OPCB is a device that functions as MODBUS RTU <> MODBUS TCP converter. It connects the industrial equipment (RS-485) to the internet (TCP/IP).

OPCB is used to connect:

- Refrigeration controllers;

- HVAC systems controllers;

- Agricultural smart devices;

- Power network relays, meters, and other electrical equipment;

- Industrial IoT devices;

- Industrial sensors and meters;

- Any other MODBUS-compatible electronics.

OPCB can be acquired as a product from www.overvis.com or manufactured by anyone using any single-board computer. This set of files automatically installs OPCB runtime and is tested with:

OPCB can be used as a stand-alone device, but its main goal is to be compatible with the Overvis monitoring system. In conjunction with Overvis it provides:

Data collection:

- Gather operational data points (any numeric values) from your equipment.

- Store history of operational data, get insights and analytics.

- Collected data is fully exportable (Excel, CSV).

- Hazard Analysis Critical Control Point (HACCP) reporting.

SMS and email notifications:

- Configure alarms for operational parameters thresholds or connection errors.

- Set up a “chain of responsibility” requiring alarm confirmations from personnel and escalating them in the absence of response.

- All alarm actions are logged and ready for review.

Real-time monitoring and control:

- Create dashboards with real-time information received from the equipment.

- Visualize the data using open SVG format.

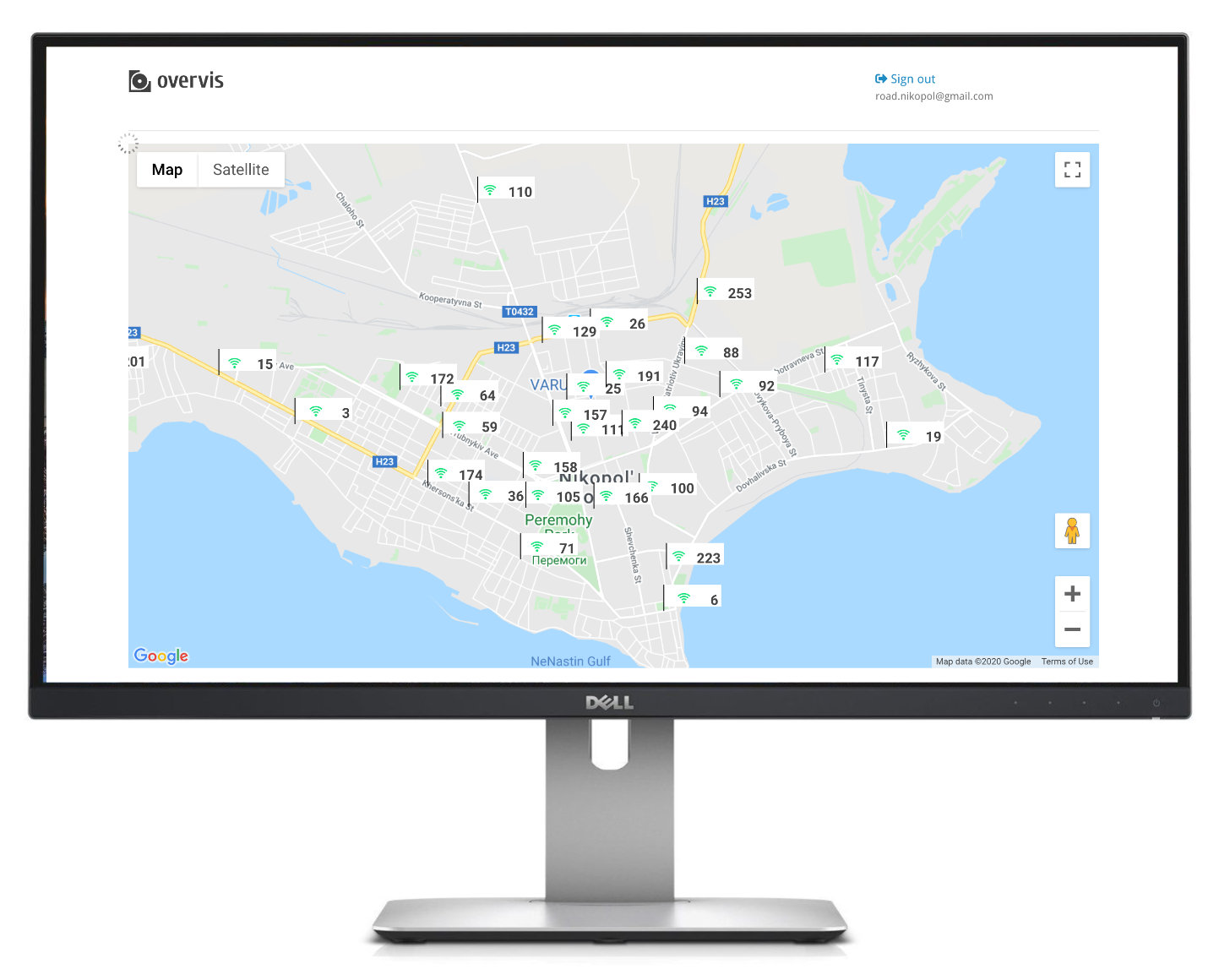

- Use Google Maps API to display objects’ locations.

- Use JavaScript and Overvis API to set up quick action controls for operation personnel.

And more:

- Use templates to quickly create devices and alarms.

- Manage access levels for different accounts inside one organization.

- Works with dynamic IPs and bypasses firewalls.

- Optimized mobile access.

- Industry-standard encryption.

- Overvis API allows the automation of control and can be used to load data into other management systems.

- MODBUS RTU/TCP converter.

- Built-in Overvis cloud support (www.overvis.com).

- Serving as TCP server or client, MODBUS RTU master or slave.

- RS-485 network extension.

- MODBUS ASCII mode support.

- Supporting LAN and/or Wi-Fi connection.

- Optional 3G/LTE connection using an external USB modem.

- Wi-Fi Access Point mode.

- Web-interface, accessible from the local network or via WiFi Access Point.

- Remote configuration (using MODBUS or web-interface).

- RS-485 network settings: baud rate, parity, response timeout.

- Multiple RS-485 networks support.

- MODBUS request debugging tools.

- Automatic or manual firmware update.

- HTTP API.

Required hardware:

- Single board computer. Orange Pi PC Plus is recommended for now.

- Micro SD card, 4GB or more.

- High-quality 2.5A micro USB power supply

- Any USB<>RS485 converter (e.g., https://www.amazon.com/Industrial-USB-RS485-Converter-Communication/dp/B081MB6PN2)

Optional hardware:

- If LAN connection is required: RJ45 (Ethernet) cable.

- If the mobile network connection is required: 3G/LTE USB modem with a local carrier SIM card.

- For debugging console in case of network connection issues: USB-RS232TTL 3.3V CH340 with pin connection cords (e.g., https://robotdyn.com/usb-serial-adapter-ch340g-5v-3-3v.html)

- Plastic case.

TODO: hardware connection schematic

- Boot the single board computer from the SD card with a fresh OS installation.

- Login to single board computer remotely using SSH or using the debugging console with USB-RS232TTL. Make sure that the computer has the access to the internet.

- Run the following Bash command:

sudo git clone --branch opcb --single-branch https://github.com/overvis/opcb-release.git /opcb && sudo /opcb/install.shEnter the password if requested.

After this command completes, OPCB services should be installed and running. Device's Wi-Fi will be

switched to Access Point mode with the name OPCB_XXXXXX where XXXXXX is the last characters of

the device's MAC address. By connecting to this Wi-Fi (without password) user can access OPCB

web-interface by using the address: http://setup.overvis.com/ or http://192.168.4.1/

TODO: web interface screenshot.

Connect your equipment to the USB<>RS485 converter and insert it into the single board computer with the OPCB services running. Consult your equipment manual for RS-485 connection.

TODO: expand this section with examples, debugging howtos and the supported equipment list.

TODO

OPCB runtime is installed as a systemd service opcb. Start, stop or restart this service as

needed.

To check the OPCB runtime log use this command:

journalctl -u opcbLog level can be changed in the OPCB configuration in the file runner-config.json.

OPCB follows semantic versioning. Each version is tagged in this repository

with a tag in the format OPCB/A.B.C

The current version of the OPCB services is displayed on the bottom of the configuration web interface page or can be accessed through the API.

Please use GitHub issues to report any errors or ask questions. We plan to release the OPCB source code as soon as it is documented.

See LICENSE