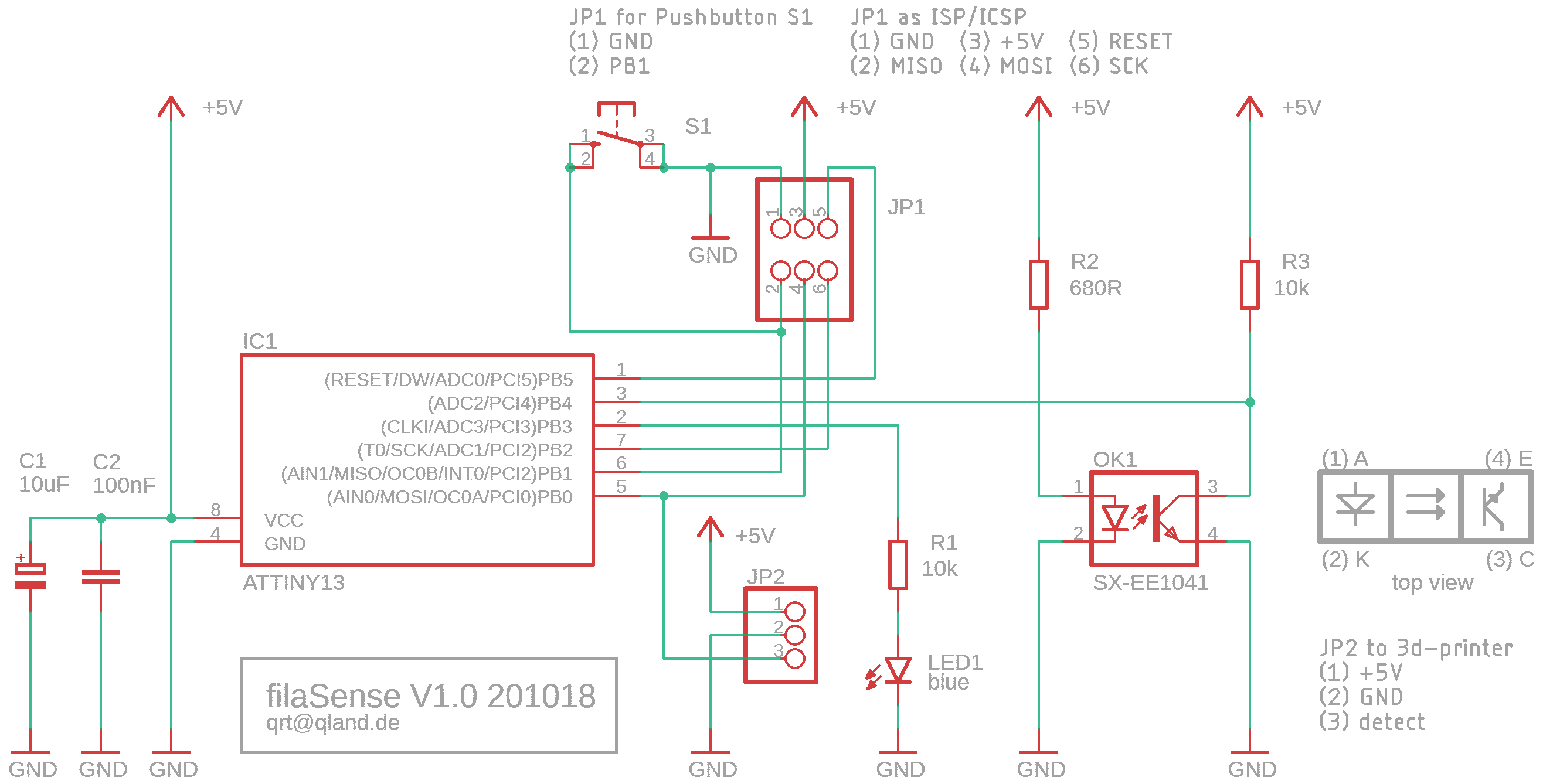

Optical filament detection is not as easy as it seems at first glance. Especially transparent filaments might focus emitter-LED light and even enhance detection levels instead of dampen them as opaque filaments do. As a consequence this is a 'change of condition sensor' that detects runout of filament but not the presence or absence of it. Nevertheless the detection of some transparent filaments is possibly not reliable.

The sensors state of operation is indicated by a LED. After a filament runout (or load) happens, the sensor reports it by a two second pulse to the 3d-printer and the LED starts long-blinking until the button is pressed.

- constantly on

sensor online - short blink

sensor offline - long blink

filament runout (or load) detected

- if sensor is online or offline

toggle online/offline - if a change was detected

make sensor online

- be sure to set ATTINY13 fuses as documented in source comments

- change the detection logic

.define LOGIC 0 ;0 LOW or 1 HIGH means detection for 3d-printer

- dampen detection level by rising SLCY

.equ SLSCY = 22 ;t = SLSCY * ct * 256, slow service cycle

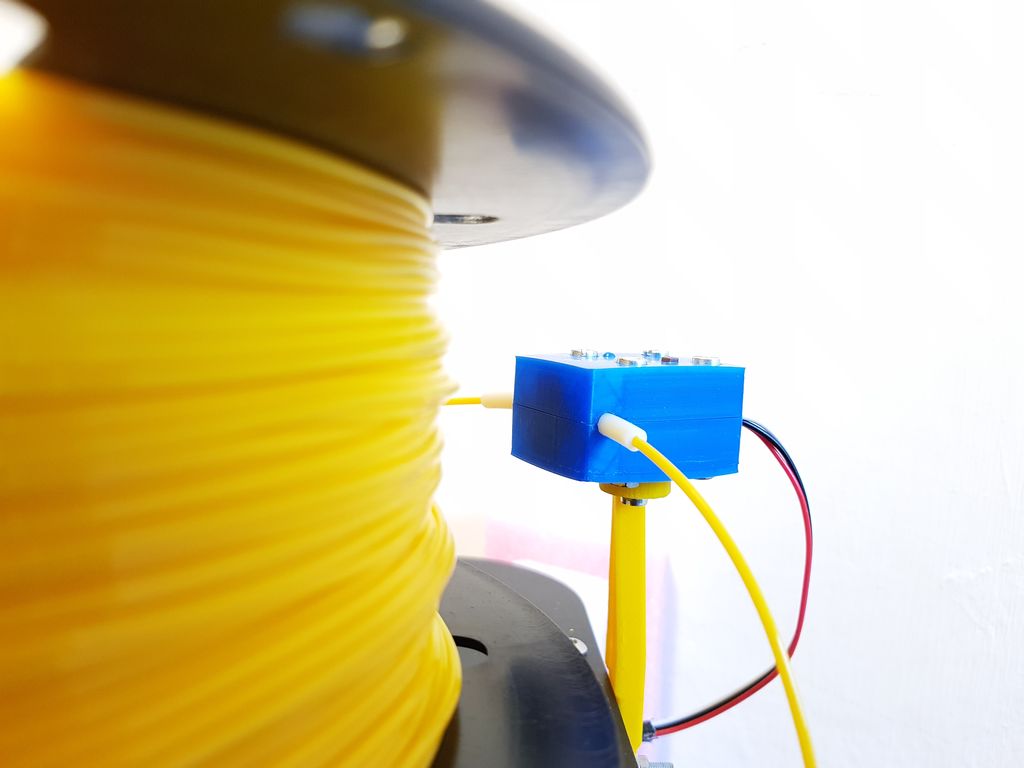

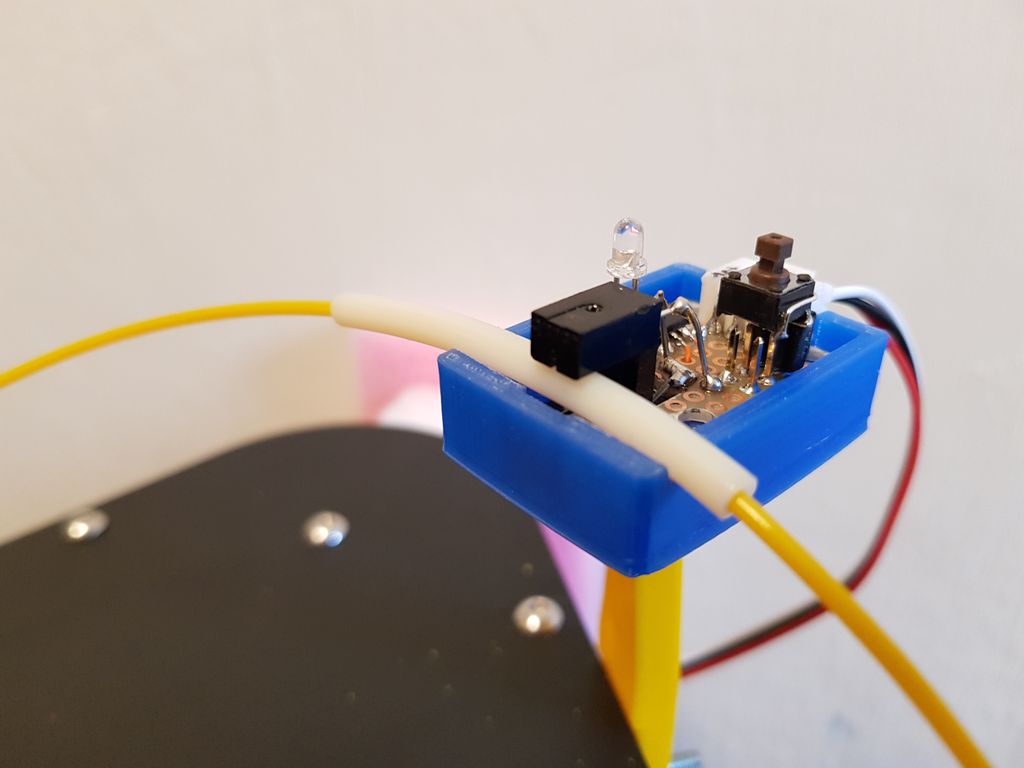

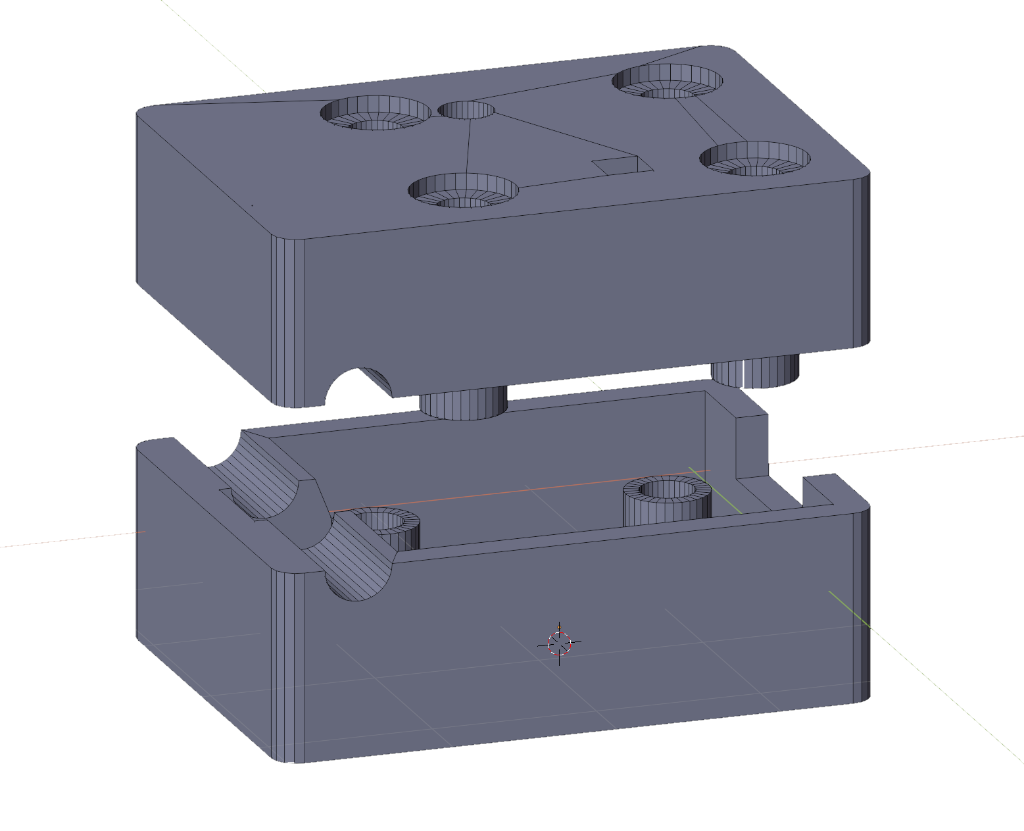

the filament teflon tube has to be exactly in the optical axis of the slotted optical sensor

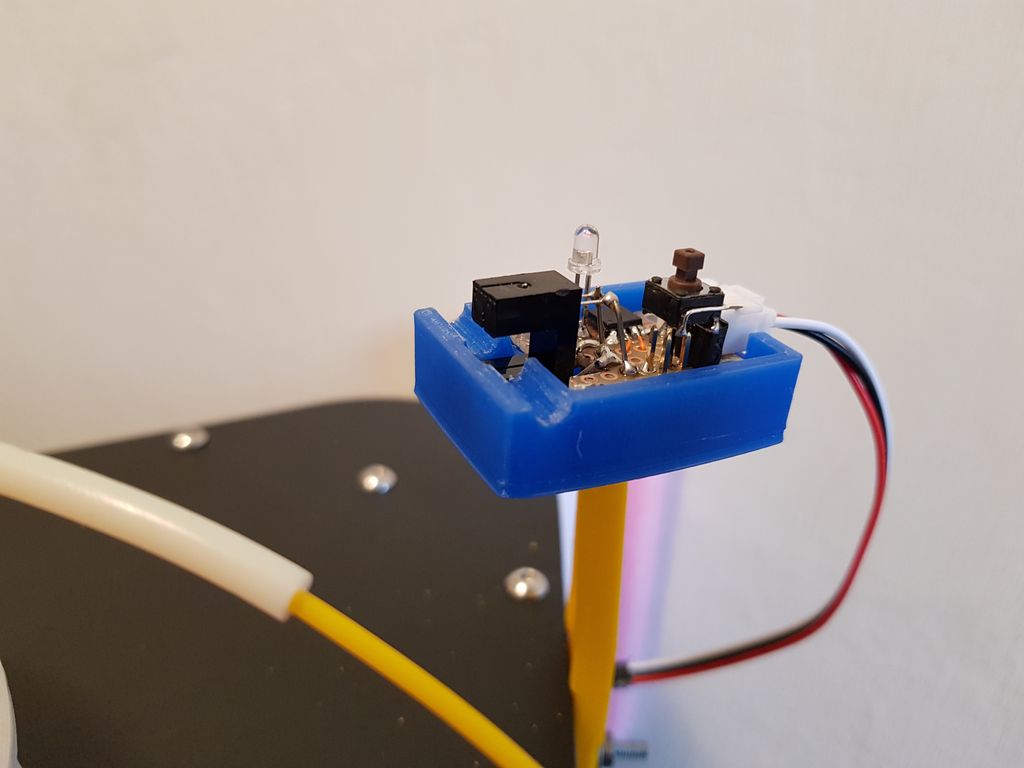

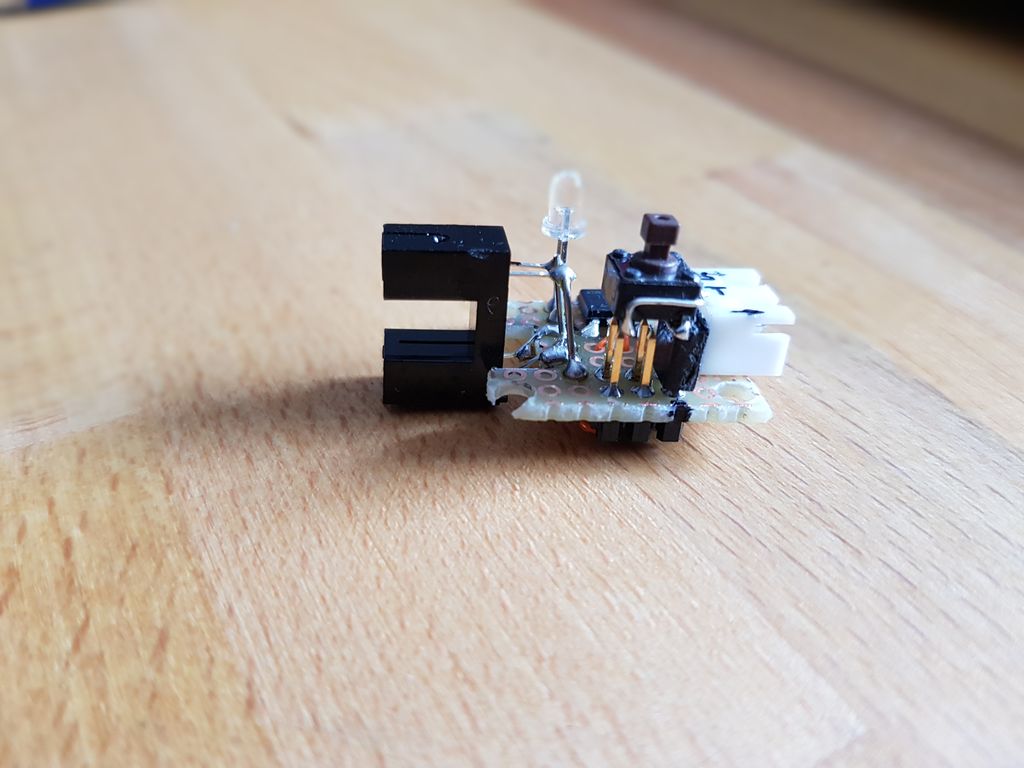

hand wired prototype, the push-button is removable to allow in circuit programming of the ATTINY13 controller

3d-print files in stl format are in the repository

qrt@qland.de 210708