This project is currently primarily for experimental purposes. You are free to use the files in this project according to the license, but I do not recommend that use them as-is

- 60% WKL

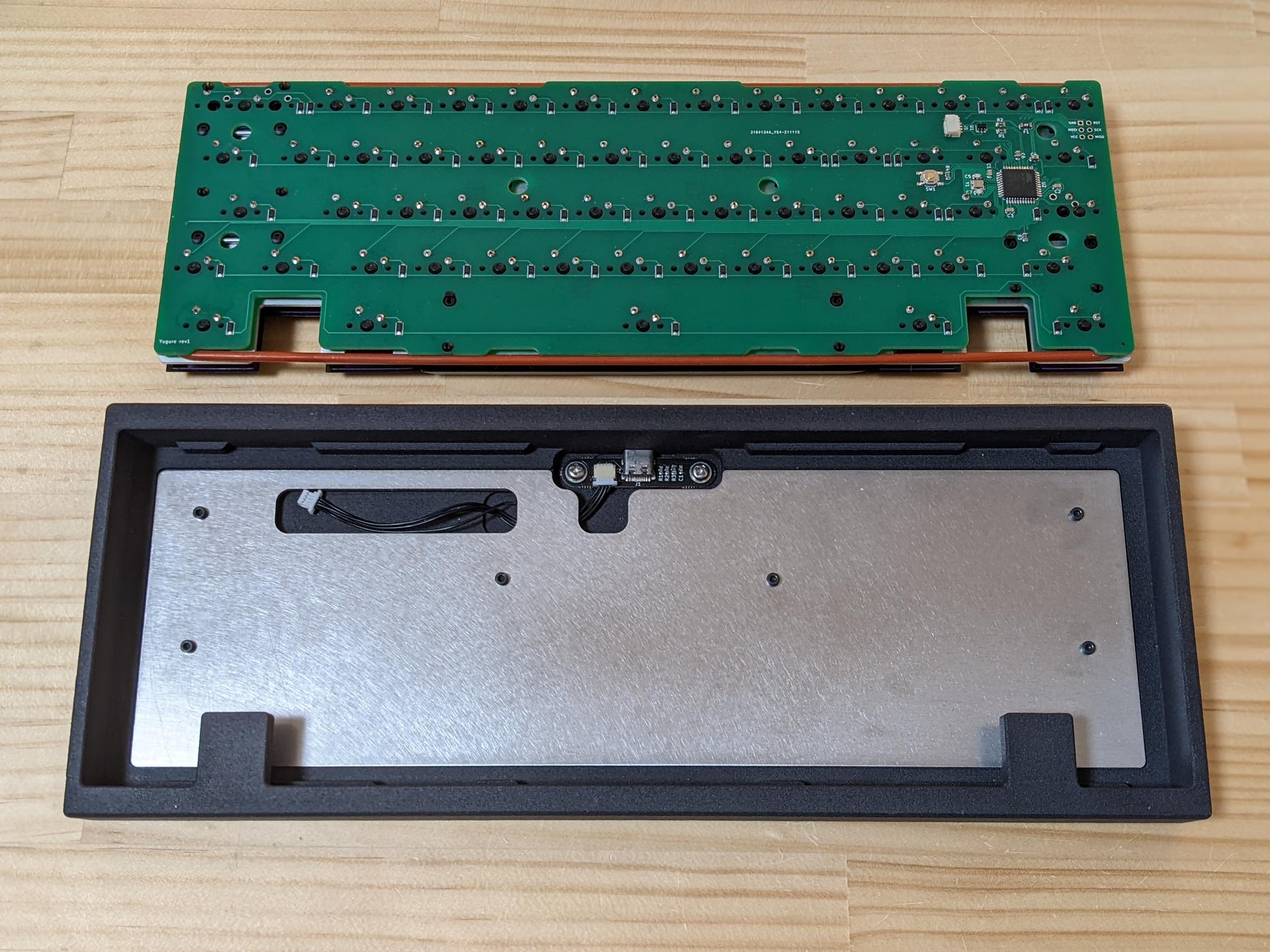

- O-ring mount (friction fit)

- Single piece tray case

- Designed for SLS 3D printing

- I've never made a WKL board before and wanted to try it out

- Experimenting with some concepts

- Unique gasket post location and shape. Testing how they affect the typing feel

- Design of weight in tray case. Exploring the size and location of weight that are effective in reducing unwanted hollow sound, rather than making the case heavier

- Case

- Use the the files contained in

casedirectory case.stepis the design of the case. Order it from a service that supports SLS 3D printingweight.dxfis the design of the weight to be attached to the case. Order 1.5mm thick from laser cutting service- Use 6 * 5mm M2 screws to secure the board

- Use the the files contained in

- PCB

- Use the the files contained in

productiondirectory - The files is designed for ordering on JLCPCB. If you are ordering from any other manufacturer, please modify it as necessary

- Use the the files contained in

- Plate

- Use the dxf files contained in

platedirectory - Order 1.5mm thick from laser cutting service

- Use the dxf files contained in

- Daughterboard

- Use the b-ken-ko's daughterboard

- Use 2 * 3mm M3 screws to secure the board

- O-ring

- Material: Silicone

- Durometer(Hardness): 50A

- AS568 number: 262

- CS(Thickness): 3.53mm

- ID(Inner Diameter): 177.39mm

- OD(Outer Diameter): 184.45mm

- This project is experimental and is not designed for serious use like production run

- You may be able to adjust the typing feel by changing the position and size of the mounting post

- There is a mounting post under the blocker, which may be difficult to make with CNC machining

- The PCB design includes the MX_Alps_Hybrid designed by ai03 as a submodule. It is distributed under the MIT license