Warning

This is not meant to enclose an active 3D printer! There isn't any kind of ventilation in this design. This is merely a dust cover for when the printer is inactive.

Warning

This is a work in progress, and is not ready for use!

Warning

My Prusa MINI+ has a bunch of extra accessories installed, so the size of this box is much larger than the "normal" Prusa MINI+ footprint.

Warning

Currently, $fn = 20; for fast rendering during development. Increase this before creating output files for production.

I wanted to keep my Prusa MINI+ 3D printer safe from dust, while still keeping it visible.

For this reason I designed a box that can be laser-cut from transparent acrylic panels.

The OpenSCAD design is parameteric, meaning that you can simply change some parameters (e.g. the size), and the code will generate a box that meets your requirements.

- Metal brackets and screws for solid construction.

- Panels slot together for additional rigidity ("tabbed edges").

- Corner braces at the bottom, to avoid cracking the acrylic panels.

- 5 x panels, generated from included OpenSCAD code (cut from for instance acrylic or MDF)

- 20 x M4 Screws, 8mm

- 20 x metal L-shaped corner brackets

- 4 x corner braces

- either 3D printed from the provided model

- or can be bought as "silicon fish tank corner protector"

Open main.scad in OpenSCAD. The most important parameters to edit are:

// inner box size

box_depth = 360;

box_height = 400;

box_width = 450;

Note that these are the inside dimensions of the desired box, so the final result will be slightly larger, depending on panel_thickness.

Use the assemble() method to get a 3D preview of the box. Use the render_2d() for a 2D view that can be used to generate a flat layout for laser cutting or similar.

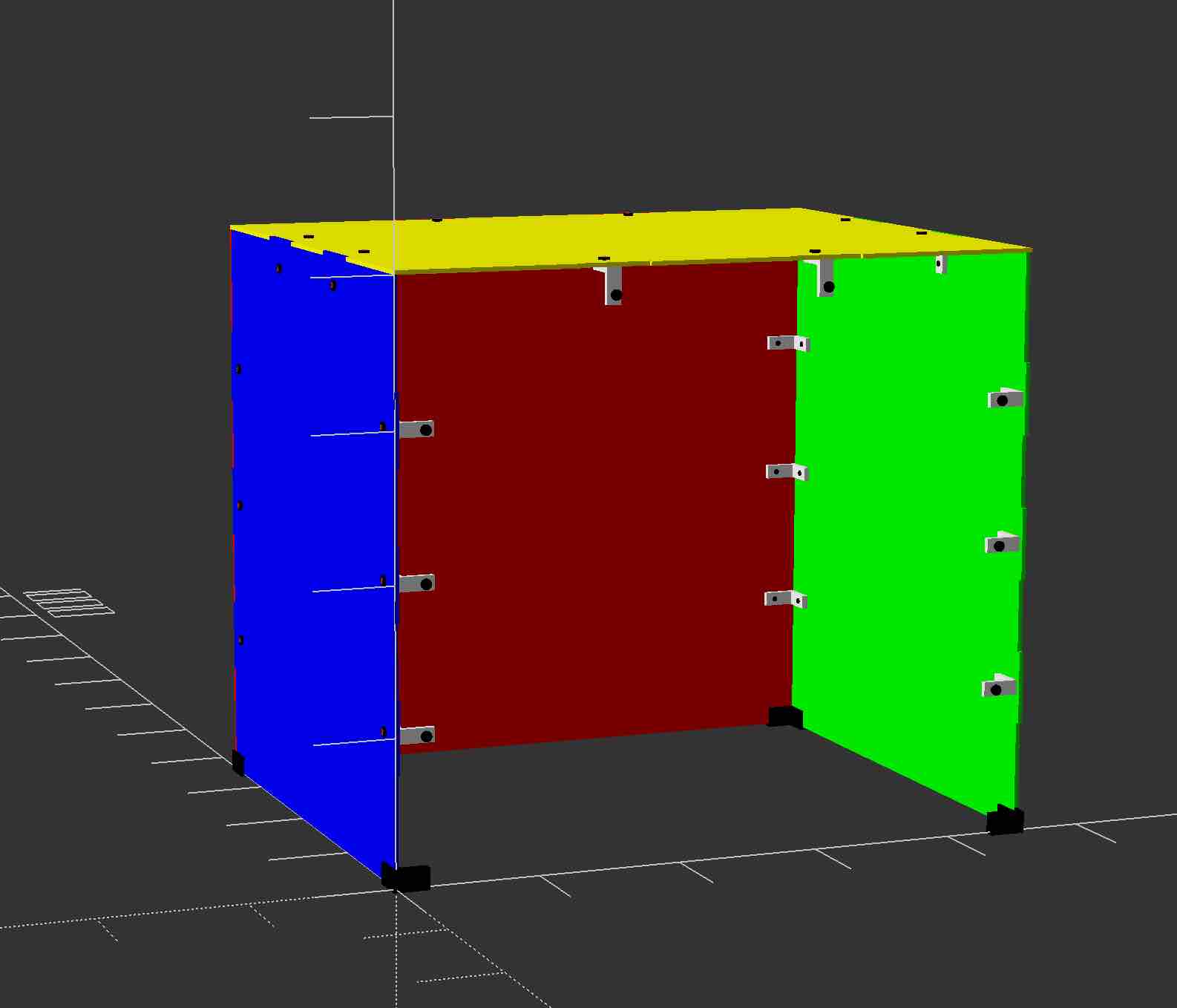

3D view (color scheme for debugging purposes):

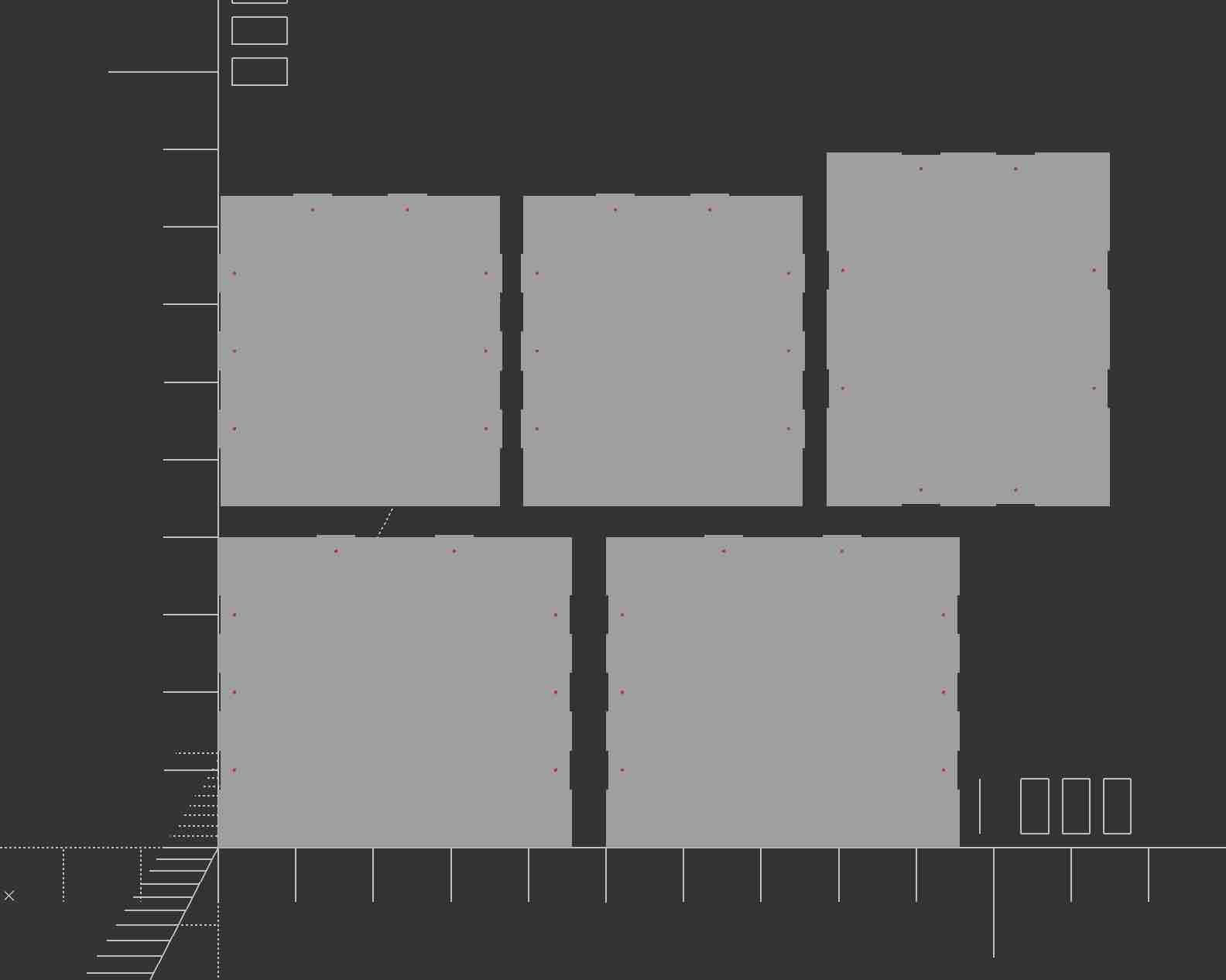

Flat layout:

- hole for cable exit?

- handle to lift cover?