SMD Soldering Station / Hotplate

WARNING! If you have no experience wiring mains, do not proceed with this project. USE THIS INFORMATION YOUR OWN RISK!!

Support my projects ❤️

It takes me countless hours to prepare and document my projects. You can support me by reading/recommending my books. Thank you!

License

See License file. GPLv3.

Introduction

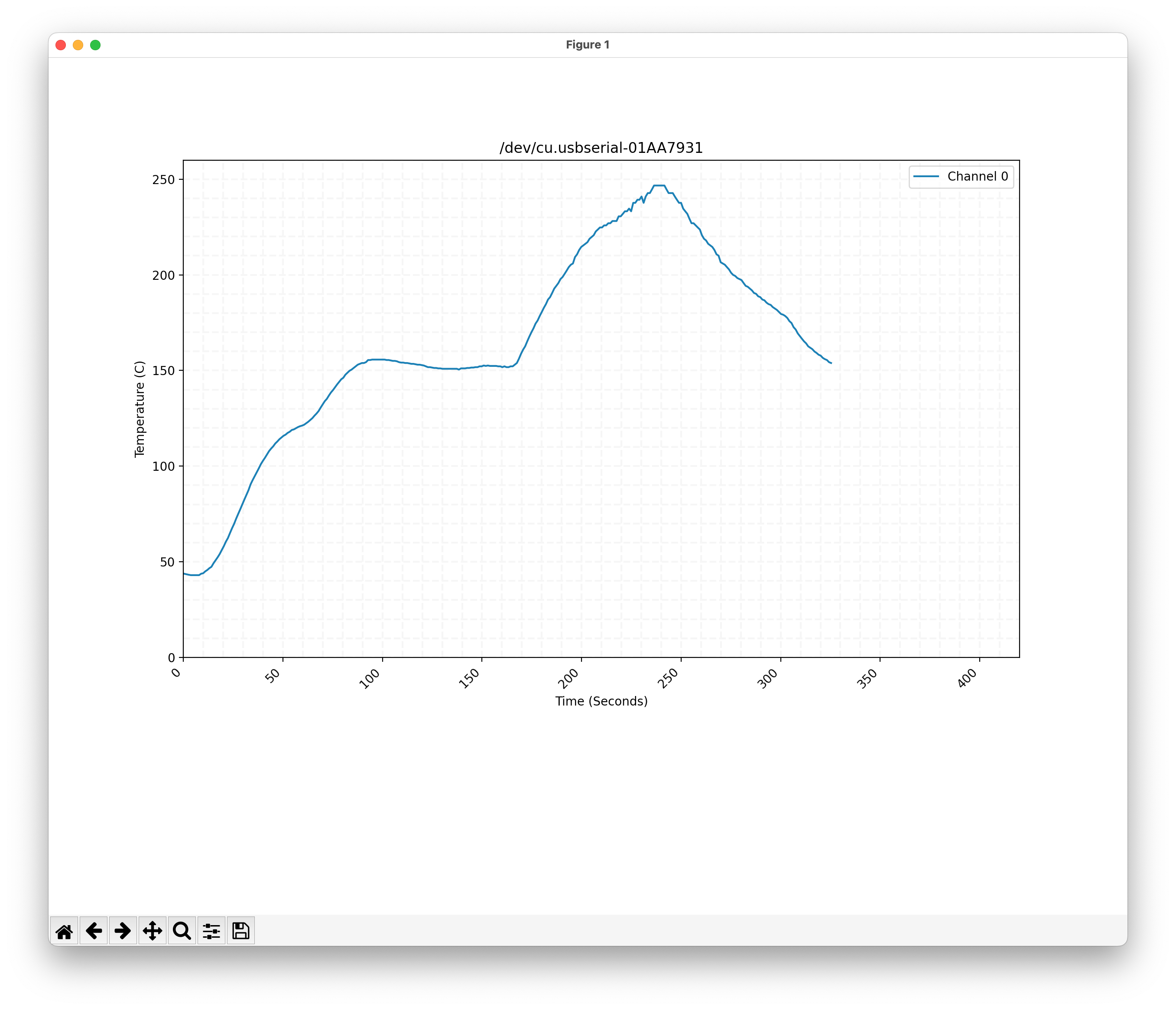

This is a project to build a DIY PID controlled hotplate. This includes a python script to create a temperature chart and a tiny PCB to extend a TTGO 1.3" OLED shield as a controller.

- ESP8266 OLED board: https://www.aliexpress.com/item/32854542718.html

- SMD Hot plate, maybe something like this: https://www.aliexpress.com/item/1005003120565125.html

- SSR-25 DA Solid State Module

- Hot plate adapter board: see

hardware/for KiCAD sources, or order here: https://aisler.net/p/AJJEAEVL - 1x4.7k, 1x10k 0603 resitor

- 1x100k Thermistor (from my 3D printer)

- 2x8pin female header

- 3x2pin JST-XH 2.50mm

- Code: see

firmware/

firmware

Open the folder firmware/ with Visual Studio Code and install recommended plugins. You can find VSC here: https://code.visualstudio.com

The trickiest part was to get the temperature readings correct.

I had the best results using the Stein-Hart model to obtain correct temperature readings (which only works above 40C, but as we want to solder somethings, this should be OK ;) ). If you are using a different setup, you will need to adapt the line in main.cpp, using values derived with this tool: https://www.thinksrs.com/downloads/programs/therm%20calc/ntccalibrator/ntccalculator.html

SteinhartHart sh(SENSOR_PIN, 4700, 1.719817401e-3, 0.3527370551e-4, 10.70472184e-7);The software has two modes: constant temperature and reflow. You can adapt the reflow curve by changing the setup code. The constructor takes the label of the phase, the temperature in C, how long to hold the temperature in millis, and the kP factor (higher value = more agressive heating = overshooting). I've set the kP high to quickly reach the max temp at end of the reflow phase:

void setupTempControl() {

tempControl.add(new TempStep("heatup", HEATUP, 120, 1 * 1000, 1.0));

tempControl.add(new TempStep("soak", HEATUP, 150, 80 * 1000, 1.5));

tempControl.add(new TempStep("reflow", HEATUP, 230, 1 * 1000, 3.0));

tempControl.add(new TempStep("reflow", HEATUP, 245, 3 * 1000, 10.0));

tempControl.add(new TempStep("cooldown", COOLDOWN, 50, 10 * 1000));

}hardware

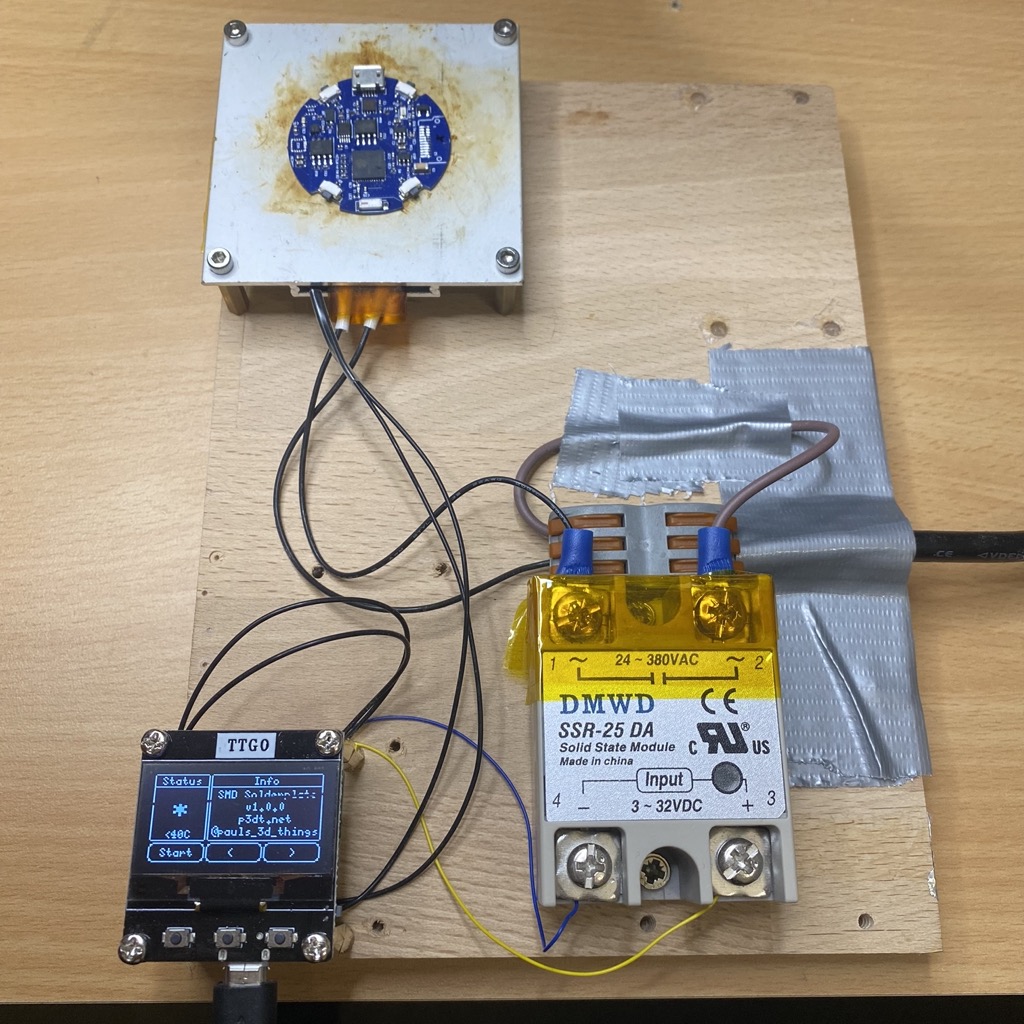

The overall setup could look like this, the setup below is only for educational purposes:

DO NOT LEAVE THE MAINS VOLTAGE TERMINALS EXPOSED!!

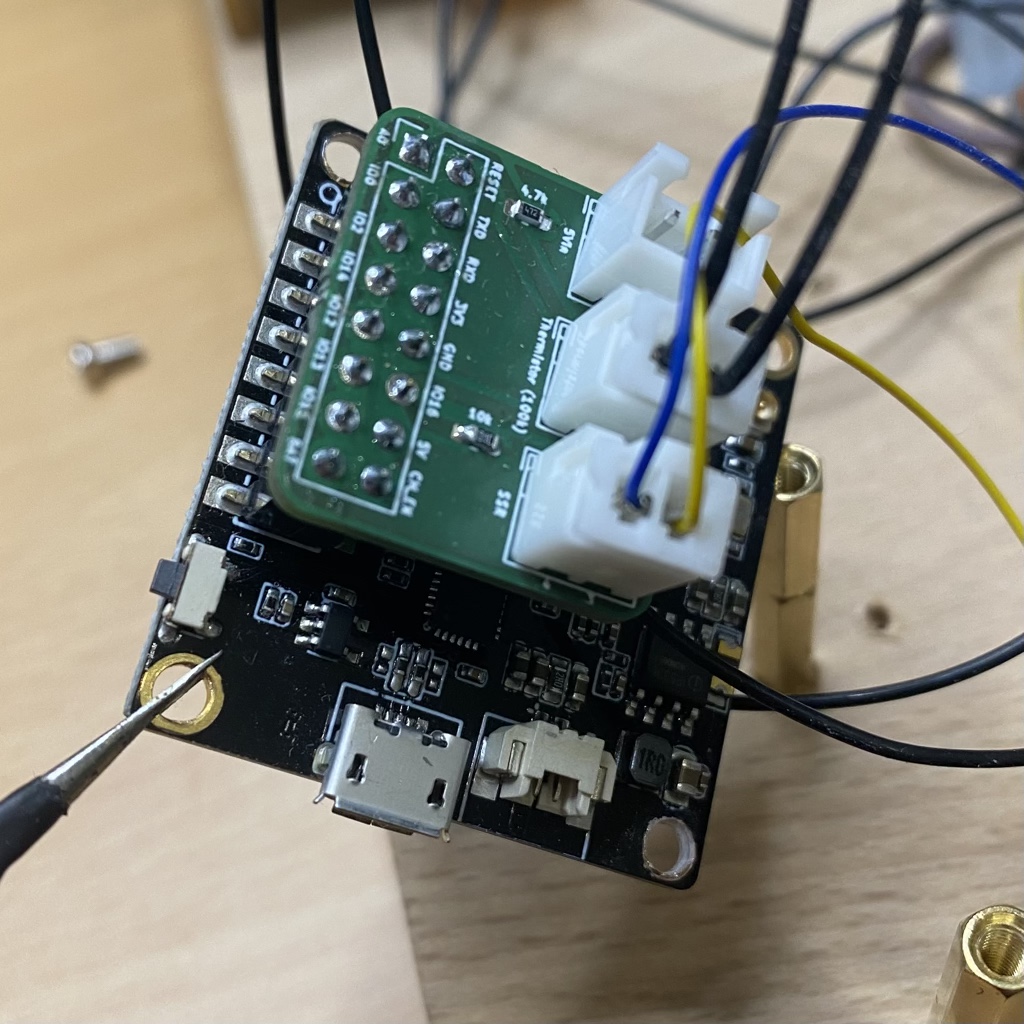

I used the following adapter to connect everything to the EPS8266 board:

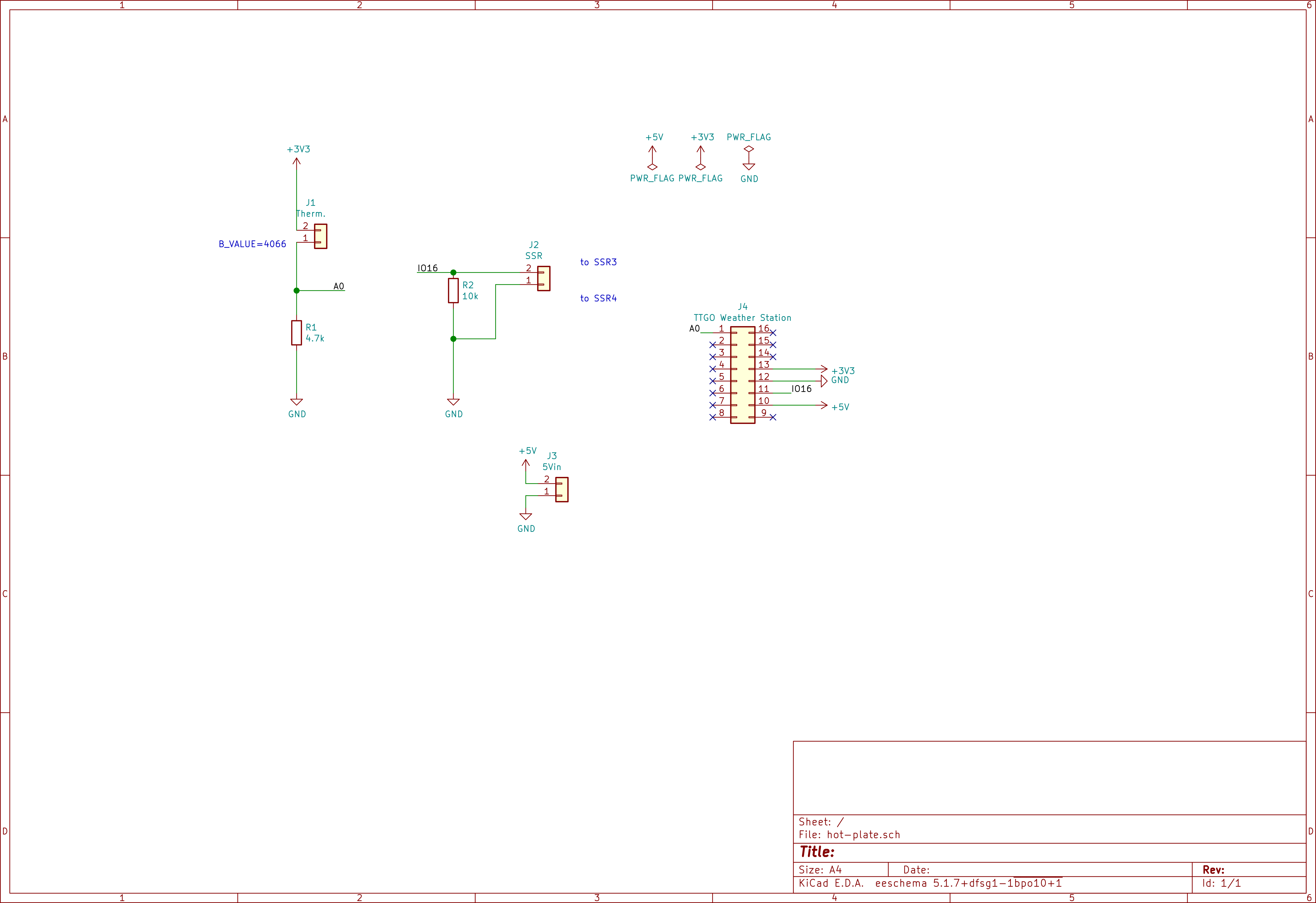

The schematics:

serial-plotter

Requires Python

pip3 install matplotlib

pip3 install pyserialUsage:

python3 main.py /dev/cu.usb... 115200On Error: can't import serial

If the import serial fails

pip3 uninstall serial

pip3 uninstall pyserial

pip3 install pyserial