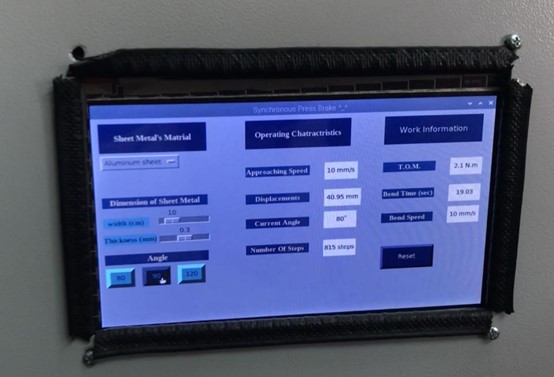

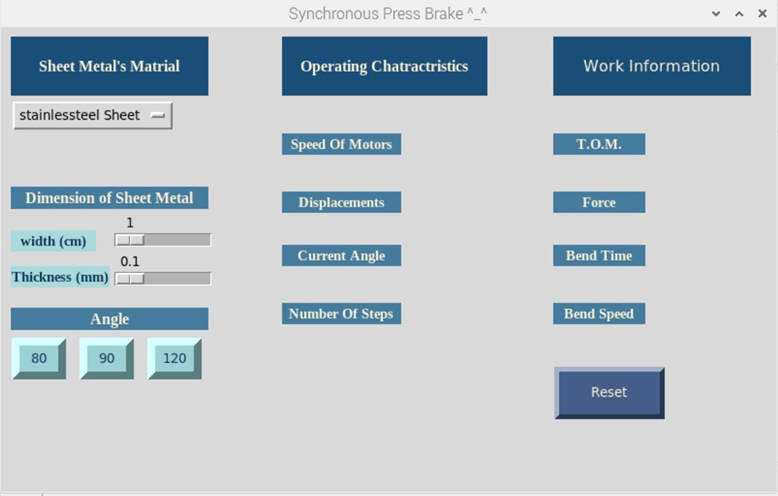

We chose to show the GUI on a touch screen connected to the Controller directly displays the user interface and enable us to choose the right choices desired and we can also change these options easily to make the controlling of the machine easier than using another device. The interfacing between machine and customer is taken place by using the HDMI touch screen. It is connected to raspberry pi (Main controller) by HDMI cable.

Setting the specifications of the main window.

Setting the controlling code for each angle

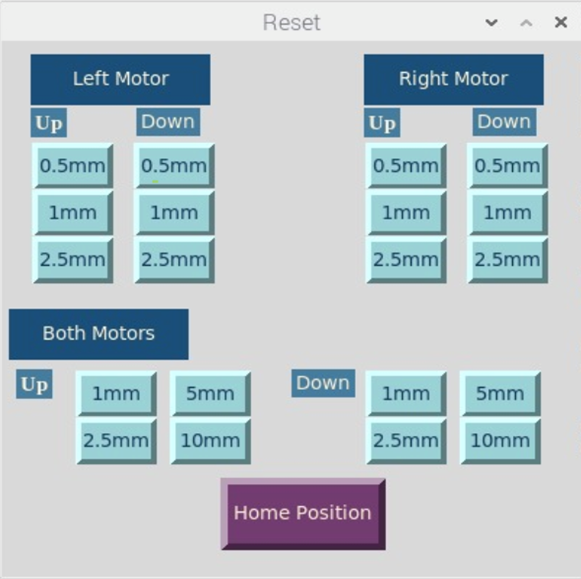

In the event of a defect in mechanical movement as a result of any reason whether loading on one side of the other machine, this will cause this load in descent of one of the motors.

Or if the mechanical parts are not able to walk together of the walking together as a result of friction between each other, this leads to the disability of the right motion of the machine, in these cases we need a system that enables us to restore this motif without stopping the machine system or conflict with the idea of the revised synchronization of the project.

The Sub-window enables us to control each motor separately, using simple buttons, without the other motor is affected and we can terminate the site of the partners and solve this problem. It also helps us to go back to the Home Position of the machine when desiring more than one bending process.

Below is the output Operating Characteristics at bending Angle 80°