This is the repository for the assembly documentation and tools for the University of Cambridge Physical Computation Laboratory's Sensor-Augmented SLS System, based on the Sintratec Kit. Three other repositories, Warp-hardware, Warp-firmware, and Sesame-logger, contain the hardware design for the Warp sensor platform, the firmware for Warp, and our Python tool (Sesame-logger) for controlling the printer and four sensor groups (the 248-channel spectrometer, the 22-sensor Warp, and the 4-sensor Bosch CISS). These repositories are included here as git submodules.

The correct way to clone this repository to get the submodules is:

git clone --recursive git@github.com:physical-computation/Sesame.gitTo update all submodules

git pull --recurse-submodules

git submodule update --remote --recursiveIf you forgot to clone with --recursive, and end up with empty submodule directories, you can remedy this with

git submodule update --initCheckout master branch and take each submodule out of the "Detached HEAD" state:

git submodule foreach git checkout masterWe created an issue template to make it easy to initiate each step of the assembly process. We created an issue for each step of the assembly process and we used issue labels to tag the steps with information such as whether a step is relevant to a sensor component integration.

The GitHub issues tagged Mechanical Assembly contain both instructions for assembly as well as pictures of our actual assembly work for every single stage of the assembly process. The picture below is a collage of some of the assembly step pictures.

We created an issue template to make it easy to initiate a new experiment using the system and to fill in detail about a print and measurement. The Sesame-logger tool initiates a print in the SLS machine and at the same time also automatically creates a new GitHub repository to contain the sensor data that results from the print.

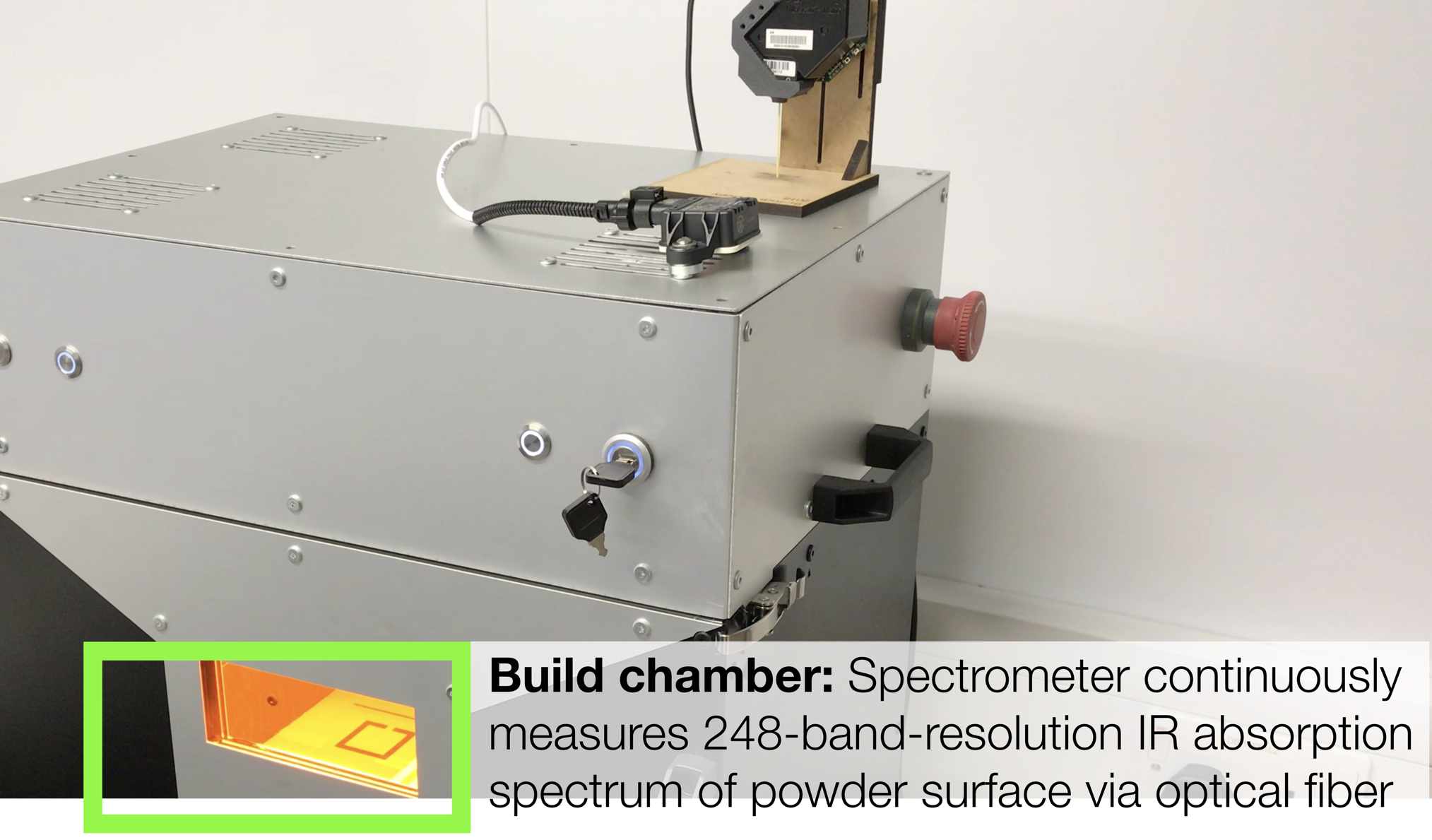

The spectrometer is mounted externally and fed by a glass optical fiber that provides a light path to the powder bed. The setup supports two different sensor arrays: Our Warp-hardware provides significantly more sensors, but you can opt to use the Bosch CISS device shown in the picture here if you do not wish to get Warp platforms manufactured:

The window of the chamber during a print:

The inside of the chamber during operation showing the glass optical fiber path:

The inside of the chamber showing the end of the glass optical fiber path:

The original assembly team consisted of Rae Zhao, James Rhodes, Vlad-Mihai Mandric, and Phillip Stanley-Marbell. Later stages of the assembly involved Youchao Wang, Andrew Kadis, and Thomas Garry. The spectrometer integration hardware and print automation software was designed and implemented by Thomas Garry.

This research is supported by an Alan Turing Institute award TU/B/000096 under EPSRC grant EP/N510129/1, by Royal Society grant RG170136, and by EPSRC grants EP/P001246/1 and EP/R022534/1.