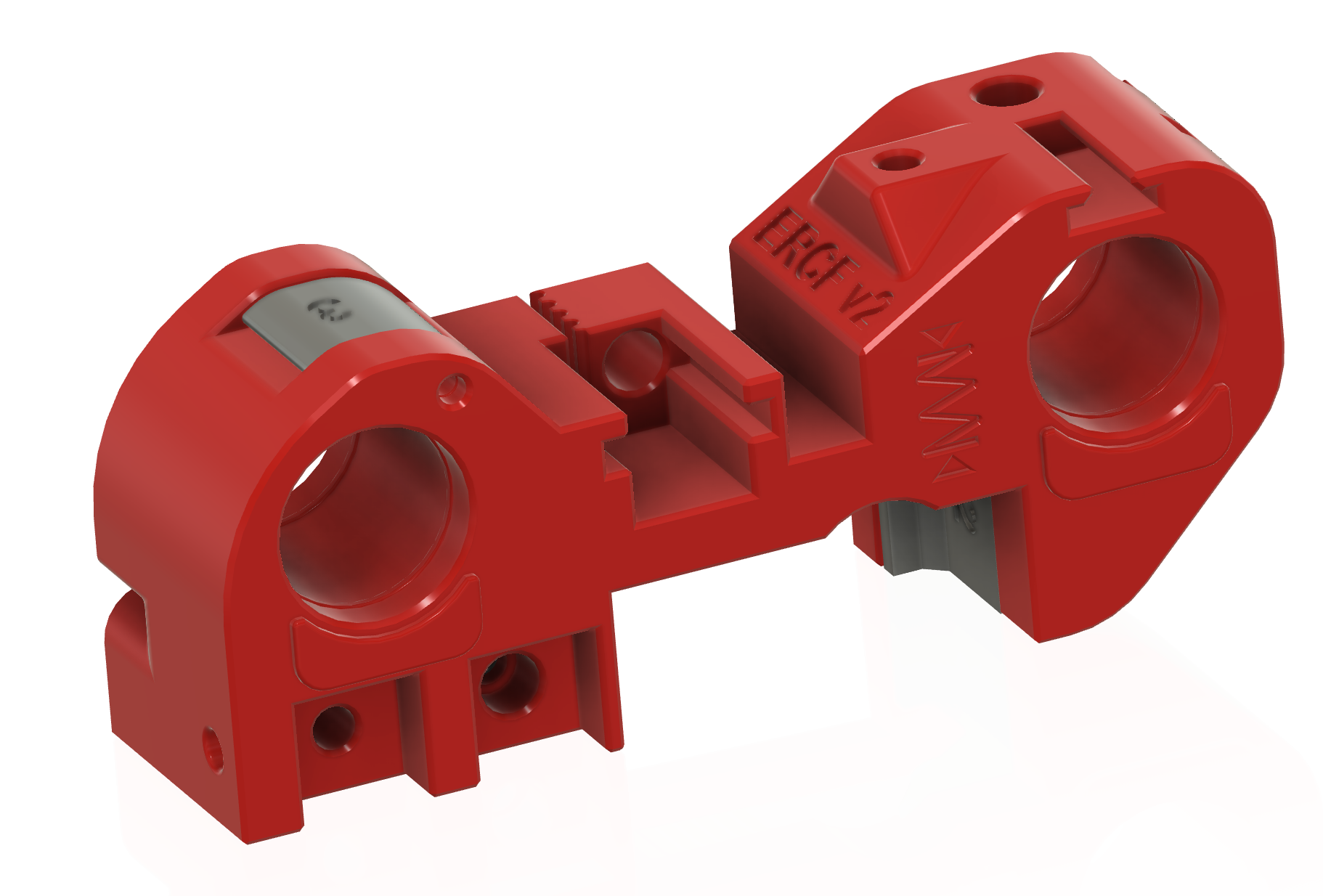

ERCF "Springy" is a modification/upgrade to the ERCF v1.1 design. One of the problems with ERCF is tuning the grip on the filament by swapping out different sized "top-hats" until sufficent grip is found. This is a hassle and, although mostly works, the problem is that the flexible nature of the connection of filament blocks and the fact that the servo arm wears over time means that it isn't reliable. Enter "Springy"...

Springy is a reworked Selector Cart (and ancillary components) with built in articulated sprung servo. The whole servo assembly moves to ensure consistent pressure to grip the filament and works with a single "universal" top-hat.

- Improved supports (gaps)

- Adjustment screw for spring (must always use the Spring_Cap.stl part). Obviously you need to add a threaded insert at the top of the spring hole -- careful you need a steady had to do this.

- Minor adjustment to servo mounting carts - they had a slightly lower resting position than desired

- The servo pivot is no longer two screws but a single M3x20. It makes is slightly more difficult to assembly because you need to attach the encoder at the same time as securing the pivot for the servo. Idea from ERCF discord channel.

- STLs Updated: `[a]_Springy_Selector_Cart.stl`, `Spring_Cap.stl`, `Springy_MG90S_Servo_Mount.stl`, `Springy_Savox_Servo_Mount.stl`

Also check out my other ERCF projects:

- Happy Hare v3 software (https://github.com/moggieuk/ERCF-Software-V3)

- KlipperScreen Happy Hare Edition (https://github.com/moggieuk/KlipperScreen-Happy-Hare-Edition)

Also, some folks have asked about making a donation to cover the cost of the all the coffee I'm drinking. I'm not doing this for any financial reward but it you feel inclined a donation to PayPal https://www.paypal.me/moggieuk will certainly be spent making your life with ERCF more enjoyable.

Thank you!

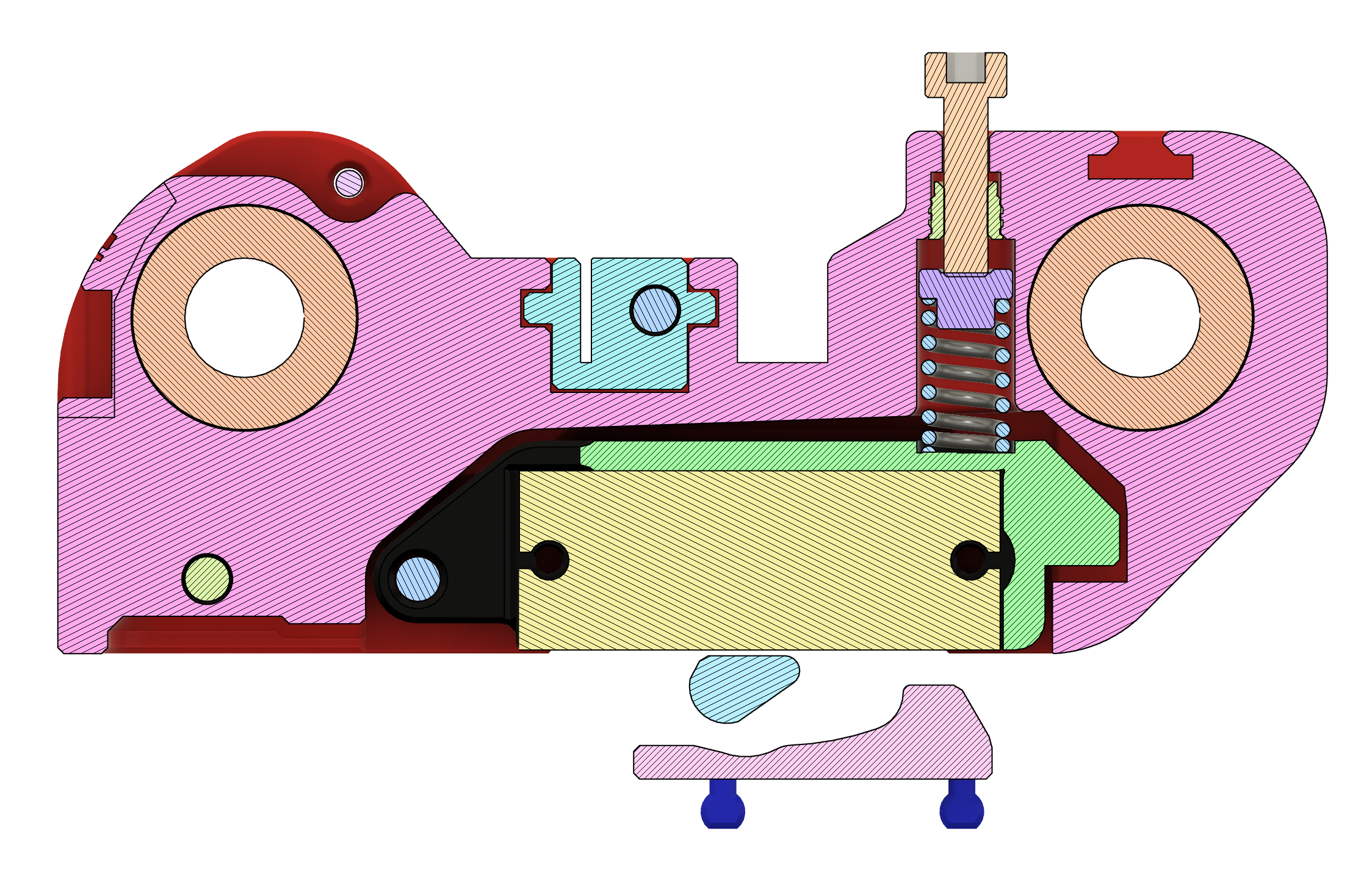

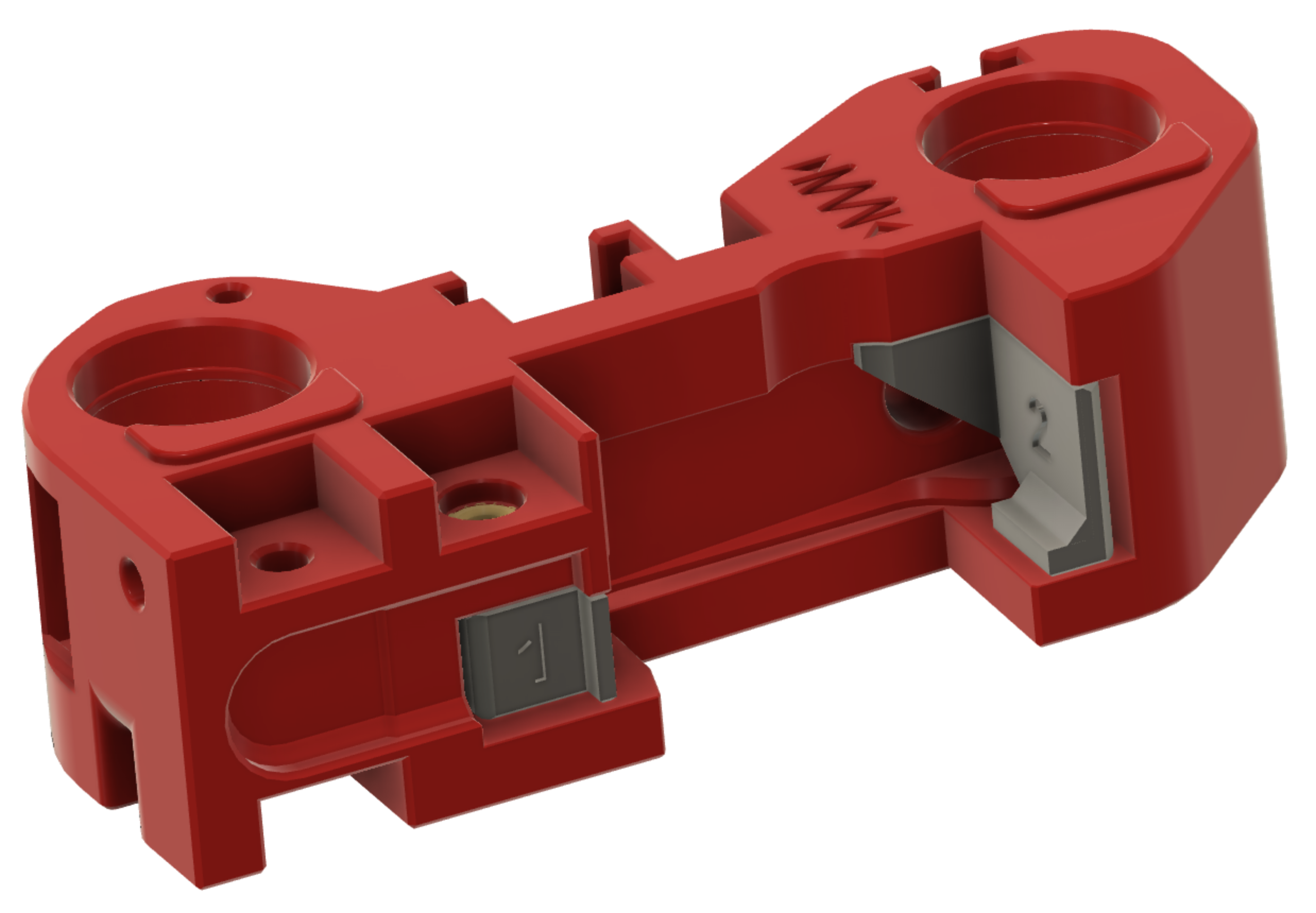

This cross section reveals how Spring works. The servo (both MG90S and Savox SH255mg are supported) pivots and provides about 2-3mm of movement. The updated servo arm design aligns with the new universal top hat and ensures constant grip with varying distances and servo arm wear.

Other changes / notes:

- The "Idler Block" at the end of the 8mm rods should be replaced to provide an enlarged pocket for servo movement.

- You must replace all your top-hats with the "universal" design supplied.

- The selector door has been strengthed in the hinge area and now locks with two 3x2mm magnets.

- Articulated servo mounts are provided for both the popular MG90S and Savox servo options.

- Springs from about 10mm to 15mm accomodated - cut it too long. You do want the 1mm s/steel wire size though to provide the correct pressure.

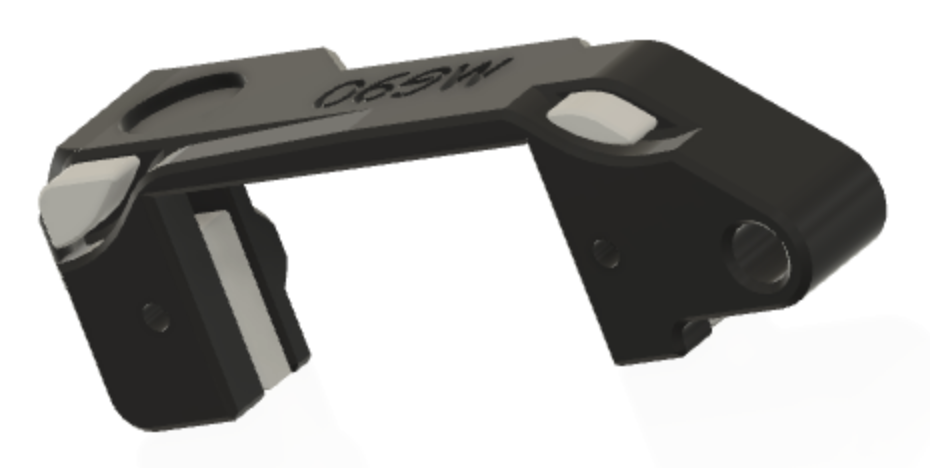

In addition to the selector cart it is important to print and fit a new "Idler Block" to ensure the servo will not bind and wires have room to move. Also make sure you use the new top-hat and correct servo arm (the MG90S and Savox are different spline patterns!)

- 1x M3x20mm SHCS bolt for articulated servo pivot. This secures both the encoder and is the pivot for the articulated servo arm.

- 1x 10mm - 15mm s/s compression spring. This should be a 6mm diameter, 1mm wire compression spring.

- 1x M3 heatset for the spring compression adjustment

- 2x 3x2mm round neodymium magnets. These are optional if you want the updated cover to lock shut.

- 2x M2x8mm self tapping "servo" screws (these are the ones that were probably supplied with servo). Note the warning about too long screws below.

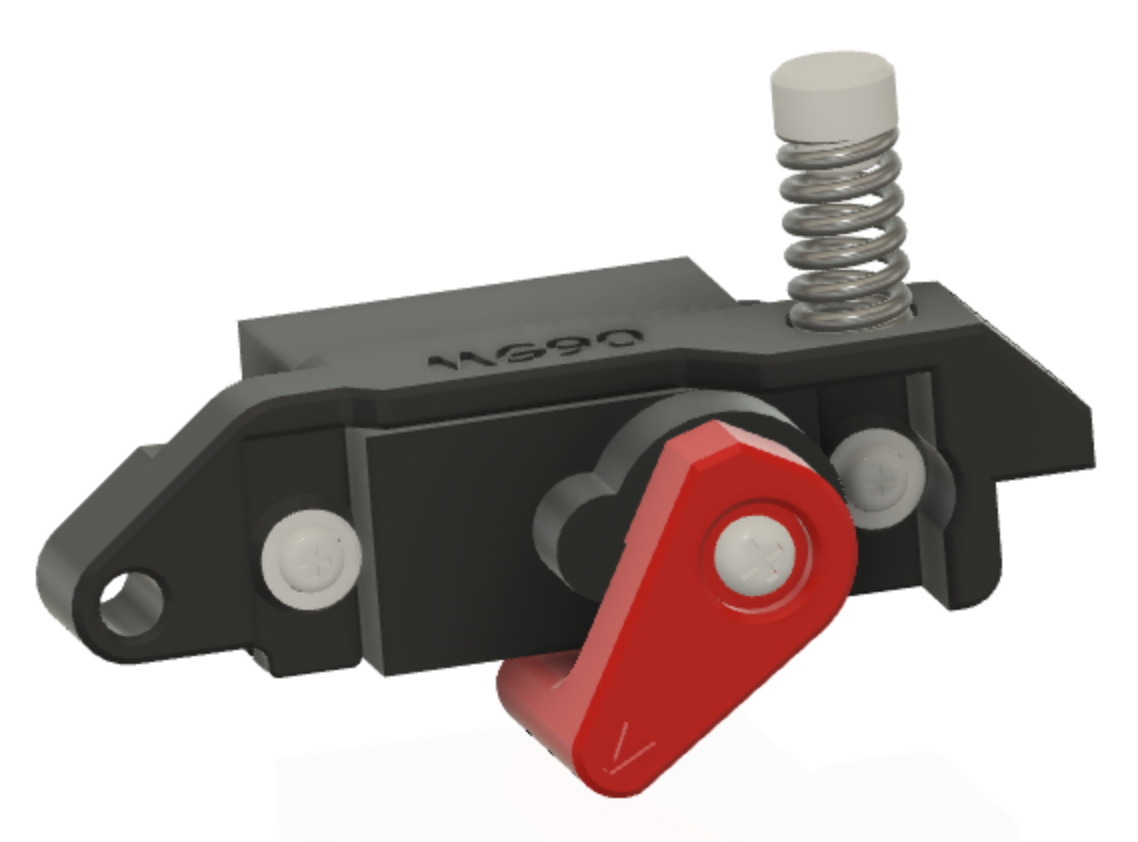

Here is the articulated servo mount showing the MG90S servo verion and a 12mm spring. The Savox mount is slightly different.

-

Dissassembly: Remove the 6mm selector belt and separate the 8mm rods from the "Idle Block" end. Remove the Encoder from the Selector Cart. Remove the old Selector Cart from the 8mm rods.

-

TO avoid clearance problems make sure to replace the Idle Block with the new one because is has a slightly enlarged cutout for servo.

-

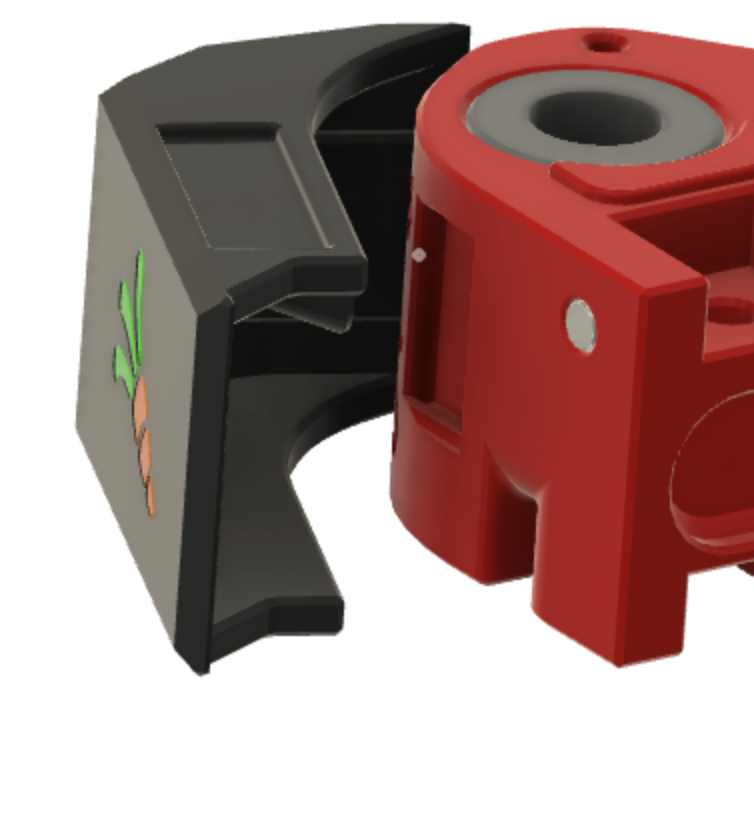

The servo mounts have break away suppports (MG90S has 4, Savox has 2) shown in grey below. [Note: The print orientation is chosen to ensure strengh in the hinge area]. The M3 brass inserts are the same as the original with one exception. The insert that forms the pivot for the servo should be set 1mm BELOW the surface. The new STL has provision for this.

- Fit the servo with two M2x6mm (or 8mm) self tapping screws. IMPORTANT: Make sure the screws don't poke through to the other side. If they do, remove then and file then slightly before refitting. I found the screws supplied by the servo vendors fitted but others can be a little long.

-

Break away the 3 numbered supports from the Selector Cart.

-

Press a M3 heatset at the back of the spring hole. Putting on the heatset on a M2 allen or small screwdriver will help guide it. CAREFULLY with a steady hand, press the heatset into the base of the hole without deforming the surrounding plastic.

-

Fit the spring and spring cap into the cart. Insert the servo assemply spring side first then depress the pivot side and secure the servo pivot with a M3x20mm SHCS bolt (the same one that will later hold the encoder).

It should articulate similar to this video: (https://www.youtube.com/shorts/Brj2L9Y7NeA)

-

Add back the encoder changing the one M3x8mm to a M3x20mm SHCS (fits into the other side of the brass insert shared with the servo pivot).

-

Secure the servo wiring as shown in the picture. The small loop will provide necessary free movement to prevent strain on the wire. Don't fit the servo arm at this stage.

-

Reassemble ERCF and reconnect wiring.

-

Replace all the Top Hats with the universal one supplied in this repo (they have a v2.0 printed on the top edge)

-

Insert a 3x2mm magnet into the new stronger connector cover and corresponding hole on the selector cart

-

Once ERCF is operational again, align the selector with one of the gates. Run

ERCF_SERVO_UPto ensure the servo is in the up position. Fit the new servo arm (Savox version has "S" on arm, MG90S is blank) on the spine that best holds the arm against the servo body (fine adjustments can be made later to the servo angle inercf_parameters.cfg) -

Run

ERCF_SERVO_DOWNorERCF_TEST_SERVO VALUE=xxxto find the angle where theVon the servo arm aligns with the tiny^on the Top Hat. This eliminates any judgement and represents the best location for the down position. **NOTE: the angle of movement is a little bit smaller than before, so don't assume your existing value is correct - test again carefully working up to the correct postion! -

For Happy Hare use:

MMU_SERVO POS=downorMMU_SERVO ANGLE=xxx

Now enjoy more reliable and hopefully less filament slippage. Note: This removes one or two variables from your setup -- friction in the filament path can still lead to problems.

Good luck. You can find me on Discord as

moggieuk#6538(\_/) ( *,*) (")_(") ERCF Ready -