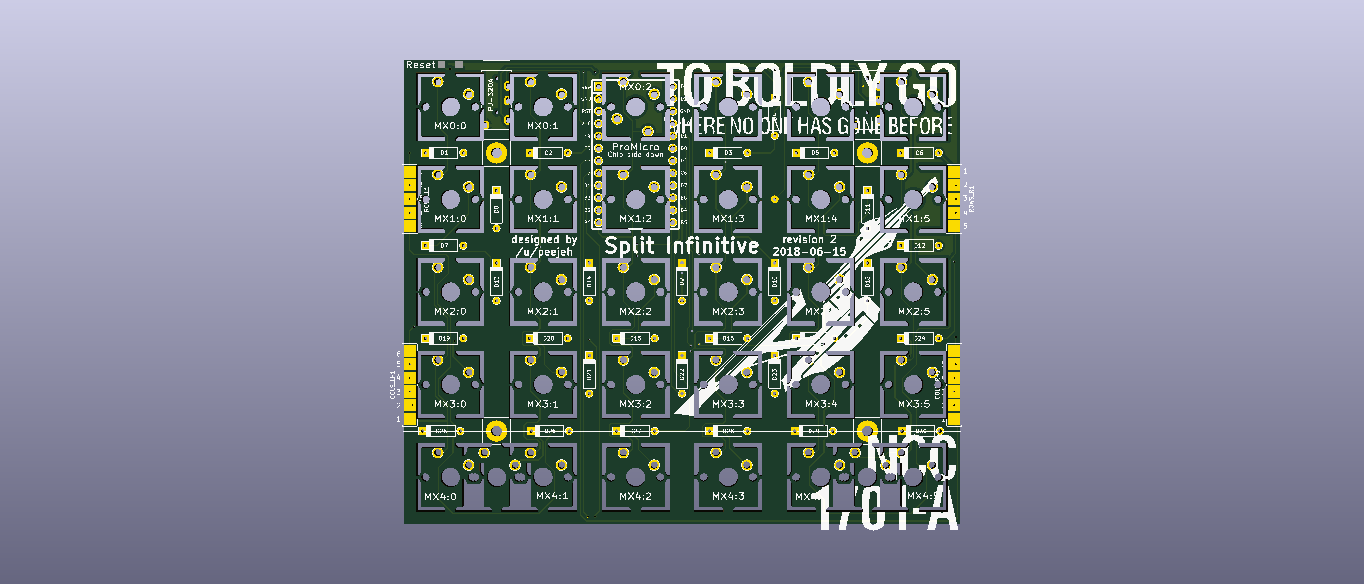

Split Infinitive is a 6x5x2 key ortholinear split keyboard PCB.

The goal of this project is to build a Let's Split keyboard clone with a number of alternative features:

- Designed to be easy to build with minimal soldering experience.

- Supports both 6x5x2 and 12x5x1 layouts and 2U keys in the bottom corners.

- Switch plate cutouts in the PCB so the same PCB can also be used as a switch plate.

- Serial communication over a TRRS cable in split configuration.

- Single sided PCB, so both halves of the keyboard are identical.

Bill of Materials (BOM)

- 4 PCBs, 2 for components and 2 as switch plates.

- 60 MX compatible switches.

- 60 1n4148 diodes.

- 1 or 2 Pro Micro controllers with headers or DIP sockets.

- 2 PJ320A 3.5mm TRRS jacks for split configuration.

- TRRS cable and micro USB cable.

- 8 2M standoffs (12mm, depending on required height)

- 16 2M screws

- 60 MX compatible key caps.

Tools

- Hacksaw blade or similar

- Flat edged file or sanding paper

- Soldering iron and solder

Ordering PCBs

PCBs can be manufactuered by a variety of online PCB fabricators, the PCB is 114x95mm. You can use PCBShopper to search for the best price.

The zip file in the gerber directory contains the gerber files your fabricator will need to make the PCB for-split.zip PCB.

When uploading the gerber zip files, use the default PCB settings. The plate PCB thickness should be 1.6mm for the switches to snap into the plate securely.

Construction

- You will need 4 PCBs.

- Use the hacksaw blade to remove the 4 support screw holes from the 2 component PCBs.

- Use a hacksaw blade to remove the cutouts for the switch plate PCBs.

- Solder the diodes onto the underside of each PCB.

- Solder on the Pro Micro headers (or a 24 pin DIP socket) onto the underside of each PCB, do not solder on the Pro Micros yet.

- In split configuration, both PCBs require a Pro Micro so add headers to both PCBs.

- In non-split configuration, only the master side requires a Pro Micro.

- Solder the PJ320A TRRS sockets onto the underside of each PCB.

- There are 2 positions per board, use the right position on the left hand PCB and the left position on the right hand PCB.

- Ensure that the pins will not foul the placement of the switches and still allow the switches to sit flat on the PCB.

- You may need to slightly bend the pins inwards away from the switch footprint.

- Insert the switches into the plate and then into the top of the PCBs.

- Insert all the switches and ensure that the pins of each switch are correctly coming through the board and are not bent under the PCB.

- The top switch that sits underneath the Pro Micro can be inserted in either a north or south facing orientation. North facing helps to prevent it shorting on the Pro Micro components.

- Solder all the switch pins.

- Solder on the Pro Micros, ensure that you get them the correct way around, the chip side should be face down towards the PCB.

- Attach the standoffs to the plate PCB with the screws.

- Connect the halves together with the TRRS cable.

- Flash both Pro Micros with the firmware, see the QMK documentation on how to build and flash the firmware.