 -1.3 0.1

70 29.7 28.5 28.6 0.1 -1.4 0.1

75 31.9 30.5 30.6 0.1 -1.5 0.2

80 34.0 32.4 32.6 0.1 -1.5 0.1

85 36.1 34.4 34.5 0.1 -1.5 0.1

90 38.2 36.3 36.5 0.1 -1.5 0.1

95 40.3 38.3 38.4 0.1 -1.6 0.2

100 42.4 40.2 40.4 0.1 -1.7 0.2

105 44.4 42.1 42.2 0.1 -1.6 0.1

110 46.4 44.0 44.1 0.1 -1.6 0.1

115 48.4 45.9 46.0 -0.0 -1.5 0.1

120 50.4 47.8 47.9 -0.1 -1.4 0.1

125 52.4 49.6 49.8 -0.2 -1.4 0.1

130 54.4 51.5 51.7 -0.2 -1.4 0.2

135 56.3 53.3 53.5 -0.2 -1.4 0.2

140 58.3 55.2 55.4 -0.3 -1.4 0.2

145 60.2 57.0 57.2 -0.3 -1.3 0.2

150 62.1 58.8 58.9 -0.4 -1.3 0.1

155 64.0 60.6 60.7 -0.5 -1.3 0.1

160 65.9 62.4 62.5 -0.5 -1.3 0.1

165 67.7 64.2 64.2 -0.6 -1.3 0.1

170 69.6 65.9 65.9 -0.6 -1.3 0.0

175 71.5 67.7 67.7 -0.6 -1.2 -0.0

180 73.3 69.4 69.4 -0.7 -1.2 -0.0

185 75.1 71.2 71.2 -0.7 -1.2 0.1

190 77.0 72.9 73.1 -0.8 -1.2 0.1

195 78.8 74.6 74.8 -0.9 -1.3 0.1

200 80.6 76.4 76.5 -1.0 -1.4 0.1

205 82.4 78.1 78.2 -1.0 -1.5 0.1

210 84.2 79.8 80.0 -1.1 -1.6 0.2

215 86.0 81.5 81.7 -1.1 -1.7 0.2

220 87.8 83.2 83.3 -1.0 -1.7 0.1

225 89.5 84.8 85.0 -1.0 -1.6 0.1

230 91.3 86.5 86.7 -1.1 -1.6 0.1

235 93.0 88.2 88.3 -1.1 -1.6 0.1

240 94.8 89.9 89.9 -1.2 -1.6 0.1

245 96.5 91.5 91.5 -1.3 -1.7 0.0

250 98.3 93.2 93.2 -1.4 -1.8 0.0

255 100.0 94.8 94.8 -1.5 -1.8 0.0