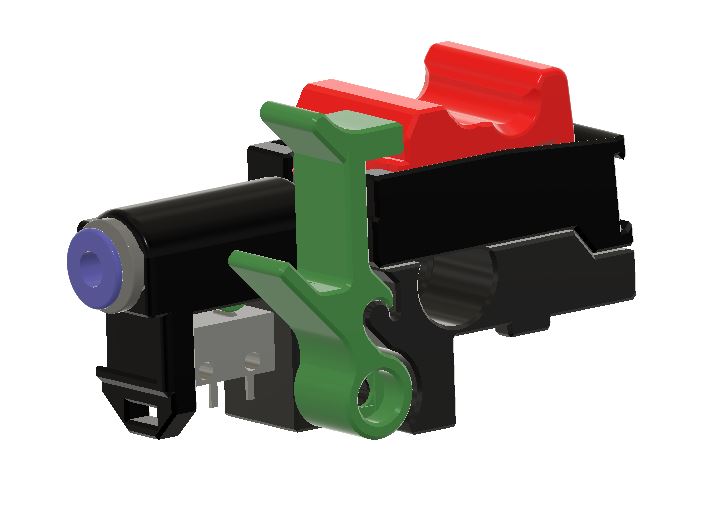

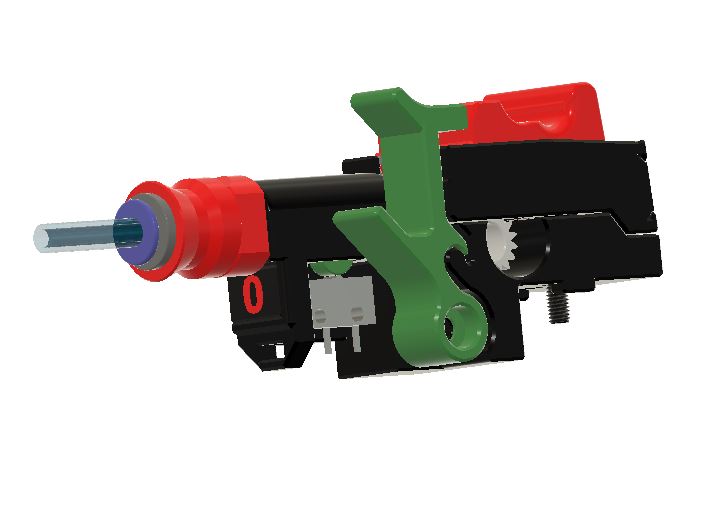

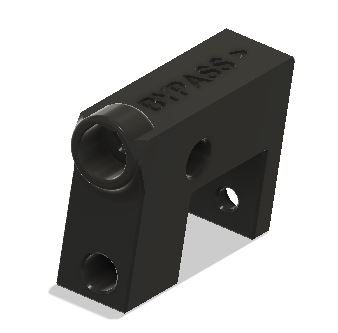

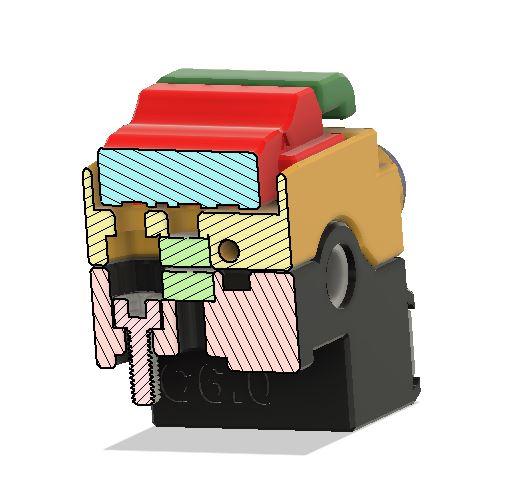

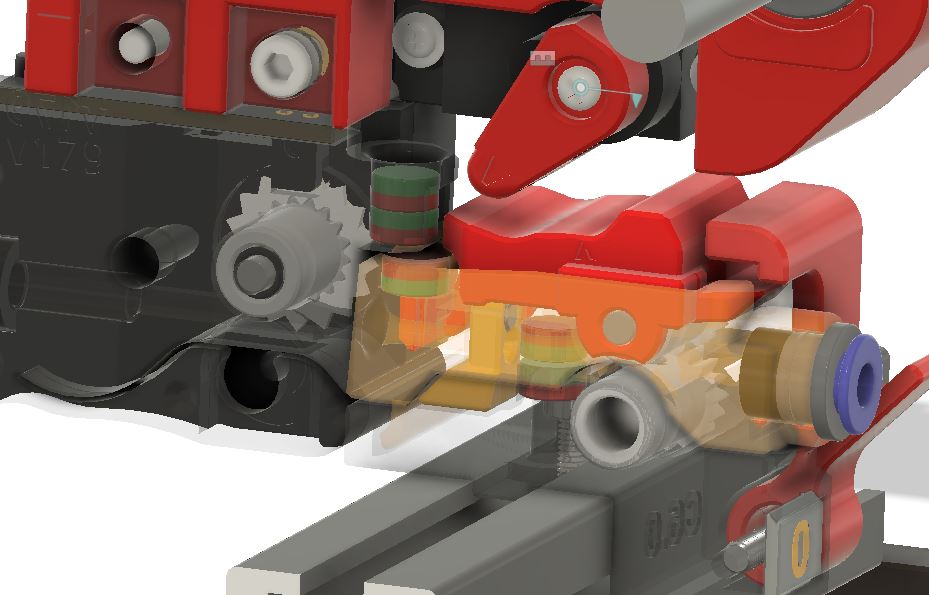

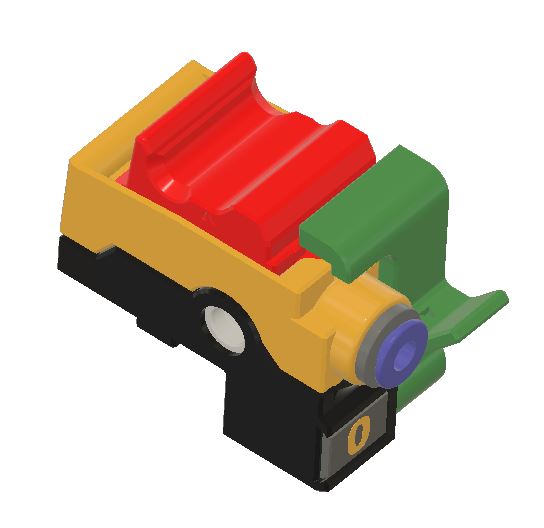

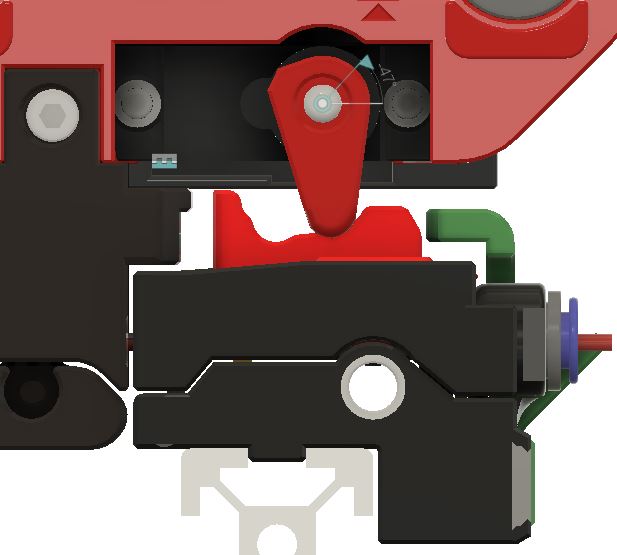

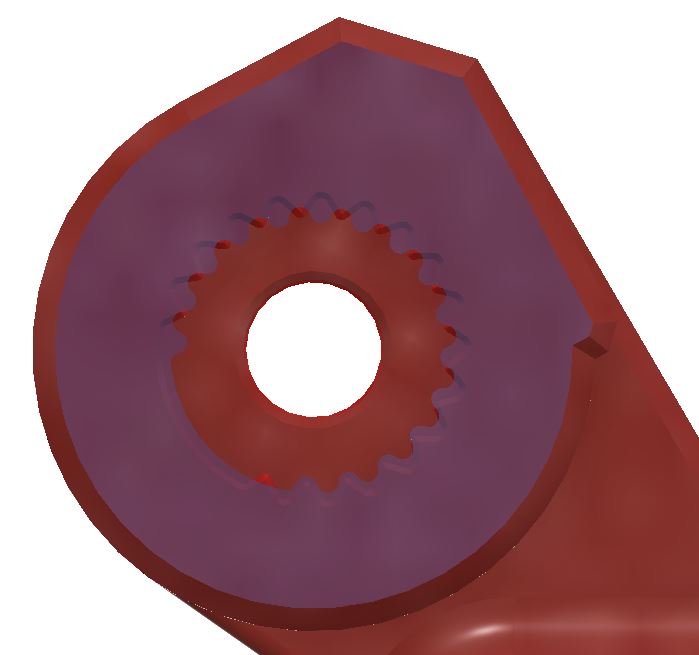

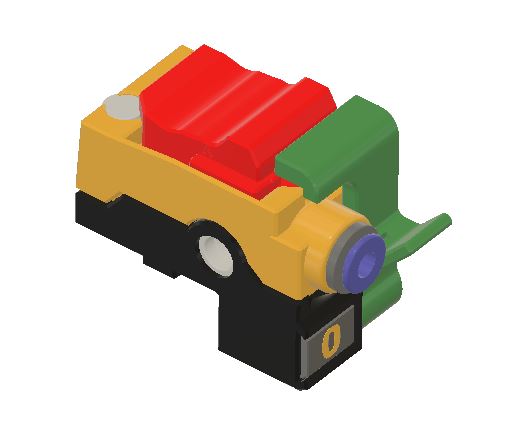

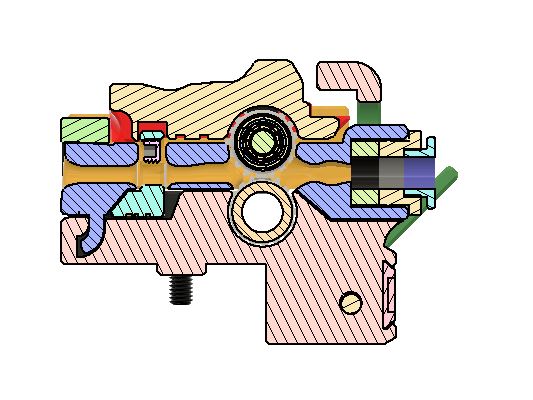

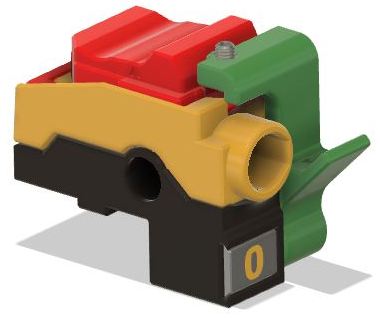

Triple Decky is based on the Sturdy Bunny filament block from Sneakytreesnake that incorporate the MR85ZZ bearing making the need for bearing blocks obsolete. It is a replacement for the filament block on ERCF V1 and Sturdy Bunny. Its goal is to avoid the filament to move in or out the filament block while loading or unloading another gate. To do that, the filament block consist in 2 hinged parts (decks), that are kept apart by magnets. The filament is lifted by 1 mm from the bottom BMG gear. The tophat comes on top of the 2nd deck and has the top BMG gear as before. An integrated tophat based on number 1 tophat locker to be used with Springy from Moggieuk on Rev B and C. Although Rev B version still has the possibility to install the magnetic gate, it is normally not needed anymore. It will not be possible to install the magnetic gates on Rev C. The width is 23.05mm as the latest Sturdy Bunny filament block that incorporate the bearing in the block. To take all the benefit of the Trple Decky Filament Block, it is recommended to use a good buffer system (preferably a single loop buffer) The PTFE tube should not apply down force on the ECAS so the magnet can do their work correctly. For people who needs a bypass block, there will be one incorporated in the "filament block end" of ERCF V2. A stand alone Bypass block that can be placed anywhere on the 2020 extrusion is also available on the triple decky Github. (Bypass_with_ECAS.STL)

- Bom

- Printing Tips

- Cleaning tips

- Assembling tips

- Triple Decky for Sturdy Bunny and ERCF V2

- Triple Decky for ERCF 1.1

If this is your first time printing Triple Decky, it is best to print the C9.x version. However if you have already printed the C7.x parts, and they are freely working together, there is no benefit to upgrade to C9.

-

Revision C9.x brings an almost build-in supports free. There is still one build-in support on the tophat.

- The latch is modified for better integration with Cotton Tail and the new modified base.

- The base is shorter and the small latch centering part should not break anymore if the screw is screwed in correctly.

- The entry tag plate is move from the base the filament path. This makes it easier to install the tag plates after the ERCF unit is build and functioning. The tag plates can then be printed in multi-color with the freshly build unit.

- The trap design is modified to accommodate the support free base. It is now connected to the base with an M2x10 screw.

- The tophat has a lower profile than the previous version. This should fix the servo down problem that some users have encountered.

- There is an optional tophat with sanp-in BMG.

- There are 2 versions of C9S which incorporate a pre-gate sensor Those versions are made for people with limited space and that does not want to use the Cotton Tail version of the pre-gate sensors.

- This version of pre-gate sensor is optimized to avoid false triggerinig if the filament have a notch ground from previous bad load.

- The 5.5mm ball is replaced by a 6x3mm magnet for more stability of the anti-false triggering device.

- Although this version works very well for automatic insertion of the filament, it may or may not work well for endless spool.

- One version uses an ECAS to hold the PTFE tube.

- The other uses magnets to hold the PTFE in the filament path.

-

The C9S Pre-gates Sensor STL are in the Optional Pre-gate Sensor folder of Rev_C9. See readme file of the folder for more details.

IMPORTANT NOTE : The C9.x parts are not compatible with the previous C7.x version.

-

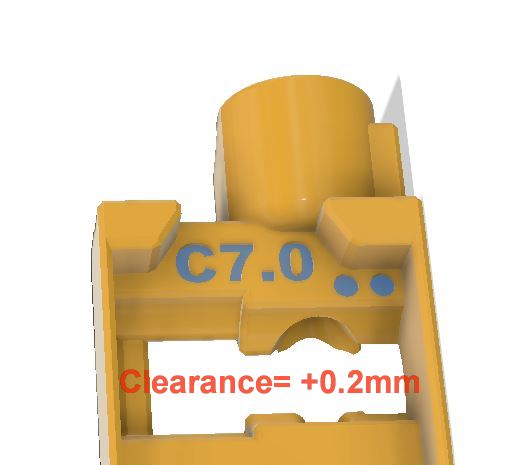

Revision C7.0 brings a few changes to the 3 main parts of Triple Decky.

- The big change is on the tophat that gives 2 alternatives.

- In one single part with a better support

- In 2 parts with one support only. The 2 parts are screwed together with M2x10 self tapping screws.

- This new revision applies only to the 3 positions servo. It will not be compatible with encoder that has the old magnets that were opening the gates on ERCF V1.1

- The filament path has 2 main changes

- It width is reduced by 1 layer (0.2mm) to make sure that they do not rub against each other in case the blocks are installed too tight together.

- The main support geometry is changed to be easier to print and removed.

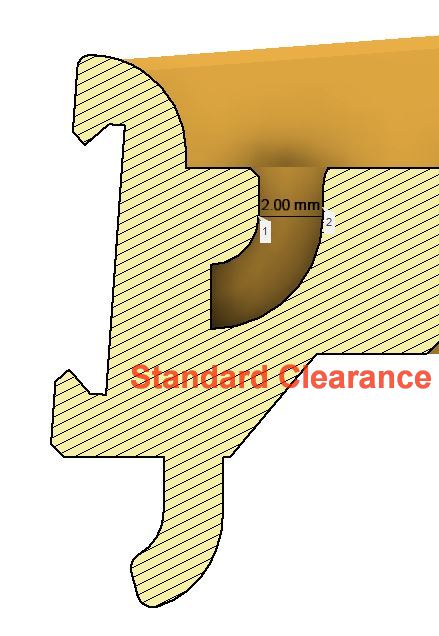

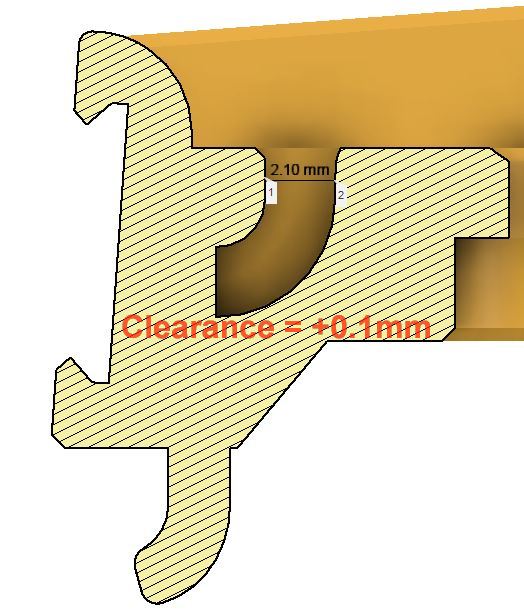

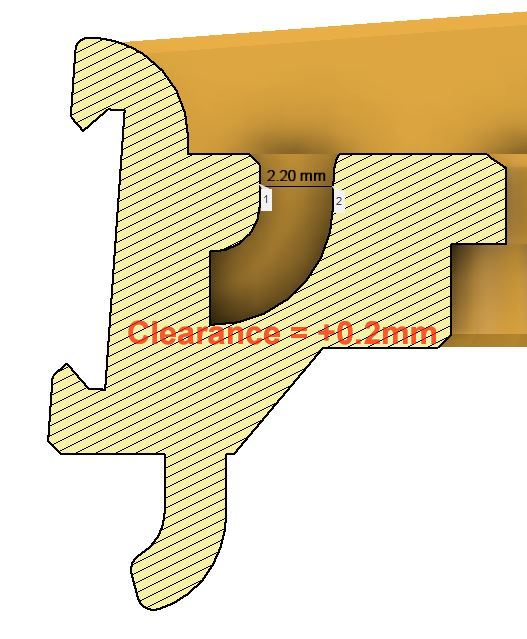

- Two optional clearance versions are available in the clearance option folder. This should make it easier to print with "not too well" tuned printers.

- the female hinge of Clearance1 is 0.1mm wider than the default part.

- the female hinge of Clearance2 is 0.2mm wider than the default part.

- The base has no significant changes beside the 2 clearance options. Also available in the clearance options folder.

- Tag plates are now available up to 15 gates.

- The big change is on the tophat that gives 2 alternatives.

On the clearance option parts, there are 1 or 2 dots beside the code "C7.0" for the 0.1mm and 0.2mm wider cavities.

-

No change in the main geometries. Only aesthetic change to blend better with filament path C6.3.

You can still find the Triple_Decky_Base_C6_0.stl in the archive folder.

-

New Filament Path Rev C6_3. Read more about it here. Aug 25, 2023

-

Triple Decky Rev C for 3 positions servo STLs. Make sure to read the Important Note Below first !!!

-

Triple Decky Rev. C. Read the details here

- ERCF V2 : at this moment, ERCF V2 is in development by a team of designers. Lots of things have been developed and are tested, but regarding the filament blocks, no decision have been taken on which version of Triple Decky or another type will be used.

- Mods in progress :

- Sturdy Bunny: https://github.com/sneakytreesnake/SturdyBunnyProject

- Springy: https://github.com/moggieuk/ERCF-Springy/tree/main

- Ejection Assisted Purge: https://github.com/bombela/EjectionAssistedPurge

- Binky: https://github.com/mneuhaus/EnragedRabbitProject/tree/main/usermods/Binky

- Mods in progress :

I have re-structured this GitHub to show only the latest versions of each type. All previous STLs are available in the Archives folder.

For each block you need :

-

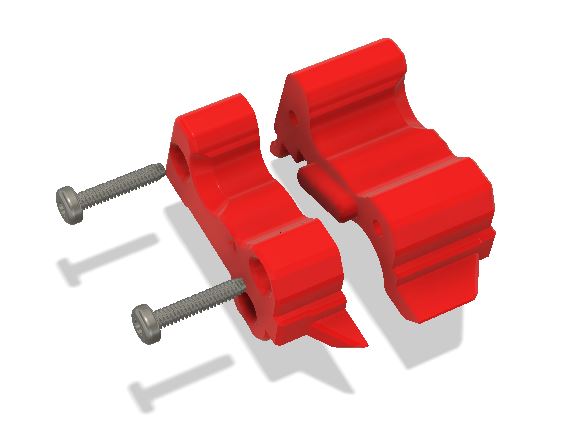

- 1 M3x8 SHSC (to mount the base on the 2020 extrusion)

- 1 M3x16 SHSC (to mount the latch on the base)

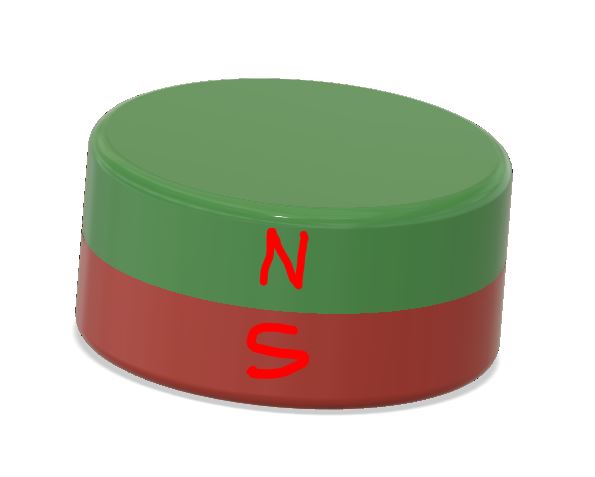

- 2 6x3 magnets (between the base and the filament path)

- 1 ECAS (on the filament path)

- 1 set of BMG (on the D-shaft in the base and in the top hat)

-

- 1 M3x8 SHSC (to mount the base on the 2020 extrusion)

- 1 M3x16 SHSC (to mount the latch on the base)

- 1 M3x3 set screw. Length: from 2 to 3mm (to install in the trap) (M3x2 can be found in BMG).

- 3 6x3 magnets (between the base and the filament path and at the back of the filament path)

- 1 ECAS (on the filament path)

- 1 set of BMG (on the D-shaft in the base and in the top hat)

-

- 1 M3x8 SHSC (to mount the base on the 2020 extrusion)

- 1 M3x16 SHSC (to mount the latch on the base)

- 1 M3x3 set screw. Length: from 2 to 3mm (to install in the trap) (M3x2 can be found in BMG).

- 2 6x3 magnets (between the base and the filament path)

- 1 ECAS (on the filament path)

- 1 set of BMG (on the D-shaft in the base and in the top hat)

- Optional : 2 M2x10 self tapping screws for the 2 parts tophat.

- Make sure your printer is well tuned, especially the first layer height. If it is too thick, the brake (trap) will be too thick and will not move freely inside the filament path.

- All STL were tested OK with ABS and ABS+

- Use voron standard print profile ( I use Andew Ellis ABS print profile).

- The hinged parts are the trickiest. Make a test with one set of parts to see if they fit together freely. Some users have reported that decreasing the "extrusion multiplier" by a few %, makes the parts go together much better.

- The 3 main parts are fitting together using a kind of hinge. They should fit together without filing and with a little bit of play.

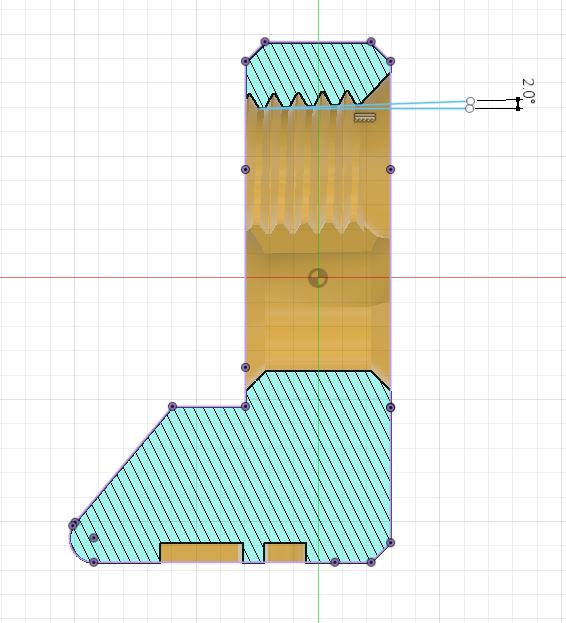

- For unknown reason, Super Slicer and Prusa slicer reports 6 open edges on the filament path STL. DO NOT try to fix it, otherwise you will have support that are filled up with infill and more than one perimeter thick.

- Make sure you have "Thin wall" enable, otherwise you won't have supports. Set also the speed for thin wall around 50% of the external perimeter speed.

- It is also better to print a few spare traps. The sides are quiet thin, and it could be possible to break one if you remove the filament path too often.

- If you plan to print the tag plates in multicolor :

- You already have a working ERCF, then no problem, just print them before assembling ERCF V2

- This is your first ERCF build. Then you have 2 possibilities.

- You can print them multicolor the old way, by changing color manually. The change of color is only 4 layers high, so it is not so difficult.

- You can print them after you have your new ERCF V2 working, and install them.

- On the base, you will have to shift each of the bases to allow the insertion of the tag plate

- On the Filament Path, just remove it, insert the tag plate and re-install the Filament Path.

-

All support should come off very easily.

-

There should be very little part cleaning necessary

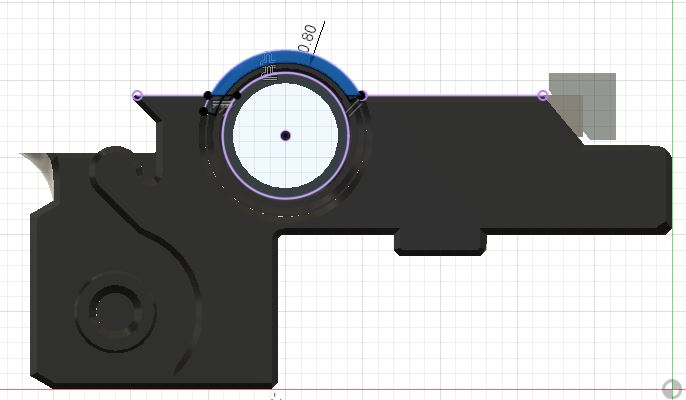

- Using a 2mm drill bit, clean the filament path

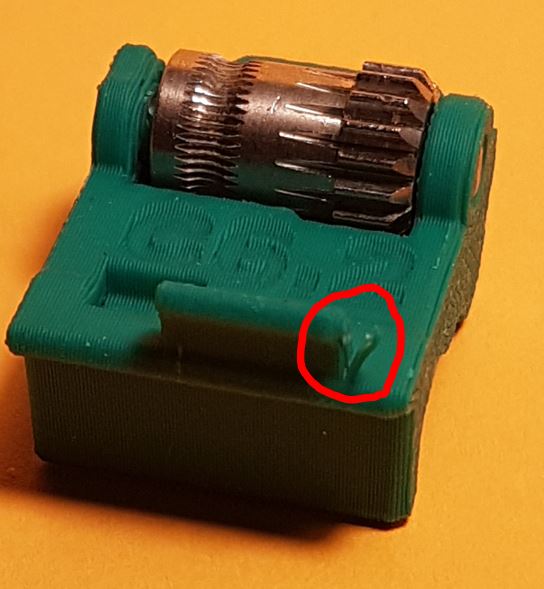

- using a needle file, clean the rectangular hole where the trap is going in on the filament path

- The trap part should have a thickness of 3.05mm, use a file to make it <= 3.05mm or tune your first layer.

- Make sure that the rectangular hole in the filament path Rev C is clean so the trap/brake can fit loosely in. There should be 0.5mm clearance.

- On the screw trap part you need to make sure that there are no plastic between the thread of the set screw and the filament. Use a sharp x-acto knive to open the space between the 2 holes.

- On Rev C with magnet brake release, make sure the hole for the back magnet is clean, the magnet should go down against the bottom of the hole.

- On the tophat up to version C6.2 it could be possible that depending on the type of ABS(+) you're using, the tophat does not move as freely as needed. To solve that, you can cut or file down one layer off from the tang on the support side. This is fixed in the next version C6.3. I only encounter that problem with my ESUN Green ABS+.

For all Triple Decky versions, when installing the blocks on the 2020 extrusion, it is not necessary to press the blocks firmly together. Just install them on the 2020 extrusion next to each other and tighten the screw. If you press them too much together, it is possible the filament pass does not move freely between their neighbors. This problem is solved in Revision C7.0

-

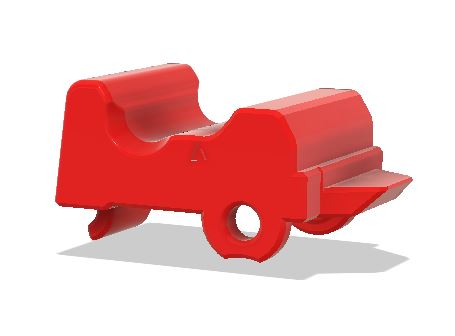

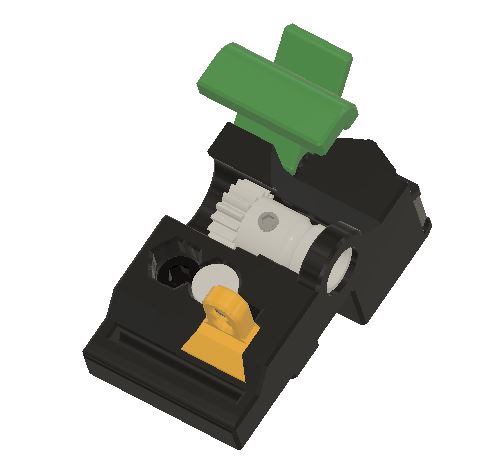

Rev B is self explanatory. The 3 parts goes together by sliding the tangs into the correponding cavities that makes the hinges.

-

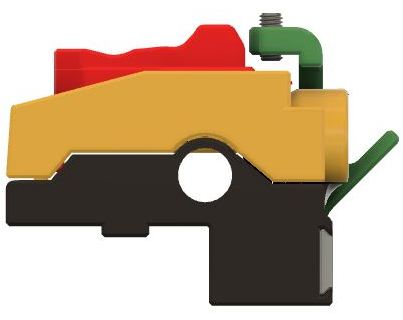

Rev C need a bit more attention to assemble the filament path on the base.

-

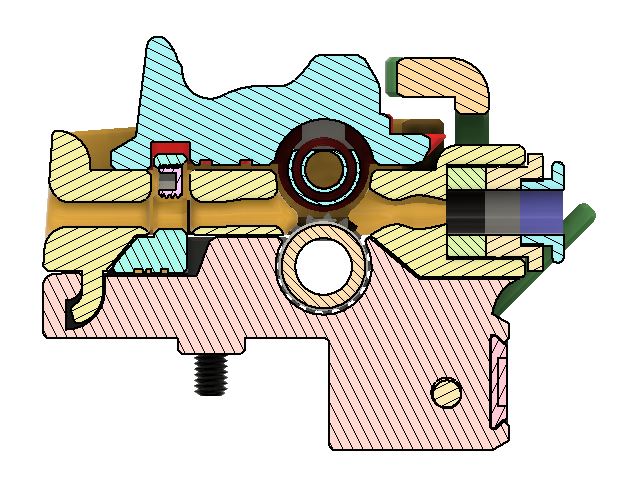

- Insert the M3x8 SHCS screw into the side hole of the base before installing the filament path. You will be able to access the screw through the filament pass later. (If you want to use 4 magnets, than you need to install the base on the 2020 extrusion before installing the magnets and filament path. 4 magnets are normally not necessary.)

-

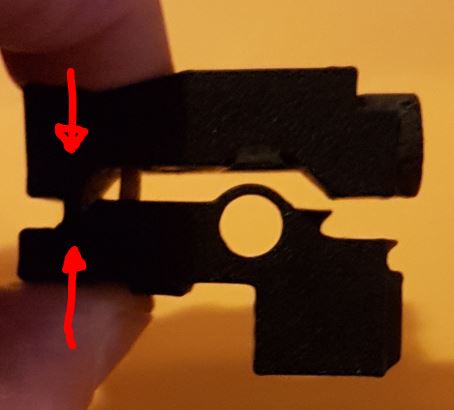

- Insert the magnet into the middle holes of the base and the filament path. The magnet must repell each other.

- Optionally, you can use another set of magnet into the side holes if needed. In that case, the screw will be unaccessible without disassembling the parts

-

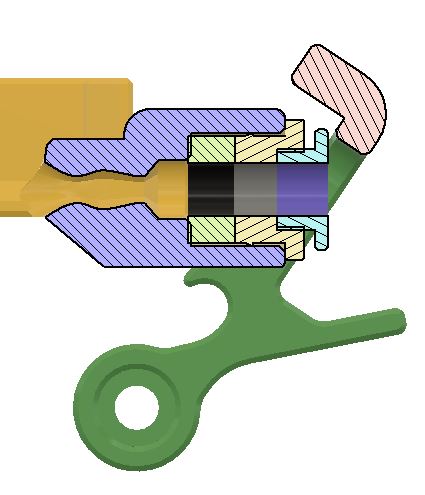

- Insert the trap into the female dovetail.

- If you use the screw trap, insert the set screw at a slight angle. The 2 holes are angled by about 2°. Insert the set screw in the top hole.

The set screw can be :- M3x3mm

- M3x2.5mm

- M3x2mm, the same that you can find in the BMG.

-

- Align the filament path above the base so they are parrallel and the top of the brake (trap) is "almost" inside his corresponding hole in the filament path and the tang of the hinge is just above the cavity of the base.

-

- Press firmly the filament path into the base. It snap into place easily.

-

-

Magnets orientation.

-

Assembling video.

This video shows how parts fits together out of the printer without any filing nor sanding. Then how Triple Decky works with one pair of magnets and the movement you should have at the back and front side. And finally how to install the trap.

It is an evolution of Rev B. with the following new features.

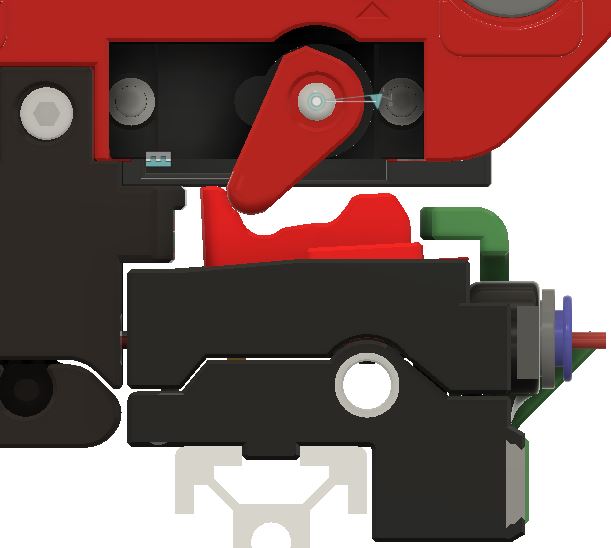

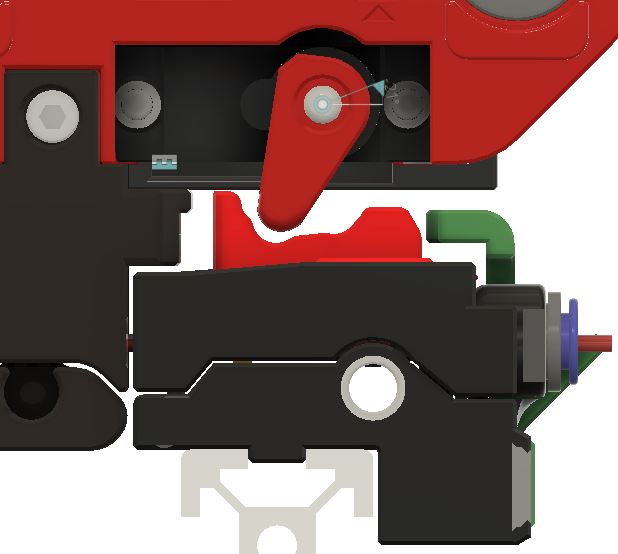

- It has a kind of brake to press against the filament when the gate is not selected. The exit side of the filament path can lift up about 0.5 mm, enough to make the filament touching the brake part (trap). To release the brake it will use either :

- with a magnet that will be pushed back by the encoder magnet.

- by using a special tophat that will need a 3rd position of the servo to be able to move the selector. (software in development)

- The brake part will be easily replaceable in case it breaks.

- The multi-color tag plates will be the same for input and output side. (Same as in version B4 Base)

- The use of the old magnetic gates will be impossible on that version.

- If you are using Happy Hare software, you should decrease the "parking_distance" in the ercf_parameters to about 15 so the filament parks inside the trap.

- It is normal that the filament does not pass the trap when inserted manually. When the gate will be selected, Happy Hare will load it without problem. If you want to lock it inside the trap, than you need to push down the exit side of the filament path with your finger and insert the filament about 5 mm further.

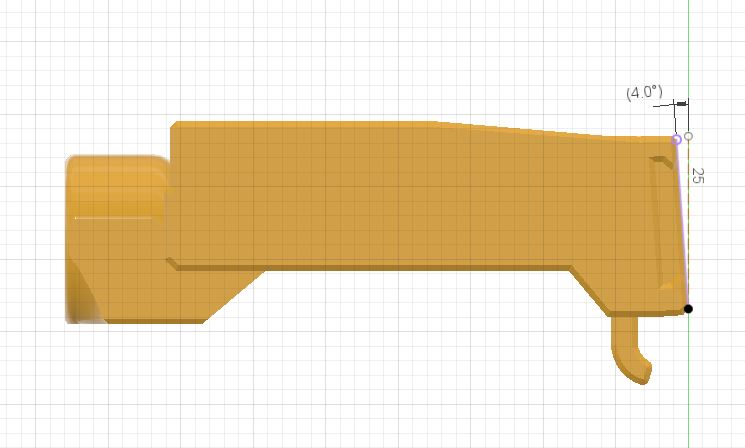

This update concern all Filament Path revision B and C for Sturdy Bunny. The ECAS is moved 4mm out to enable the insertion of the PTFE tube inside the part. I recommend to use it over the previous versions.

-

This allow for easy threading of the filament and keeps also the geometry for Endless Spool function.

-

It avoids the ECAS to go slowly out of its cavity after some time.

This is an update from Rev C5 that fixes the following issues:

-

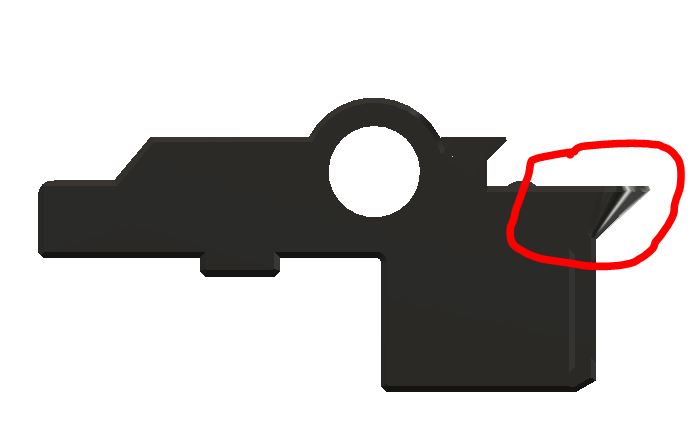

wall around the bearing cracks

-

filament path output side rubbing on the encoder and get pushed down.

-

It has the following new feature :

-

Warning: * C6_x base need to have C6_x filament path * C6_x filament path need to have C6_x tophat * C5_x base is compatible with C6_x filament path * C5_x filament path is compatible with C6_x tophat * For all Rev C, only the integrated tophat are available, and needs the Springy servo holder to work. (see above in mods in progress)

-

This version uses the servo to push the filament path down so the filament is free to move when the gate is selected.

-

When the gate is not selected, the filament will be hold still by the trap.

-

New integrated tophat based on number 1 tophat locker to be used with Springy from Moggieuk

-

If you want to use the C6 with 3 positions servo YOU HAVE TO USE the latest Happy-Hare software (HHv2) that support the servo 3rd position. It is public now. Otherwise IT WILL NOT WORK.

You need also to update KlipperScreen for Happy Hare. -

The base is the same for both Rev C versions (Triple_Decky_Base_C6_3.stl).

-

The taps are the same for both Rev C versions (Traps folder).

-

If you are already using the magnet version, you can still use it if you print the universal tophat ([a]Triple_Decky_Tophat-integrated_Universal_Mag&3PS_C6_3.stl). DO NOT USE THIS STL IF YOU DO NOT HAVE ENABLED THE 3rd POSITIONS FOR SERVO IN YOUR SOFTWARE!!!

You must have the servo_move_angle defined in the mmu_parameters.cfg -

If this is your first use of Rev C 3PS, then it is better to use the dedicated tophat for 3PS ([a]Triple_Decky_Tophat-integrated_3PS_C6_3.stl).

-

For better results, you should use the special servo arm with rounded edges for this repo (Servo Arm MG90S_for_3PS.stl or Servo_Arm_Savox_for_3PS.stl) .

-

Software parameters

-

Add "servo_move_angle: (move position angle)" in mmu_parameters.cfg

- For MG90S

- servo_move_angle: 45

- servo_up_angle: 24

- servo_down_angle: 115

- For Savox SH0255MG

- servo_move_angle: 95

- servo_up_angle: 115

- servo_down_angle: 45

- For MG90S

-

Change the "encoder_parking_distance:" in mmu_parameters.cfg so the filament parks in the trap. (for me I change it to 15, it was 23)

-

-

Servo positions

Make sure to adjust the 3 position of your servo arm so the arn does not hit the tophats when the selector is moving. See picture below to fiind out where the position should be for the 3 positions.- Servo Up. (trap released / print without sync)

- Servo Move. (trap locked / selector movement)

- Servo Down. (trap released for Load/unload or print with sync mode)

-

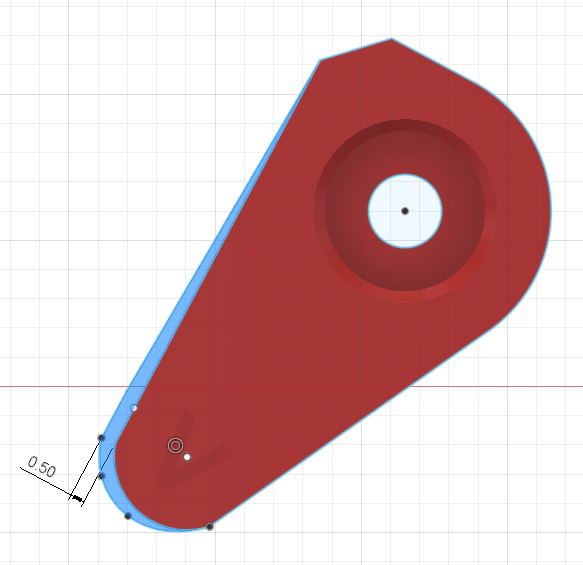

Servo arm geometry for 3 positions servo

The servo arm is based on the Springy servo arm. To have a better effect when using the 3 positions servo, the geometry is modified as shown on the picture below. The blue area shows the added part. This make the "UP" position pushing a bit more to release the trap. The length is also increased by about 0.3mm in the "DOWN" position. It is, therefore, better to use it with Springy from @moggieuk. This version is available for MG90S and Sävox SH-0255-MG in the "Rev_C/Filament_Path_for_3_position_Servo" sub-directory of this repo.

.

- Servo splines differences The servo arm splines are different between the MG90S (blue shade on the picture) and the Sävox SH-0255-MG (in red on the picture). Be sure to use the arm the matches your servo.

-

This version uses the encoder magnet to push the filament path down so the filament is free to move when the gate is selected.

-

When the gate is not selected, the filament will be hold still by the trap.

-

New integrated tophat based on number 1 tophat locker to be used with Springy from Moggieuk

-

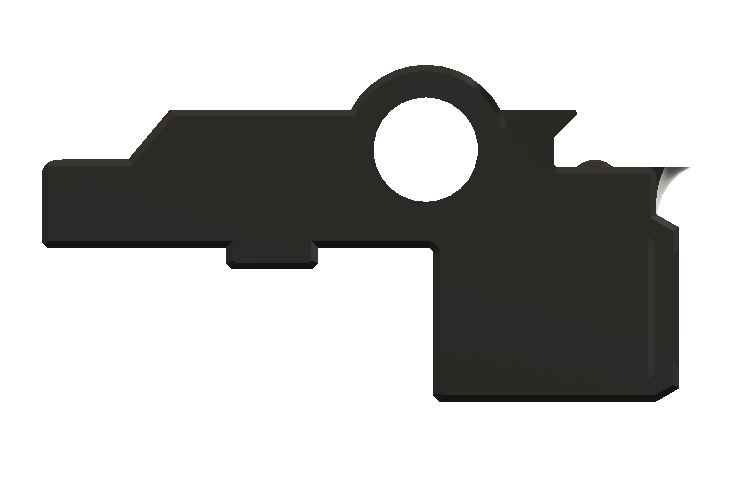

The output side of the filament path has been tilted by 4° to avoid rubbing on the encoder when the selector is moving.

-

The input side tag plate is rotated 90° for better printing without support.

-

New multicolor tag plates for 12 carts on the input side.

-

New multicolor gate plates for 12 carts on the output side to replace the magnetic gate.

-

New integrated tophat based on number 1 tophat locker to be used with Springy from Moggieuk

-

optional base to use the old magnetic gates. In that case, the small part of the hinge of the filament path must be cut at the mark.

-

The latch has an optional set screw to apply a little bit of friction on the filament. This help the filament to stay still in case of vibrations.

-

Since this version has no real brake system. It is better to use a single loop buffer system that provide more stability of the filament when it is in the buffer.

-

This is for the original design that is build with M5 all threaded rod. This version will not be developed further because almost all users / builders are moving to Sturdy Bunny, or the coming (soon) ERCF V2.