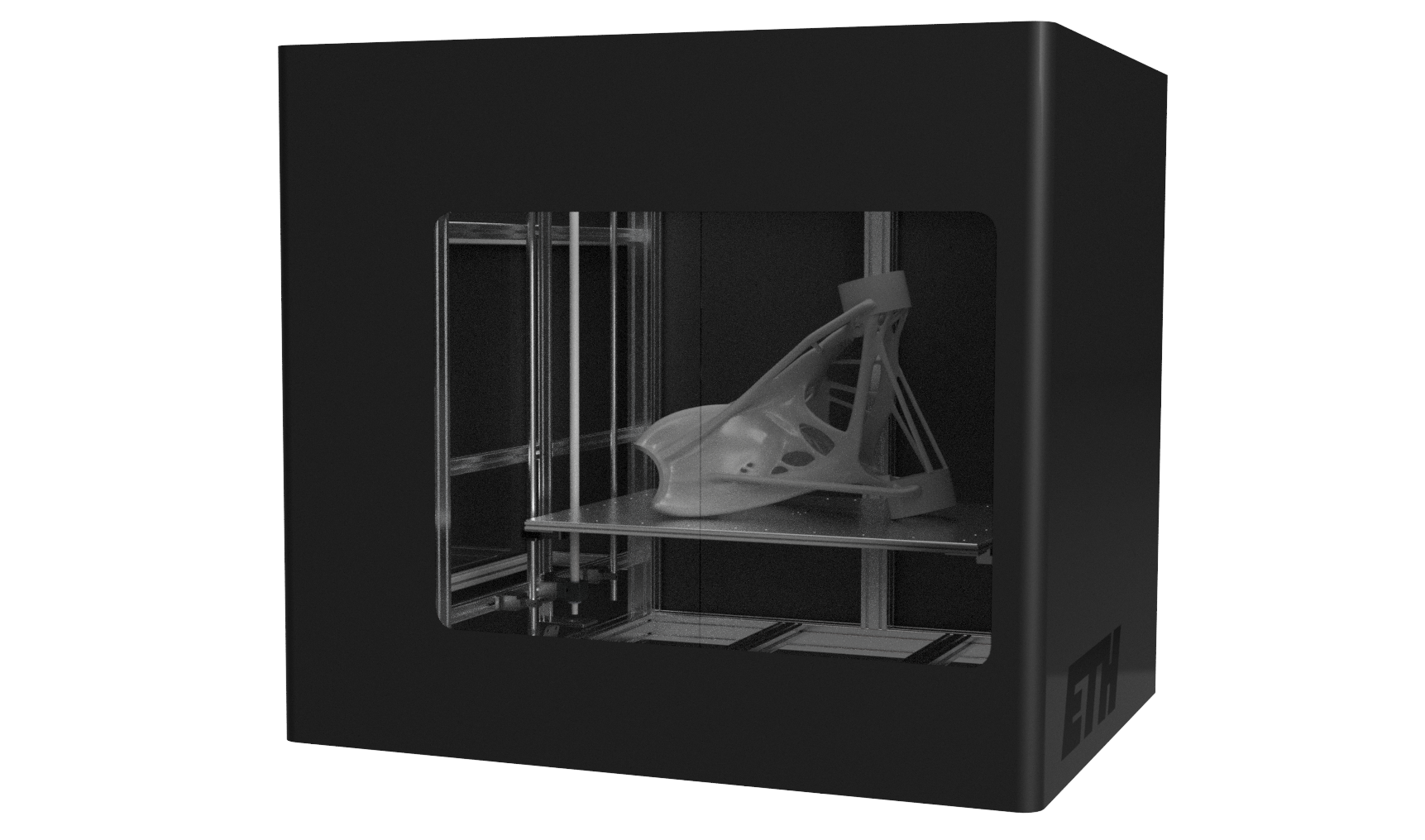

The ETH Zürich's Student Project House's "Bulky but Fabulous Printer" - (BFP)

The ETH Zürich's Student Project House's "Bulky but Fabulous Printer" - (BFP) is a large H-bot / CoreXY style FDM printer with a build volume of 1㎥ ( 0.8 × 1.2 × 1.1 ). It was built by members of the Student Project House (SPH) and is intended to be used by any user of the SPH (after a machine introduction).

- Large build volume 1㎥ ( 0.8 × 1.2 × 1.1 ),

- Capable of large volumetric flow rates,

- Can print much stronger (and larger) parts,

- Can print wide range of materials, e.g. fibre reinforced filaments, polycarbonate (PLA to PEEK) - PTE default,

- Removable print platform,

- Auto mesh bed leveling,

- Print heads can be swapped,

- Cura slicer

Please see here the BOM. Some parts, such as the aluminium brackets, mountings and X-axis, were machined. The some profiles were also cut down to size.

The 'interesting' components are listed below:

- Duet3D ethernet controller board with breakout board,

- 80W E3D Volcano hot end

- IR differential height sensor

- Optical endstops

- Stepper motors,

- Stepper Controllers,

- HiWin linear motion, rails and ball-screw,

- aluminium Extrusions,

- 2 × 24V 6.5A Power supply

- 1 × 24V 13A Power supply

- 12 × Build-tak (300×300)

- 220V 500W heater pads, switched with a SSR

Finding the right print settings is a time consuming task. Use the existing presets.

Some general information:

⚠ Electrical Hazard! Large capacitors are used to smooth the power for the motors, this means significant power could be stored in the electrical cabinet even though it is powered down, do not mess with the electronics if you don't know what you're doing, ⚠ Never Disconnect the motors while the printer is on. The motors are connected through XLR plugs.

Every now and then the kinematics should be cleaned and oiled.

|

|

|

Hopefully coming sometime, maybe even soon,

- Tool Changer

The initial work has been done for this. The mounts are machined. It's a matter of remounting the hotend and making the changing part of the tool changer.

- Silicon Printing

- For printing moulds

These settings should **not** need to be changed, but are supplied here for reference.

It is recommended to tune the PID values for the hotend (and bed).

Use the autotune method described M303 H1 SXXX where XXX is the temperature to tune for. Then use M307 to output the values.

Then in the appropriate filament configuration file, filament/<TYPE>/config.g, add M307 H1 AXXX.X CXXX.X DX.X S1.00 V24.0 B0 as per the duet instructions.

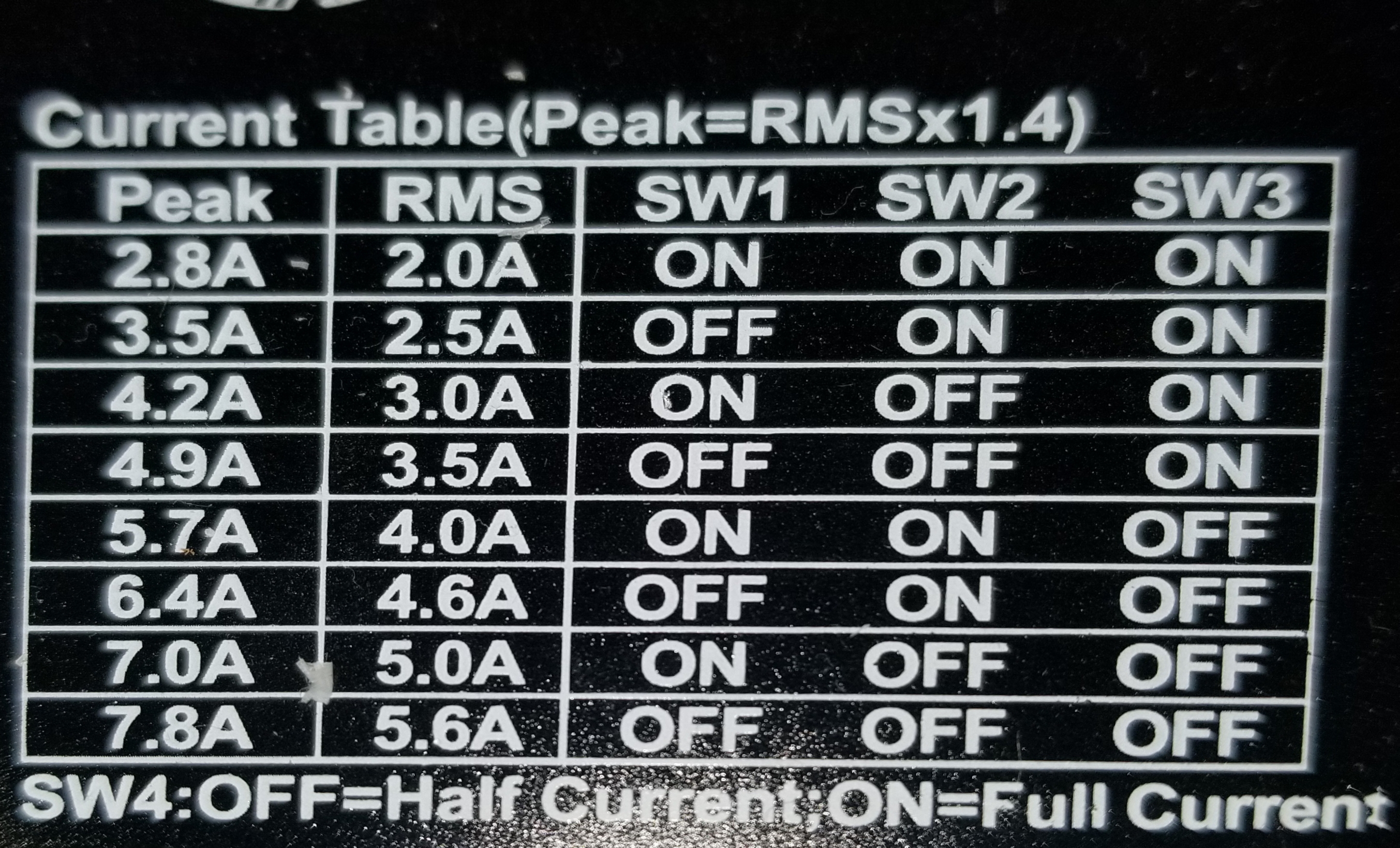

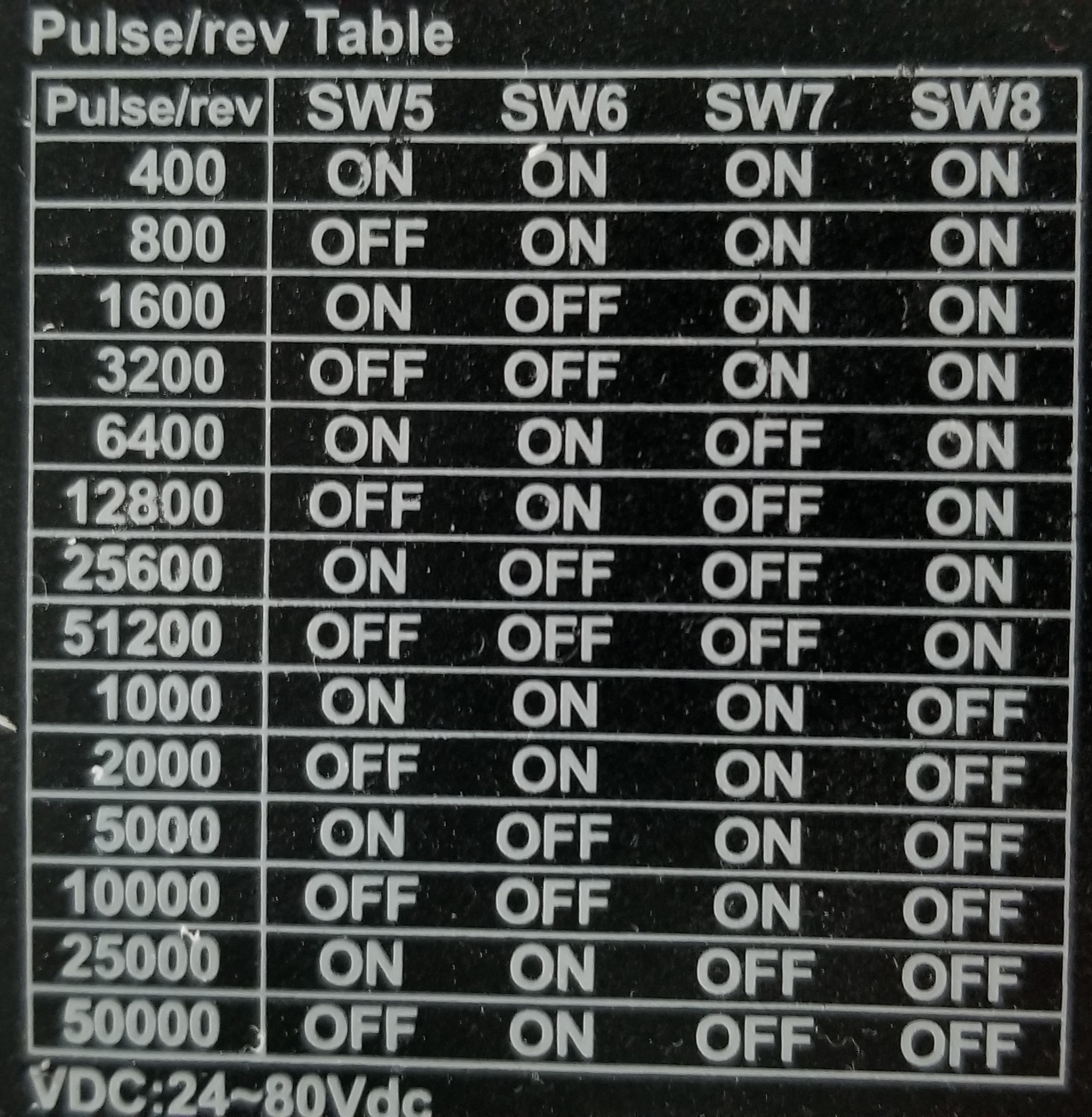

The micro-stepping and motor-controller current settings are controlled by DIP switches on the controllers, these differ for the Z and XY motors.

A corresponding micro-stepping setting much also be changed with a corresponding M-Code for the controller.

The controllers settings are encoded in GCode, a copy of the file from 2020-09-05 is here

The HTTP server is configured for 192.168.1.3.

GCode Reference: GCode Reference

All steppers use the same micro-stepping setting of 3200 pulse/rev = ×16 μStepping (motors are 200 steps/rev = 1.8° per step), (SW5, SW6 OFF SW7, SW8 ON)

The X-Y stepper controllers should have their current settings of 2.8A peak, 2.0A RMS (SW1, SW2, SW3; ON, SW4 OFF), this is done to reduce vibrations.

The Z stepper controller use 7.8A peak, 5.6A RMS (SW1, SW2, SW3, SW4, OFF).

Z Motor Controller:

Duet3D documentation Important things to note are:

- For wiring and connections, see the Duet connections here.

- External stepper-controllers are used,

- Power for the Heated bed is done through an SSR,

- On

192.168.1.3, see 'BFP' host entry in/etc/hosts

This project would have not been possible without the generous support of our sponsors:

- HiWin - for linear movement components, to ensure BFP is Fast, and Beautiful,

- Duet3D - for the electronics that control the printer is Fast,

- Item - for the aluminium profiles that gives the printer so much Beauty, (and Bulkiness).

Of course credit also must go to the Student Project House, for funding and providing the tools and space for our Big, Fantastic Printer.

Also thanks to those that helped in the design, construction, and assembly of the printer:

- Andrea Perissinitto - Project Lead

- Oliver Harley,

- Killian Hanke,

- Max Schäfer