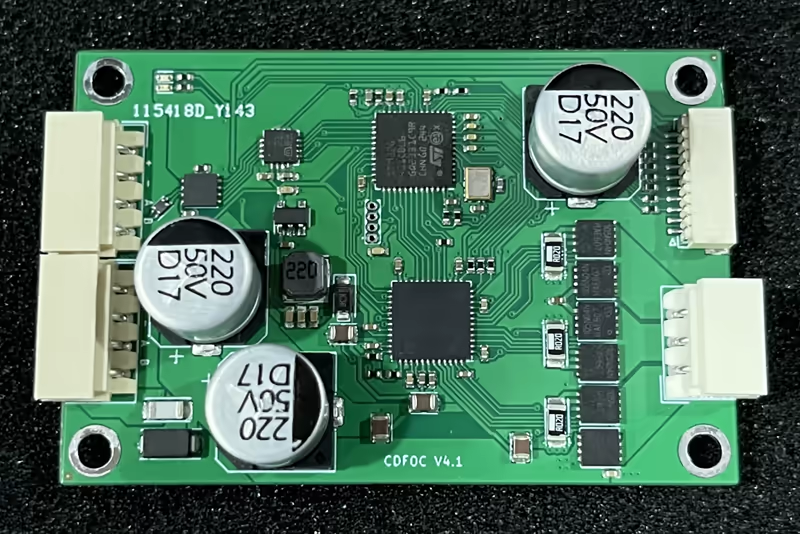

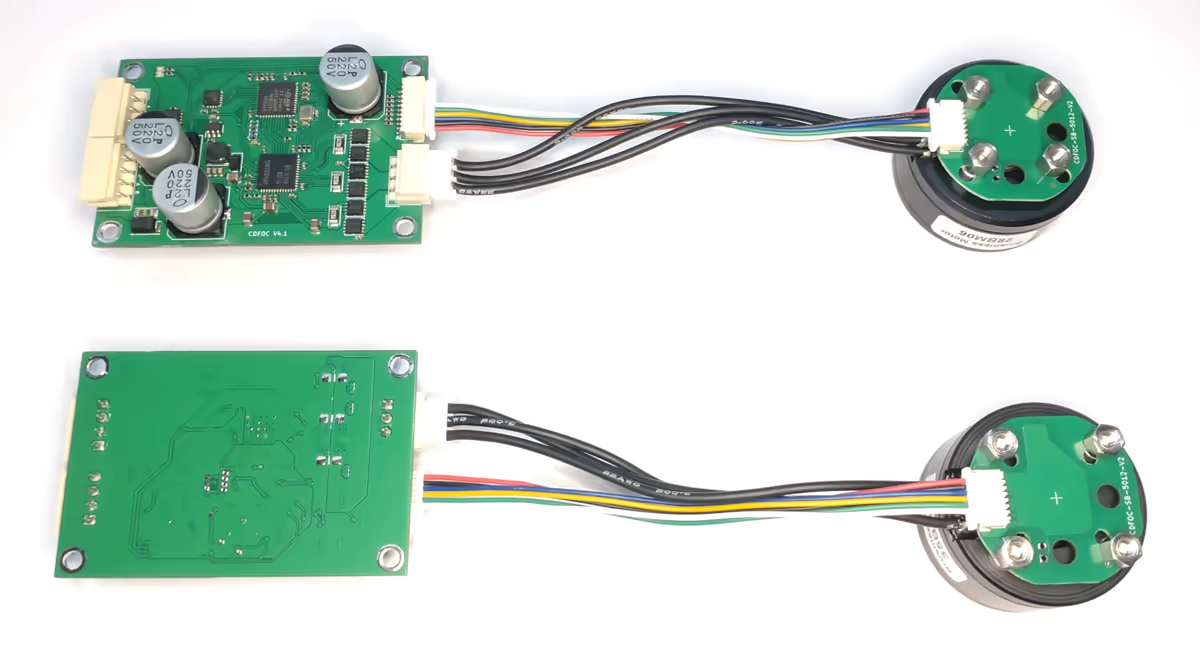

Sockets: RS-485: molex 5264 (4 pin x 2), motor: molex 5264 (3 pin), sensor: sh1.0 (10 pin)

Download this project:

git clone --recurse-submodules https://github.com/dukelec/cdfoc

CDBUS GUI Tool: https://github.com/dukelec/cdbus_gui

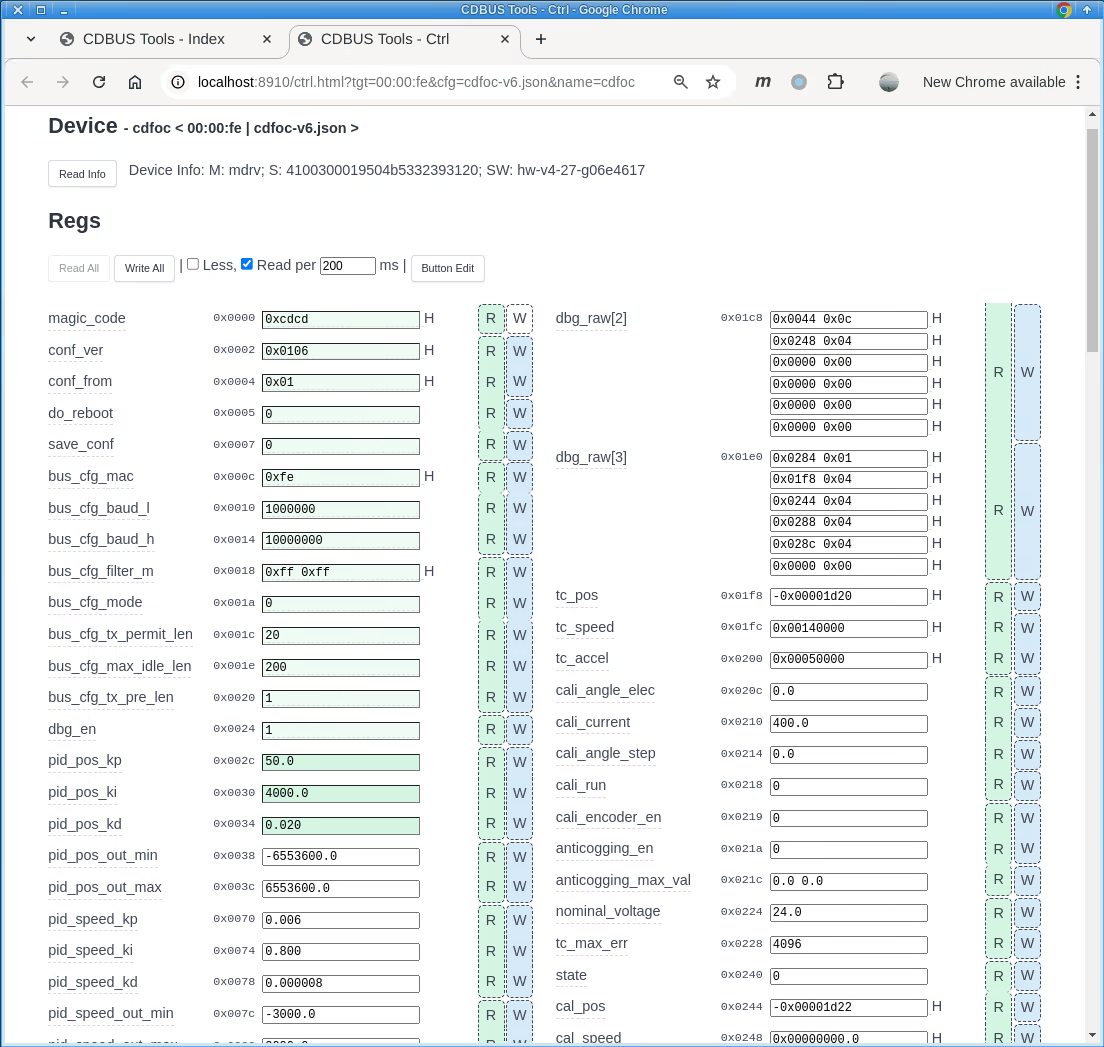

After power on, first write 5 to state, then write the target position to tc_pos, then the motor will rotate.

After modifying the configuration, write 1 to save_conf to save the configuration to flash.

If you need to restore the default configuration, change magic_code to another value and save it to flash. Then reapply power.

Plots:

The CDFOC communication protocol is the same as CDSTEP except for the differences in the register lists, please refer to: https://github.com/dukelec/cdstep

When switching between different modes, you need to write 0 to state first to return to idle mode.

Do not connect any loads to the motor during calibration.

First, set the appropriate value to cali_current. It is recommended to set the value a little bit smaller to prevent the motor from overheating.

Then write 1 to state to enter the drag mode, where a constant current is continuously passed through some of the motor's coils

(please complete the subsequent operations as soon as possible, and then write 0 to state to prevent the motor from overheating).

Remember the initial position of the motor, then rotate the motor by hand, see how many times the motor jumps back to the initial position,

write the number of jumps to motor_poles, then write 1 to save_conf to save it.

Write 1 to dbg_en to ensure that you can see the debug print in the GUI interface.

Start by setting the appropriate value for cali_current, it is recommended to set the value a little higher to allow the motor to lock more accurately.

Also be careful to prevent the motor from overheating.

Then write 1 to state to enter the drag mode, where a constant current is continuously passed through some of the motor's coils

(please complete the subsequent operations as soon as possible to prevent the motor from overheating).

Write 1 to cali_run to start the calibration, the motor coil will be energized sequentially, the motor will turn clockwise first, then counterclockwise,

and finally print the calculated encoder offset value, write it to bias_encoder, and finally save it.

Write 1 to cali_run as soon as possible after writing 1 to state, so that the coils can be energized in turn, sharing the strain on individual coils.

If the motor does not rotate clockwise first during calibration (the encoder value not increases), you will need to swap any two wires of the motor to change the direction of motor rotation.

Write 2 to state to enter torque mode, or current mode.

The motor can then be rotated by writing the appropriate current value to cal_current.

The unit of current is the LSB value of the 12bits ADC.

Write 3 to state to enter speed mode.

Then write the appropriate speed value to cal_speed to rotate the motor.

One revolution of the motor is divided into 0x10000 units, e.g. from 0 to 0x10000 is one full revolution.

The unit of speed is: how many position-units / second.

Write 5 to state to enter position mode.

Then just write the appropriate values to tc_pos, tc_speed, tc_accel.

Alternatively these parameters can be updated using the quick-exchange command by default.

Mode 4 of state is a position mode without acceleration or deceleration and is not normally used.

The address of the state itself is 0x0219 and its length is 1 byte.

To lock the motor and enter position mode after power up, send the following data to port 5:

20 19 02 05

20 is the subcommand write, 19 02 is the little-endian for address 0x0219 (little-endian is used unless otherwise noted),

and 05 is the value to be written.

The complete command containing the CRC is (host address defaults to 0, motor address defaults to 0xfe, 3rd byte is data length, last two bytes are CRC):

00 fe 05 05 20 19 02 05 88 f5

The complete response package is:

fe 00 01 40 crc_l crc_h

Where 0x40 means no error, for more information please refer to the description of CDSTEP and CDNET.

qxchg_set uses only one element by default, pointing to the area where the table entries tc_pos, tc_speed and tc_accel are located.

If you want to change the target position parameter tc_pos to 0, you can write data 20 00 00 00 00 to port 6 (20 is the subcommand number).

If you need to change both the target position and the target speed, e.g. position to 0x00010000 and speed to 0x00005000, writes: 20 00 00 01 00 00 50 00 00.

Goes to 0 degrees, full command with CRC:

00 fe 06 06 20 00 00 00 00 63 99

Goes to 180 degrees, full command with CRC:

(0x10000 units for one revolution, 0x8000 for 180 degrees)

00 fe 06 06 20 00 80 00 00 62 71

Rotates to the 5th revolution position and sends the speed value (0x00140000 or 14 revolutions per second) with the CRC:

00 fe 0a 06 20 00 00 05 00 00 00 14 00 fe 6e

Demonstration of return data for the above three commands:

fe 00 0b 40 xx xx xx xx yy yy yy yy crc_l crc_h

where 0x40 means no error, xx and yy are defined by qxchg_ret to return 8 bytes of data such as cal_pos.