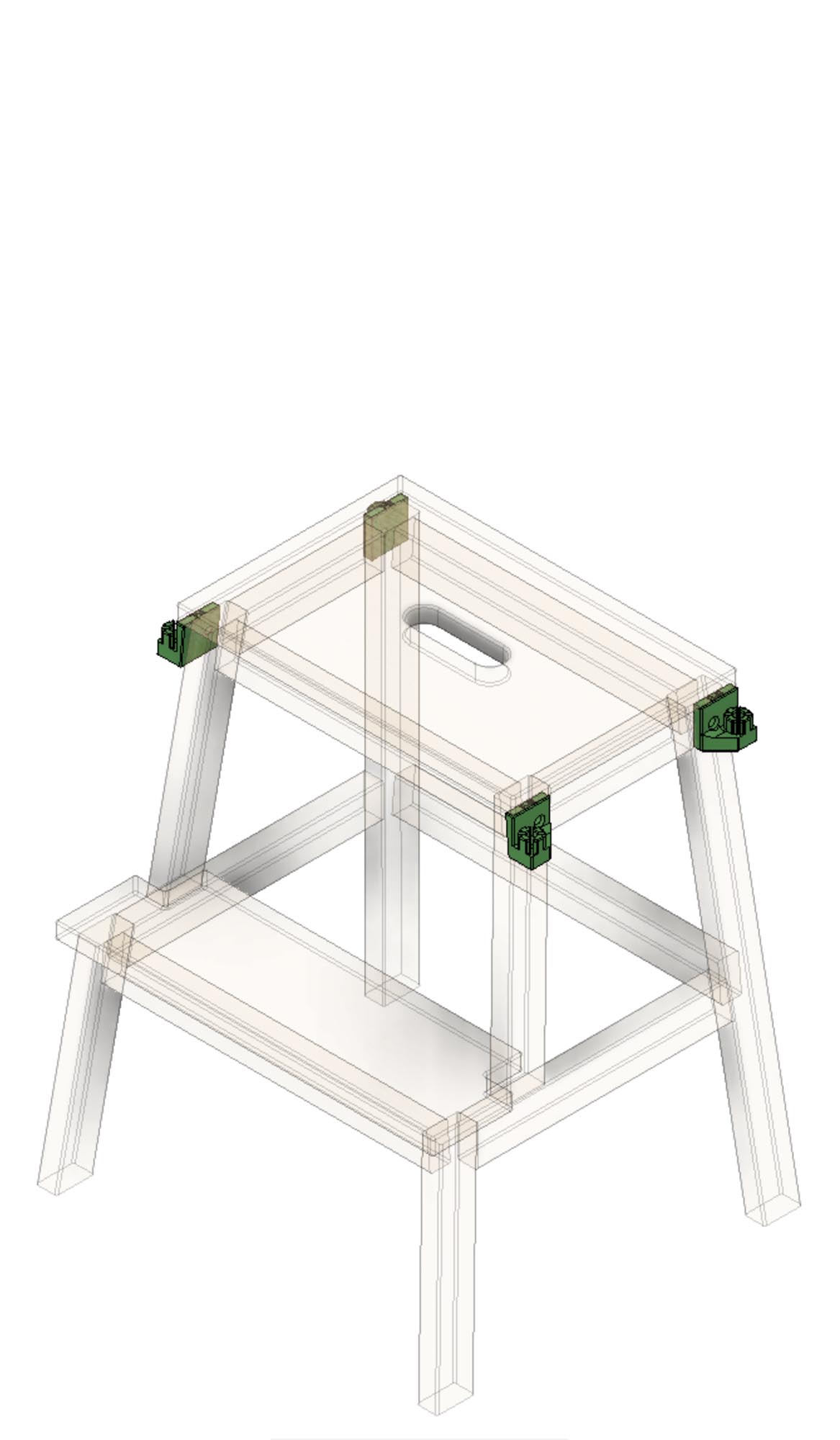

Learning tower for kids made of an IKEA step stool, aluminium extrusions and 3d printing, online 3D preview.

I was looking to buy a learning tower for my little monkey, so he can start playing independently and safely on worktops that are designed for adults. There are many designs available online but they are usually either expensive for what they offer or unattractive (for my taste). I decided to build one on my own and since there is a DIY trend that uses an IKEA step stool for this matter, I followed that path. Initially, I made an extension for the IKEA step stool made out of oak scrap wood. It turned out super nice but I used a series of advanced tools to achieve a professional result. Then, I started thinking how I could put together a simple bill of materials that pretty much anyone could source and assemble without any required cutting or drilling. I considered a few options but aluminium extrusions are too sexy to be ignored. I paired it with 3D printing, mainly for the connections between the step stool and the aluminium structure. My goal is to use the stool's existing holes and screws and make it easy to remove the aluminium structure when it is no longer needed. Arguably, not everyone has a 3D printer but getting access to one is not that difficult and there are many online services available these days.

Towards the end, I list some thoughts for a future version. Feel free to add issues on GH for future product improvements or corrections of the current version. I have also included the source files (Fusion 360) in case someone wants to modify the design.

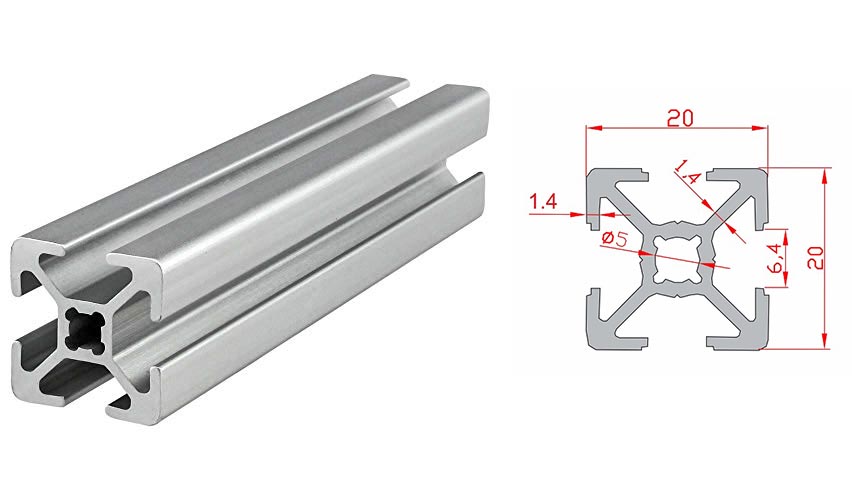

I have included an example online source for every part but you might need to do some research and find a relevant suppliers based on your location. Aluminium extrusions are widely spread and there are plenty of online shops that ship the extrusions pre-cut at your desired length. There are many ways to connect the extrusions, I chose the corner connectors because they are cheap, discreet, easy to source and easy to install.

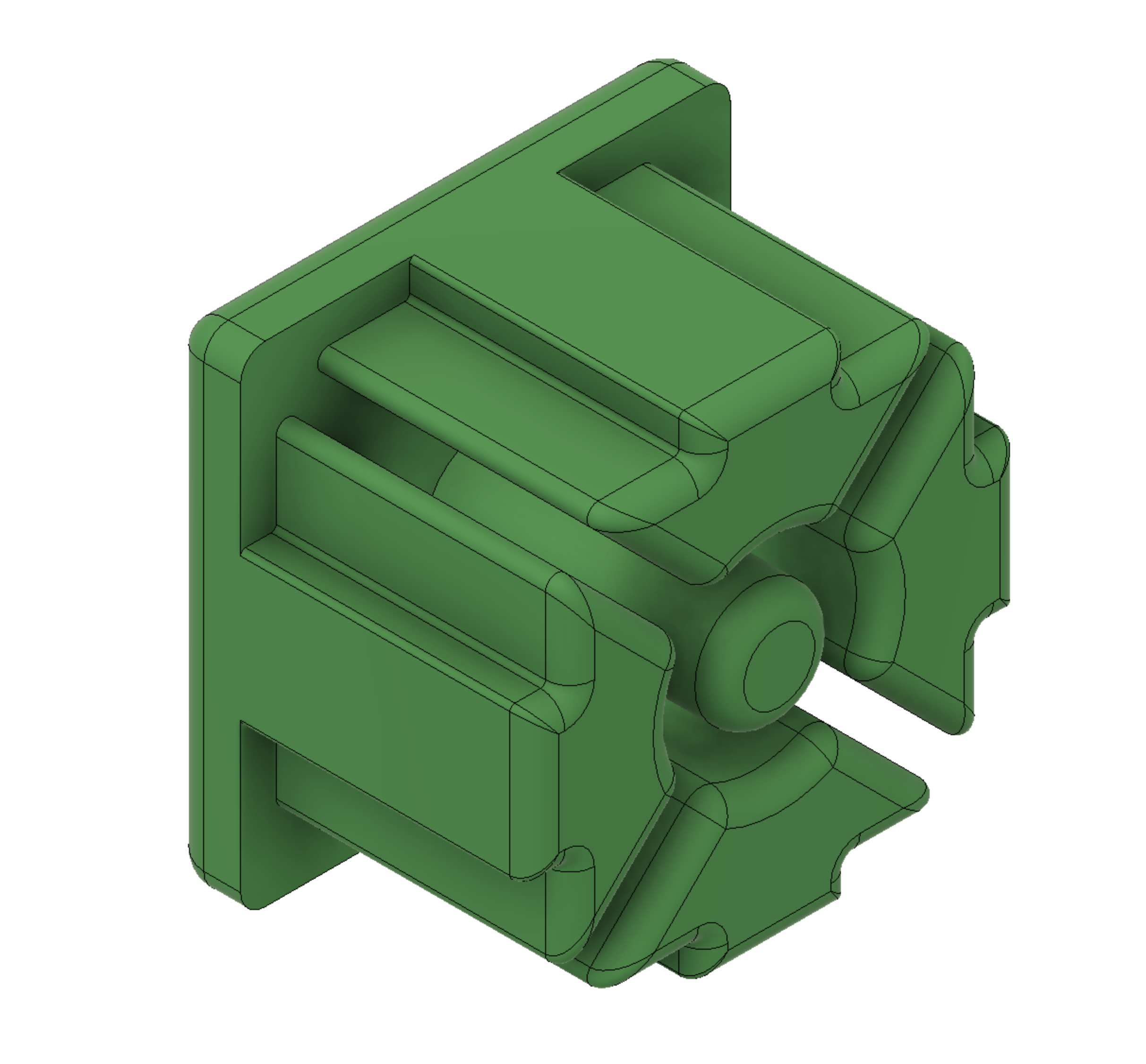

You need to print (or order online) the following parts:

| Name | Quantity | Photo |

|---|---|---|

| End Cap - 3D printed | 4 |  |

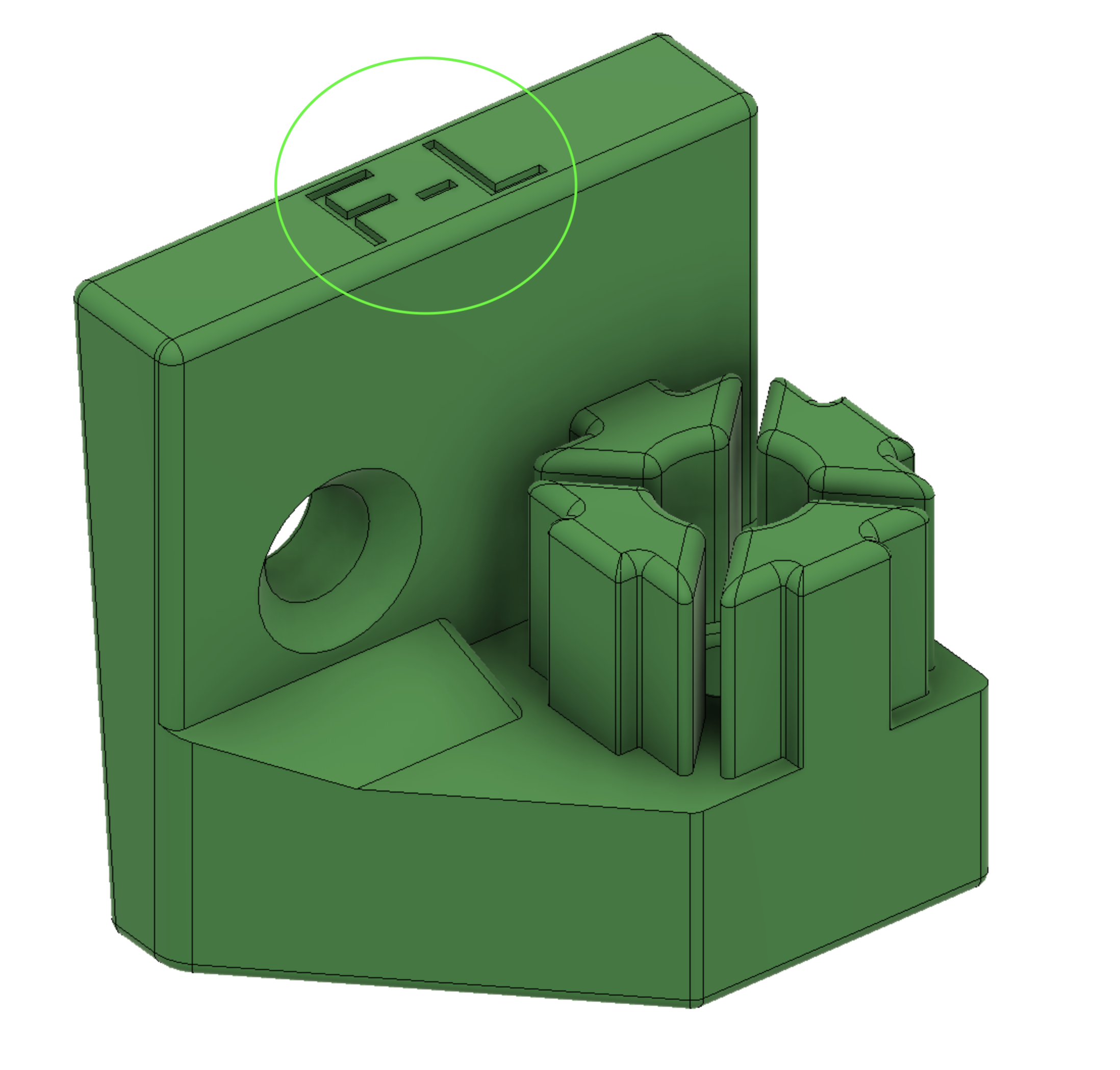

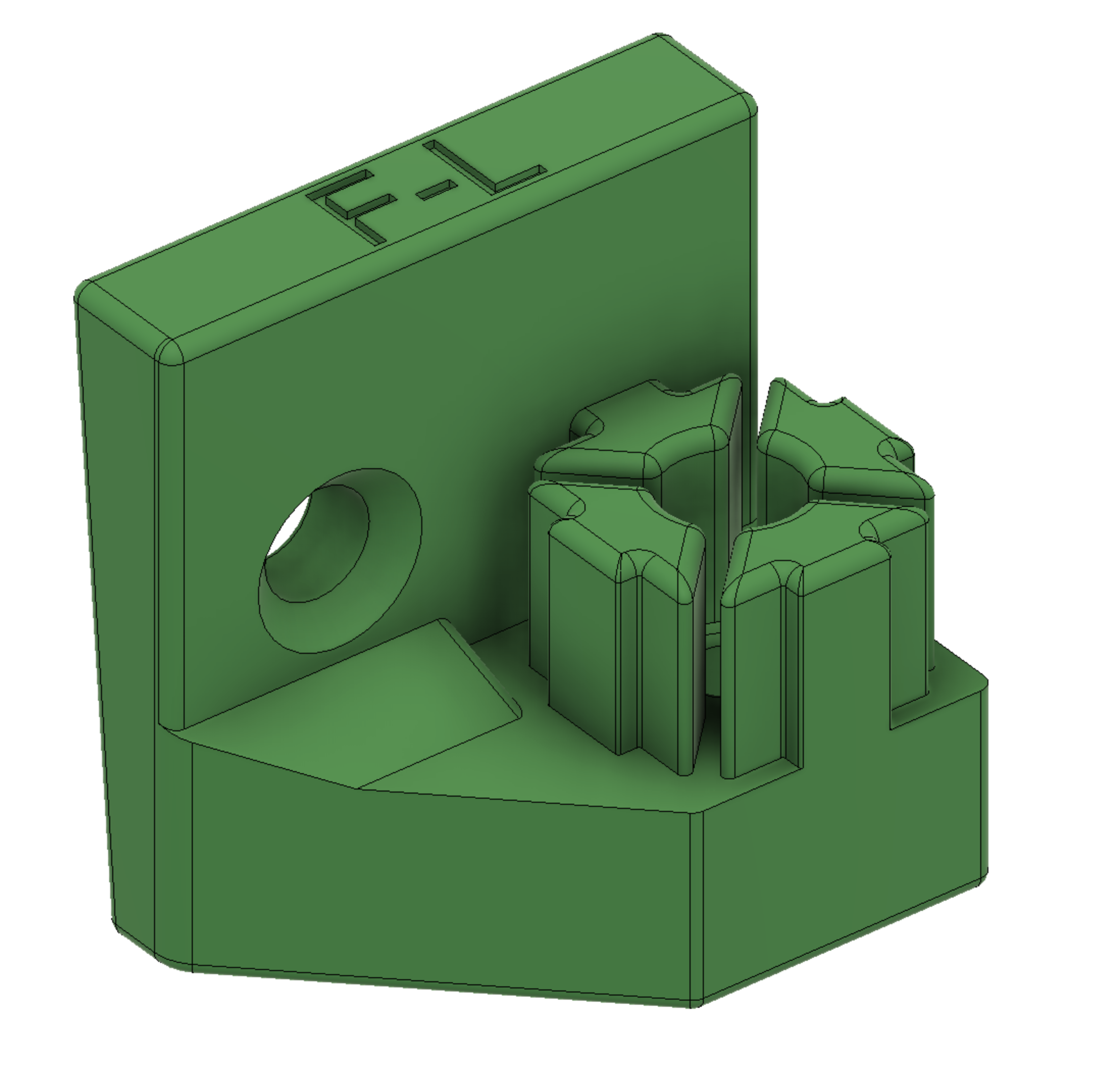

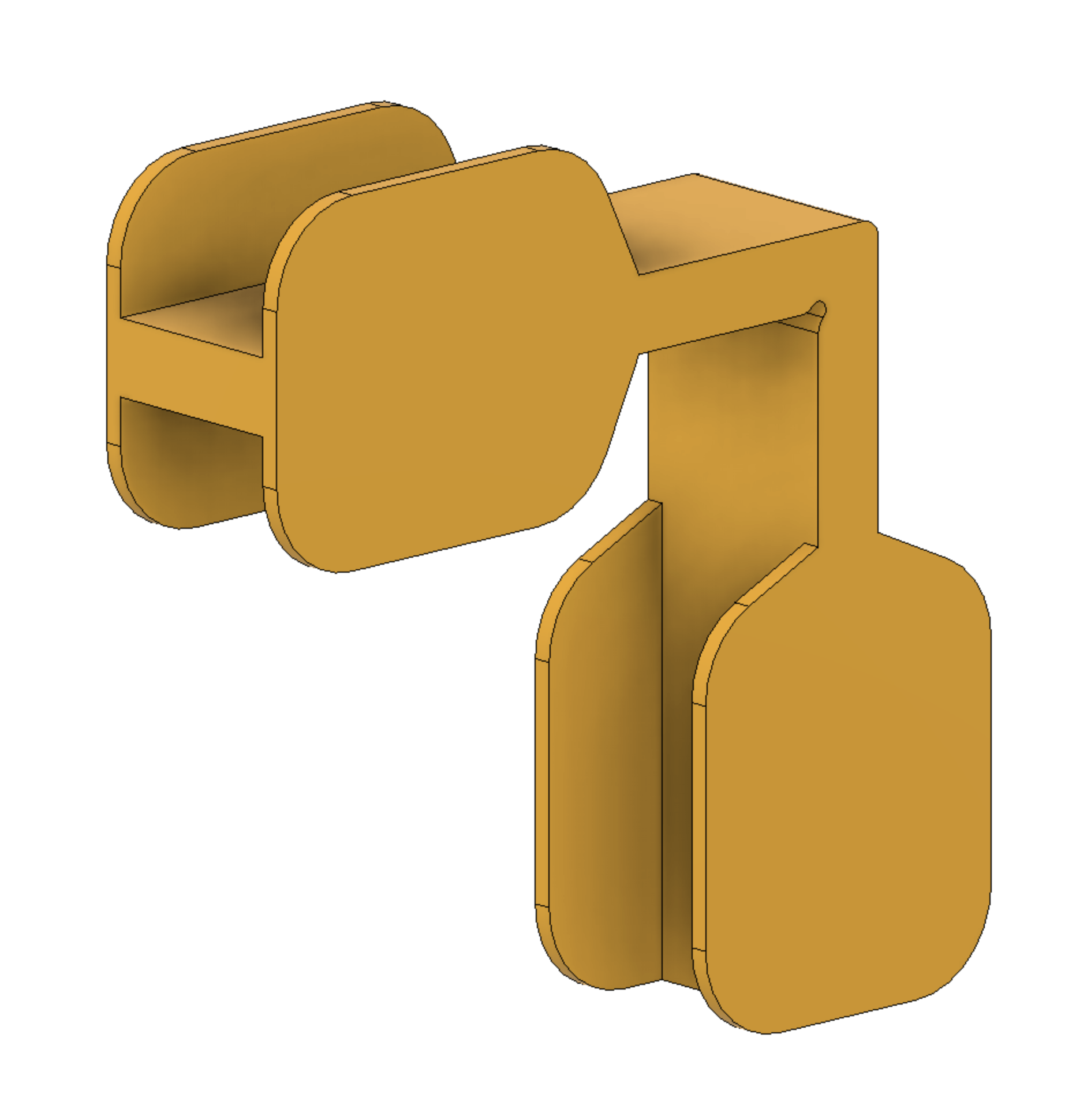

| Adapter F-L - 3D printed | 1 |  |

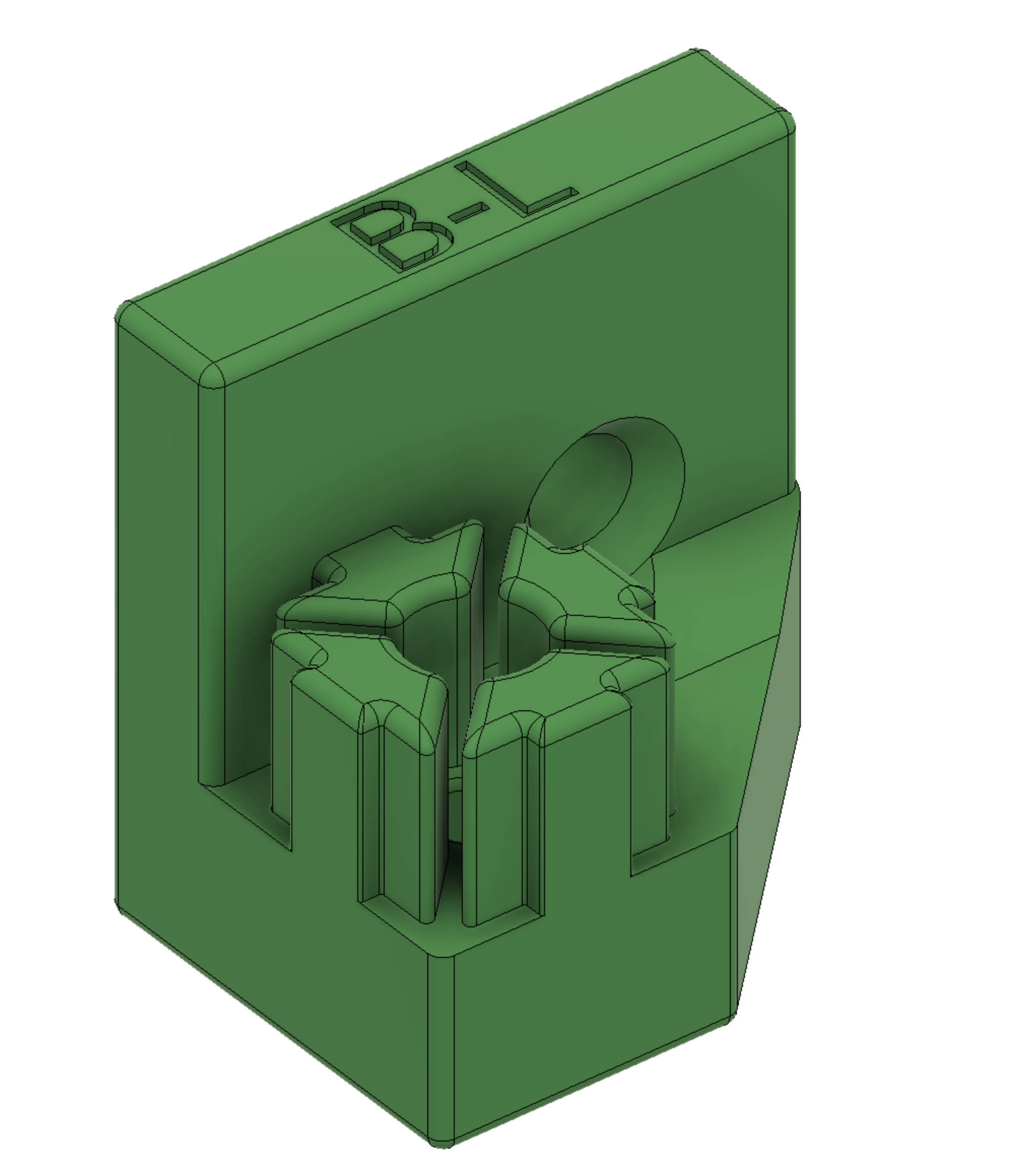

| Adapter B-L - 3D printed | 1 |  |

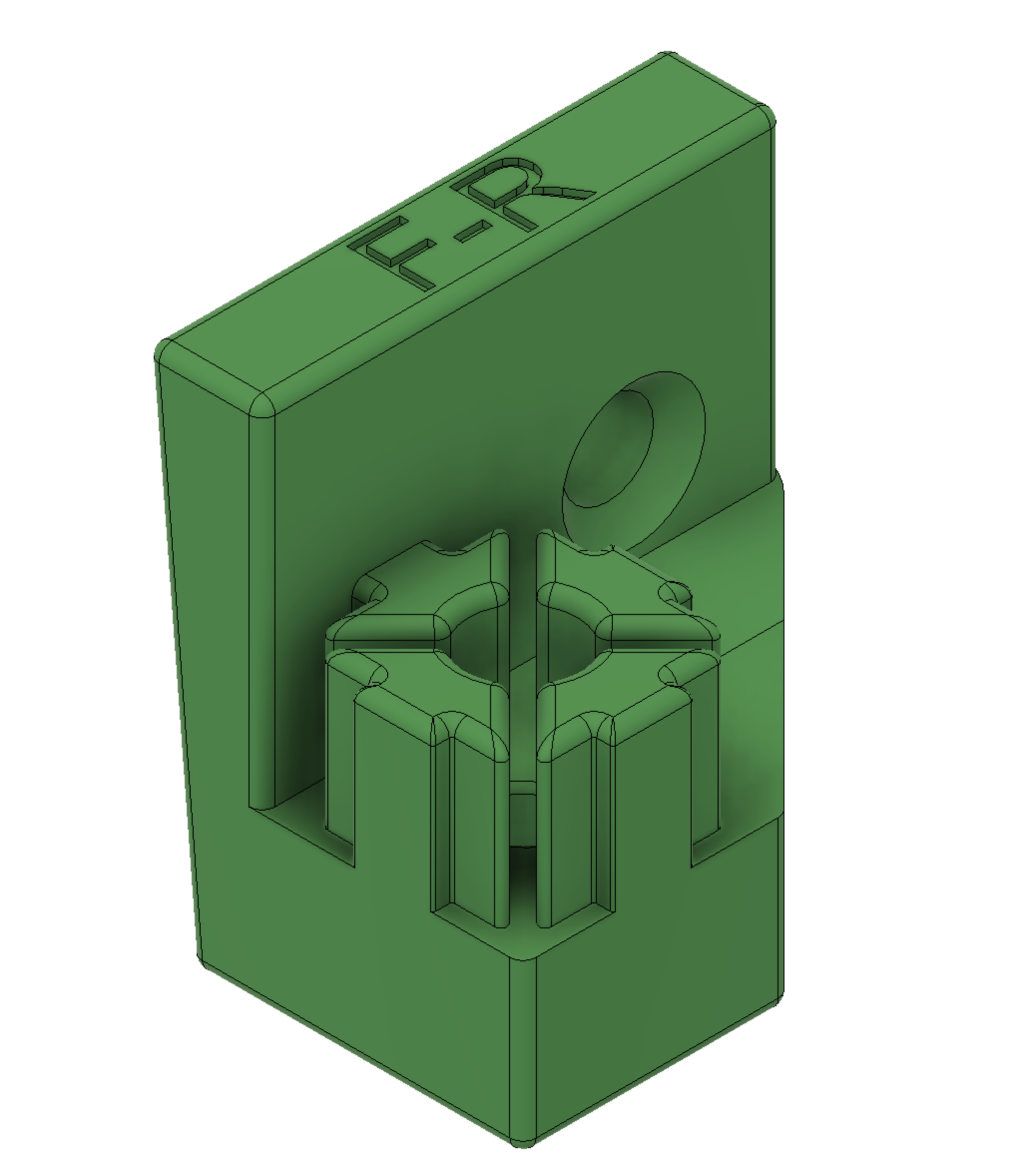

| Adapter F-R - 3D printed | 1 |  |

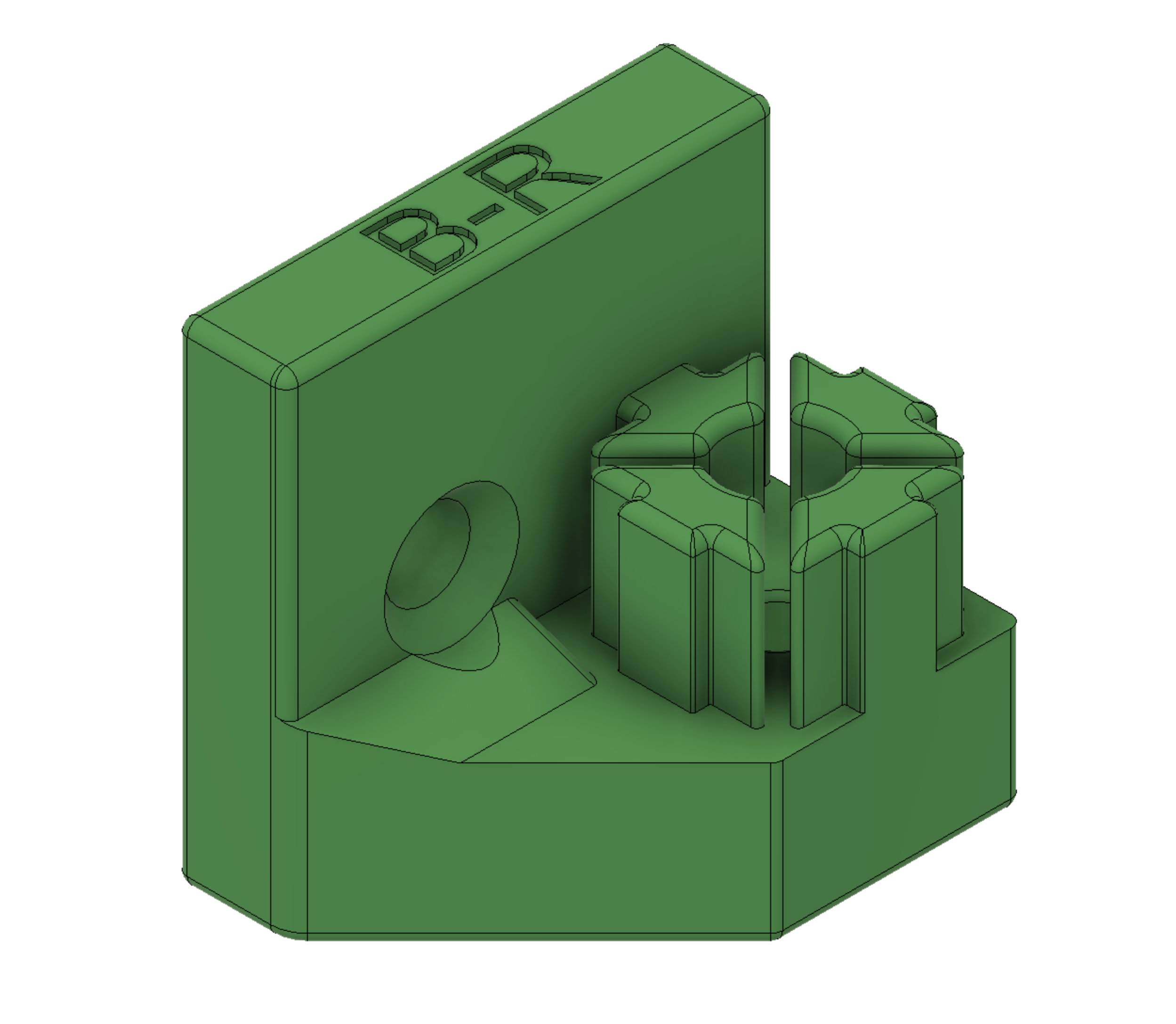

| Adapter B-R - 3D printed | 1 |  |

| Assembly Jig - 3D printed | 1 |  |

Printing settings

- Infill: 70%

- Wall thickness/ Perimeters: 4

- Top and bottom layers: 6

- Material: PLA is ok but you could use more advanced materials like PETG

- Support: Support is not required apart from the Assembly Jig

Notes

- For safety reasons, I cranked the printing values up to make sure I get parts that can withstand stress

- It's a good idea to print a sample Adapter and test how strong it is. The Adapters support the whole structure so not having reliable parts defeats the purpose of the project.

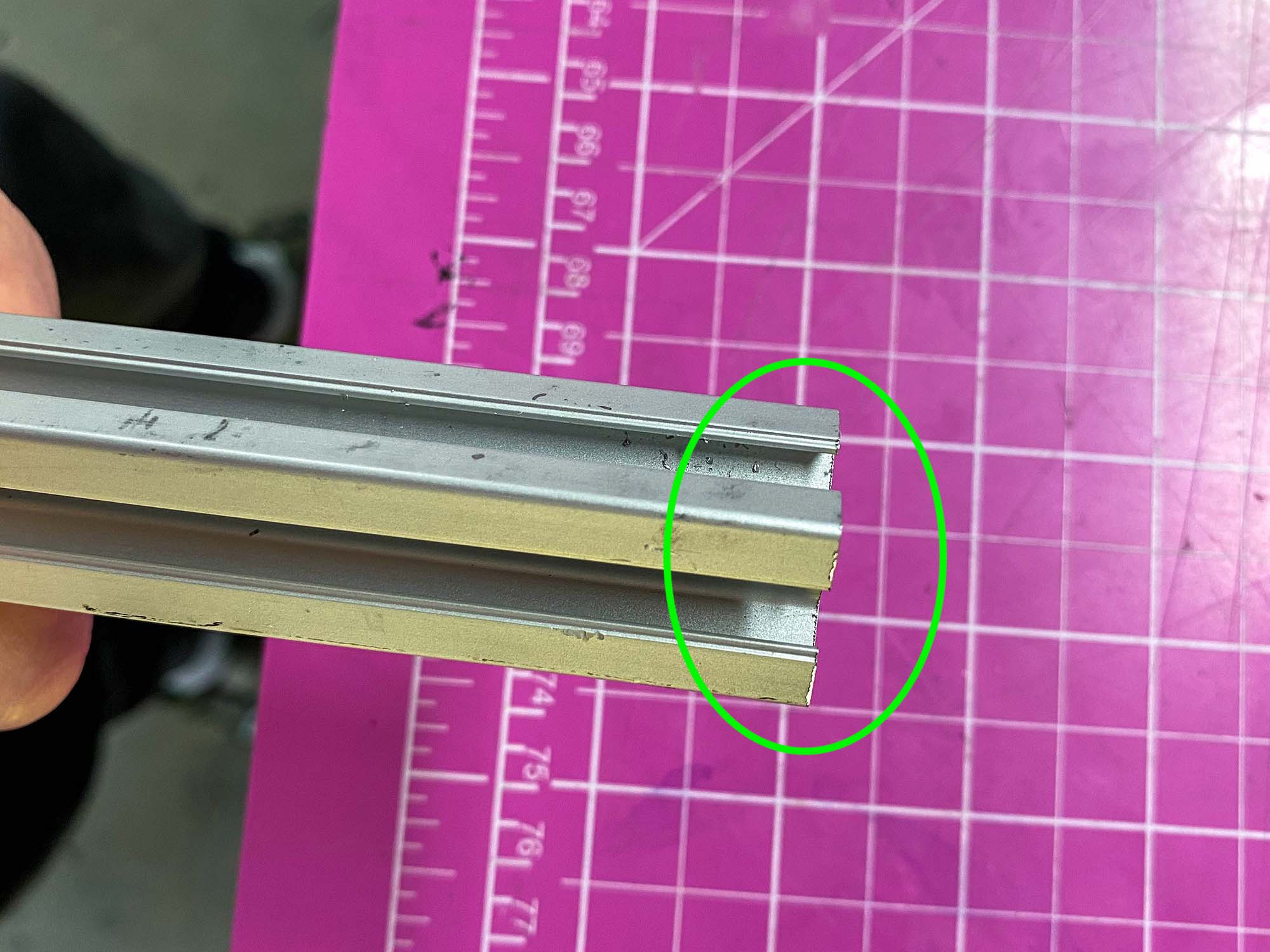

Aluminium extrusions' edges are usually rough and potentially dangerous so I strongly recommend smoothing all the edges with a file or sandpaper.

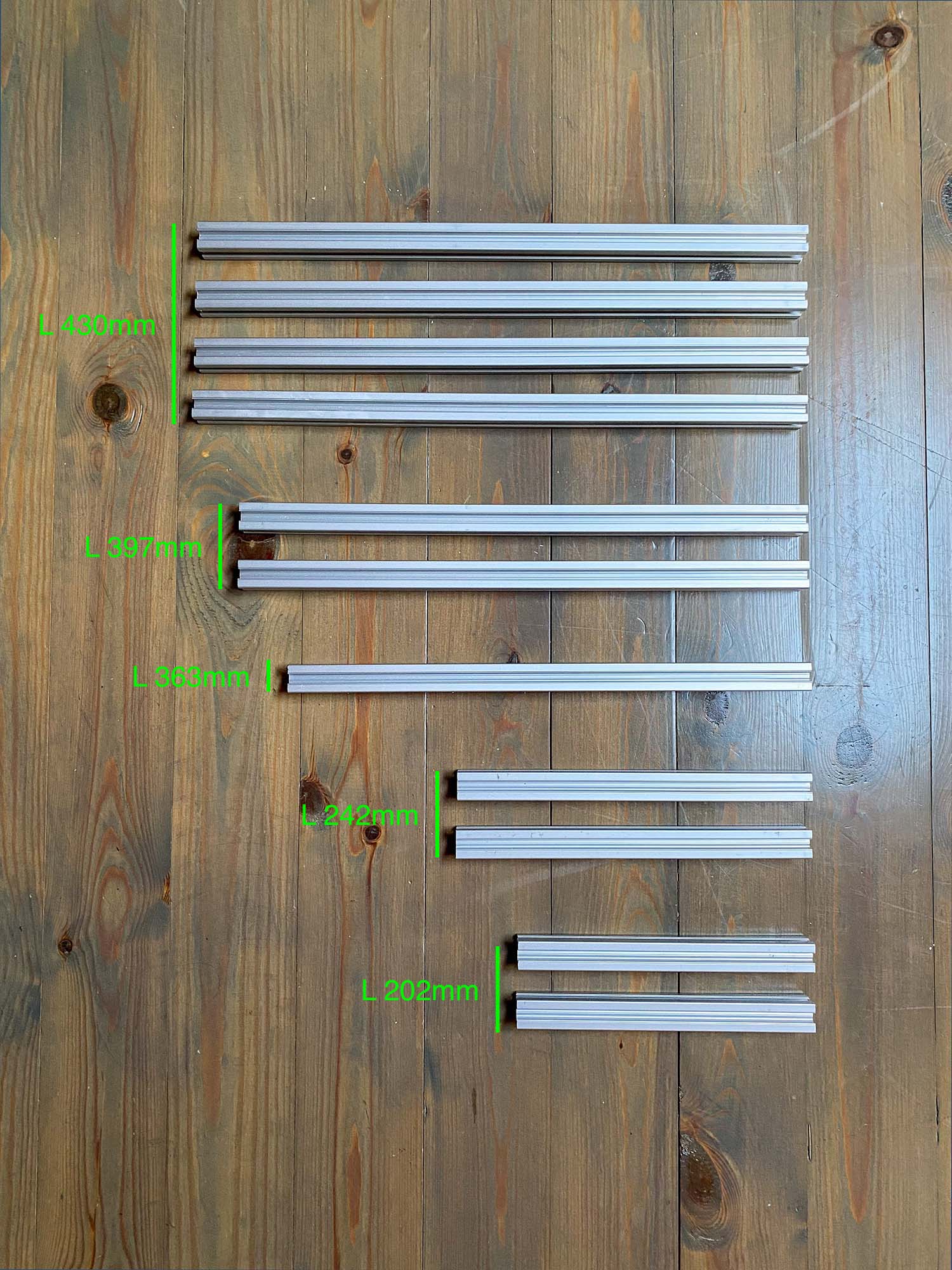

Lay down all the extrusions by length, this will make assembly way easier

| Name | Photo |

|---|---|

| Phillips screwdriver |  |

| Allen key 2.5mm |  |

| Allen key 4mm |  |

| Tape measure |  |

| Pencil |  |

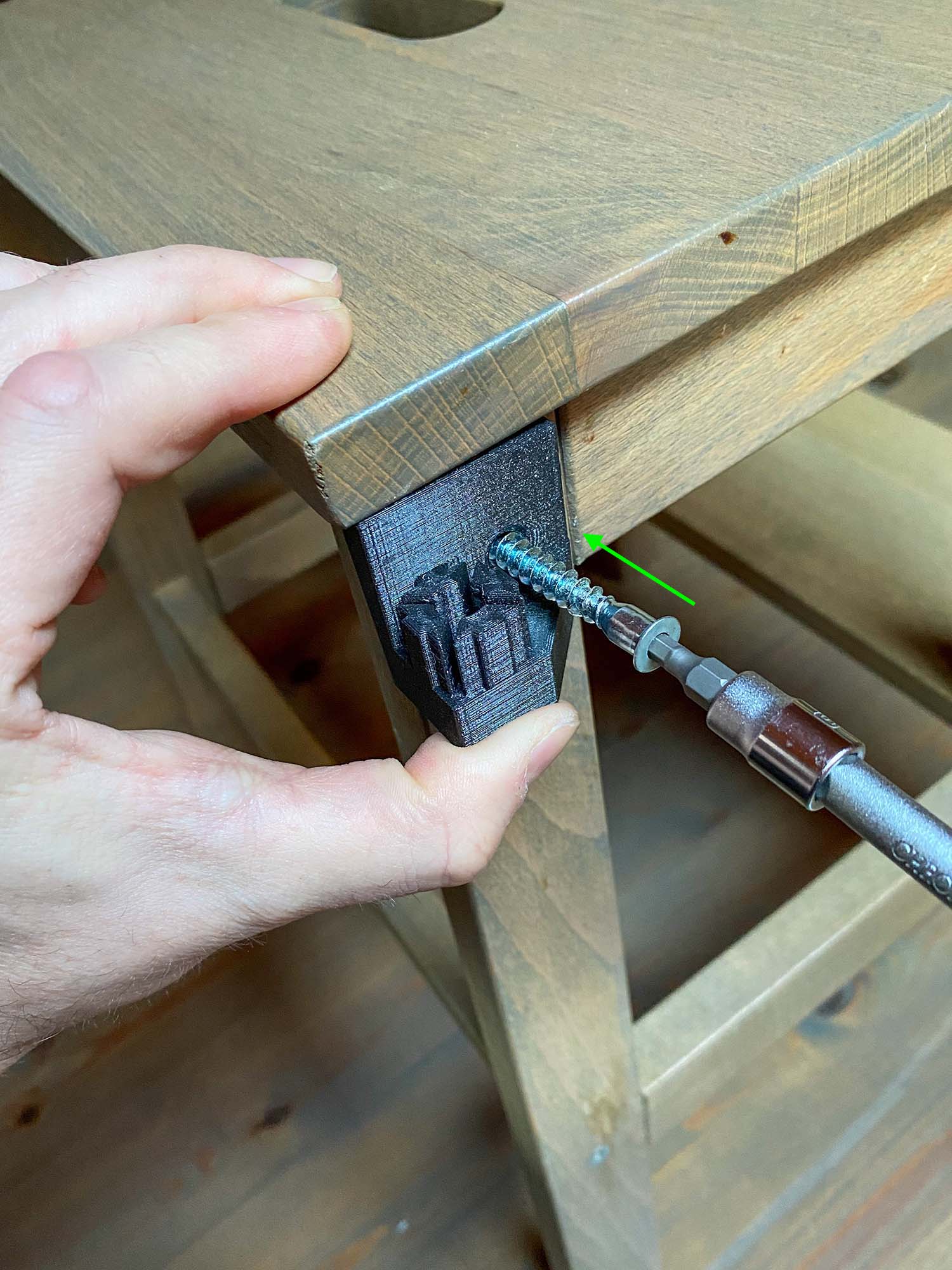

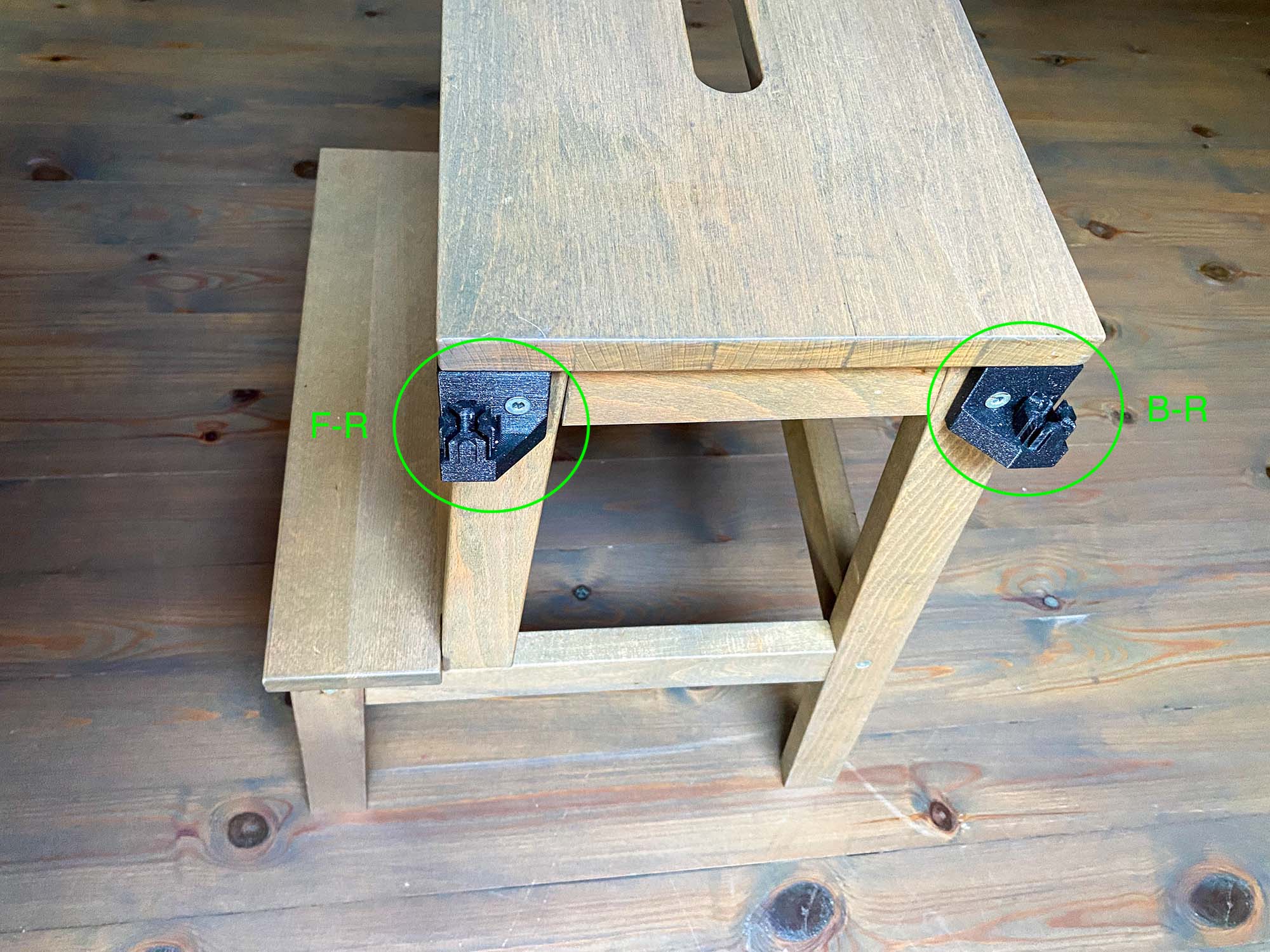

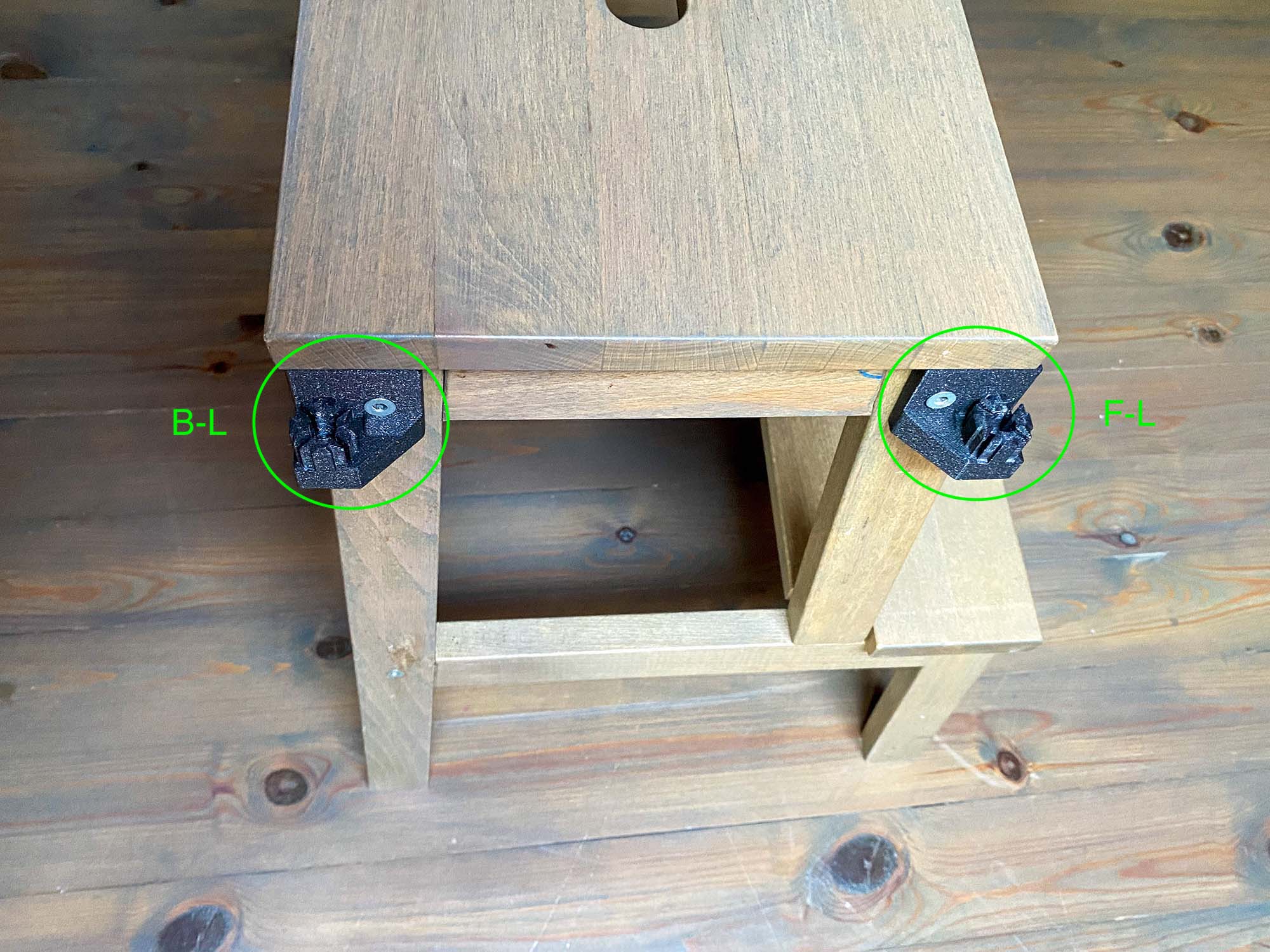

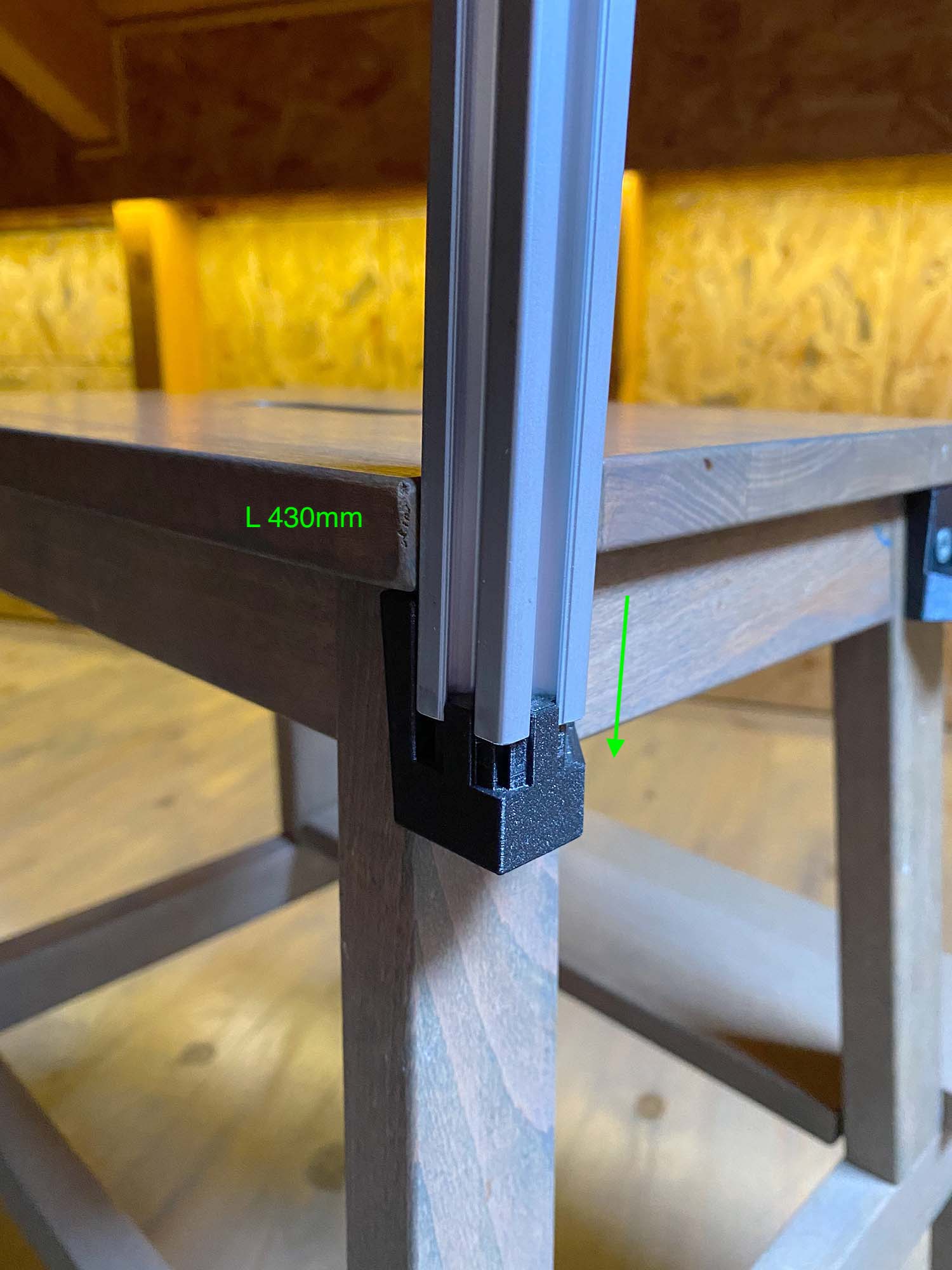

3. Use the screws you removed to secure the Adapters in place, make sure the Adapters are installed in the correct location

- Every adapter has a letter combination marking (F for front, B for back, R for right, L for Left)

- Do not fully tighten the screws

5. Insert another L 430mm extrusion to the opposite Adapter at the back, make sure it is fully inserted

- The corner connectors should point towards the front side

- Push the extrusion all the way downwards but don't tighten the connector yet

- You might need to hammer it lightly

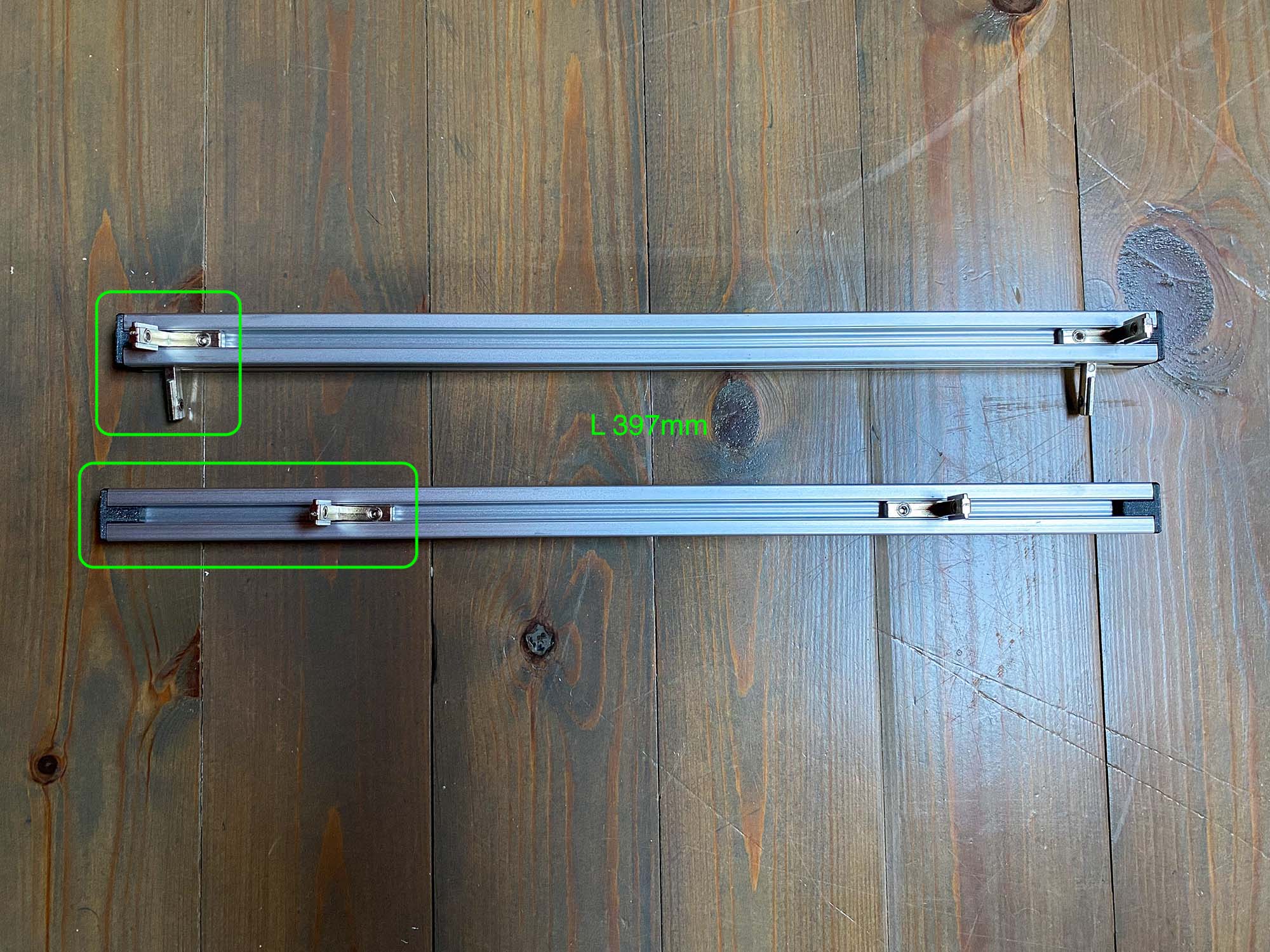

9. On the other end of the same extrusion, insert 4 corner connector as in the picture below and then insert an End Cap to lock that end

- Pay close attention to the direction and location of each corner connectors

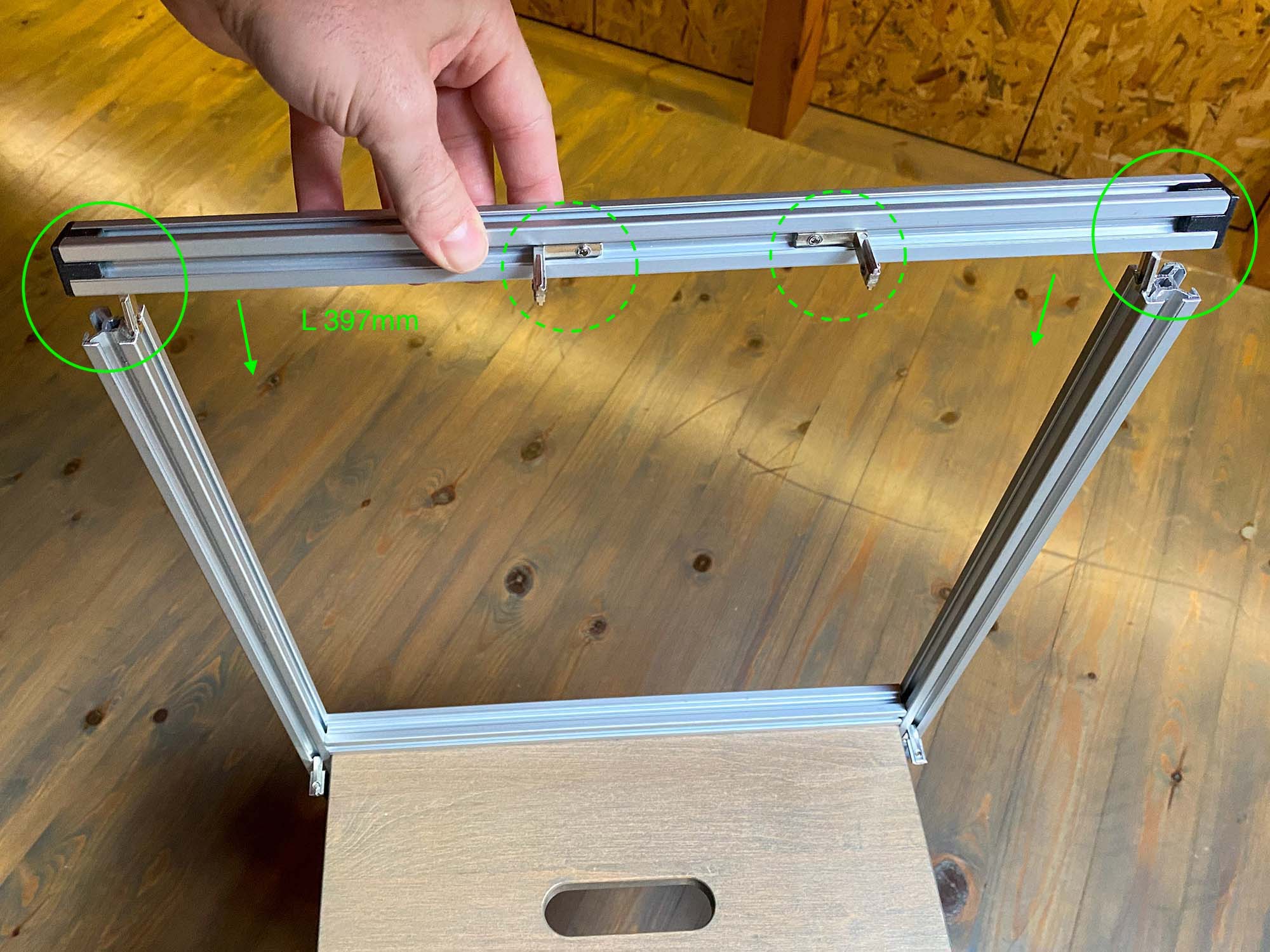

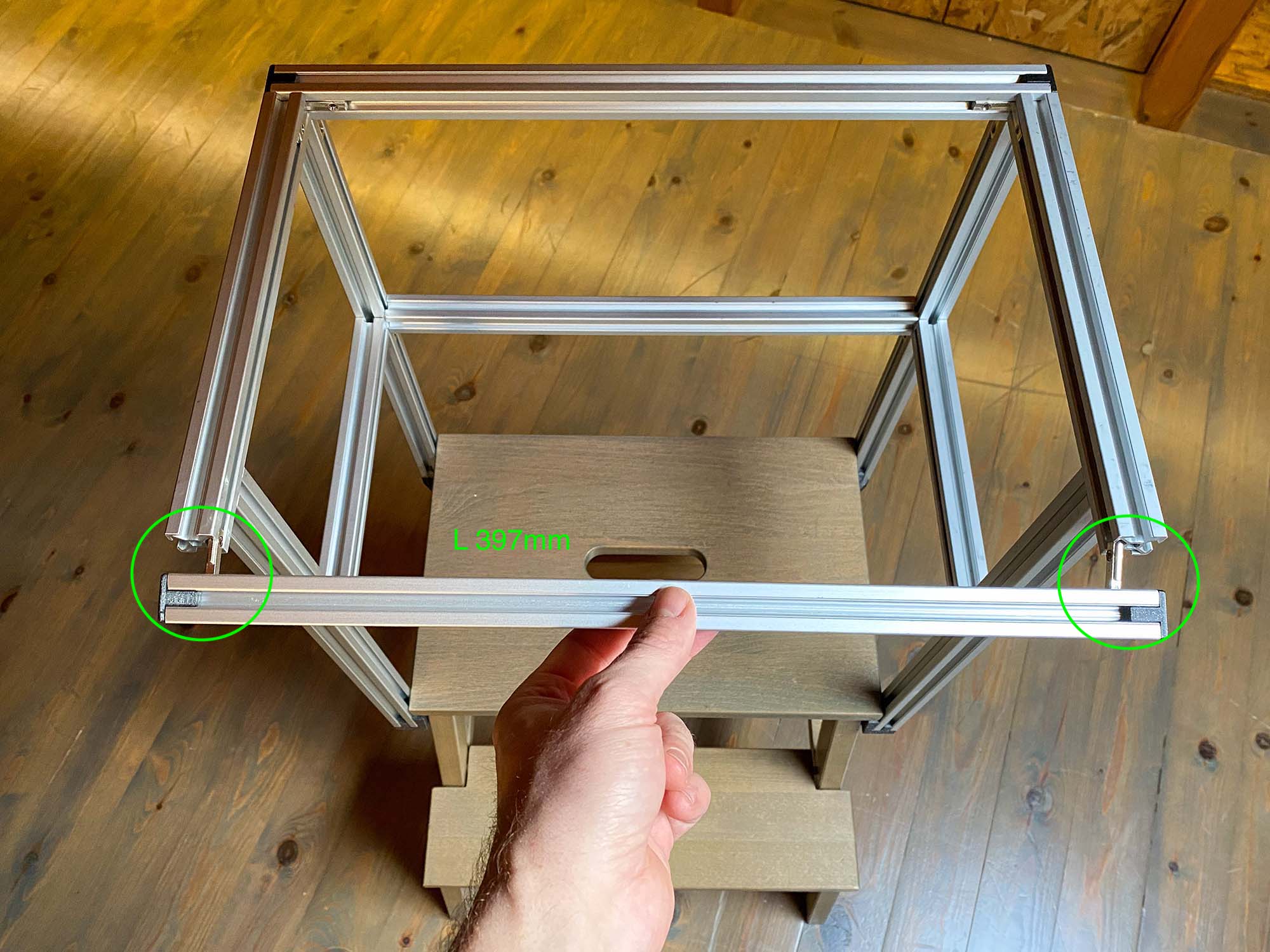

10. Repeat the previous two steps with the other L 397mm extrusion, this time insert only 2 corner connectors as in the picture below

- Pay close attention to the direction of each corner connector

- Spend some time to fasten the connector gradually, this will give you a better alignment

14. Using the tape measure, put a pencil mark at around 20cm from the top extrusion, do this on both sides

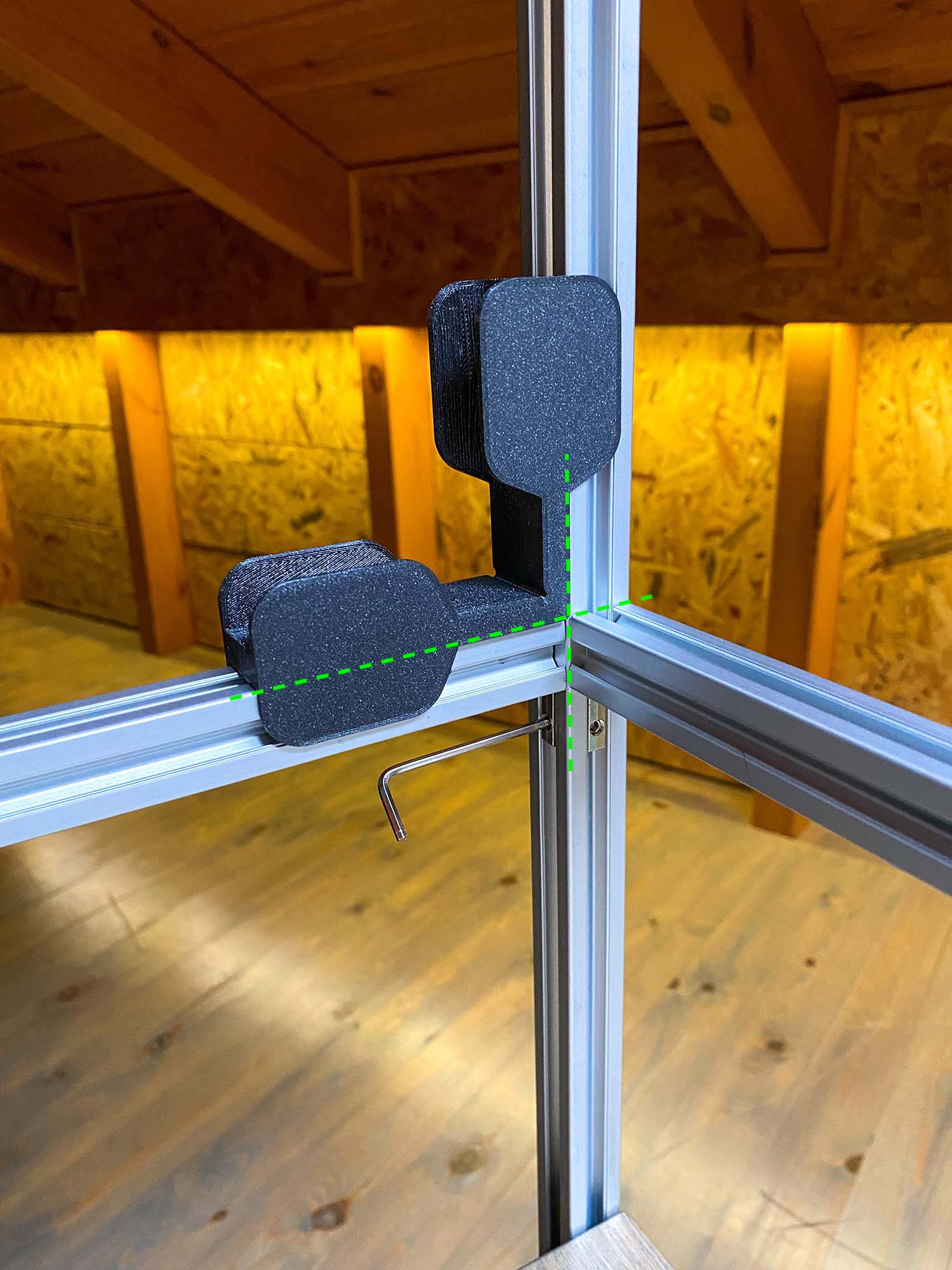

15. Lift the L 363mm extrusion and align it with the pencil mark, use the Jig to align the extrusions and tighten the corner connector

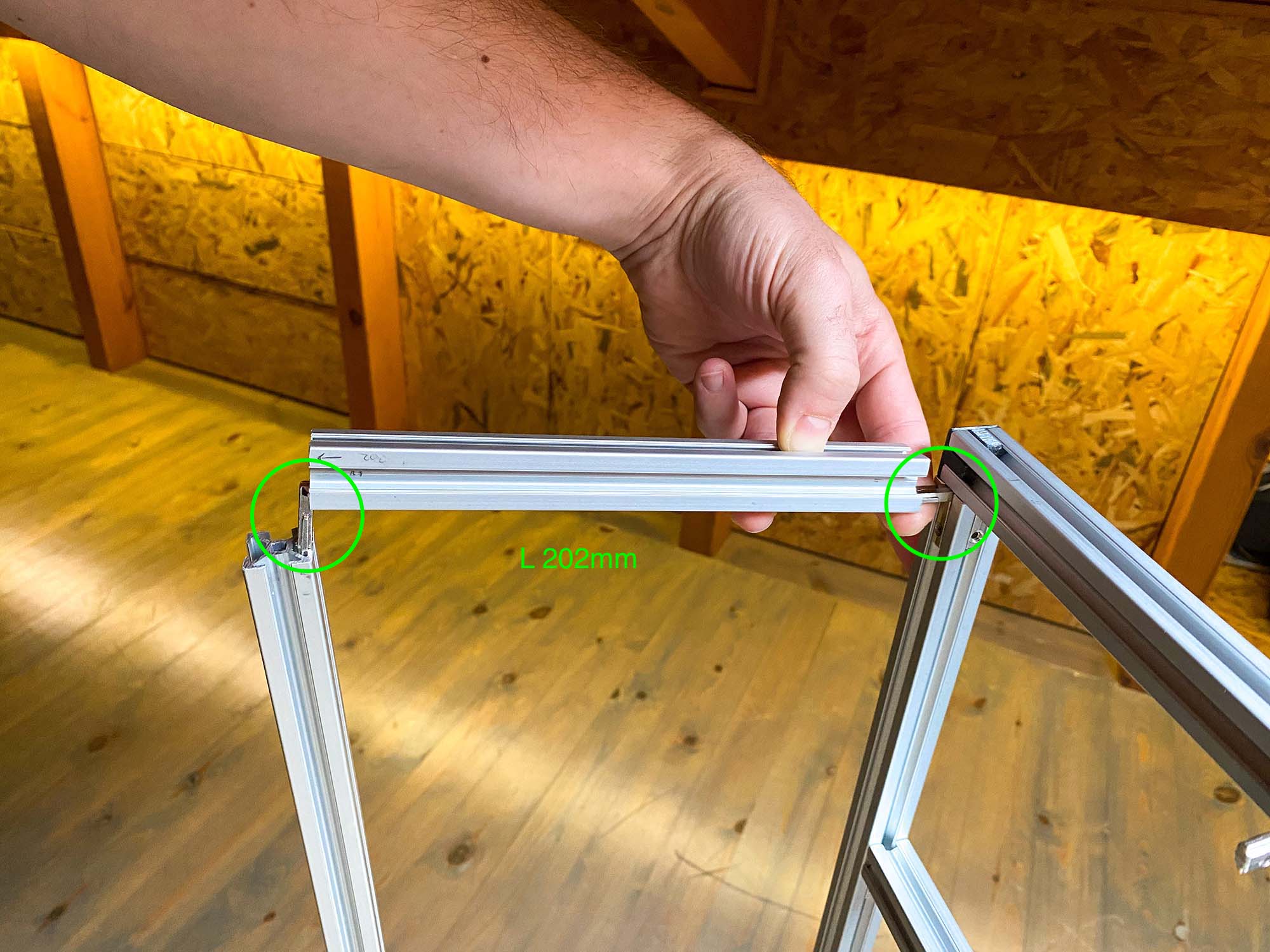

17. Insert an L 202mm extrusion on one of the stool sides. You need to use the corner connector you inserted earlier on the L 430mm extrusion, plus a new one on the other side. Do not tighten the connectors yet.

19. Insert an L 242mm extrusion on one of the stool sides. You need to use the corner connector you inserted earlier on the L 397mm extrusion, plus a new one on the other side. Do not tighten the connectors yet.

- Pay attention to the orientation of the corner connectors

21. Use the Assembly Jig to align the L 242mm to the L 397mm extrusion and tighten the corner connector

22. Using the tape measure, put a pencil mark on the L 430mm extrusion at around 20cm from the top of the L 242mm extrusion, do this on both sides

23. Use the Assembly Jig to align the L 202mm to the L 430mm extrusion and tighten both corner connectors, do this on both sides

24. Now go back and tighten the remaining corner connector of the L 430mm and L 242mm extrusions, do this on both sides

25. Insert the last extrusion, L 397mm (with 2 corner connectors), to the L 242mm extrusions. Tighten both corner connectors.

26. Insert the 4 wood screws to the bottom of the 4 Adapters, so that the screw secures the L 430mm extrusions. Do not overtighten these screws.

- Important note: using wood screws on extrusions is a bit unusual. The center hole on the extrusion is meant to be tapped so it can accept a standard bolt, something like an M6 in this case. This would however require some more advanced tooling, like an M6 tap (feel free to go down that path if you fancy), so I decided to stick to a screw that is easy to install. A 5mm (diameter) wood screw fits nicely on my extrusion profile, and its length provides enough grip for the threads. However, the diameter of the extrusion's center hole varies slightly from manufacturer to manufacturer, so I highly recommend testing the screws before assembly and making an effort to find a screw that fastens securely.

- I don't love that the 4 adapters differ slightly in dimensions to match the stool's holes accordingly. I'd prefer one simpler adapter design that fits all 4 corners but this requires some experimentation.

- The adapters have a tight fit with the extrusion's T-slot internal profile. This could potentially vary from profile to profile which could render the adapter unusable.

- The rails of the extrusions occasionally trap food and dirt and they are not super easy to clean. There are some profiles that have one or two sides plain (no rail) which might be a decent solution.

- Because of the extrusions, it's easy to convert the aluminium structure to something else when it's no longer needed (like a chair or a table or something) but I haven't explored that aspect yet.