Three-dimensional bin packing [1] is an optimization problem where the goal is to use the minimum number of bins to pack items with different dimensions, weights and properties. Examples of bins are containers, pallets or aircraft ULDs (Unit Load Device). 3D binpacking problems may include various objectives and requirements. Basic requirements are boundary and geometric constraints, which require that items be packed within bin boundaries and without overlapping, respectively. There may be additional requirements on the stability of the packing, flatness of top or bottom layers, fragility and weight distribution, etc., which are not modeled in this formulation. In this example, both items and bins are cuboids, and the sides of the items must be packed parallel to the sides of bins.

This example demonstrates a formulation and optimization of a three-dimensional multi bin packing problem using a constrained quadratic model (CQM) that can be solved using a Leap hybrid CQM solver.

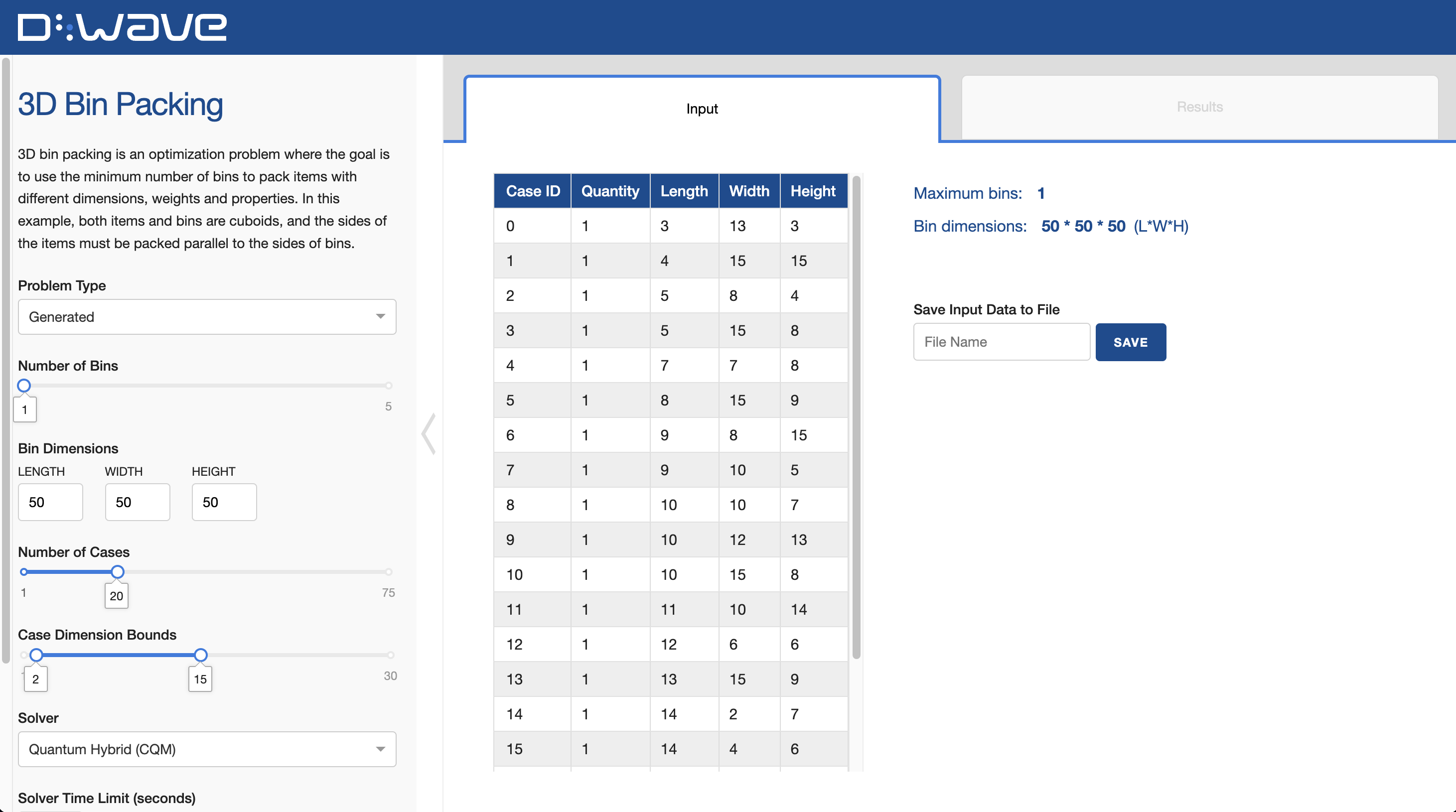

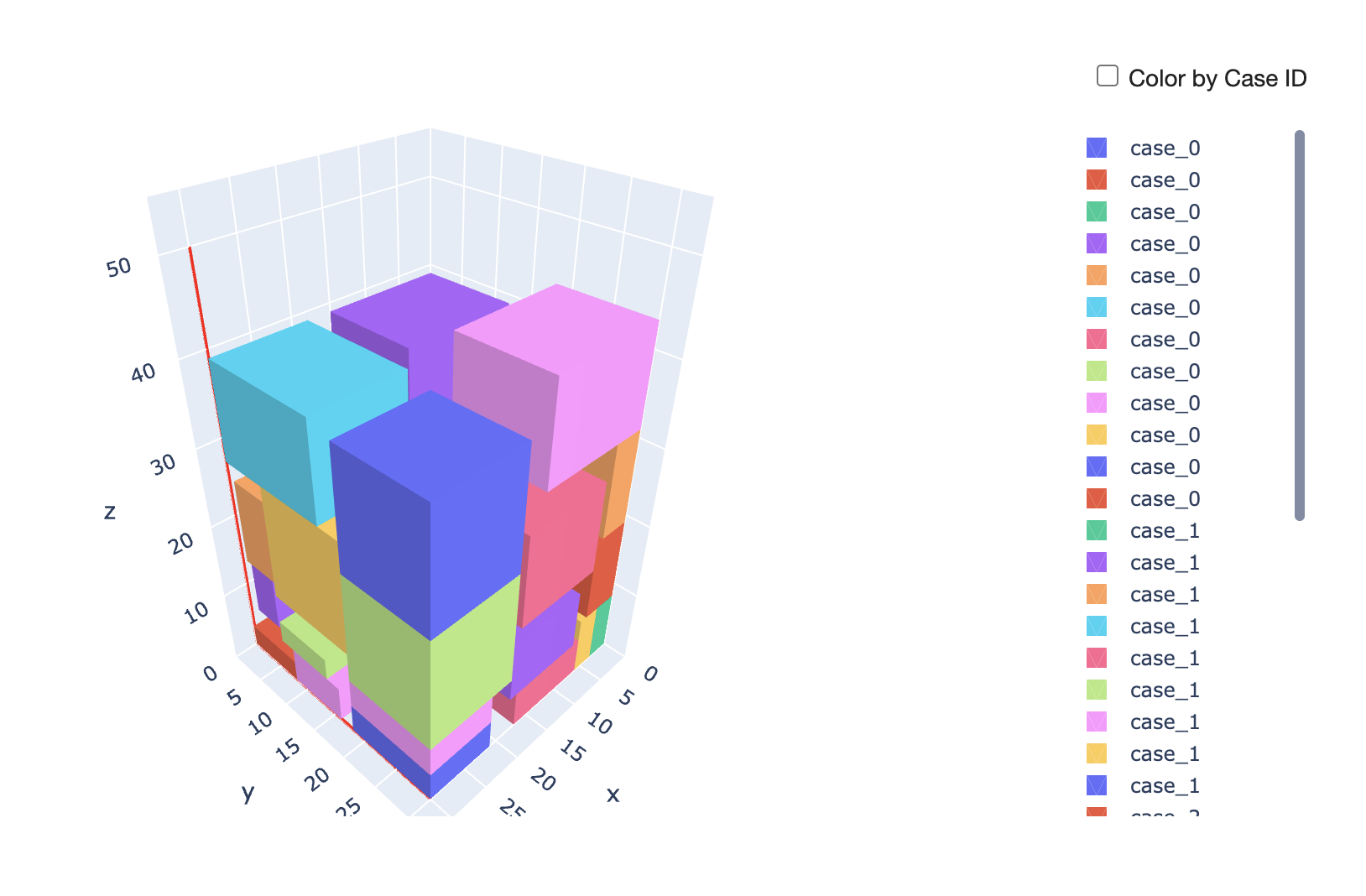

Below is an example output of the program:

You can run this example without installation in cloud-based IDEs that support the Development Containers specification (aka "devcontainers") such as GitHub Codespaces.

For development environments that do not support devcontainers, install requirements:

pip install -r requirements.txtIf you are cloning the repo to your local system, working in a virtual environment is recommended.

Your development environment should be configured to access the Leap™ quantum cloud service. You can see information about supported IDEs and authorizing access to your Leap account here.

Run the following terminal command to start the Dash application:

python app.pyAccess the user interface with your browser at http://127.0.0.1:8050/.

The demo program opens an interface where you can configure problems and submit these problems to a solver.

Configuration options can be found in the demo_configs.py file.

Note

If you plan on editing any files while the application is running, please run the application

with the --debug command-line argument for live reloads and easier debugging:

python app.py --debug

Alternatively, one can solve an instance of a problem through the terminal by typing:

python packing3d.py --data_filepath <path to your problem file>

There are several examples of problem instances under the input folder.

This is an example of a 3D bin packing input instance file with 1 bin and 35 cases.

# Max num of bins : 1

# Bin dimensions (L * W * H): 30 30 50

case_id quantity length width height

--------- ---------- -------- ------- --------

0 12 5 3 8

1 9 12 15 12

2 7 8 5 11

3 7 9 12 4

Note that:

- all bins are the same size.

- there are several cases of each size (

quantitysets the number of cases of identitycase idwith all having the dimensions defined in that row).

Run python packing3d.py --help in the terminal for a description of the demo program's input

parameters.

The program produces a solution like this:

# Number of bins used: 1

# Number of cases packed: 35

# Objective value: 104.457

case_id bin_location orientation x y z x' y' z'

--------- -------------- ------------- --- --- --- ---- ---- ----

0 1 3 15 0 0 3 5 8

0 1 3 9 0 0 3 5 8

0 1 6 9 17 0 8 3 5

0 1 3 0 25 0 3 5 8

0 1 3 12 0 0 3 5 8

0 1 2 20 0 0 5 8 3

...

Note that only a portion of the solution is shown above. Also, there are multiple rows with same

case_id as there are several items of the same size.

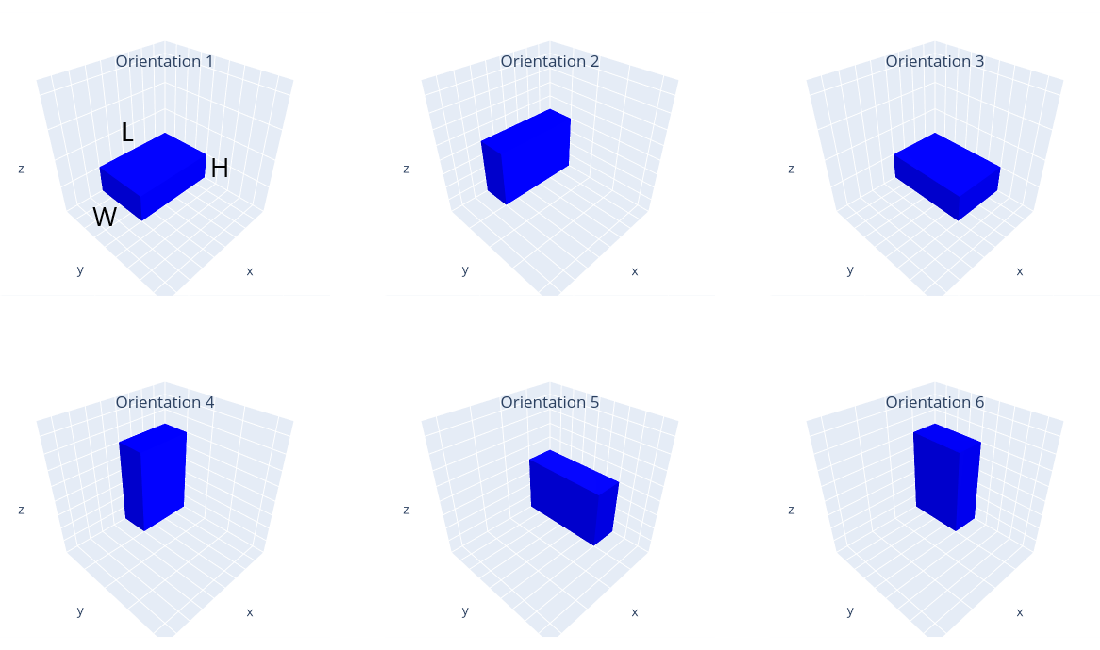

The number under the orientation column shows the rotation of a case inside a bin as shown in the

following figure.

The graphic at the top of the README is a visualization of this solution.

Note that in this example, we do not model support or load-bearing constraints for cases. Therefore, it is possible that larger cases are packed over smaller cases without having full support.

The goal of the 3D bin packing problem is to ensure that the cases are securely packed within the fewest bins possible. The model sets the following objectives and constraints to achieve this goal:

Objectives: minimize the height of the packed cases and number of bins used.

Constraints: the constraints for this problem fall into multiple categories. Orientation constraints focus on restricting cases to a single orientation. Case and bin assignment constraints ensure that each case is placed in exactly one bin, that the chosen bin is in use, and that there are no gaps between bins. Geometric constraints are used to make sure cases aren't assigned to positions that would cause an overlap with another case. Bin boundary constraints enforce that cases are placed completely inside their designated bin.

In this example, to model multiple bins we assume that bins are located back-to-back

next to each other along x-axis of the coordinate system. This way we only need to use one coordinate system

with width of W, height of H and length of n * L to model all bins,(see below

for definition of these parameters).

That means that the first bin is located at 0 <= x <= L, second at L < x <= 2 * L,

and last bin is located at (n - 1) * L < x <= n * L.

We apply necessary constraints to ensure that cases are not placed between two bins.

These are the parameters of the problem:

n: number of binsJ: set of bins{1, ..., n}m: number of casesI: set of cases{1, ..., m}K: possible orientations{0, 1, ..., 5}Q: possible relation (e.g., behind, above, etc) between every pair of cases{0, 1, ..., 5}L: length of the binsW: width of binsH: height of the binsl_i: length of caseiw_i: width of caseih_i: height of casei

v_j: binary variable that shows if binjis usedu_(i,j): binary variable that shows if caseiis added to binjb_(i,k,q): binary variable defining geometric relationqbetween casesiandks_j: continuous variable showing height of the topmost case in binjr_(i,k): binary variable definingkorientations for caseix_i,y_i,z_i: continuous variable defining location of the back lower left corner of caseialongx,y, andzaxes of the bin

Note that we can determine some variables before the optimization. For example, without loss of

generality we can assign the first case to

the first bin. Therefore u_{0,0} = 1 and u_{0,j} = 0 for any j\ne 0.

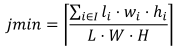

We can also estimate a lower bound on the number of occupied bins:

The first jmin bin variables v_j can therefore be set equal to 1 without

loss of generality. In what follows, the set of bins J is {jmin, ..., n}.

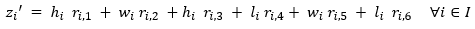

Expressions are linear or quadratic combinations of variables used for easier representations of the models.

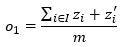

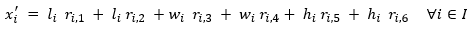

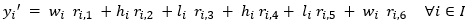

x'_i,y'_i,z'_i: effective length, width and height of casei, considering orientation, alongx,y, andzaxes of the bino_1,o_2,o_3: terms of the objective

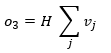

Our objective contains three terms:

The first term is to minimize the average height of the cases in a bin which ensures that cases are packed down.

The second term in the objective ensures that the height of the topmost case in each bin is minimized. This objective is weakly considered in the first objective term, but here is given more importance.

Our third objective function minimizes the total number of the bins.

Note that we multiplied this term by the height of the bins so its contribution to the objective has same weights as the first and second objective terms. The total objective value is the summation of all these terms.

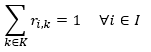

Each case has exactly one orientation:

Orientation defines the effective length, width, and height of the cases along x, y, and z axes.

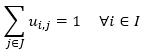

Each case goes to exactly one bin.

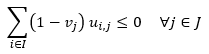

Only assign cases to bins that are in use.

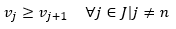

Ensure that bins are added in order; i.e., bin j is in use

before bin j + 1.

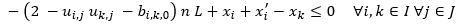

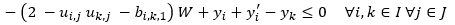

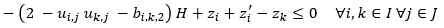

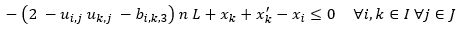

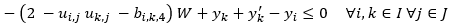

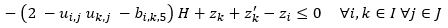

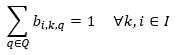

Geometric constraints, required only for three-dimensional problems, are applied to prevent overlaps

between cases.

In the following constraints, "left" and "right" refer to the position of the case along the x

axis of a bin, "behind" and "in front of" to the y axis, and "above" and "below" to the z axis.

To avoid overlaps between each pair of cases we only need to ensure that at least one of these

situations occur:

- case

iis on the left of casek(q = 0):

- case

iis behind casek(q = 1):

- case

iis below casek(q = 2):

- case

iis on the right of casek(q = 3):

- case

iis in front of casek(q = 4):

- case

iis above casek(q = 5):

To enforce only one of the above constraints we also need:

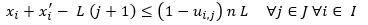

These sets of constraints ensure that case i is not placed outside the bins.

When u_{i,j} is 0 these constraints are relaxed.

Note that the width constraints do not involve the variables u_{i,j}. This is because the bins are

virtually placed along the x-axis and all the cases have to satisfy the width constraints in a

similar manner. Similar considerations apply for the height constraints, however, here we want to

track the bin height s_j.

[1] Martello, Silvano, David Pisinger, and Daniele Vigo. "The three-dimensional bin packing problem." Operations research 48.2 (2000): 256-267.

Released under the Apache License 2.0. See LICENSE file.