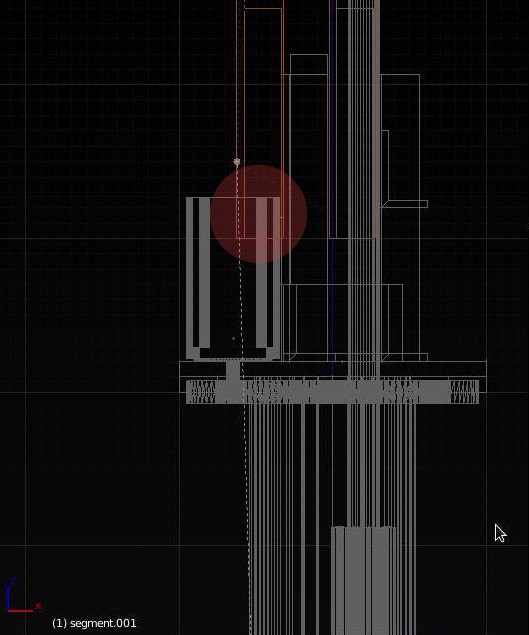

Joint 0,1 collide

faerietree opened this issue · 1 comments

faerietree commented

faerietree commented

joint 0 redesign benefits

- Luckily the common gear is half as expensive as the ring|internal gear.

- Also nice is that the bearing plastic sheet is obsolete now as the gear is made from plastics which also reduces friction with the pinion gear at the motor.

- As the motor becomes static now electricity supply wire twisting is prevented in the new design, too.

- Another positive side effect is that now there is enough space for the bigger NEMA34 compatible motor, resulting in 5 times as much torque which may be required to overcome joint0 static friction despite grease or oil bath in the .0006 clearance.

- Allows to use module 2 instead module 1.5 tooth size, resulting in a more rigid design. This makes it possible to mount an even bigger motor, i.e. maybe even allow to control yaw of spider leg variant this way.