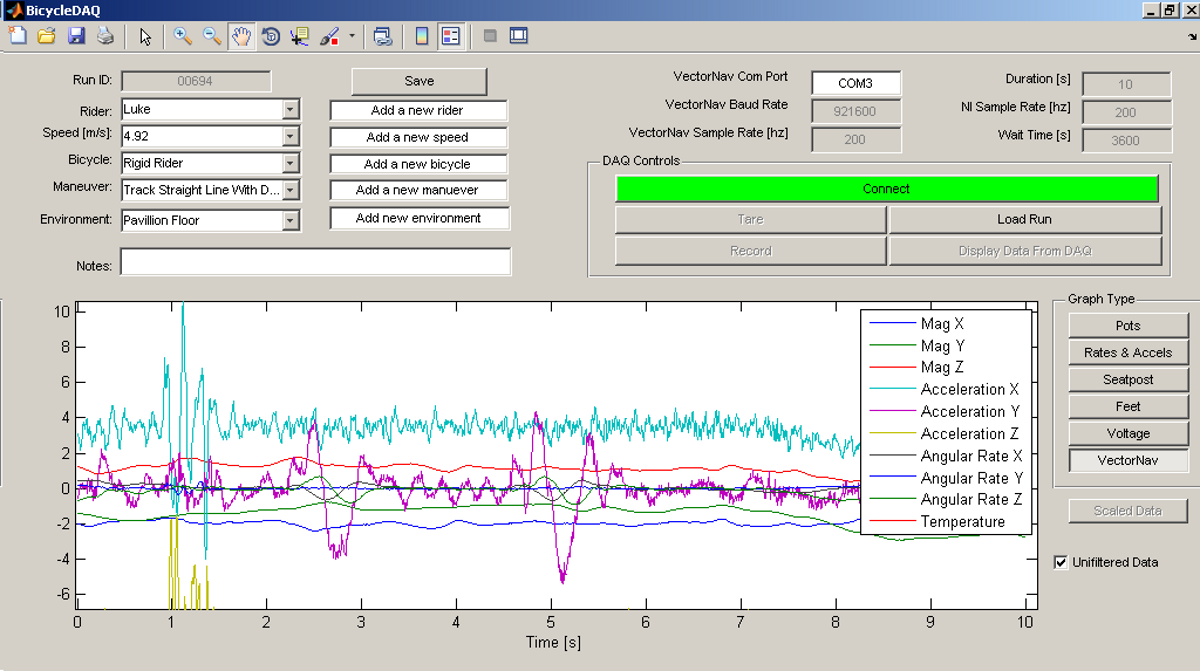

This a simple graphical user interface used to collect data on the Davis Instrumented Bicycle. The software connects to both a National Instruments USB-6218 and a VectorNav VN-100 development board through USB connections in a laptop PC. It makes use of the Matlab Data Acquisition Toolbox, NIDAQmx driver, and the Matlab Serial interface to collect data from the devices.

BSD 2-Clause License, see LICENSE.txt.

If you make use of this software we kindly request that you cite our work, either [Moore2012], the relevant DOI, and/or other relevant references.

These dependencies are not necessarily that strict but were the only ones the software was tested with.

- ASUS Eee PC 1001P-MU17-WT

- VectorNav VN-100 Development Board

- National Instruments USB-6218

- Davis Instrumented Bicycle

- Windows XP Pro

- Matlab (7.8.0 R2009a) + Data Acquisition Toolbox

The GUI can be run by simply starting the Matlab interpreter from the root directory of this repository and calling the main script:

$ matlab >> BicycleDAQ.m

Meta data and recording settings for the trial can be specified in the various

input cells. To initialize the system and connect to the two hardware devices,

press the "Connect" button. Once the system is connected, the "Tare" button

will tare the VN-100. When ready to start a trial press the "Record" button and

the system will wait for the handlebar button trigger to be pressed. Once the

trigger is pressed, data will be collected for the specified duration and be

automatically saved to disk in a local data/ directory. After the

recording, the time series traces can be inspected in the graph window by

selecting the different graph type buttons. Once recording of all the trials in

a session are completed, the "Disconnect" button will disconnect from the

hardware. Finally, the GUI window can be closed.

When not recording any previously recorded .mat file can be loaded for

graphical inspection. The meta data for that file can also be edited and

overwritten with the "Save" button.

There are three sensors that require periodic manual calibration: the steer

angle potentiometer, the roll angle potentiometer, and the pull force load

cell. Typically, all three should be calibrated before each trial session and

at any point when there may be reason to think the sensors are no longer

calibrated. There is a single script in the tools/ directory that can

calibrate each sensor using a static procedure. The script can be run with:

$ cd tools $ matlab >> calibrate.m

A simple UI will guide the user through the calibration process. Details of the

calibration procedure can be found in the comments of calibrate.m and in

the dissertation chapter on the Davis Instrumented Bicycle. Each calibration

saves a .mat file to disk, described below, in the data/CalibData

directory.

Sample data collected with this software for a set of experiments can be downloaded from Figshare:

Trial Data: http://dx.doi.org/10.6084/m9.figshare.1164632

Calibration Data: http://dx.doi.org/10.6084/m9.figshare.1164630

After a trial is collected via the GUI interface, the resulting .mat file

is stored in the data/ directory with a filename XXXXX.mat where

XXXXX is a unique sequential 5 digit number for that trial. Each .mat

file contains several variables described in the following sections.

A structure which contains key value pairs that map chars representing column

headings for the NIData matrix to integer values which correspond to a pin

number on the NI USB-6218.

PushButton: 0SteerPotentiometer: 1HipPotentiometer: 2LeanPotentiometer: 3TwistPotentiometer: 4SteerRateGyro: 5WheelSpeedMotor: 6FrameAccelX: 7FrameAccelY: 8FrameAccelZ: 9SteerTorqueSensor: 10SeatpostBridge1: 11SeatpostBridge2: 12SeatpostBridge3: 13SeatpostBridge4: 14SeatpostBridge5: 15SeatpostBridge6: 16RightFootBridge1: 17RightFootBridge2: 18LeftFootBridge1: 19LeftFootBridge2: 20PullForceBridge: 21ThreeVolts: 22FiveVolts: 23RollPotentiometer: 24

An N x M matrix of doubles containing the time histories of the signals

collected by the NI USB-6218 DAQ box. N is the number of samples and M is the

number of signals. The columns correspond to the values in InputPairs plus

1 (for Matlab 1 indexing).

A structure which contains key value pairs of the primary meta data for the trial.

AccelerometerCompensation, char- This is the raw char from the VN-100 that gives the programmable compensation parameters for the accelerometers.

AccelerometerGain, char- This is the raw string from the VN-100 that gives the programmable gain for the accelerometers.

ADOT, 1 x 1 double- Asynchronous Data Output Type. This tells you what the asynchronous output

is of the VN-100. It can either be

14or253.14is the Kalman filtered data and253is the unfiltered. Refer to the VN-100 documentation. Baudrate, 1 x 1 double- This is the baud rate at which the VN-100 is connected at.

Bicycle, char- The gives the bicycle name and/or configuration.

DateTime, char- The date and time of data collection. Formatted as

DD-Month-YYYY HH:MM:SS. Duration, 1 x 1 double- The duration of the run in seconds.

Environment, char- This is the location, building and/or equipment where the data was taken.

Options include:

'Pavilion Floor','Laboratory','Hull Treadmill'. FilterActiveTuningParameters, char- This is the raw char from the VN-100 that gives the programmable active tuning parameters for the Kalman filter.

FilterTuningParameters, char- This is the raw char from the VN-100 that gives the programmable Kalman filter tuning parameters.

FirmwareVersion, char- This is the raw char from the VN-100 displaying the device's firmware version.

HardSoftIronParameters, char- This is the raw char from the VN-100 that gives the programmable hard/soft iron compensation parameters.

HardwareRevision, char- This is the raw char from the VN-100 displaying the device's hardware version.

Maneuver, charThe particular maneuver being performed. Some options are:

'System Test': This is a generic label for data collected during various system tests.'Balance': The rider is instructed to simply balance the bicycle and keep a relatively straight heading. The rider should look into the distance and not focus on any close objects.'Balance With Disturbance': Same as 'Balance' except that a lateral force disturbance is applied to the seat of the bicycle.'Tracking Straight Line': The rider is instructed to focus on a straight line that is on the ground and attempt to keep the contact point of the front wheel aligned with the line. The line of site from the rider's eyes to the line on the ground should be tangent to the front of the front wheel.'Tracking Straight Line With Disturbance': Same as'Tracking Straight Line'except that a lateral perturbation force is applied to the seat of the bicycle.'Lane Change': The rider is instructed to perform a lane change trying to keep the bicycle on a line on the ground. For the Pavilion Floor, the line is taped on the ground and the rider is instructed to do whatever feels best to stay on the line. They can use full preview looking ahead, focus on the front wheel and line, or a combination of both.'Steer Dynamics Test': These are for the experiments setup to determine the friction in the steering column bearings.

ModelNumber, char- This is the raw char from the VN-100 displaying the device's model number.

NISampleRate, 1 x 1 double- The sample rate in hertz of the NI USB-6218.

NINumSamples, 1 x 1 double- The number of samples taken during the run on the NI USB-6218.

Notes, char- Notes about the run.

ReferenceFrameRotation, char- This is the raw char from the VN-100 that gives the programmable direction cosine matrix.

Rider, char- This gives the first name of the person riding the bicycle or 'None' if no one is on the bicycle while the data was taken.

RunID, 1 x 1 double- The unique five digit number for the run.

SerialNumber, char- This is the raw string from the VN-100 displaying the device's serial number.

Speed, 1 x 1 double- The desired speed of the bicycle during the trial. This is slightly redundant, the rear wheel speed motor voltage should be used for the actual speed.

VNavComPort, char- The Windows communications port that the VN-100 is connected to. This is

typically

'COM3'but could be others. VNavSampleRate, 1 x 1 double- The sample rate in hertz of the NI USB-6218.

VNavNumSamples, 1 x 1 double- The number of samples taken for the run on the VN-100.

Wait, 1 x 1 double- This is the time in seconds that the software waits for the rider to press the collect data trigger. If the rider doesn't push the button before this time, the program crashes due to software limitations.

This cell array contains the ordered names of the data signals collected from

the VN-100. These depend on what par.ADOT is set to.

For par.ADOT = 253, only the raw measurements are returned:

- Mag X

- Mag Y

- Mag Z

- Acceleration X

- Acceleration Y

- Acceleration Z

- Angular Rate X

- Angular Rate Y

- Angular Rate Z

- Temperature

For par.ADOT = 14 the Kalman filtered data is returned:

- Angular Rotation Z

- Angular Rotation Y

- Angular Rotation X

- Mag X

- Mag Y

- Mag Z

- Acceleration X

- Acceleration Y

- Acceleration Z

- Angular Rate X

- Angular Rate Y

- Angular Rate Z

A matrix of doubles containing the time histories of the signals collected by

the VN-100. N is the number of samples and the VN-100 reports 10 or 12 signals.

This is a lightly processed version of VNavDataText. This data has NaN

values for any corrupt lines from VNavDataText.

An N x 1 cell array of chars which contain the RAW ASCII strings output by the VN-100 at each of the N samples. Some lines are corrupted and the array may be approximately equal to N, as some corrupted lines are interpreted as 2 corrupt samples.

After a calibration is collected via the tools/calibrate.m script, the

resulting .mat file is stored in the data/CalibData directory with a

filename XXXXX.mat where XXXXX is a unique sequential 5 digit number

for that calibration. Each .mat file contains several variables described

in the following sections.

Each file contains a single structure named data and it contains the

following variables:

accuracy, char- The absolute accuracy of the measurement in in calibration, e.g.

'0.1'. calibrationID, char- The string representation of the unique 5 digit calibration identification

number, e.g.

'00015'. name, char- The name of the sensor being calibrated, e.g.

'PullForceBridge'. notes, char- Any notes about the specific calibration, e.g.

'redoing calibration'. offset, 1 x 1 double- The y-intercept for the best linear fit of the voltage to sensor output

curve, e.g.

-95.1499. rsq, 1 x 1 double- The R-Squared value of the best linear fit, e.g.

1.0000. signal, char- The name of the sensor output, e.g.

'PullForce'. slope, 1 x 1 double- The slope of the best linear fit of the voltage to sensor output curve, e.g.

32.7438. timeStamp, char- The date and time of the calibration, e.g.

'29-Aug-2011 15:48:22'. x, 400 x n double- The NI USB voltage recorded for a 2 second duration at 200 hz (400 samples) at each of n data collection points.

y, n x 1 double- Either the known angle or known load applied to the sensor at each of the n data collection points.

v, n x 1 double- The sensor power supply voltage recorded for a 2 second duration at 200 hz (400 samples) at each of n data collection points.

units, char- The units of the recorded known angle or known load, e.g

'pound'. calibrationSupplyVoltage, n x 1 double- The mean voltage supplied to the sensors for power during each sampling, e.g

5.0. runSupplyVoltage, 1 x 1 double- The voltage that should be assumed for the sensor power during an actual

trial. This is used only if the power supply voltage is not measured for

this sensor in during trials, e.g.

5.0. runSupplyVoltageSource: char- The label of the voltage channel which measures the sensor's power source.

e.g.

'na'or'FiveVolts'. sensorType, char- The type of sensor, either

'LoadCell'or'potentiometer'.

This material is partially based upon work supported by the National Science Foundation under Grant No. 0928339. Any opinions, findings, and conclusions or recommendations expressed in this material are those of the authors and do not necessarily reflect the views of the National Science Foundation.

| [Moore2012] | Moore, J. K. Human Control of a Bicycle. University of California, Davis. 2012. |