The Minimizing Aerosolization In Non-invasive (MAIN) Ventilation COVID-19 mask is a sealed, filtered, full-face mask minimizing virus aerosolization and enabling the use of Non-Invasive Positive Pressure Ventilation (NIPPV) machines for patients with COVID-19, or similar symptoms. The mask adaptor is the primary connection between the sealed facemask and standard medical 22mm respiratory tubing, fittings and filters. An additive manufacturing method, also known as 3D printing, was used to produce the mask adapter because of its relative speed to make objects of complicated geometries and availability. Due to the medical nature of the adapter, certain specifications must be followed in its production to prevent any infectious transmission from the patient to health care workers and other patients.

- 3M Scott AV-2000 Facepiece

- 3M Gasket seal

- 3D printed adapter (ABS)

- Adapter Version: v1.0

- Filament Material: ABS

- Printer Nozzle: 0.4mm

- Infill Percentage & Pattern: 100% Infill, Rectilinear infill

- Wall thickness: 2.0mm (5 wall/perimeters with 0.4mm nozzle)

- Top and bottom thickness: 2.0mm (5 top and bottom layers at 0.2mm layer height)

- Supports: Required

- Raft: Not preferred; Printing on the bed creates a smoother finish

- Orientation: Mask face on the bed, Outer face upwards (See Figure 1)

Additional Slicer Settings:

- Use ‘random start points for all perimeters’ (Cura)

- Use ‘Connect infill lines’ (Cura)

- Use ‘Random start points for all perimeters’ (Simply3D)

Figure 1: Orientation of Adapter v1.0 on Print Bed

- NOTE: ABS is prone to thermoplastic contraction (shrinkage). If the slicing software does not already compensate for this shrinkage, consider measuring the product to ensure the correct scale. Amount of contraction can vary between different brands of ABS – printing calibration tools and test-prints recommended to determine exact percentage to scale.

Ensure the following:

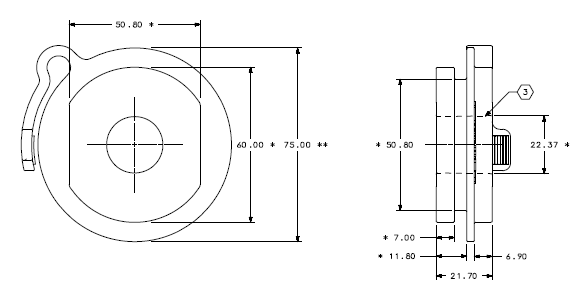

- Inside diameter of female port on outward face should measure between 22.37 +0.1/-0.15mm on outside face (see Figure 2). Use of digital calipers strongly recommended.

- Note tolerances for other dimensions post printing (also see Figure 2).

- Layers adhere properly to each other

- Walls are completely fused together

- Surfaces (outer and inner) are smooth without gaps, burrs, blobs

- The print has decent flexibility (i.e. latch)

Figure 2: Critical part dimensions

For each batch printed, the following items must be logged:

- Material used

- Lot number of material used

- Colour of material

- Date of print

- Machines used for print