- World's smallest "to scale" Wii console

- Powered by USB-C

- HDMI for lossless digital audio and video (powered by GCVideo)

- Bluetooth for Wii remotes and accessories

- MicroSD card stores games and saves, instead of disc drive & memory cards

- 4 GameCube controller ports

- Power, reset, and sync buttons

- Power indicator LED and iconic blue glowing disc slot

- Soft shutdown, power on/off via Wiimote

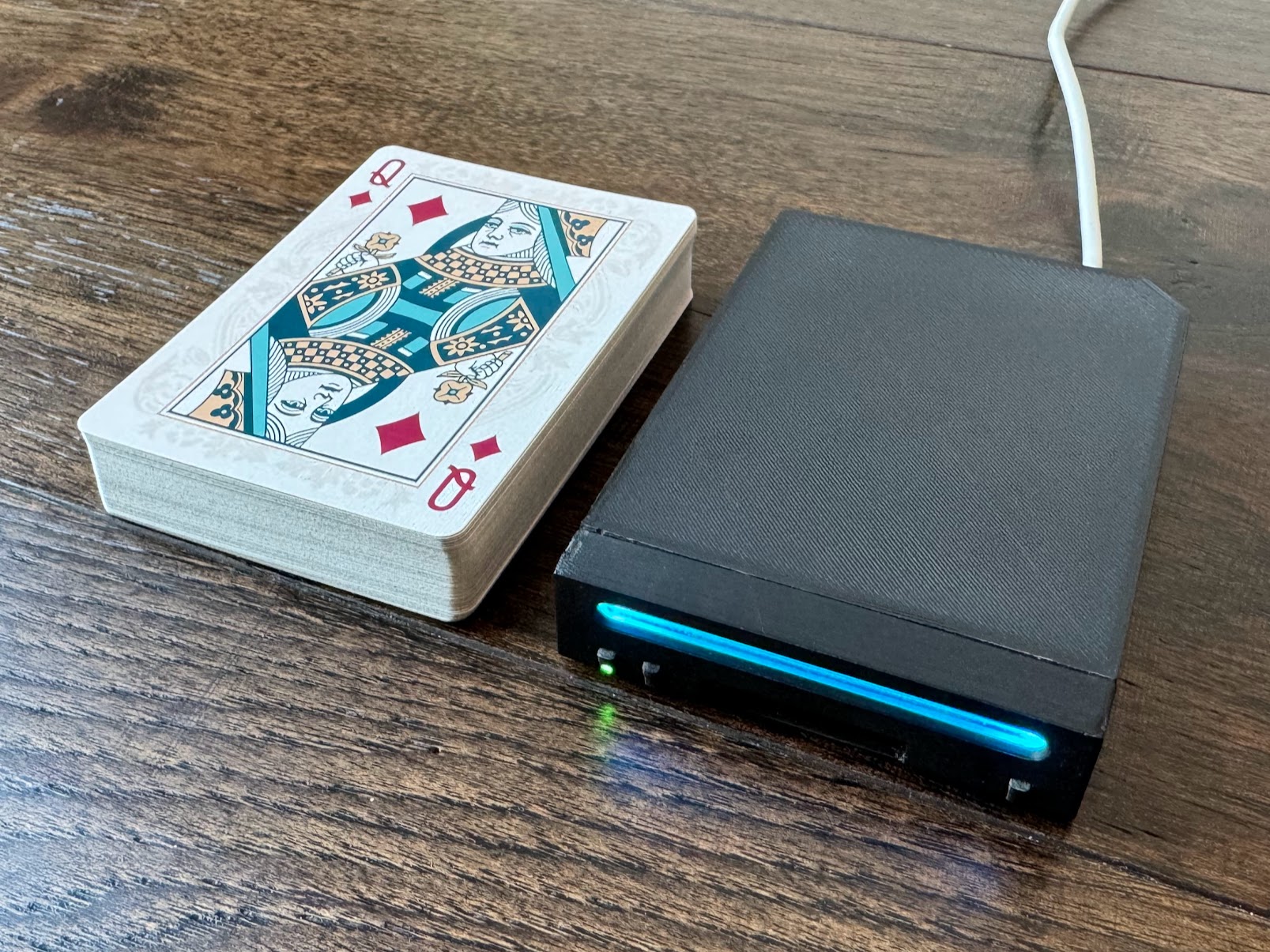

This is a 1:2.38 scale model of an original Nintendo Wii console, but since that is hard to visualize here are some other stats:

- Same size as a typical deck of playing cards

- 7.4% the volume of an original Wii console

- You could fit 13.5 of these inside an original Wii

I'm pretty sure this sets the record for the smallest functional scale-model Wii console, but let me know if I'm wrong!

Yes! It is definitely possible to go smaller than this. My version of the Omega trim keeps all four main mounting holes, which makes it around 7mm wider than a classic Omega trim. Additionally Wesk has managed to get a Wii motherboard down to 52x52mm on his final destination trim, which is a a full 10mm narrower than my trim. I estimate you could reduce the volume by a further 25-30% without losing any functionality, but it would be an incredibly tight fit and tricky to assemble.

As the name implies, Short Stack is built from a stack of custom PCBs, and a custom heatsink, that are all designed to fit together in a compact and modular way.

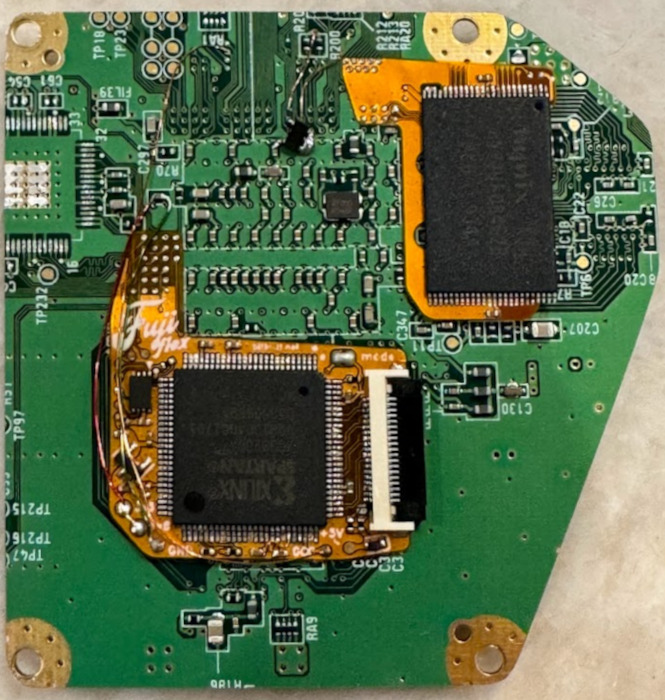

Making a tiny build like this is made possible by trimming the Wii motherboard down to the bare essentials. The result is a board which is just 62x62mm, but still contains the CPU, GPU, RAM and flash memory.

Since we removed the original power circuitry and trimmed off the USB, Bluetooth, and GameCube connectors, we need to provide power and data to the board another way. I designed a couple of boards which solder directly to the front of a trimmed Wii motherboard to provide power and data, which help avoid a tangled mess of wires.

The Wii Power Strip supplies power to the Wii motherboards using a Molex Pico-Lock connector, and additionally has footprints to help relocate of a couple of capacitors which are typically removed when trimming a Wii.

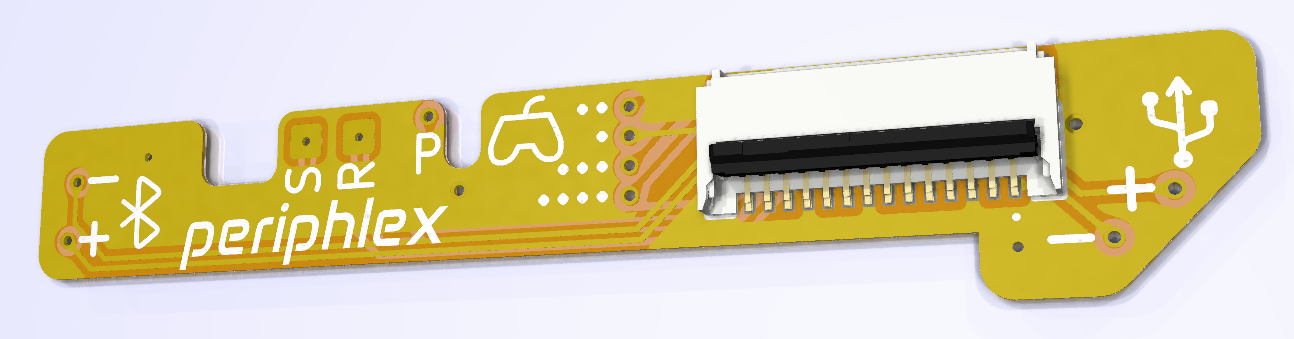

Periphlex is a flex PCB which breaks out the Bluetooth, USB and GameCube controller data lines, as well as the power, shutdown, and reset GPIOs. These are then made available via a 14-pin FFC connector. This approach replaces 11 magnet wires with a single, removable ribbon cable.

On the back of the motherboard, I'm using two open-source boards designed by the very talented YveltalGriffin. fujiflex provides digital A/V output using GCVideo, and nandFlex relocates the Wii's NAND memory chip, to enable the tight trim.

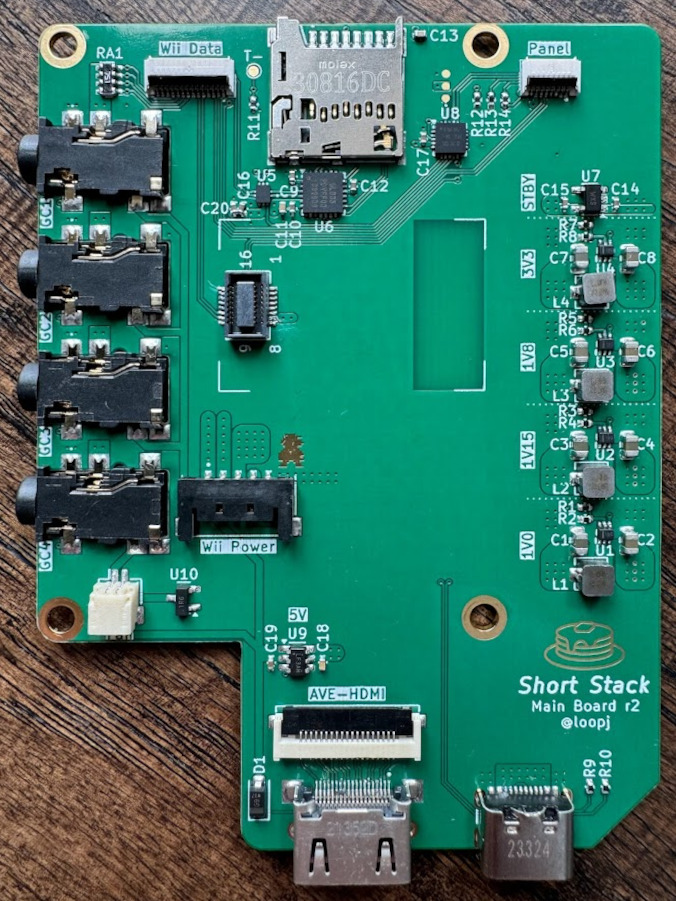

In addition to the modular boards on the motherboard, I designed two PCBs specific to Short Stack which provide the rest of the functionality for the console.

The main board PCB hosts the power regulators, USB to microSD logic, HDMI connector, GameCube ports, and a microcontroller for power management. A 14-pin ribbon cable connects this board to the Wii motherboard via Periphlex, and a power cable delivers power to the Power Strip.

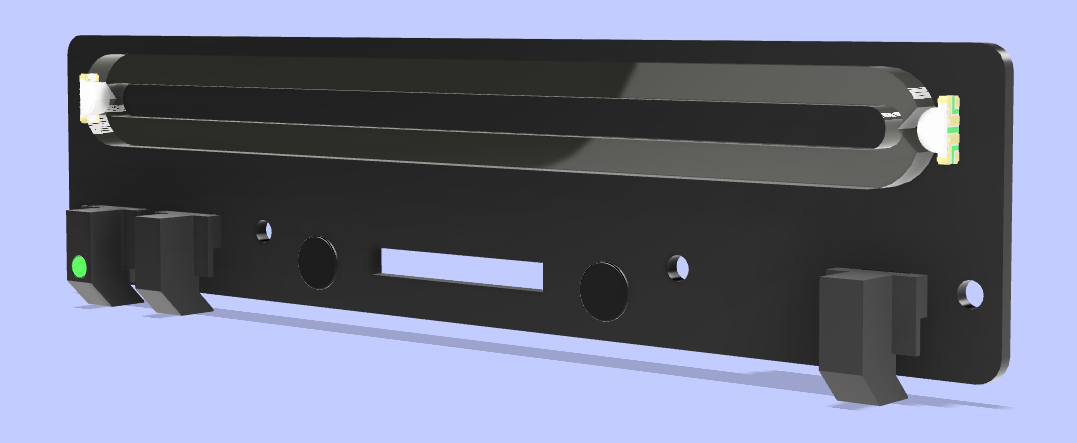

The front panel PCB hosts the power, reset, and sync buttons, as well as the power LED and disc slot LEDs. This board connects to the main board via a short 8-pin ribbon cable.

Since the GameCube controller connectors on the original Wii wouldn't fit cleanly on a build of this size, I use TRRS headphone connectors instead. This is the exact same approach used on the amazing GC Nano and in fact I made sure the dongles are pinout compatible!

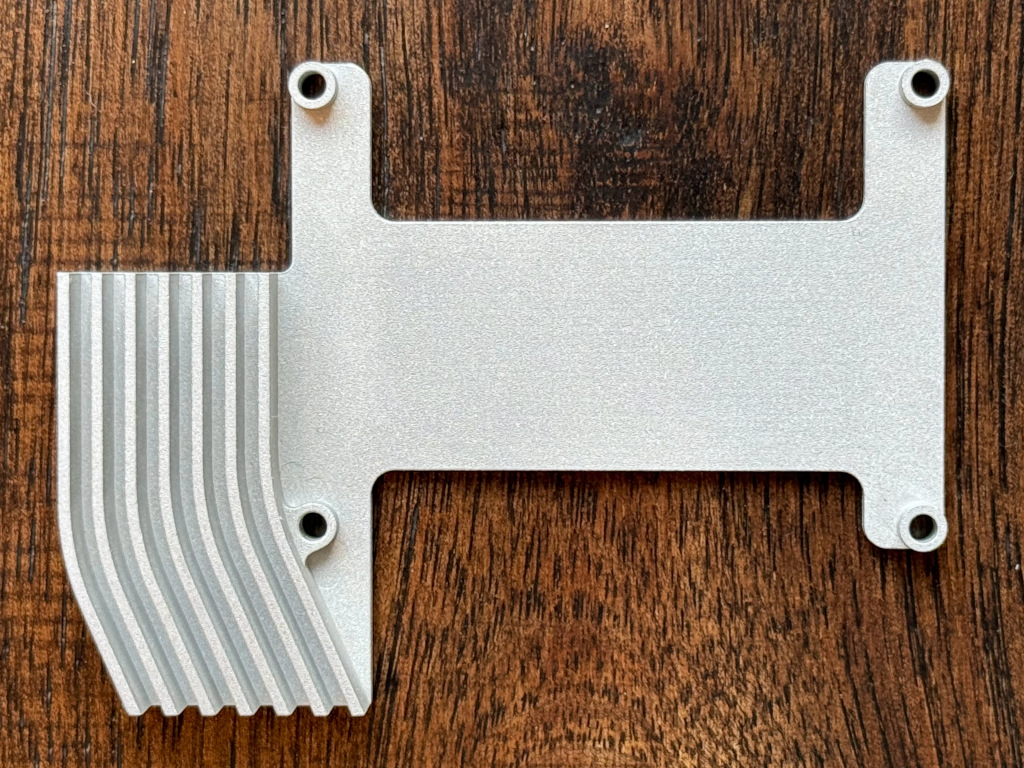

The final part of the "stack" is a custom heatsink which is designed to be as low profile as possible, while still providing adequate cooling for the Wii's CPU and GPU. The heatsink is designed to be machined from aluminum or copper, and incorporates mounting holes which align with those on the Wii motherboard.

I managed to find a tiny 5V blower fan (Pelonis AGB208N) which measures just 20x20x8mm and somehow puts out 0.84 CFM of air. This blows air through the heatsink fins, out the side of the case.

The stack is housed in a custom 3D printed case, secured with four M2.5 screws and spacers. The rest of case is assembled using self-tapping M1.2 screws. The screw locations and fan vents are positioned to match the original Wii case as closely as possible, to minimize visible screws.

You can access files on the SD card by connecting the console to a computer via USB, but I also included an access panel on the front of the case where the original Wii SD card slot is found. This panel is held in place by magnets and can be removed to access the SD card without opening the case. Shout out to Wesk for the magnet idea!

To keep the clean aesthetic of the original Wii I wanted to hide the GameCube controller ports behind a panel. I always hated the hinged design of the original, and it is quite difficult to replicate at this scale, so I redesigned this panel to be a sliding panel.

The Wii's iconic disc slot lights are recreated using a 1.5mm thick custom cut acrylic light diffuser, which is illuminated by two side-mounted addressable LEDs on the front panel board. The power, reset, and sync buttons are all also 3D printed, and the power button hosts a tiny light pipe to allow the power LED to shine through.

I FDM printed the case on a Voron 2.4 in ABS using a 0.4mm nozzle at 0.1mm layer height, but it should print fine in PLA or PETG on a well-tuned printer. At this scale, dimensional accuracy is important. In theory it should be possible to print this on an SLA printer, but I haven't tried it.

Caution

This is not a beginner project! This build requires performing a challenging motherboard trim, fine pitch soldering, and PCB assembly. If you are not comfortable with these tasks, I would recommend starting with a simpler project and working your way up - check out the BitBuilt forums for some awesome project worklogs.

- 4-layer Wii motherboard

- nandFlex board (or 4Layer Technologies RVL-NAND)

- Assembled fujiflex (or ElectronAVE)

- Assembled Wii Power Strip - must be revision 1!

- Assembled Periphlex

- Short Stack main board - 1.2mm thickness, stencil recommended

- Short Stack front panel - 0.8mm thickness, black soldermask, stencil recommended

- Heatsink - machined from aluminum or copper

- Light diffuser - cut from 1.5mm thick acrylic

- The components and hardware from the bill of materials

- Assemble main board and front panel PCBs

- I recommend using a solder stencil and a hot plate or reflow oven

- If using a hot plate, hand solder the headphone connectors after reflowing the rest of the components

- Secure two 3 x 1mm magnets inside the holes on the front panel board using a dab of CA glue

- Flash the main board firmware

- Prepare and trim the Wii motherboard

- Relocate the NAND, test it still boots

- Perform a wireless U10 relocation, test it still boots - you may wish to wire a magnet wire to the

SHUTDOWNvia first - Install fujiflex, and test digital A/V output works

- Trim the motherboard (see trim dimensions)

- Assemble and install Power Strip (see instructions)

- Assemble and install Periphlex (see instructions)

- Connect the boards

- Connect the main board to the motherboard via a 14-pin FFC cable to Periphlex

- Connect the main board to the motherboard via a 5-pin Molex Pico-Lock cable to Power Strip

- Connect the front panel board to the main board via an 8-pin FFC cable

- Connect the fan to the main board

- Apply thermal paste to the CPU and GPU

- Stack the components: heatsink, motherboard, M2.5 x 3mm spacers, main board

- Install the stack to the case bottom using M2.5 x 12mm wafer head screws

- Secure the top of the case to the bottom using four M1.2 x 4mm screws

- Secure the front panel PCB to the front of the case using two M1.2 x 3mm screws

- Secure the front of the case to the bottom of the case using two M1.2 x 4mm screws

- Press-fit two 3 x 1mm magnets into the holes on the sd card cover, make sure they match polarity with the magnets on the front panel PCB

- Slide the side panel into the case

This project would not be possible without the amazing BitBuilt community, I'm truly standing on the shoulders of giants here.

In particular, I'd like to thank:

- Wesk for setting the bar so high with renders, for the suggestion of using magnets in the case assembly, and for the inspirational GC Nano

- Aurelio for pointing me in the right direction to help figure the soft shutdown and power on via Wiimote.

- YveltalGriffin for PCB design feedback, helping me when I was documenting the bluetooth module, and of course for fujiflex and nandFlex

- CrazyGadget for helping me fix my GL823K on the first revision of my boards, and for the inspirational GC Nano

- Y2K and supertazon for joining the PCB assembly live stream and being super supportive

Permissively released under the Solderpad Hardware License v2.1