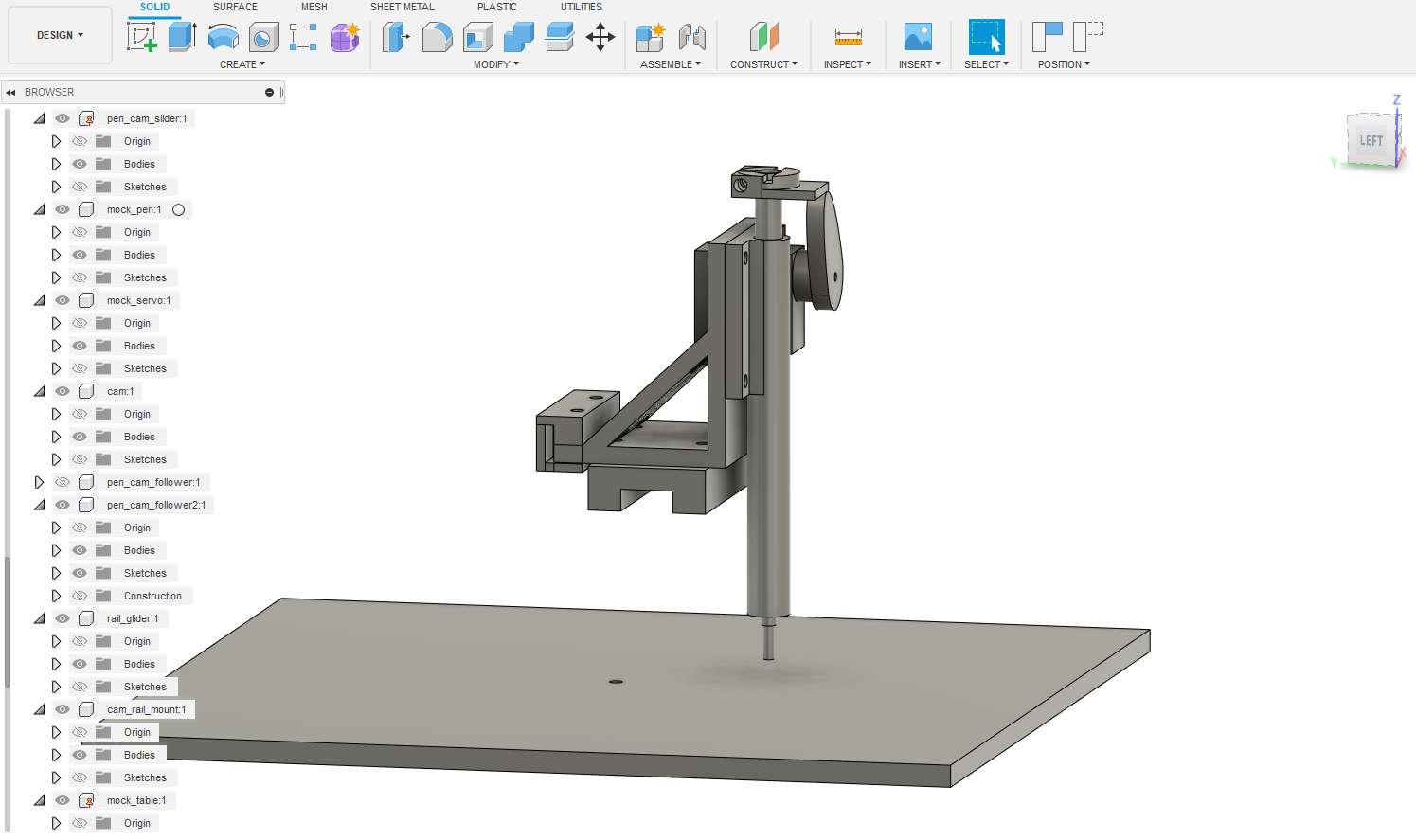

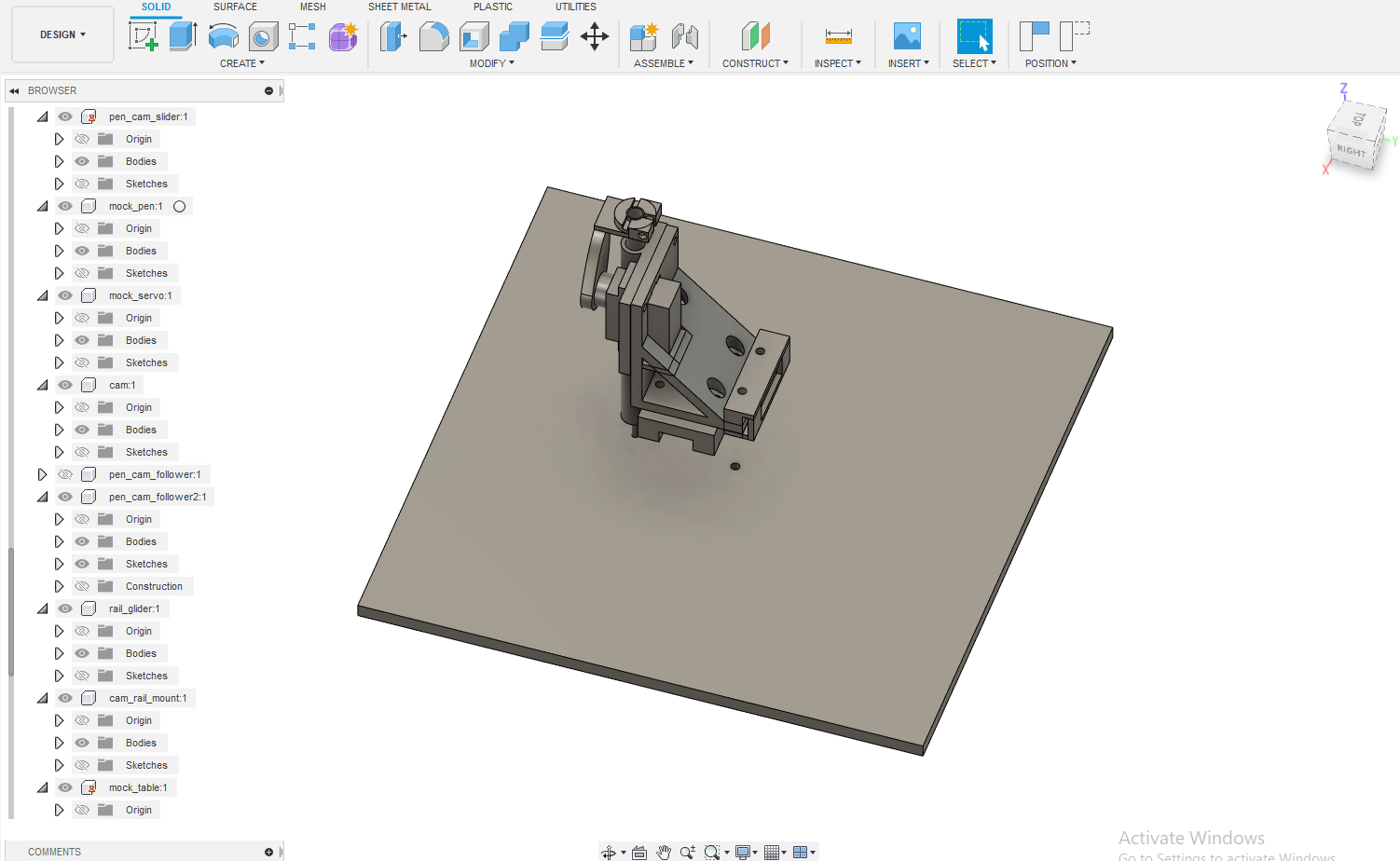

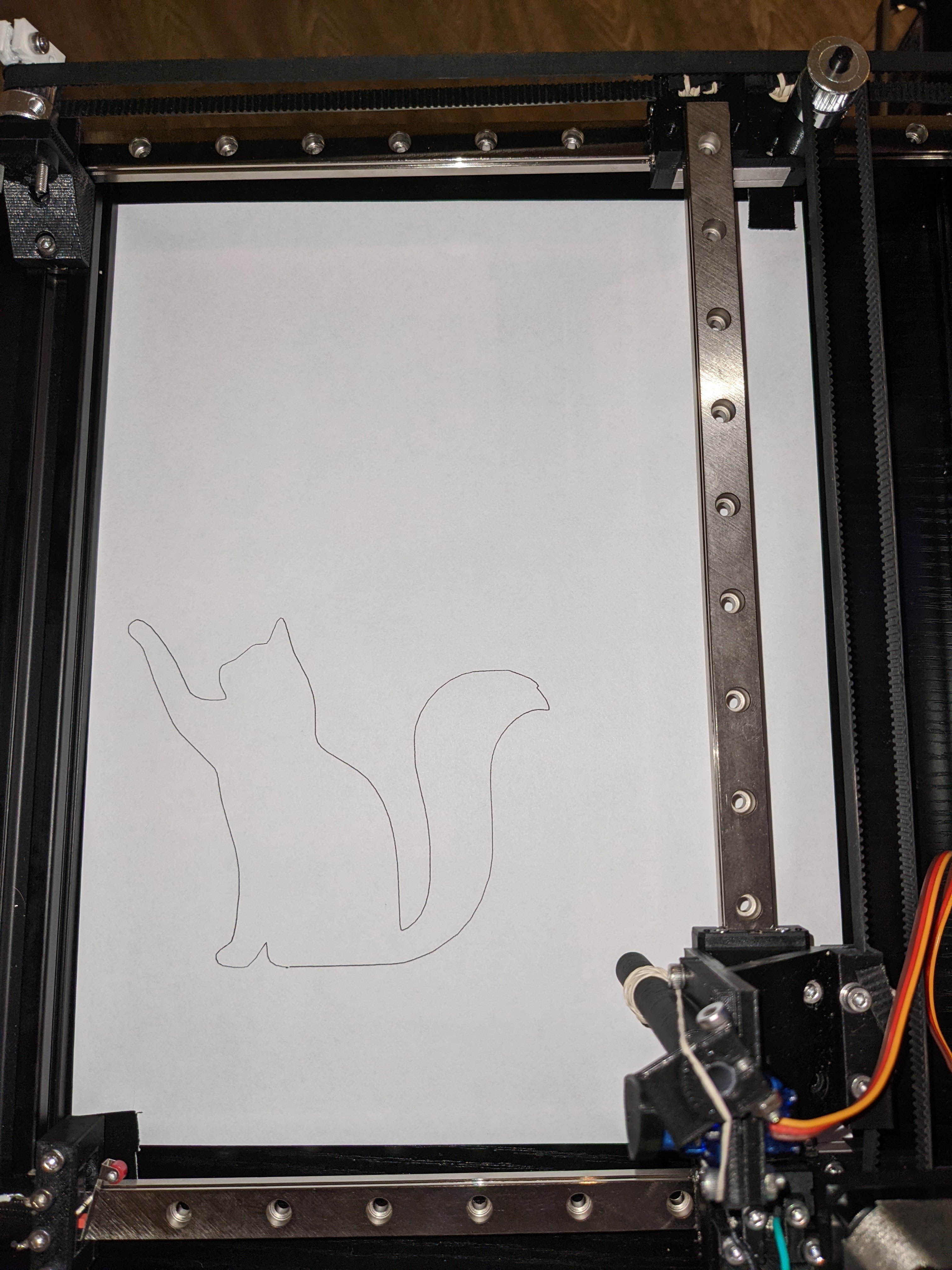

Hey there! I recently have been working on creating my own CNC Pen Plotter - essentially a machine that creates drawings by moving a pen around on a stationary piece of paper. I wanted to write up this post to share the project with others and document some of the challenges I faced along the way.

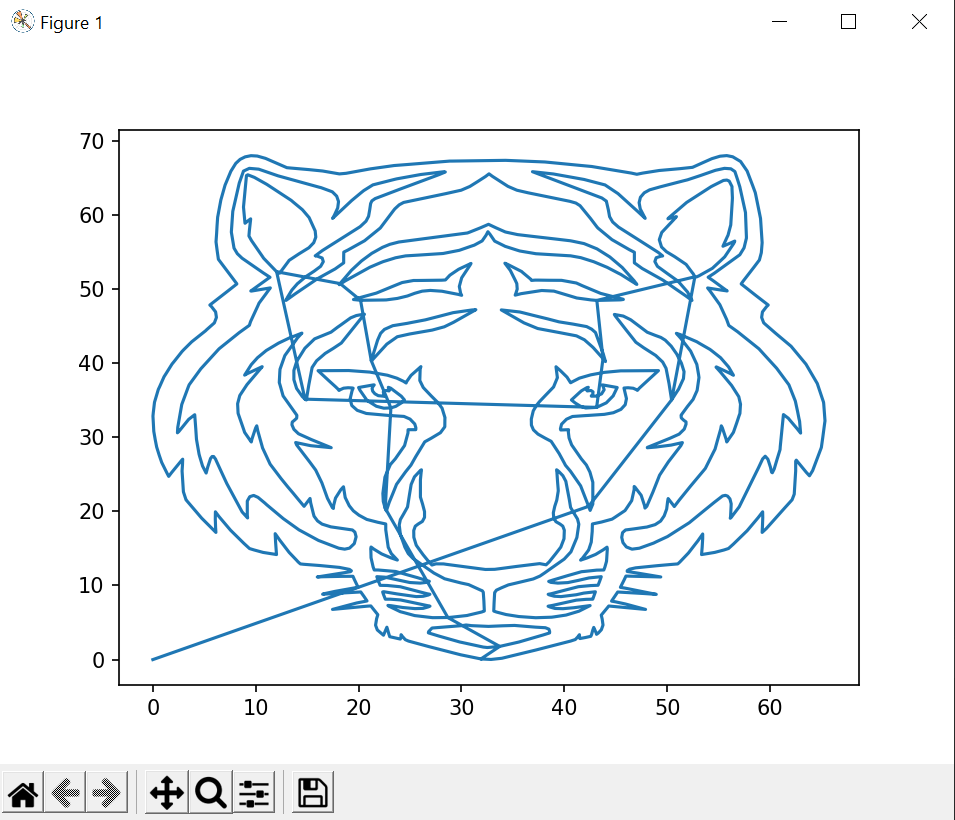

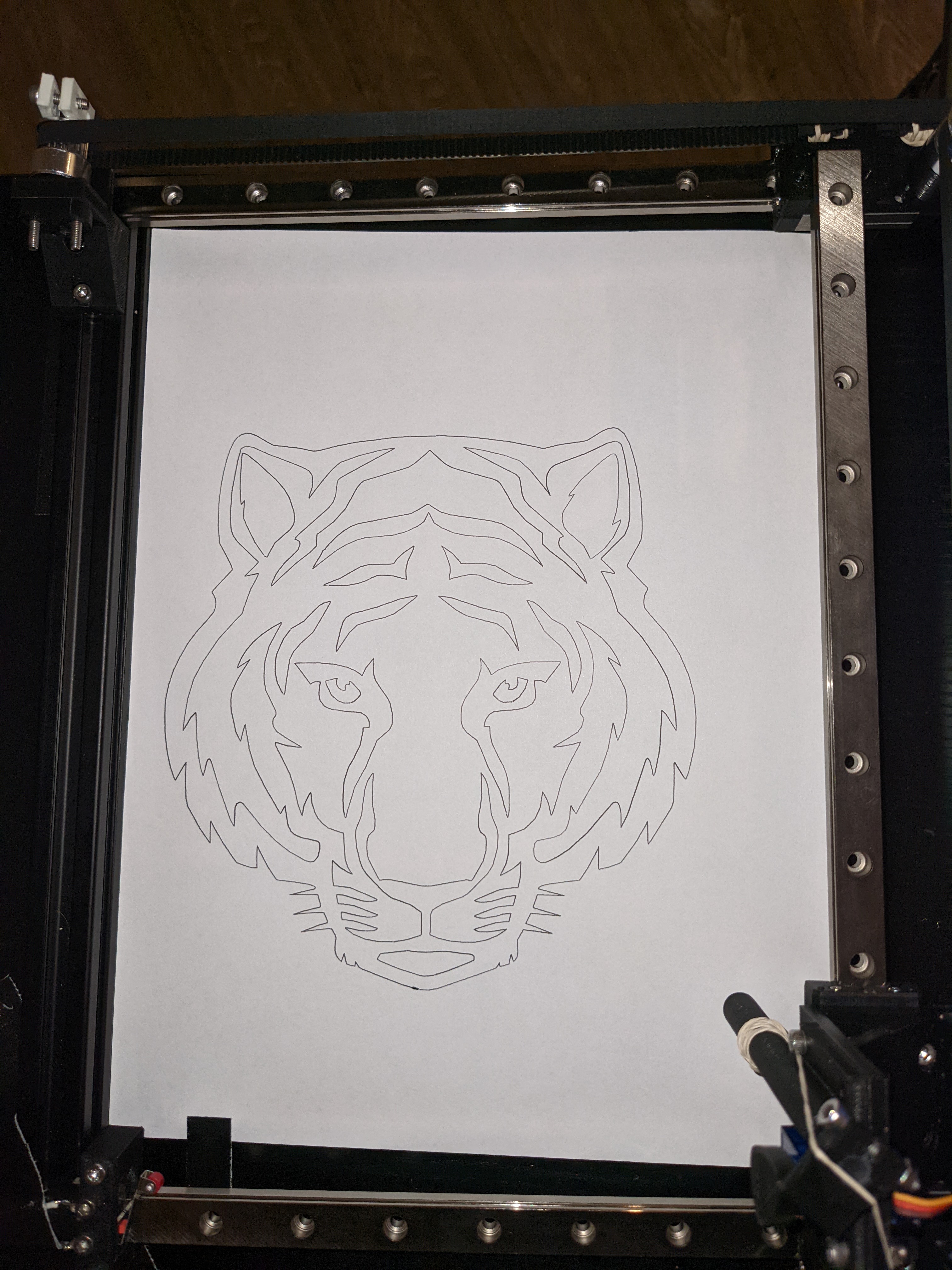

See the full video of this drawing on youtube.

| Original Image | Pen Plotter |

|---|---|

|

|

|

|

|

|

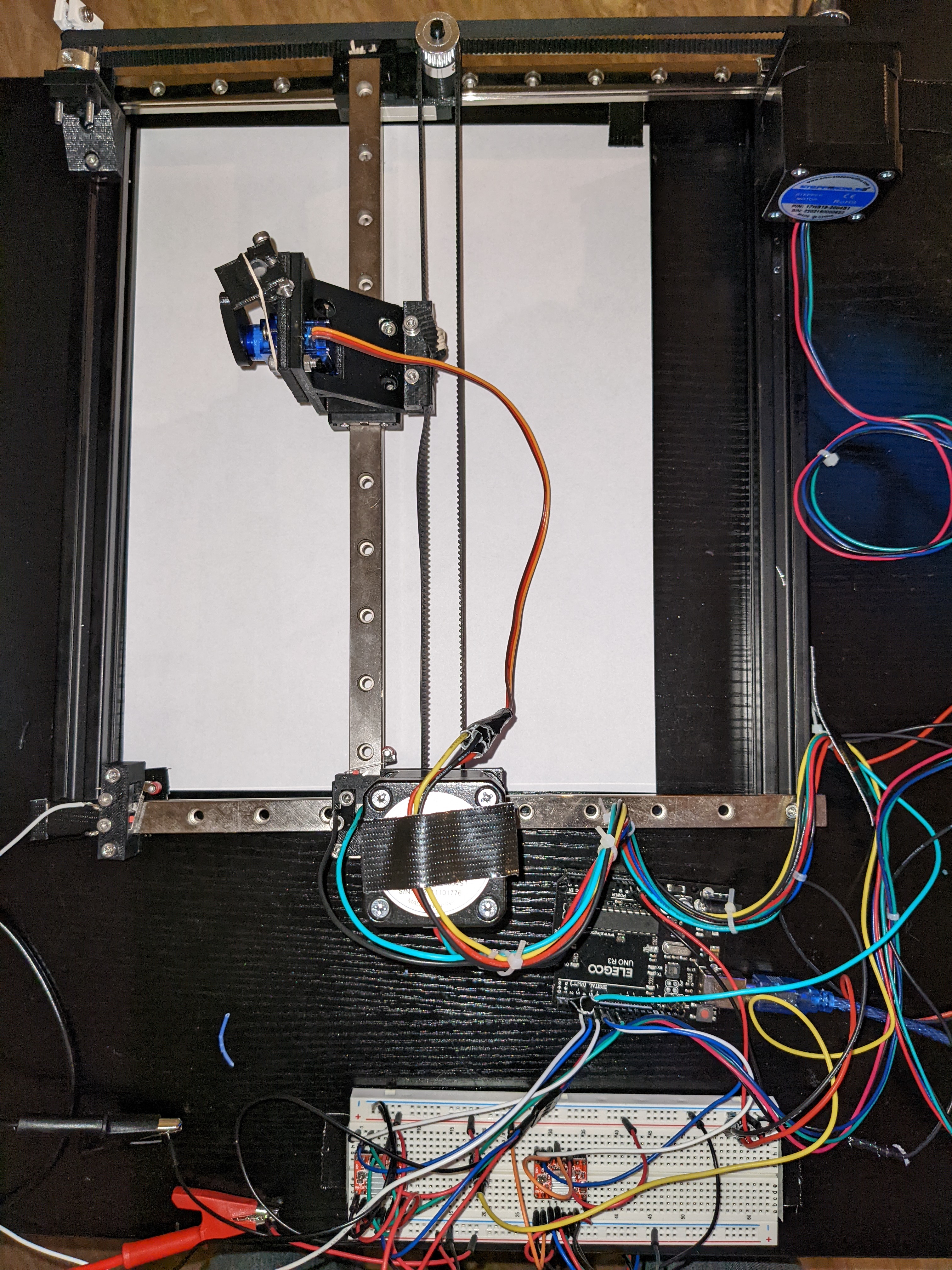

The design is fundamentally 3 linear rails on-top of 2 aluminum bars with around 15 different 3D-printed compnents mounting stepper motors, pulleys, timing belts, and a servo to the frame.

The 3 linear rails give smooth motion across the X and Y axes. The stepper motors move the pen around the plane and the servo moves the pen up and down.

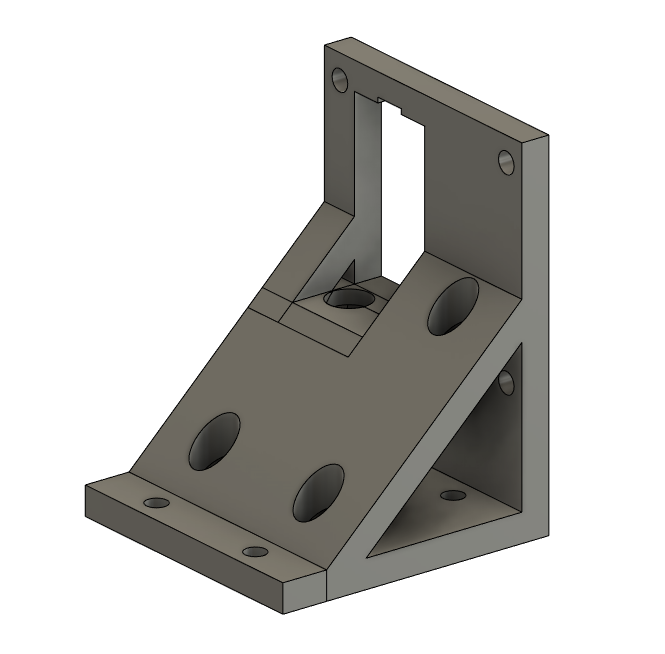

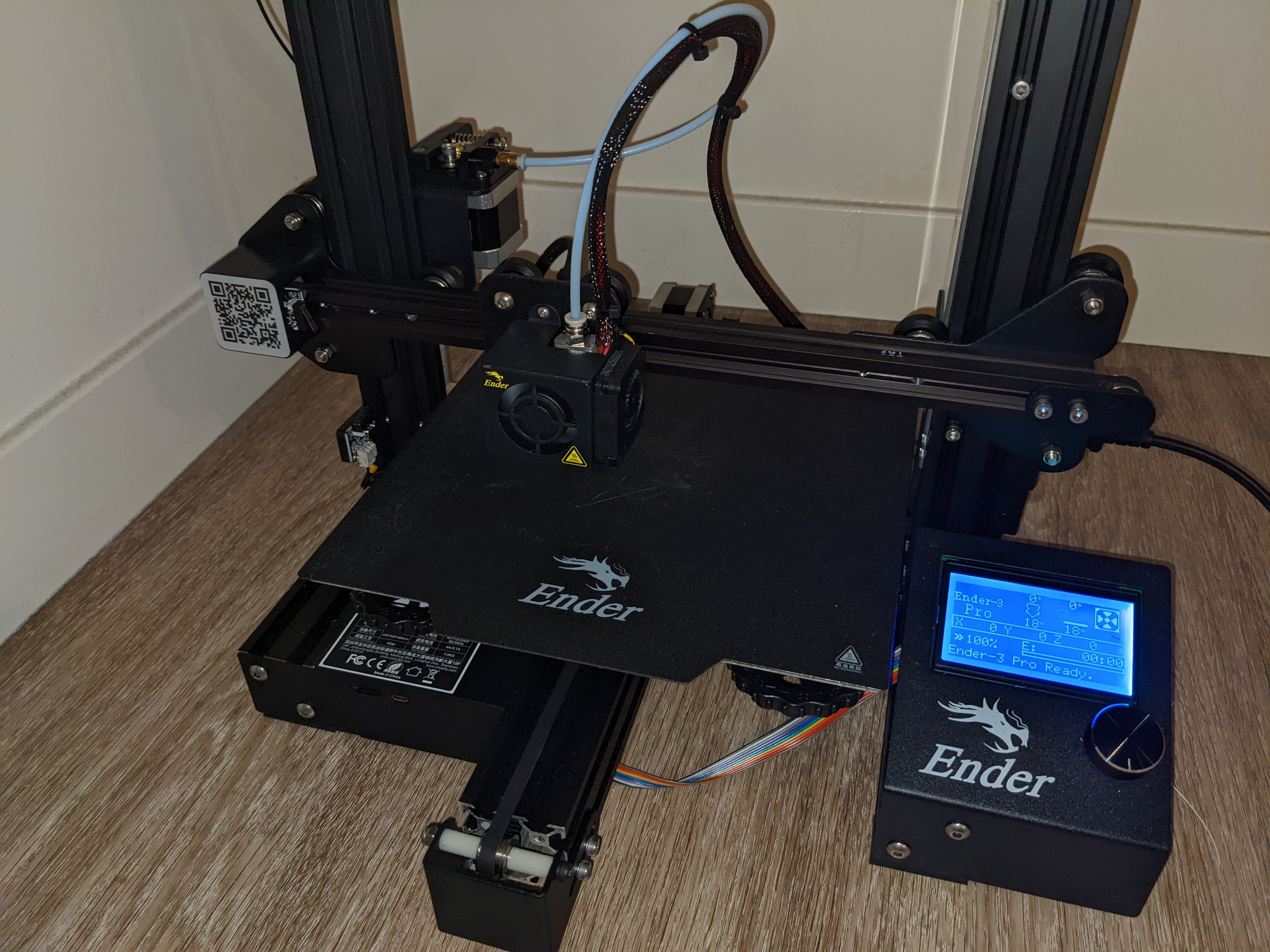

All the custom parts were designed with Fusion 360 and printed on an Ender 3 Pro. Here's a few of the highlights:

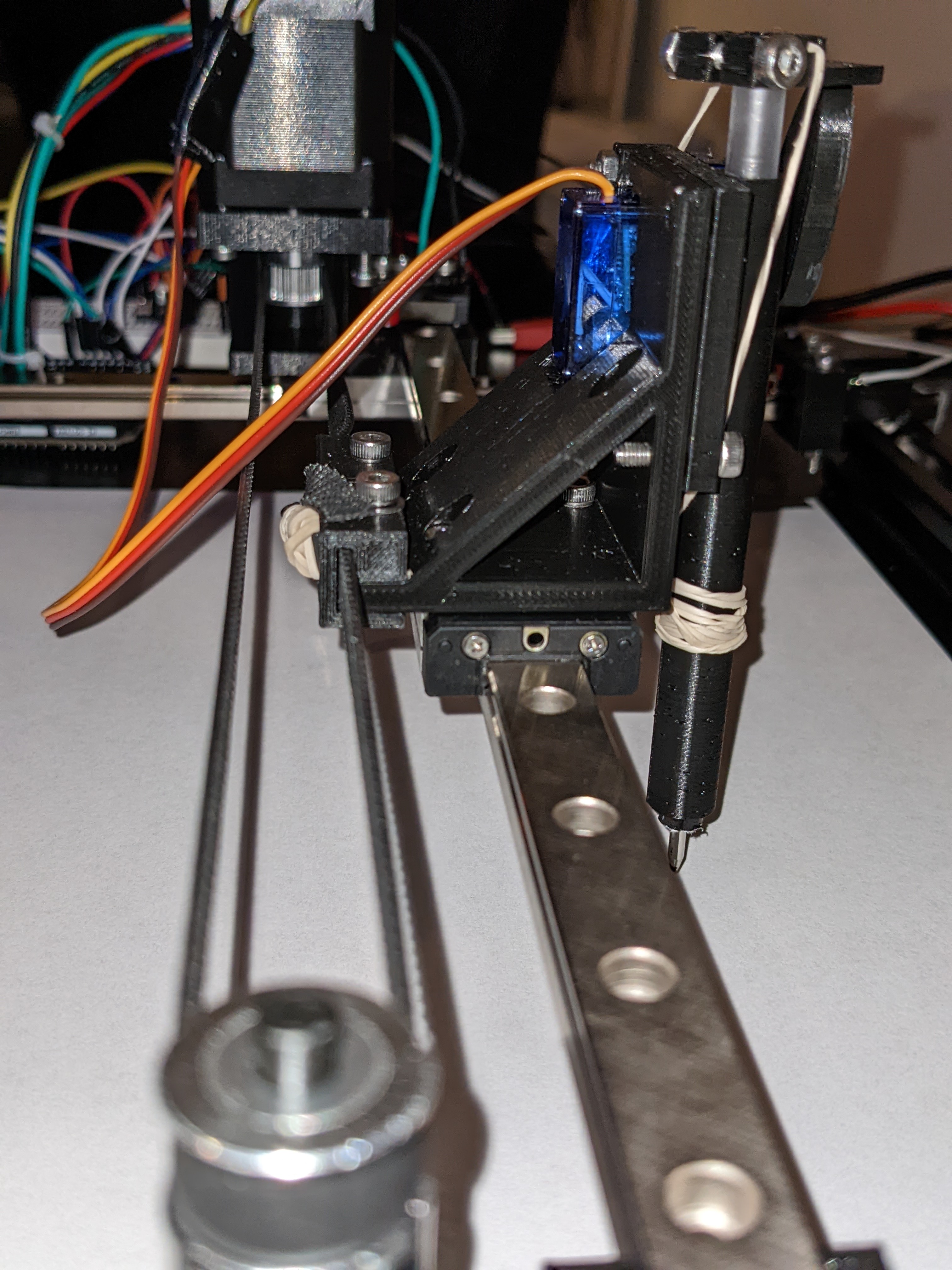

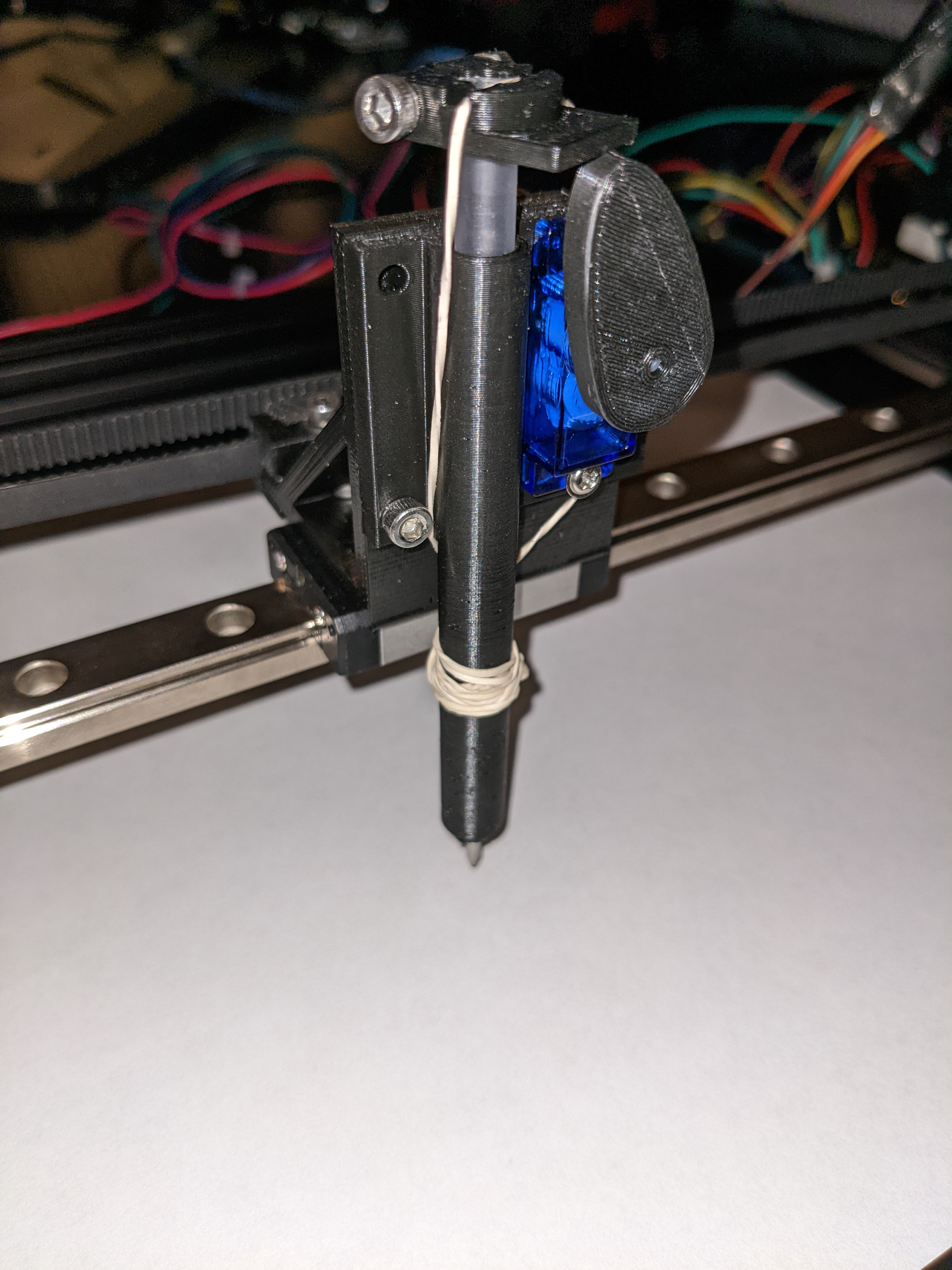

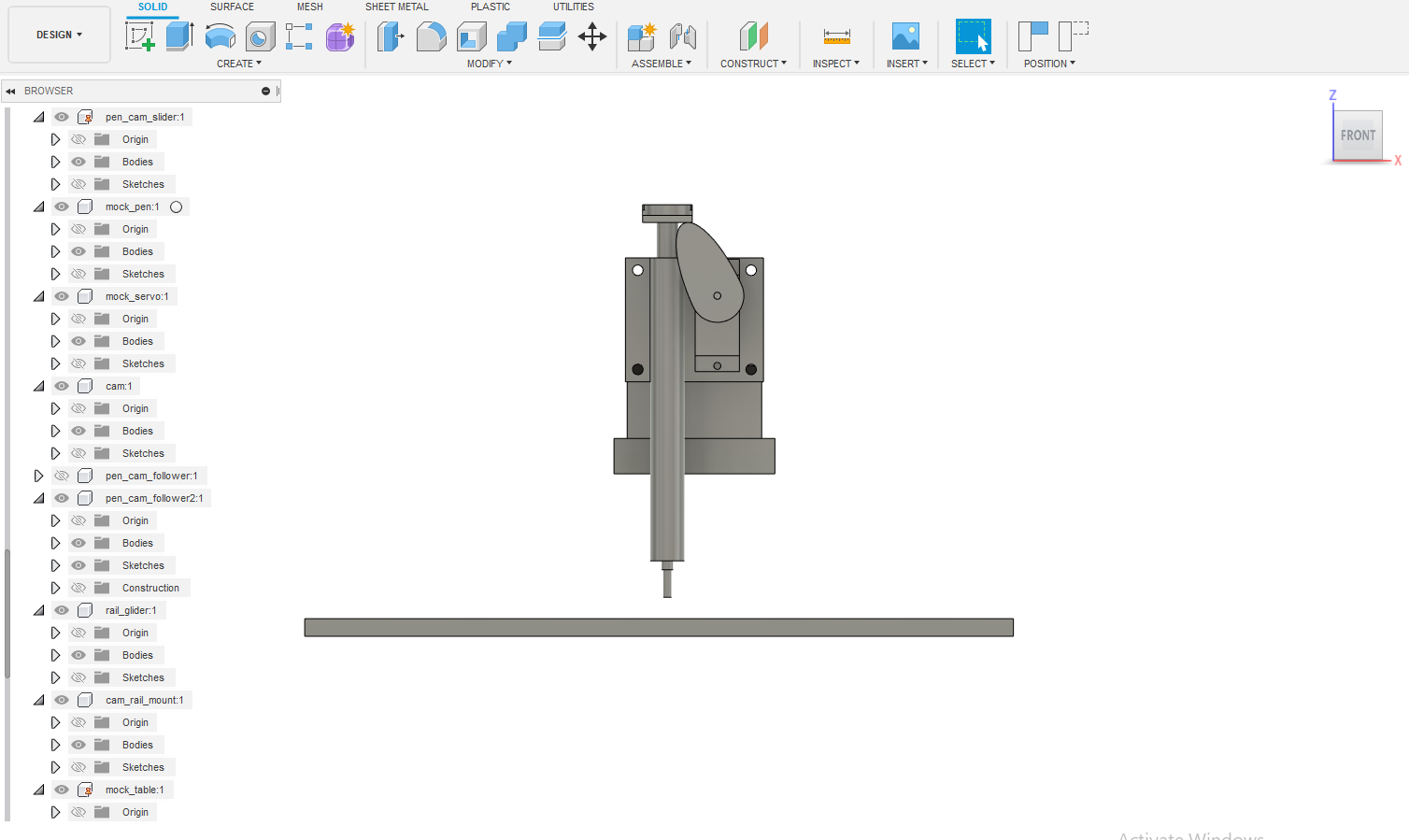

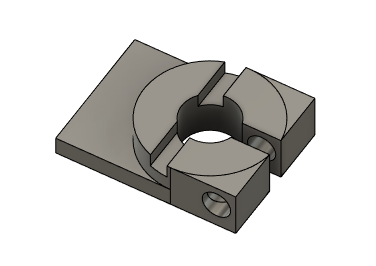

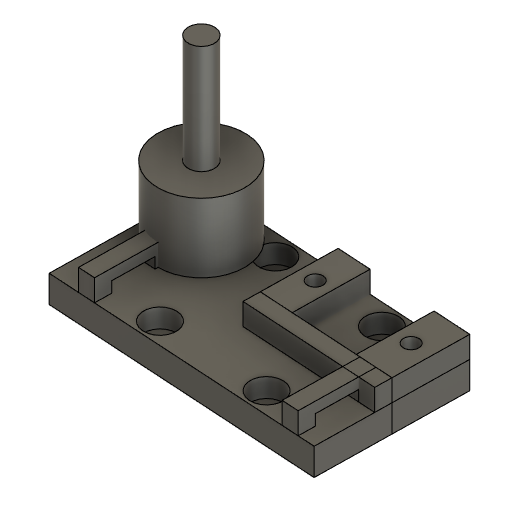

The most complex part (by far) is the pen holder, this is the part that moves the pen up and down. A rubber-band pulls the pen down, which gives it enough pressure to write on the paper (otherwise it just glides along on top of the paper without leaving any ink). A cam and follower mechanism allows the servo to raise the pen ~5mm above the paper.

This is the main body of the pen holder. Although the geometry is fairly simple this part was challenging because it needs to mount the servo and pen at just the right height to allow the pen to write, but still allow the pen to be lifted off the paper.

This piece mounts on top of the pen ink cartridge. A rubber-band is threaded through the cut-out on the top to give the pen enough pressure on the page to write.

This piece is the core of the X axis. A timing belt attaches to the two cut-outs on the sides which moves the pen along the X axis. It also contains the mount for the pulley and rail of the Y axis.

There are 15 different 3D printed parts on this pen plotter, so I can't go into detail on all of them, but there are more screenshots in the images directory.

Once designed, all the custom components were 3D printed on an Ender 3 Pro with PLA filament. The small parts took around 30 minutes each and the larger parts took a couple hours each.

The long printing time meant I generally tried to avoid re-designing any of the larger parts, even if they weren't perfect (and many weren't).

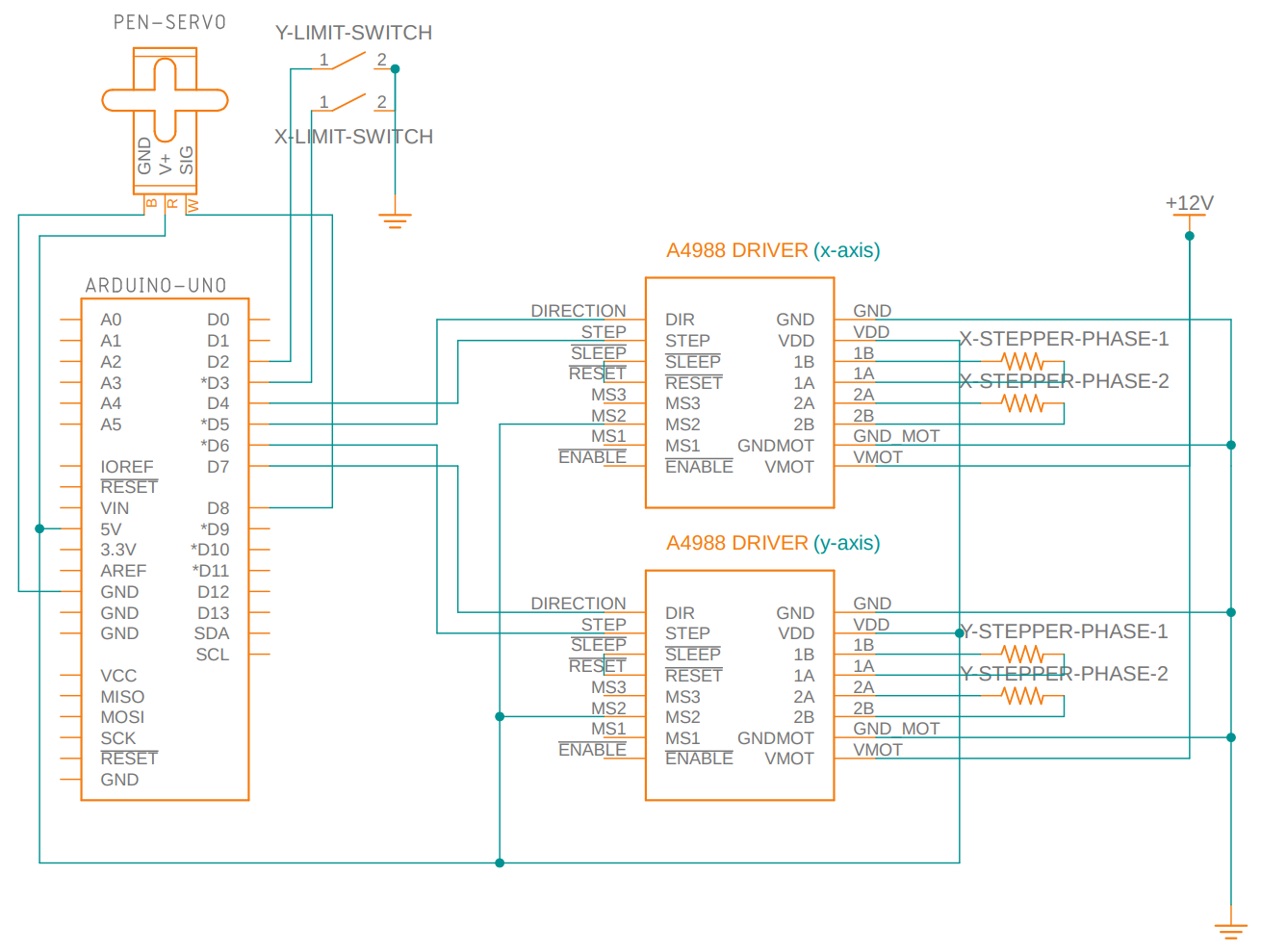

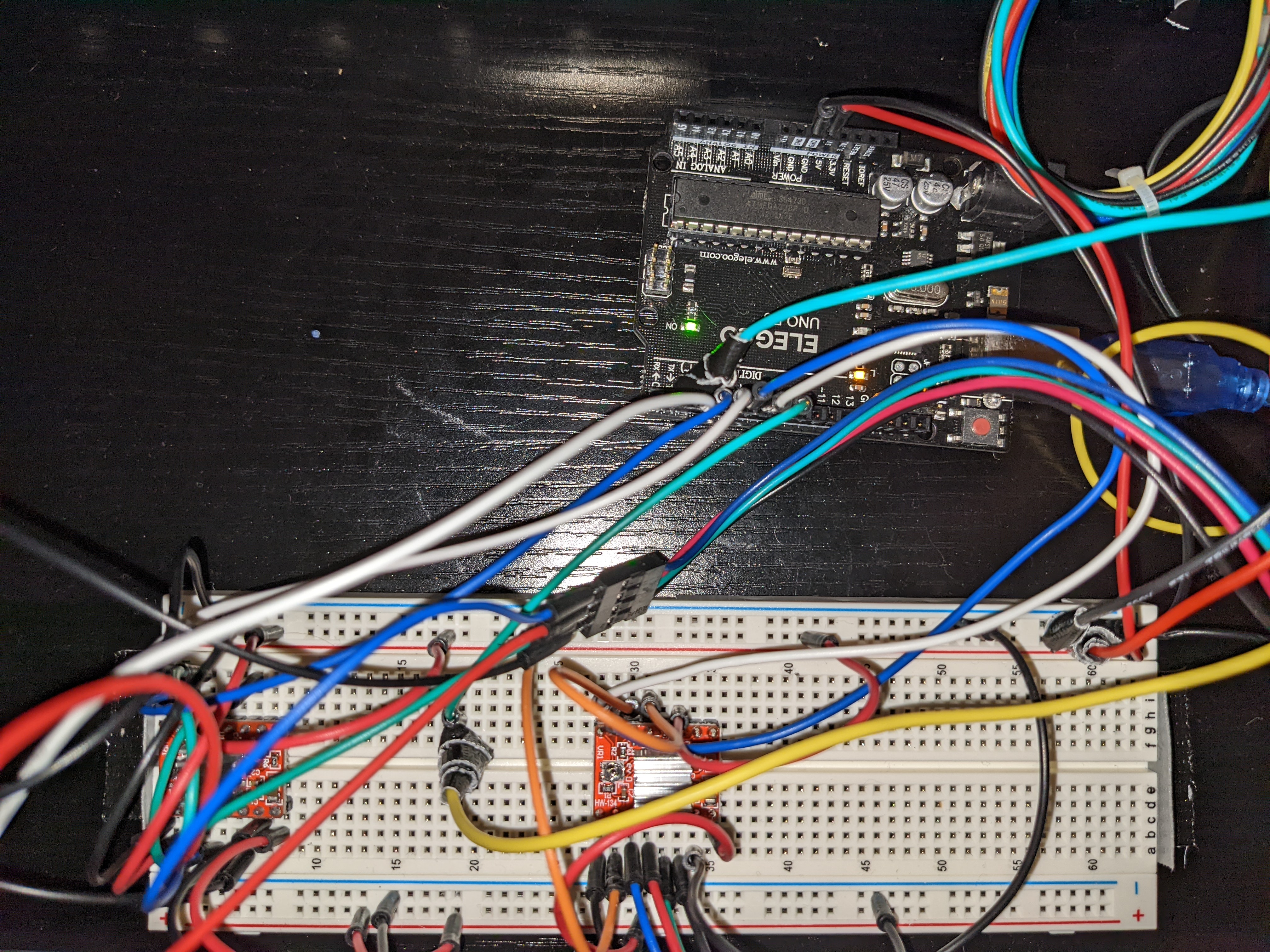

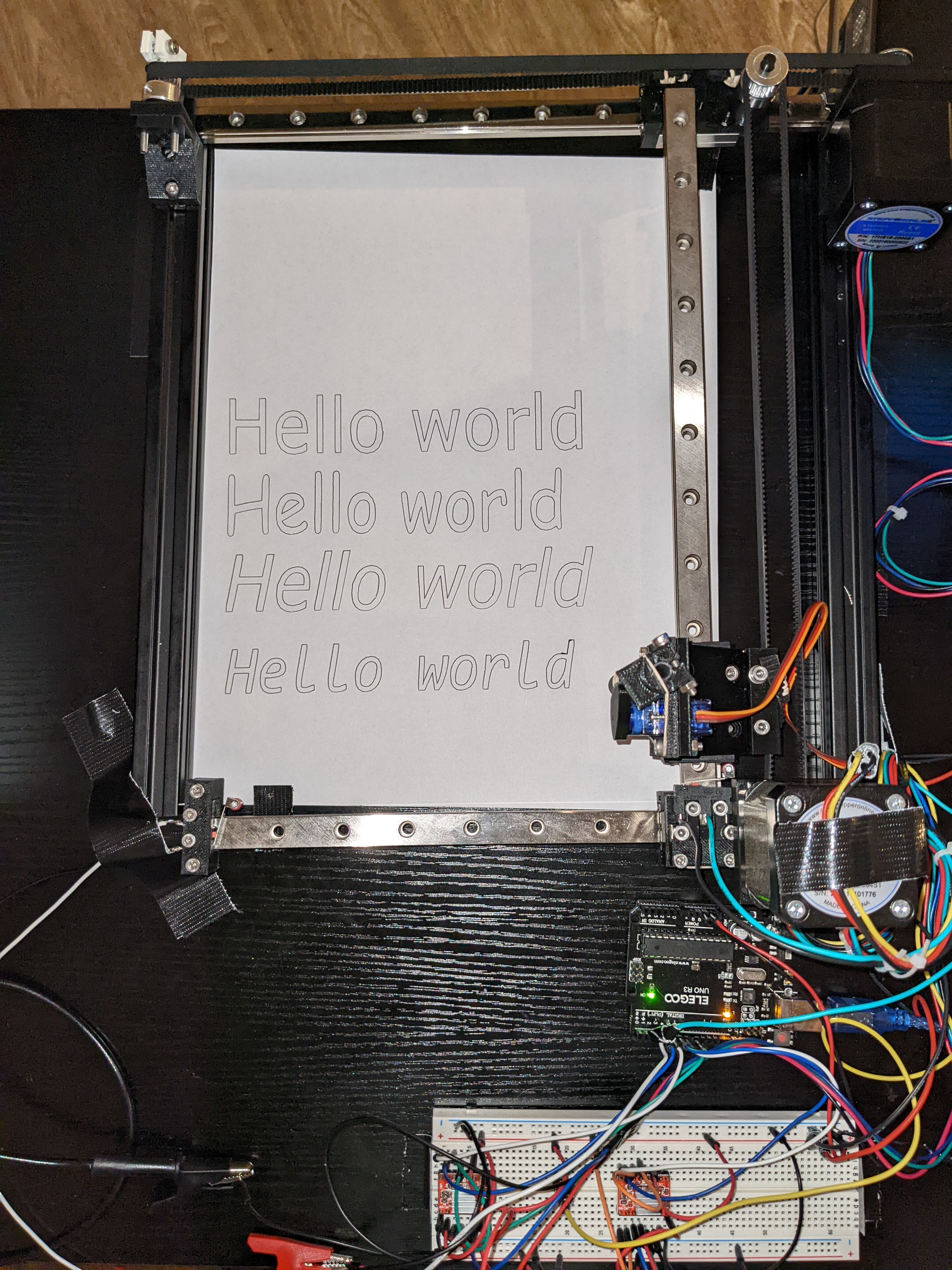

There are two stepper motor drivers, two switches, and one servo connected to an Arduino Uno.

Here's a diagram of the circuit I made (also created with Fusion 360):

And this is what that looks like wired up on a breadboard:

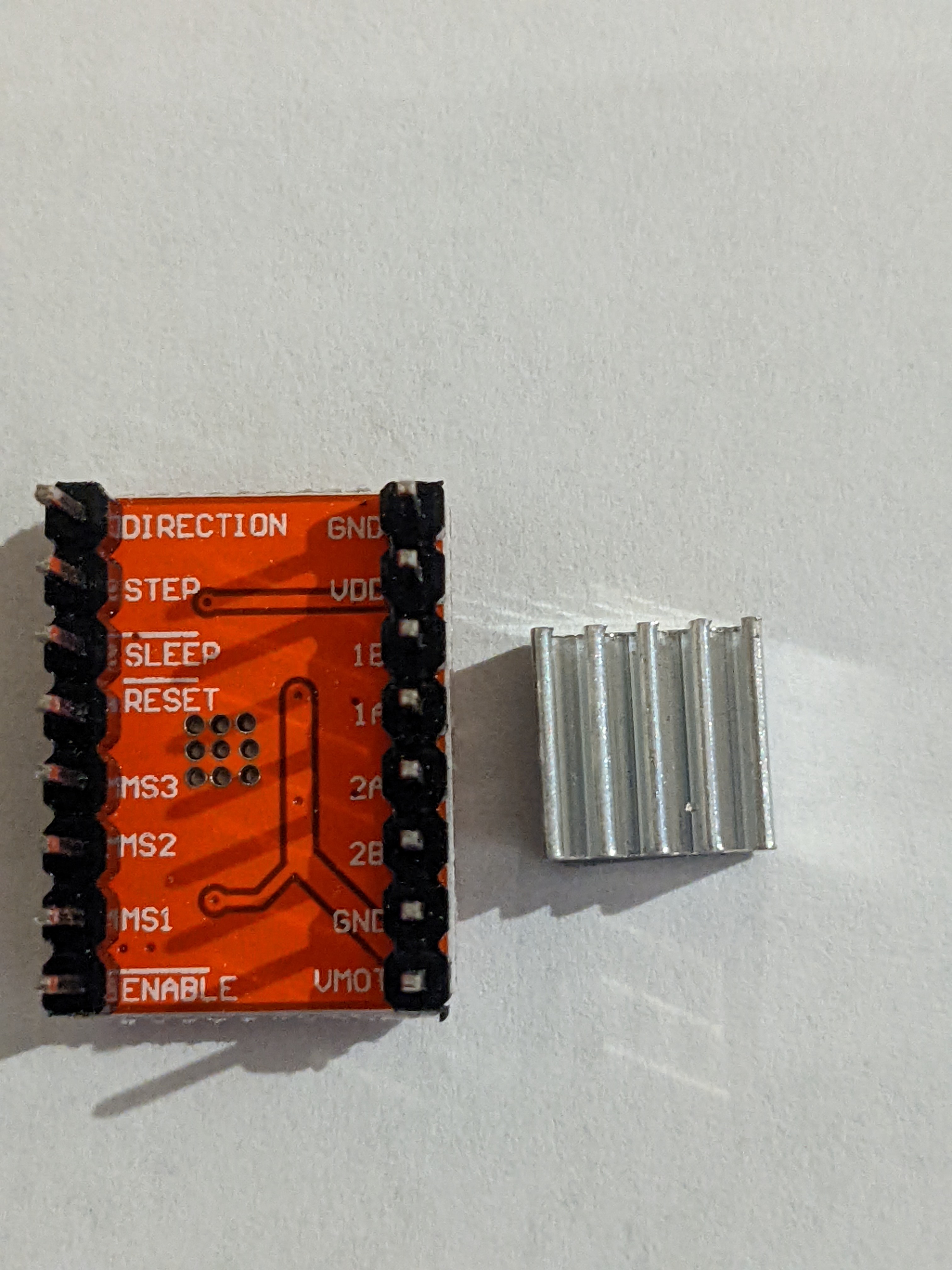

The stepper motor drivers are an "A4988" chip, which makes running a stepper motor

much simpler. Pulses to the STEP pin cause the stepper motor to turn by some constant

angle. Setting the DIRECTION pin high or low changes whether the rotation is clockwise

or counterclockwise. Three more pins MS1, MS2, and MS3 are used to configure

microstepping, which allows the motor to take extremely tiny steps.

On the stepper motors I used in this project, Nema 17s, every step turns the shaft 1.8 degrees. Microstepping is where the driver energizes the two phases of the stepper motor just right to allow a smaller rotation than one full step. In my case, I have it configured to do quarter steps. This means every pulse to the STEP pin actually turns the motor 0.45 degrees. This gives much smoother motion and better precision for small drawings.

With all the mechanical components and electrical wiring setup, the pen can be moved around the XY plane and can be raised and lowered. The challenging part is figuring out how to put these 3 pieces together to draw a picture.

The first problem is that stepper motors have no feedback. All you can do is turn the shaft in one direction or another. When the machine turns on, it has no idea where the pen is. If it just starts drawing somewhere, it's bound to crash the pen into the frame and potentially break the motors or the plastic parts. Therefore, we need some reliable way to consistently put the pen into a known location before we start drawing anything.

The solution is to mount a small switch to each axis, called a limit switch, that the machine will bump into. When both switches are closed, we know exactly where the pen must be. This position marks the (0,0) coordinate, and all other coordinates are relative to this position.

When the machine turns on, the first thing it does is to start moving the pen along each axis until it bumps into the switch.

To draw anything, it suffices to draw straight lines. Any arbitrarily complex drawing can be approximated with straight lines.

Drawing a line sounds pretty simple, but remember that the only control over the stepper motors is one pin for direction, and another pin to tell it to turn one microstep. The code that uses these two primitives to draw straight lines is the real core of the software.

You can see the code for yourself at void Plotter::MoveTo(float x_mm, float y_mm)

in plotter.cpp but the gist is that it uses a hot loop

which either steps one motor, both motors, or no motors at each iteration.

Sophisticated CNC software will also prevent jerkiness by carefully controlling the acceleration, which I didn't end up implementing to save time, but this is definitely something I want to explore in a version 2. Instead I have to run the plotter relatively slowly to prevent it from knocking itself out of alignment.

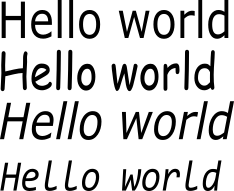

After implementing straight lines, we can in theory draw anything. But we still need some way to convert a drawing into a series a straight lines. Thankfully, Inkscape has an excellent plugin: Inkscape Laser Tools. Evidently from the name, it's intended for laser engravers, but it will work just fine for a pen. The plugin allows you to generate G-code for an image with just a few clicks.

G-Code is the programming language used by CNC machines. Here's what the start of the G-Code for the tiger drawing shown above looks like:

;Inkscape Lasertools G-code

;https://github.com/ChrisWag91/Inkscape-Lasertools-Plugin

G90 ;Absolute programming

G21 ;Programming in millimeters (mm)

M03 S1 ;Activate laser and set power to 0 (CUSTOM)

; START perimeter strategy

G01 F700.0

S1

G00 X31.89 Y0.09 F3000.0

S100 F3000.0

G01 X31.46 Y0.21 F700.0

G01 X30.06 Y0.6 F700.0

G01 X29.92 Y0.65 F700.0

G01 X28.04 Y1.32 F700.0

G01 X26.97 Y1.71 F700.0

G01 X26.84 Y1.75 F700.0

G01 X25.91 Y2.1 F700.0

G01 X24.85 Y2.5 F700.0

G01 X24.54 Y2.69 F700.0

G01 X24.25 Y3.14 F700.0

G01 X24.13 Y3.36 F700.0

- G00 means "move to these coordinates as fast as possible"

- G01 means "move to these coordinates in a controlled manner" (for drawing/cutting)

- S100 means "turn the laser on" (except we don't have a laser)

At this point the most robust solution is to write a G-code interpreter for the Arduino (or use an open-source one). I didn't want to use an open-source interpreter because I wanted to do almost everything from scratch to better understand CNC machines. I also wasn't quite-yet ready to spend the time and effort it would take to write a proper G-code interpreter.

I decided to instead write a python script that would read the G-code and produce a plot of the planned path and a C++ file with a huge array of coordinates. This has a lot of limitations, but it was really quick and easy to write, so I think it makes sense for a prototype like this. Here's what the produced plots look like:

(The seemingly out-of-place lines are when the pen moves without writing, so they don't show up in the final drawing)

And the generated array looks something like this:

#include "plotter.h"

const float tiger_gcode[] PROGMEM = {

PEN_UP,

PEN_UP,

31.8900,

0.0900,

PEN_DOWN,

PEN_DOWN,

31.4600,

0.2100,

30.0600,

0.6000,

29.9200,

0.6500,

28.0400,

1.3200,

26.9700,

...This is a single array of floats which contains both coordinates and instructions about moving the pen up and down. This can then easily be loaded and executed by the Arduino, which was how all the drawings shown above were produced.

Packing instructions alongside coordinates like this does feel a little dangerous, but the Arduino Uno only has 32k of flash which is only 8192 4-byte floats (and we still need space for the rest of the program too, so we can't actually use all of that!). Given space was such a scarcity, I wasn't willing to sacrifice space to have a better G-code representation.

I had no experience with mechanical design, Fusion 360, or 3D-printing going into this project, so there are still many components I'm not quite happy with. I wanted to produce a working (though imperfect) version 1 rather than endlessly optimizing, so I decided to keep moving forward as long as the pieces mostly worked. Here are a few of the major problems with this iteration:

- There are no bearings on the pulleys, which cause a lot of vibration and noise. The vibrations can knock the machine out of alignment and ruin the drawing. A version 2 will definitely use bearings.

- The software doesn't support constant acceleration, so the machine can jerk around on sharp corners. Again, this knocks the whole machine out of alignment and ruins the drawing. Likewise, version 2 should really have a better algorithm for controlling the steppers.

- Many of the pulleys and belts are not perfectly aligned and are off by a few millimeters in either direction. This causes more vibration and some positional error that shows up in the drawing. I only learned how to align the components in CAD halfway through the project, so the components I designed earlier on are not perfectly aligned.

I learned a ton from this project and am reasonably happy with how the result turned out. It was a really magical moment seeing it draw an actual picture for the first time after spending weeks designing and 3D-printing every component.

I'm also really glad to have spent the time learning how to use CAD software. Being able to design and 3D print plastic parts is going to unlock a lot of capabilities in future projects that were previously inaccessible to me.