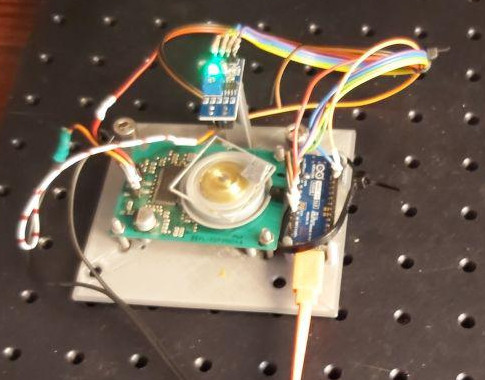

The rotor balancer can be used to balance propellers from flying drones or laser mirror motors.

The instrument is also a tachometer and can record the speed of rotors.

The Nano 33 BLE pulses the motor via hardware pwm and records the accelerometer signal via the onboard LSM9DS1 accelerometer chip.

During rotation the signal of a TCRT5000 IR LED is read out to detect the position of the rotor.

The amplitude of the accelerometer signal is proportional to the unbalanced mass. The phase difference between the infrared LED and the accelerometer indicates the position where a balance weight, aka. putty, has to be placed.

In the case of two plane unbalance, the phase difference between the IR Led and the accelerometer can be dependent upon rotor speed.

So far, I have only used the single-plane 2 run method to balance the rotor. Multi-plane balancing is not implemented.

Compile the firmware with Platform IO, a plugin for VSCode, and upload it to the Arduino Nano 33 BLE.

Connect to the board with a baudrate of 115200. Five options are available; start samples, calibrate IR sensor, spin polygon,

check pulse frequency and set pulse frequency.

Place an aluminum foil sticker on your rotor. Ensure the infrared sensor detects the sticker and set the threshold using a screwdriver on the TCRT5000 IR LED sensor so it only changes when it detects the sticker. Use other menus to check if the polygon is spinning and set the pulse rate.

Menus can typically be exited by pressing the 1 key and sending it with enter.

A program to collect measurements is available for python.

The python program is installed as follows, install requirements;

pip install -r requirements.txtInstall package;

pip install -e .Program is run as follows;

python main.py --plot --frequency 20 --filename '20hertz.p'An alternative is to run it via the python interpreter;

from rotorbalancer import tools

tools.runtest(10,11,1,'test')Example measurements can found in the measurements folder.

I made a video of the setup for a better impression.

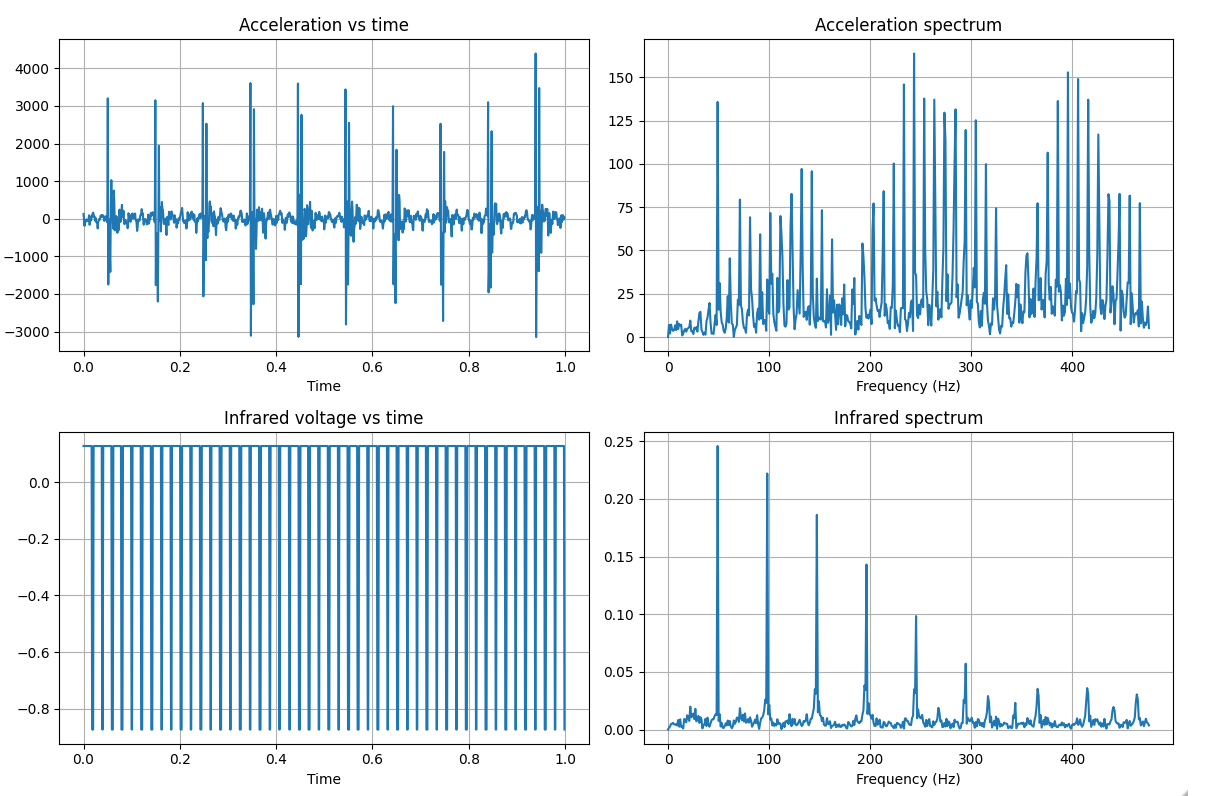

For each measurement, the rotor is pulsed at a certain frequency for 20 seconds to spin it up.

The motor is kept on and the acceleration and infrared signal are measured for 1 second.

Sampling is equidistant at 952 Hertz as this was the maximum sampling frequency of the accelerometer.

In single plane balancing it is assumed that the angle of the force is not dependent upon speed.

The phase-difference between the ir sensor and the acceloremeter determines the location where putty needs to be applied.

The frequency and amplitude are determined via a Fourier transform. Using a peak detection algorithm, the first peak is selected.

Results are repeatable and standard deviation is in the range of 10-3 percent. Results are shown in the notebook folder.

A balance weight of 0.060 gram Weicon resin putty is applied. I used an AG204 Delta range from Mettler to measure the weight of the putty accurately.

As a lower cost alternative, pieces of aluminium tape could be used, as there is a direct relation between mass and surface area.

A small piece of aluminum tape is applied to trigger the IR Led sensor.

Futher literature can be found in Science direct and at the site of National Instruments.

The measurements are available in the measurements folder.

I had to remove modemmanager as this caused problems with arduino.

sudo apt --purge remove modemmanagerThe accelerometer libary from Sparkfun is used in a slightly modified form.

Prism:

4 sides, 30x30x2 mm

Mirror motor:

Panasonic AN44000A, other moters require different pins to be pulsed.

Mirror motors have 5 pins; PWM, MOTOR_EN, GND, Voltage and LCK_PIN.

PWM is speed control. Relation is not linear for all motors. GND is ground. Voltage is the supply voltage, ideally 24V. LCK_pin is

false if encoder and signal are not in sync. I cannot confirm the function of LCK_pin and MOTOR_EN.

Changing them or looking at their input does not reveal any activity.

They are fixed for now to guarantee repeatability.

Accelerometer:

The accelerometer of the LSM9DS1 is used, as it available on the Arduino Nano 33.

IR sensor:

The TCRT5000 IR LED sensor see DIY LP turntable. I bought one here

Balancing putty:

In the industry two systems are used. A 2 component epoxy resin putty by Weicon

A single component UV curable expory resin system, e.g. by Shenk. In german it is called Wuchtkitt. The compound has a ceramic filling and the density is 2 gram per cubic centimer. Component was ordered via modular. The kitt becomes green upon mixing. After several hours it becomes very hard and can no longer be removed from prism.

An alternative is to use lead or metal tape. Lead has a density of 11 gram per cubic centimer.

Optical plate:

Used an optical aluminum breadboard from Thorlabs with M6 screws as base. Do not attach the device to something heavy this make the measurements worse. Typically, you want it decoupled from the external world and place the object under study on foam or hang it on cords. During measurements, the prism was suspended in air with strings.