A fabricatable machine is a computer-controlled fabrication machine that can be made using a standard set of existing computer-controlled machines; with minimal use of speciality parts, processes or skills. The type of machines include CNC-milling, lasercutter, and 3d-printers.

We want to enable individuals and communities to build their own production machines, to expand their own capabilities. Build more machines to increase production, build cheaper to increase availability, or build specialized machines tailored for specific purposes.

December 2016

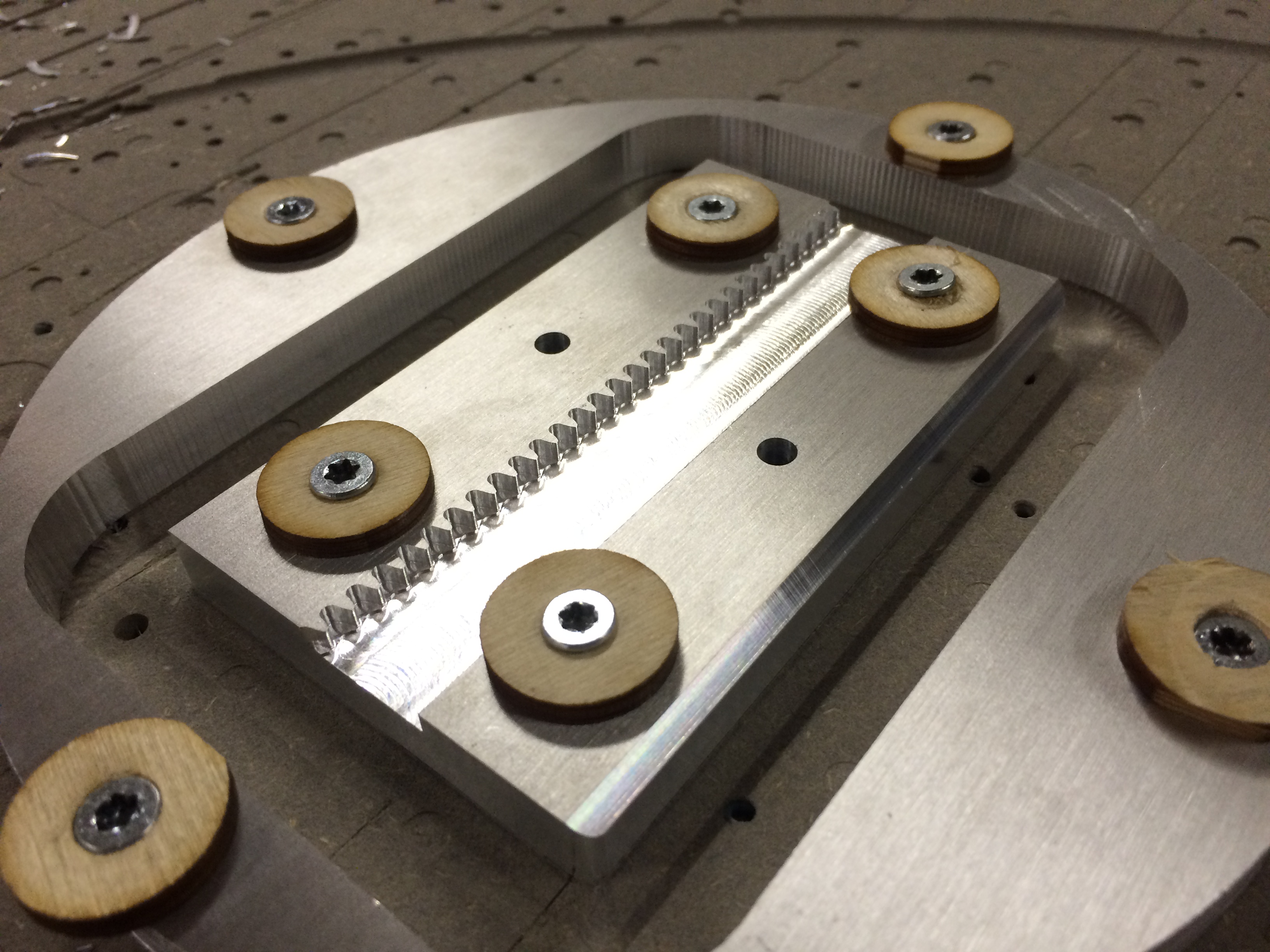

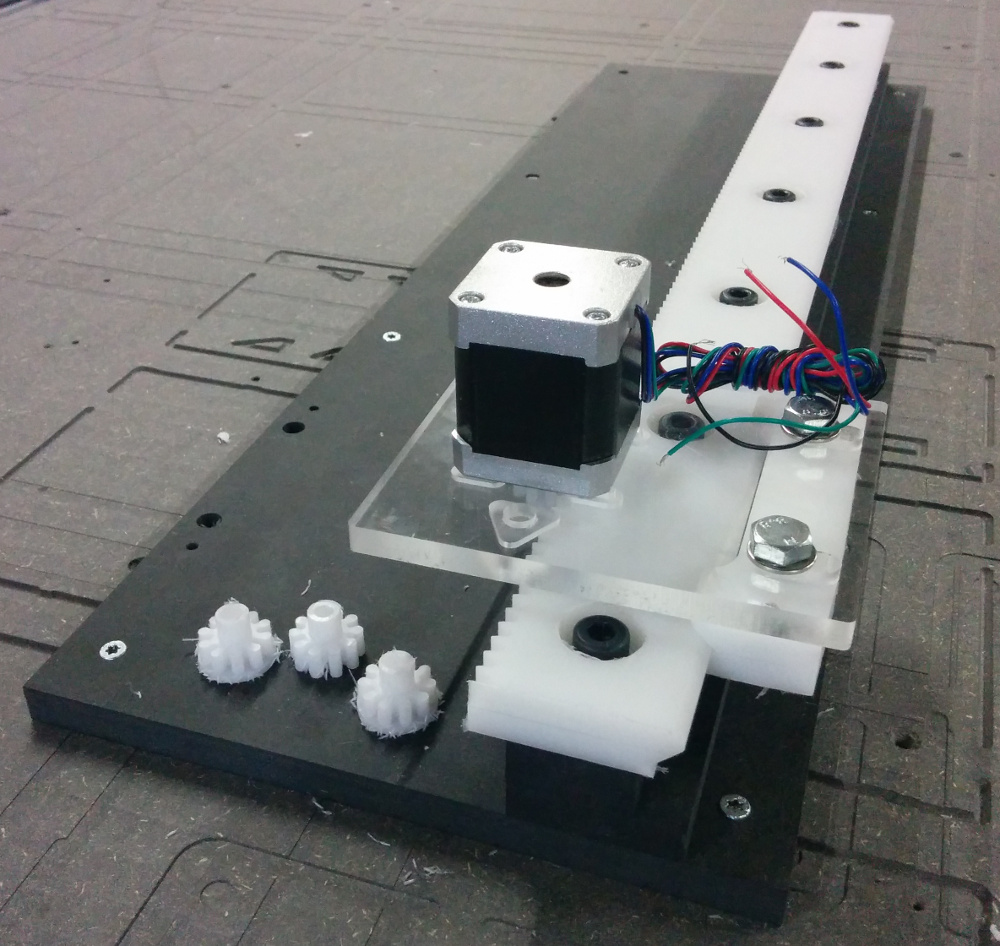

A linear actuator with rack & pinion drive system, designed to be CNC-milled. This is a simplified version of the axis system from V-bird and Simple Gantry, which can be reproduced using only standard CNC operations and bits (chamfering using a 90deg V-bit).

Additionally the pitch is slightly smaller, for higher resolution and torque.

The files included here are for NEMA17 sized motor.

December 2016

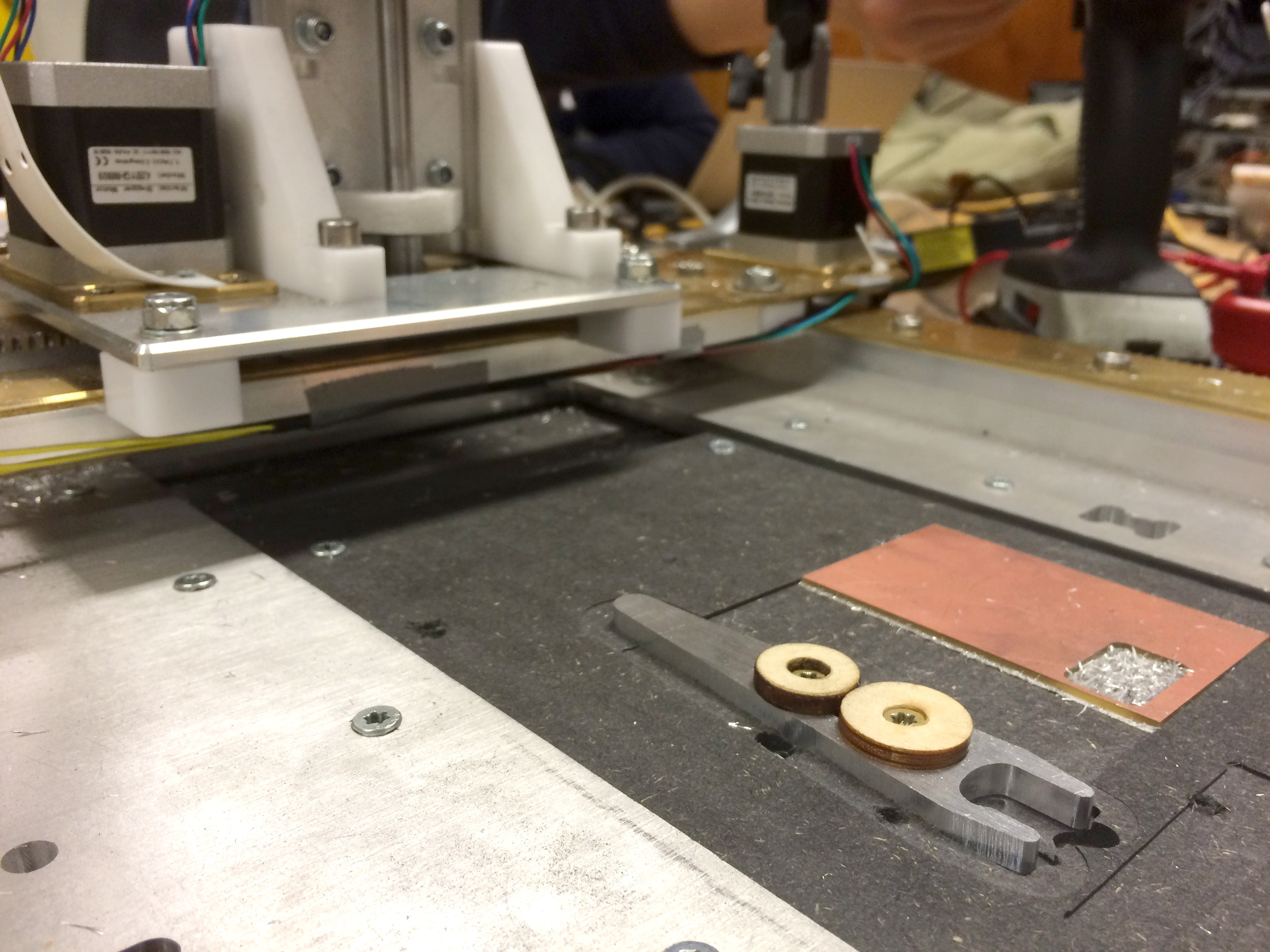

- CNC mill experiment from extra parts left after award plotter trophy

- Chamferrail rack and pinion based Z-axis

- Validated that the roller rack and pinion system can deliver high quality motion

- Validated the potential for self production

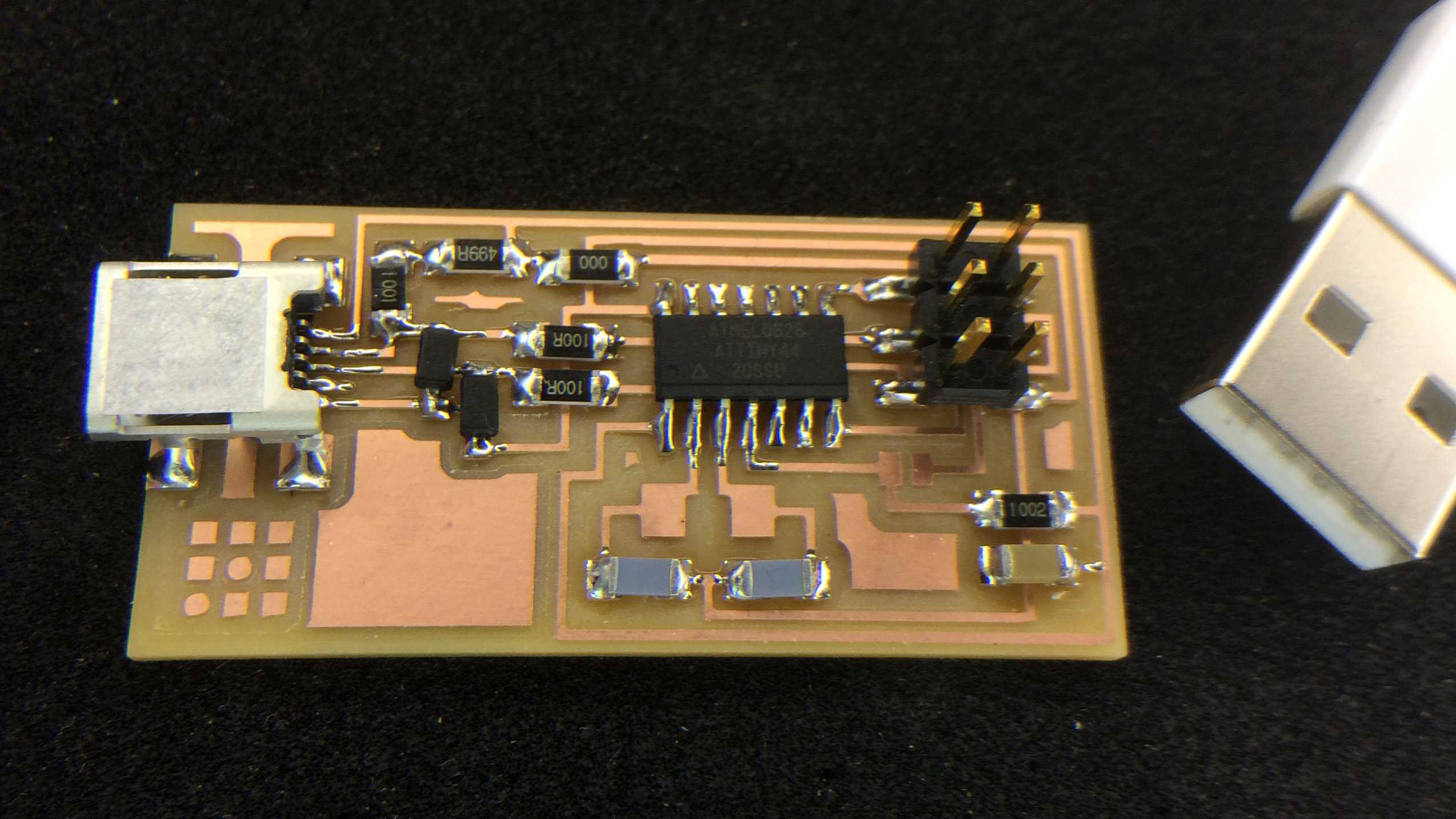

- Able to produce high quality PCBs

- Able to mill 5mm aluminium and 2mm steel

October 2016

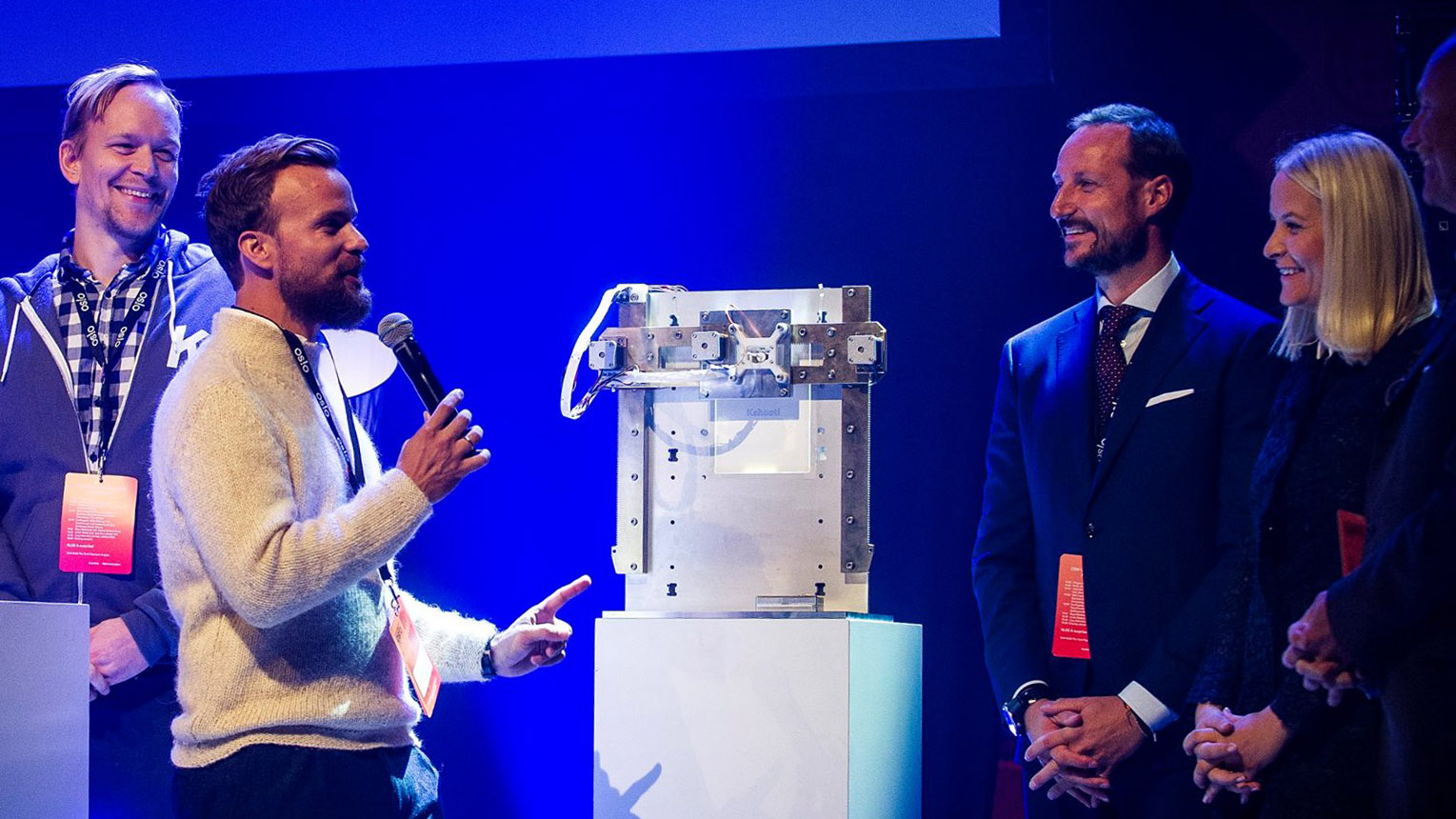

- Pen plotter

- Trophy for the 2016 Oslo Innovation Award

- Prints as many dipomas as the winner wants

- Servo-based Z-axis

October 2016

- Compression mold for recylcling plastic waste into sheet material

- Works well with PLA from 3D prints

- PLA sheets are easy to lasercut and CNC mill

- Rape seed oil makes good mold release

- Works ok with one sided heat from cooking plate

- Can be improved with two-sided heat source. Maybe cartridge?

- Needs improved geometry for faster mold release (cycle time)

Goal: A fabricatable system for making shopBot sized sheets from waste in a fab lab

August 2016

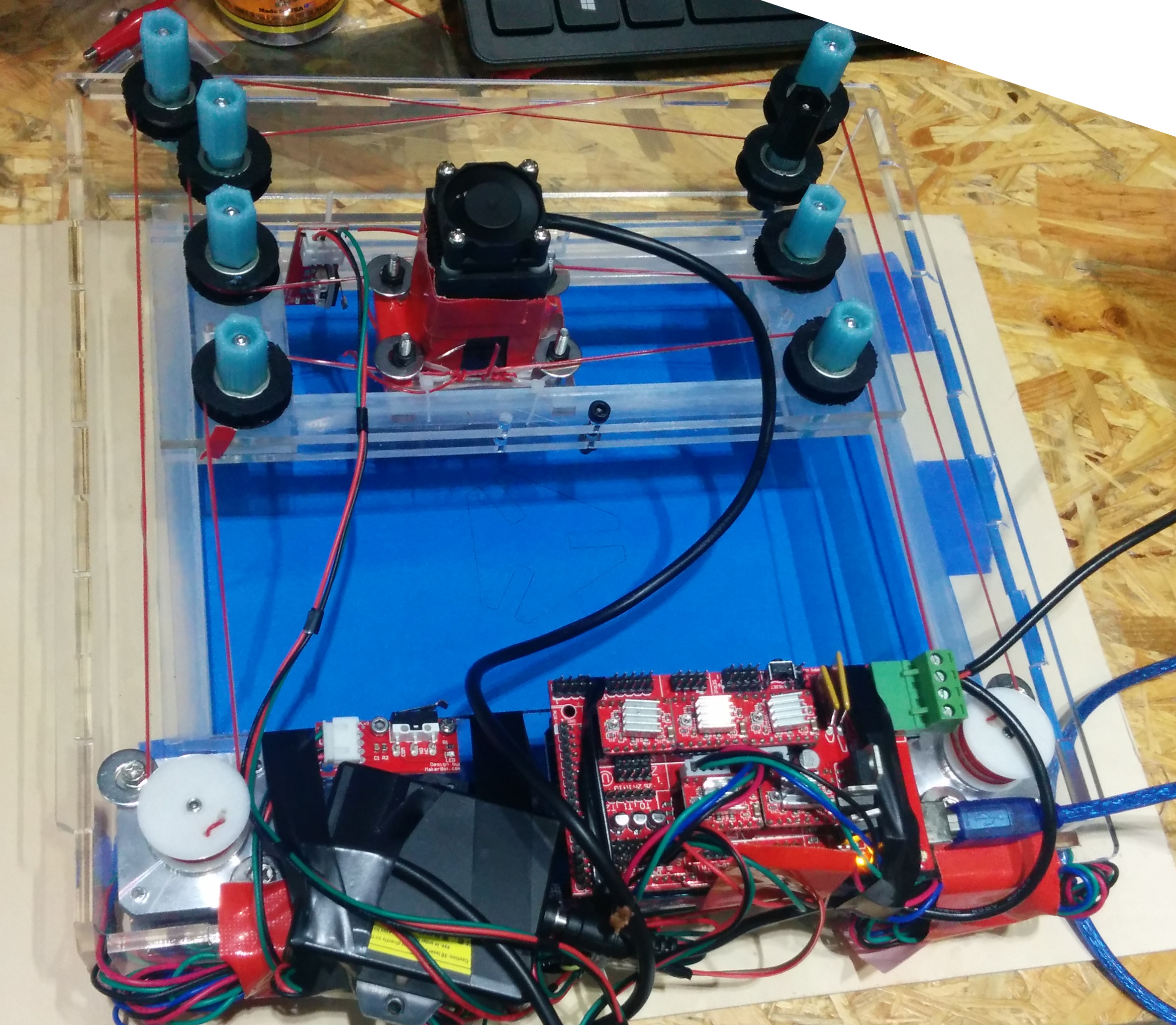

- A CoreXY-based motion platform using low-friction tape for plain bearings

- Designed for low-force end-effectors, easy reproduction using lasercutter + FDM 3d-printer.

August 2016

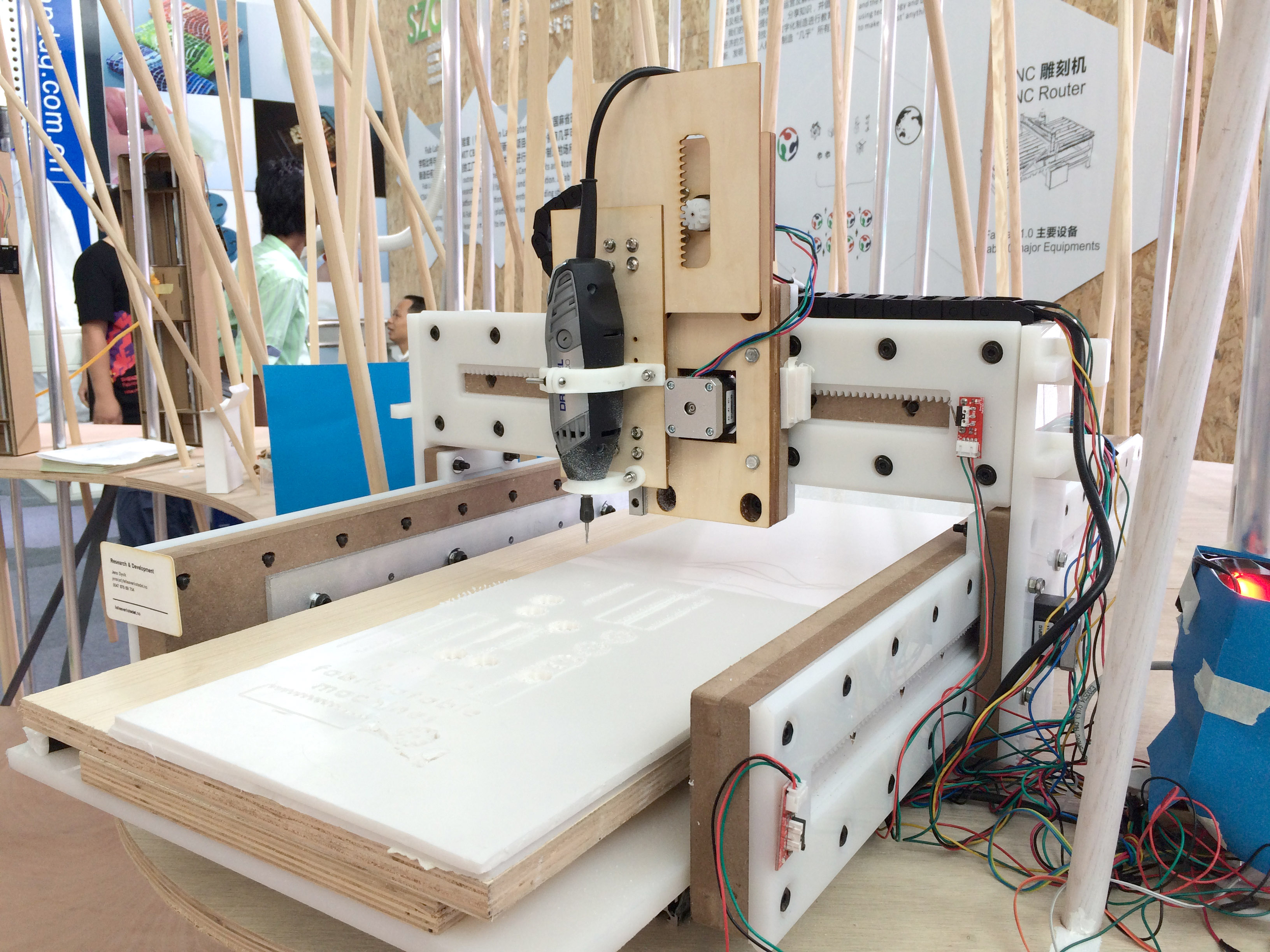

- Presented during the FAB12 conference.

- Standardized axis

- Assembled together into a CNC-mill

- Validated the potential of fabricatable modular rack and pinion stages

July 2016

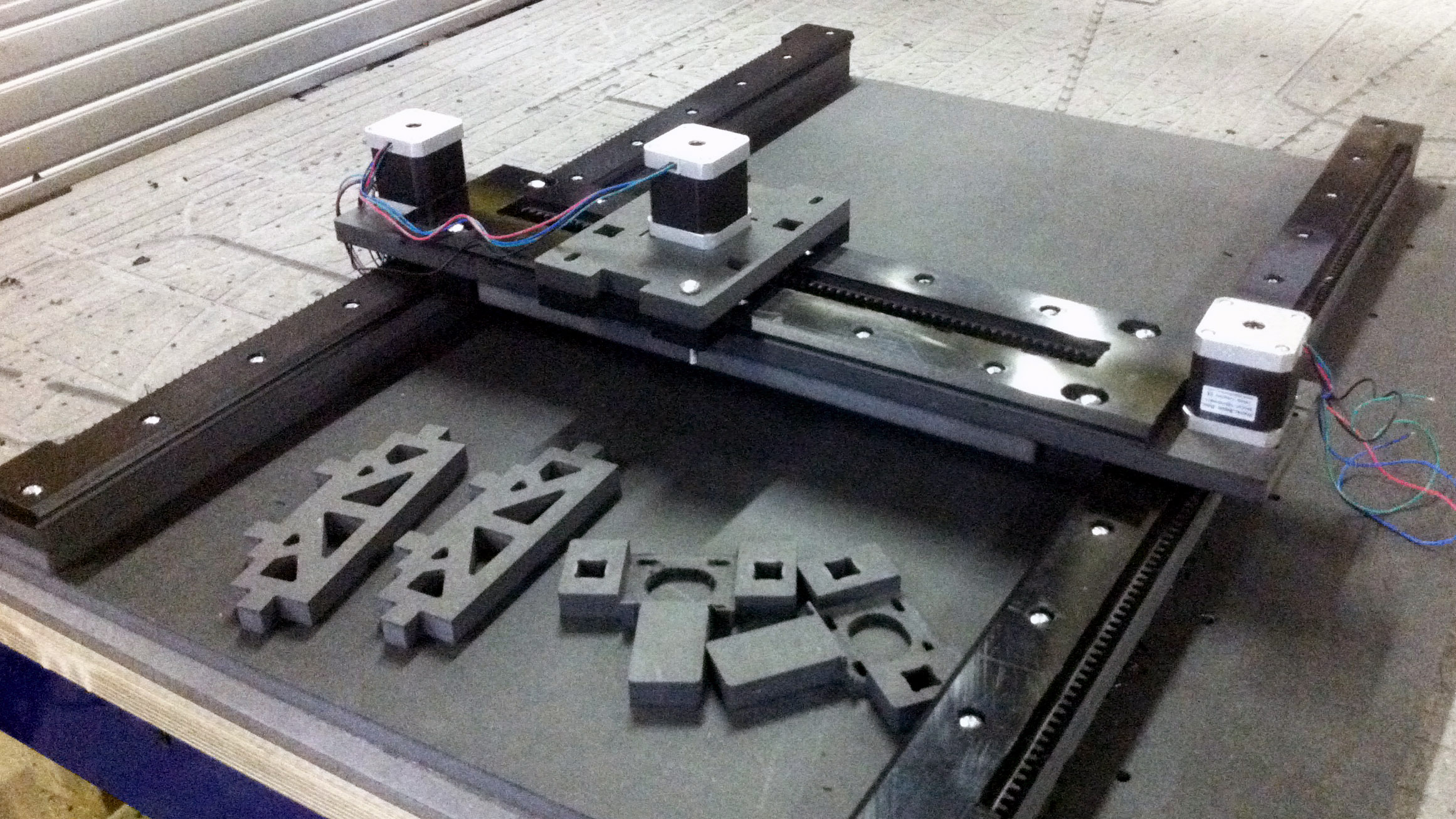

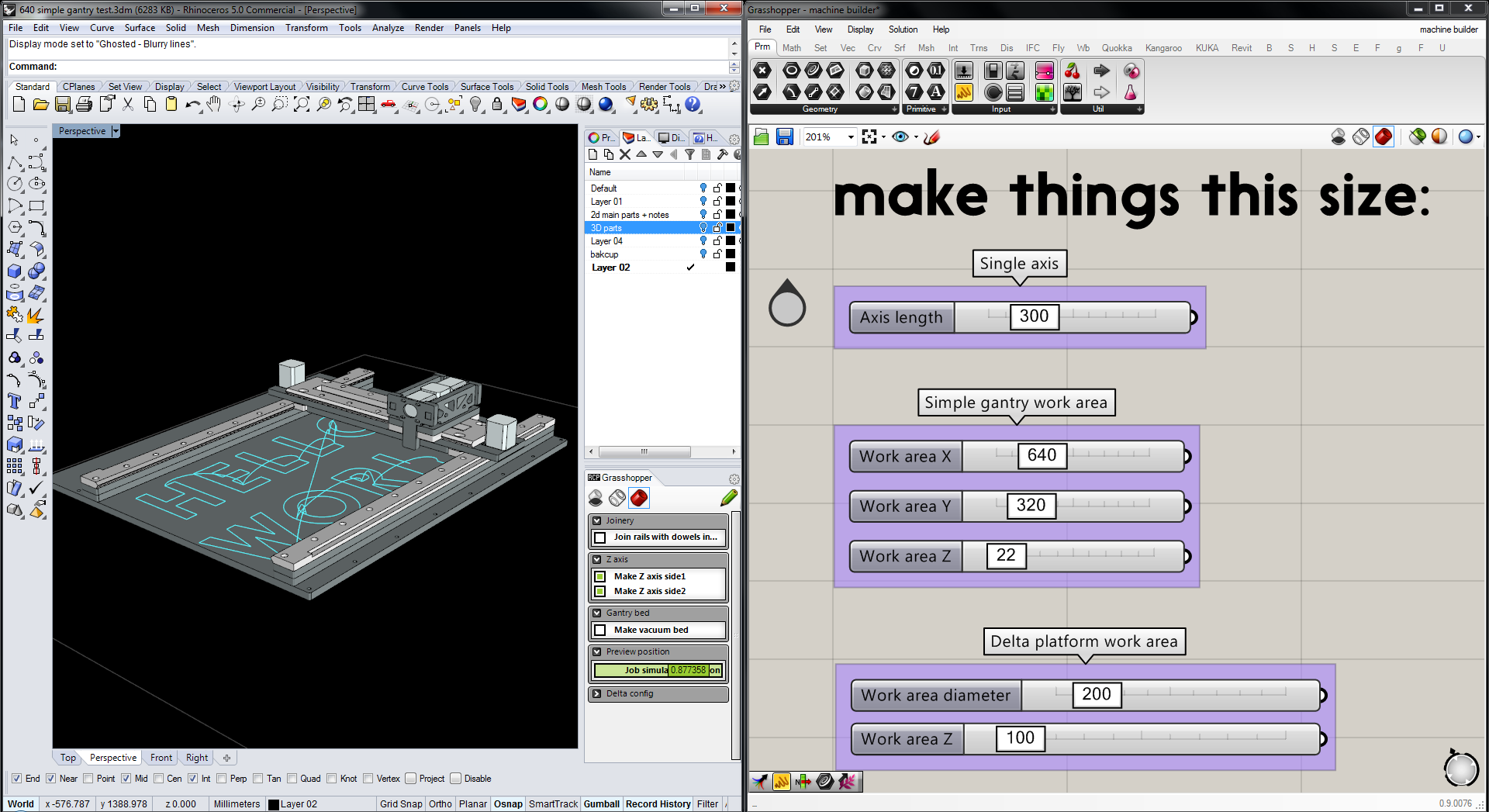

Our first complete XY platform designed to be fabricated in a Fablab. It can be used to build custom digital fabrication machines, from laserengraving to light-duty milling. Initial prototype is for a gantry-based vinyl/laser-cutter. Video from fabricating the first gantry rig here

No longer developed

- Using a birdbeak bit to make V-profiles, both inner and outer.

- Using technical low-friction plastics (UHWMPE/POM) motion/contact parts

- Assembling and contining to machine the axes on the CNC itself

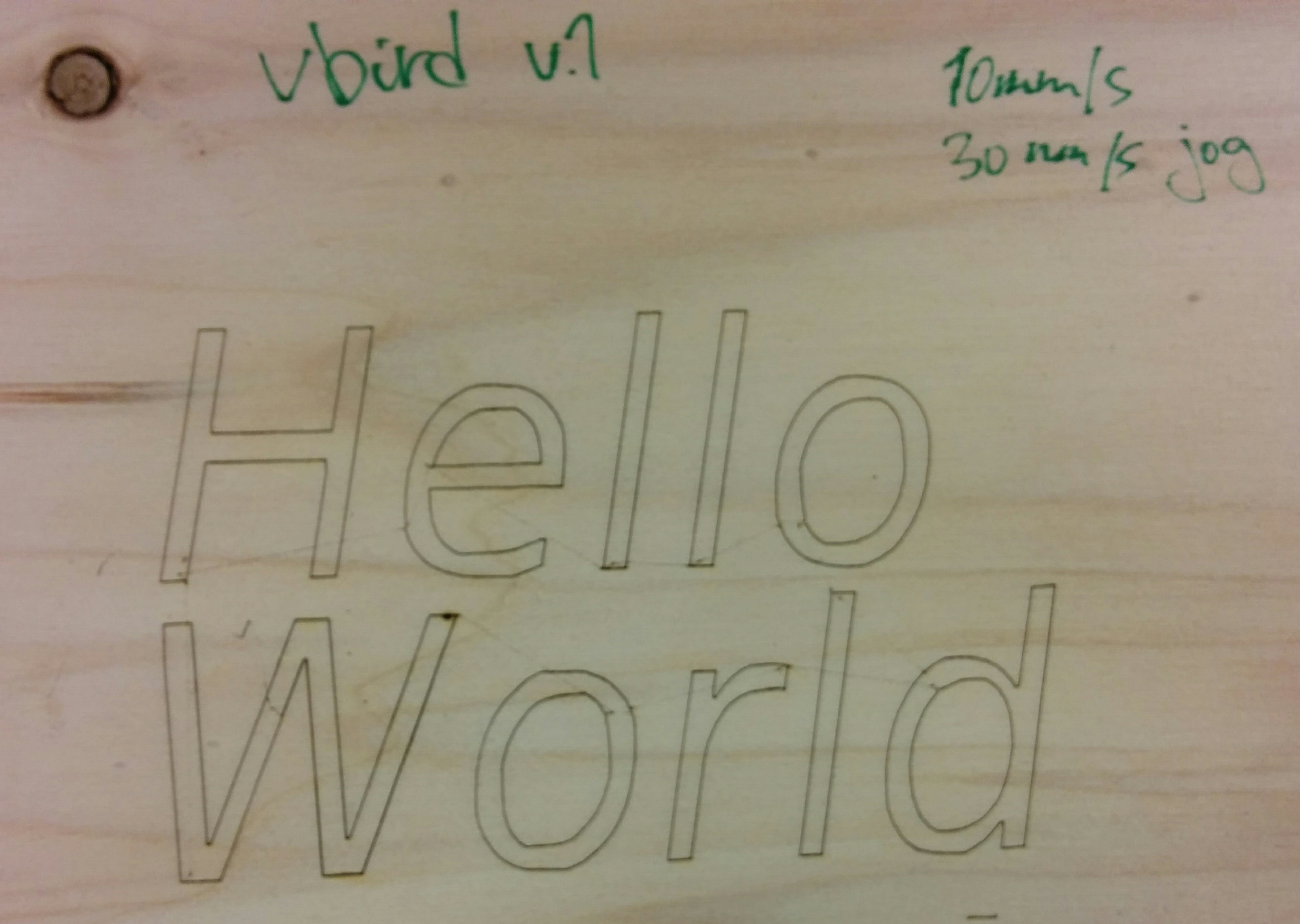

Laserengraving

- 10mm/s workspeed, 20 mm/s jog, 0.9 Amps laser power.

- Gcode generated by Cura, from a STL.

- No software control of the laserdiode (manually turned on off)

- Some of the bad lines are actually due to the poor quality font rendering

- At this speed will also (generally) cut through standard white printer paper

September 2015

- Test of a tecnnique for making rack and pinion geometry by moving a v-bit along a specific angle

- Seemed promising, but required sofisticated milling skils and tooolpath software

- Requires perfect positioning of pinion on motor shaft

- Has been replaced by the much simpler roller rack and pinion system, used on the Chamfer rail

April 2015

- Test of CNC mill v-bit engraved rack with SLA 3D printed pinions and V-wheels

- Sla 3D prints tends to shrink over time

January 2015

- Test of making linear motion with a column and carriage

- Is a bad idea bacouse a column can only be attached at top and botoom

- Makes a weak structure, and a complicated acrriage to farbricate

- Using a regular 60 degree V-bit to engraving rack was a success

- Make an axis that is longer than the workarea. Either by moving the workpiece, or machine in stages.

- A machine has been reproduced independently by someone else

- Use the machine in for realizing a project

- Have a machine that can fully reproduce itself

- Fabricate V-wheel for standard bearing using Shopbot with birdbeak/birdmouth bit

Open source lasercutting software

- http://www.shapeoko.com/wiki/index.php/Laser_Cutter

- http://www.shapeoko.com/wiki/index.php/CAM#2D_.28Laser_or_plasma_machines.29

- https://hackaday.io/project/4828-raster-2-laser-gcode-generator

CAM in your browser

- http://www.makercam.com/

- http://fabmodules.org/ now ith support for replicape https://github.com/Madouc/fabmodules-html5

To develop a complete inventory of fabricatable machines is a goal of the Fablab Network.

The Reprap aims to build self-replicating machines, where each individual machine can make itself. Mostly focused on FDM 3d-printers.