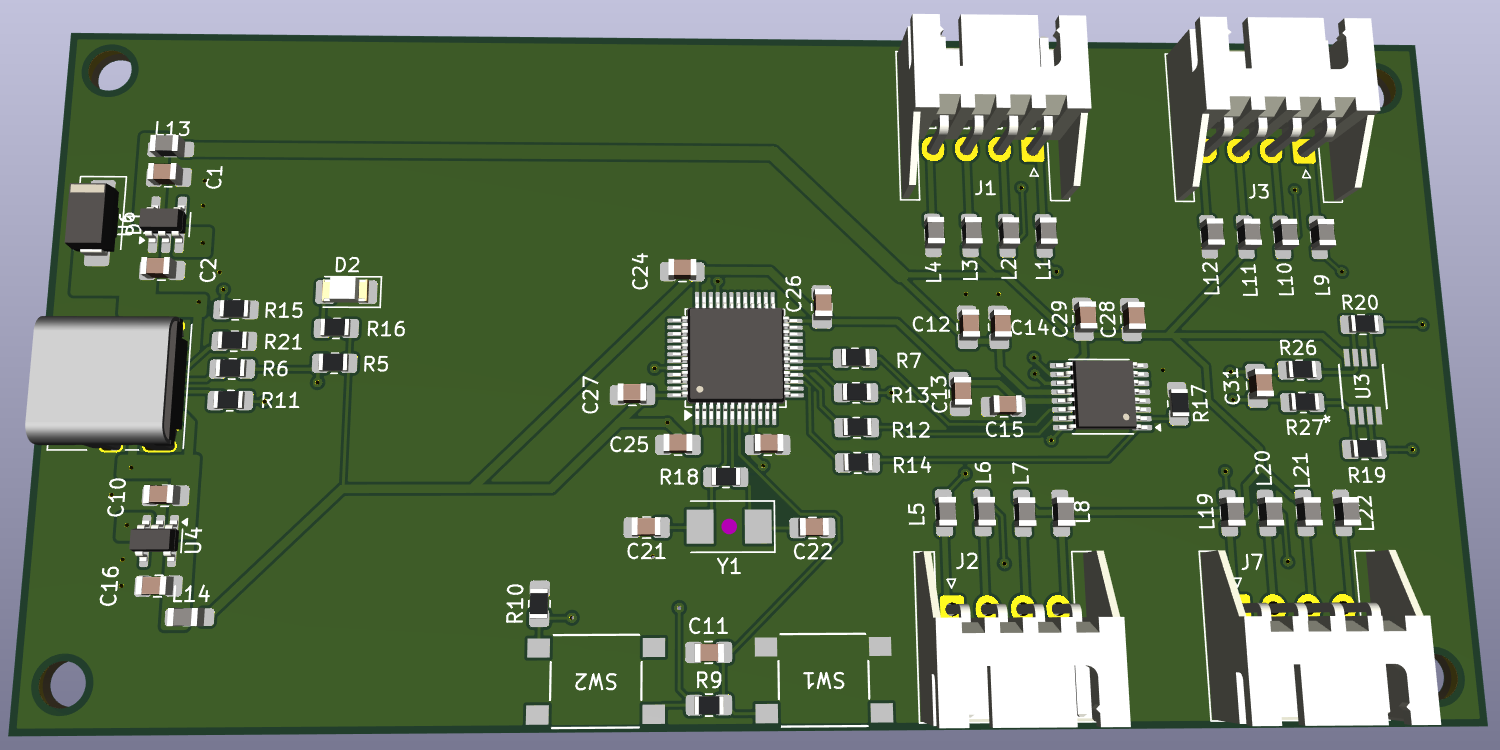

A board for connecting up to 4 Load cells to an ADS1220

This board is intended to be a reference design for eventual commercial boards that want to implement load cell probing. We intend to tackle the following problems found with simple prototyping boards that connect via SPI I/O pins:

- Produce a clean 5V power supply on board for low noise load cell bridge measurements

- Reject common 3D printer electrical noise sources including: Voltage Regulators, Steppers, Heaters & 50Hz/60Hz line noise

- Gracefully handle Voltage Spikes & Ground Loops

- Provide Amplification/Gain to support low sensitivity (1mV/V) load cells to be able to measure 1g of force change

- Ability to connect up to 4 load cells in parallel to measure force on a printer's bed

Eventually we would like individuals to be able to order a board from a board house, once we nail down the component selection.

This is currently in the prototyping stage. Prototype goals are as follows:

- Get it to work!

- Prototype and test one 5V supply architecture (12V -> 5V via low noise switching regulator)

- Test 5V to 3.3V via LDO

- Test with and without 1 differential amplifier.

- Investigate voltage spikes and ground loops.

Future prototypes will refine the board:

- Investigate additional 5V suppy architectures

- Investigate additional amplifiers

- Design for Supply Chain an Manufacturability: investigate component alternatives that are asier to get in the CN component supply chain.

- ADC: Texas Instruments ADS1220

- Additional differential amplifier: TK (prototype will try the Microchip MCP6V92 )

-

- 4 x 4 pin JST HX connectors for full bridge load cells

- MCU: STMicro STM32F103C8T MCU, Arm® Cortex® Cortex M4 @ 75Mhz

- Klipper and Katapult support this chip well, including flashing over CAN if we decide to enable that later

- USB C for communicating with a klipper host

- Physical Boot and Reset buttons

Several printers have shipped with the HX711 ADC chip which only supports 80 samples per second (SPS). We consider this to be too slow for use as a Probe in the 3D printer as probing speed is limited to ~2mm/s. There is a faster variant, the HX717, that supports 320 SPS. This shipped in all of Prusa's Nextuder products and those support probing at up to 10mm/s. We consider this the minimum sample rate required for a 3D printer.

Both of these chips have the disadvantage of not being standard SPI devices and requiring a lot of MCU overhead to support communication. Their data sheets are also lacking a lot of detail and the HX717 datasheet isnt available in English.

The ADS1220 is a good match for the capabilities of the HX717. Specifically:

- It supports faster sample rates close to 320SPS: 330, 350, 600, 660, 1000 & 1200. Higher sample rates improve the safety margin for probing if the noise can be kept low and the sensitivity is high. Other ADC chips tend to have a large gap in the sample rate range from around 300SPS to 1000SPS.

- It has a PGA that supports up to a gain setting of 128

- Supports standard SPI

- TI provides a detailed datasheet and have reference designs

- Relatively cheap and widely available in the supply chain. Cost is a large factor in getting a part into a commercial 3D printer board.

Features lacking on the ADS1220:

- The SPI speed is slow

- It lacks a "power reset" register. Reboots due to voltage spikes cant be detected at runtime. The HX711 & HX717 also lack this feature. Higher end TI product do have this e.g. ADS1263. If we were shipping a commercial product we would insist on this safety feature.