- Very Important Links

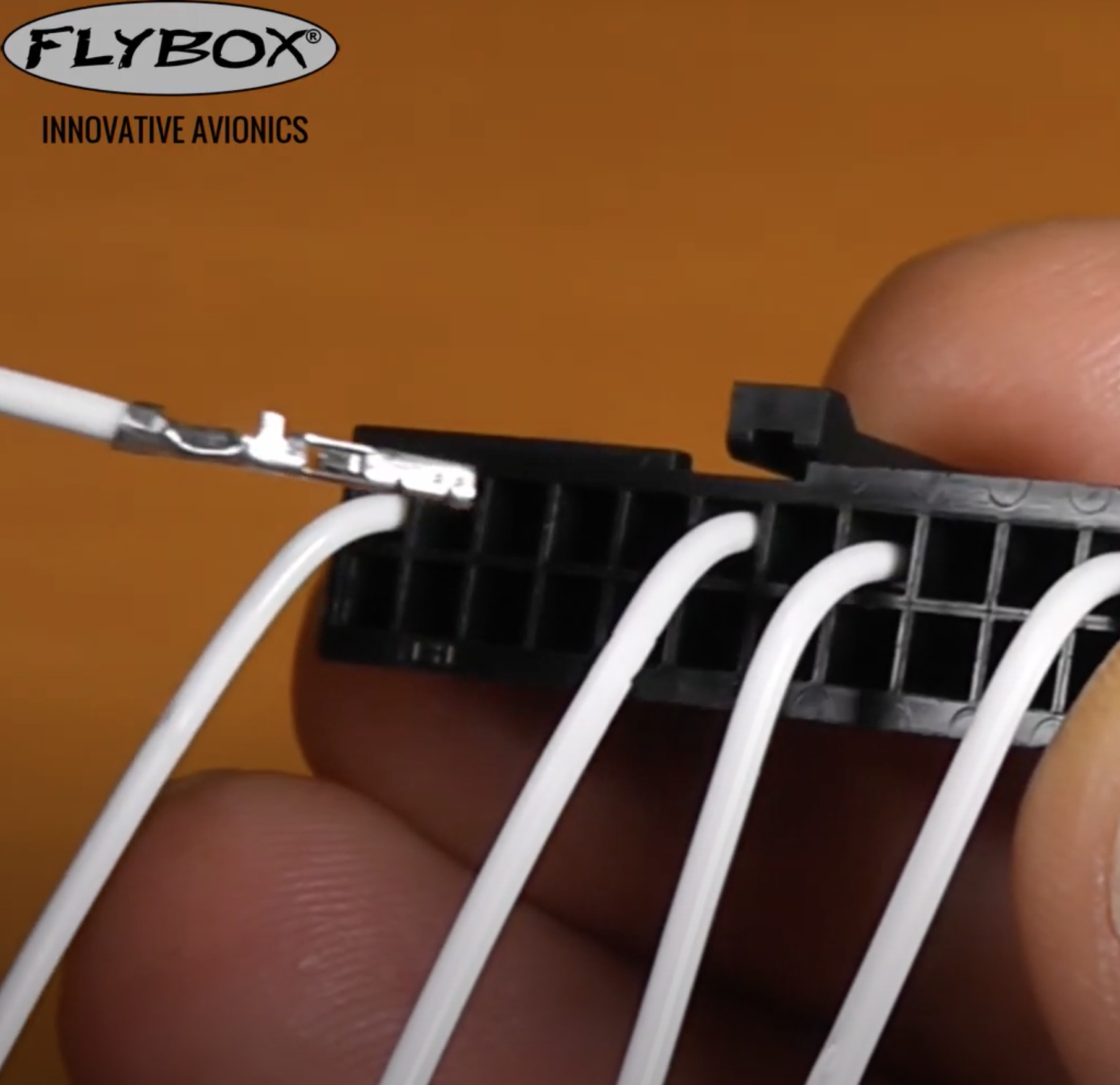

- Crimping Microfits

- Voron Afterburner PCB setup

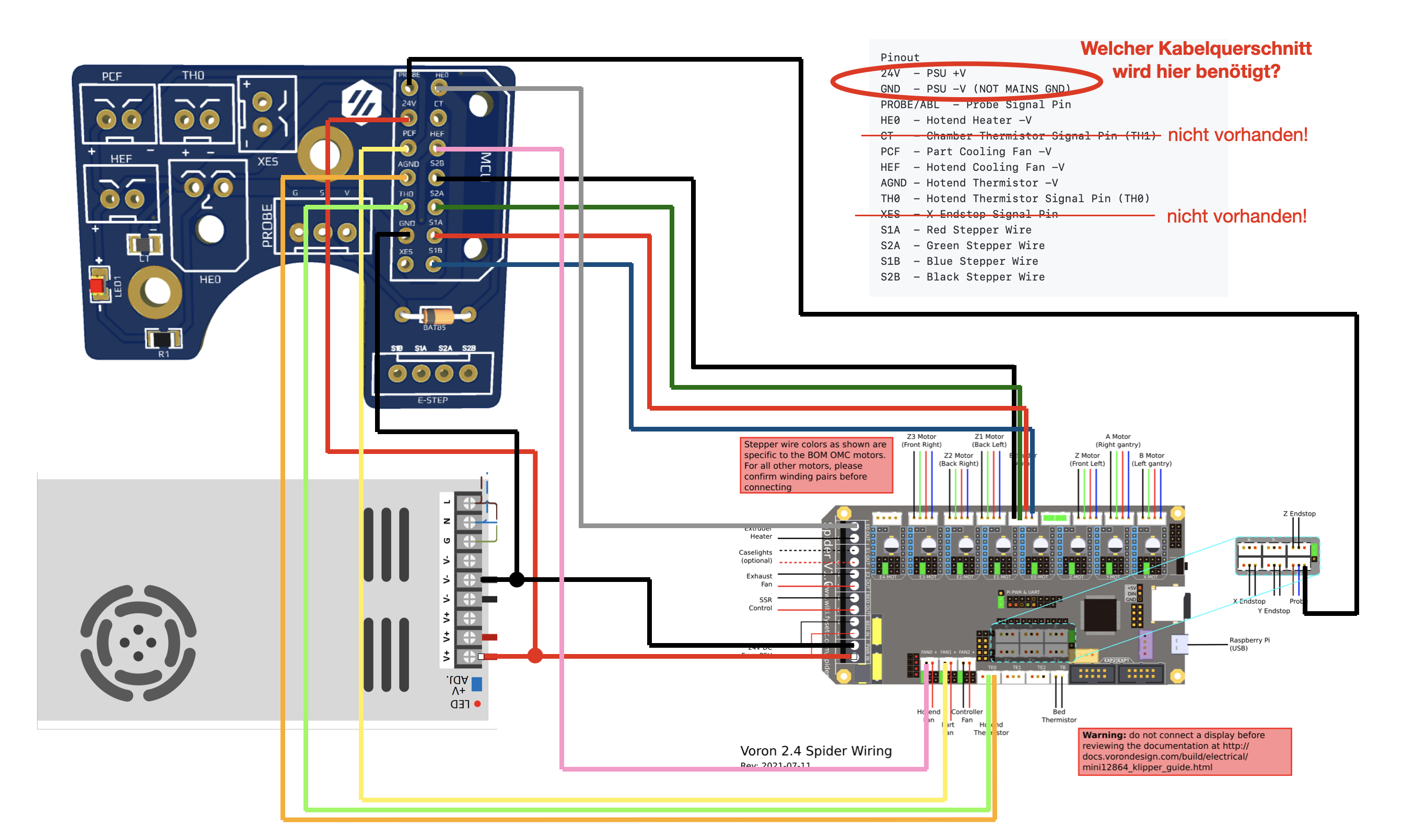

- Fysetc Spider Wiring

- Klipper Firmware

- Initial Setup

- Notes from Steve Build

- Spider Setup

- Shopping List

- Neopixels

some mods

correct way to insert crimp to microfit3:

Pinout

20/Red 24V - HE0 +V

20/Black GND - PSU -V (NOT MAINS GND)

24/Red PROBE/ABL - Probe Signal Pin

20/Black HE0 - Hotend Heater -V

24/Red CT - Chamber Thermistor Signal Pin (TH1)

24/Black PCF - Part Cooling Fan -V

24/Black HEF - Hotend Cooling Fan -V

24/Black AGND - Hotend Thermistor -V

24/Red TH0 - Hotend Thermistor Signal Pin (TH0)

24/Red S1A - Red Stepper Wire

24/Black S2A - Green Stepper Wire

24/Red S1B - Blue Stepper Wire

24/Black S2B - Black Stepper Wire

no XES - X Endstop Signal Pin

I did the wiring according to the following:

Read the following: Voron V2 - Fysetc Spider Wiring

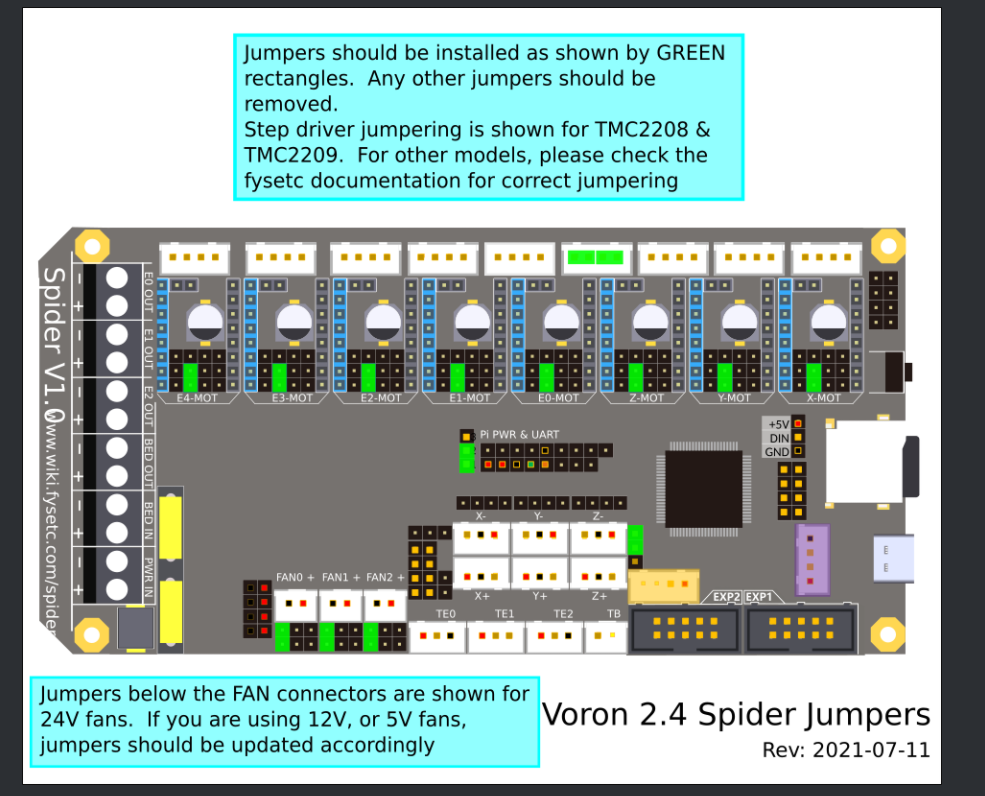

it referenced here that for the jumpers we need to do (do not put a jumper on the jst port):

you can also check mhoush for wiring.

I connected the X/Y end stops as following:

- X endstop to X-

- Y endstop to Y-

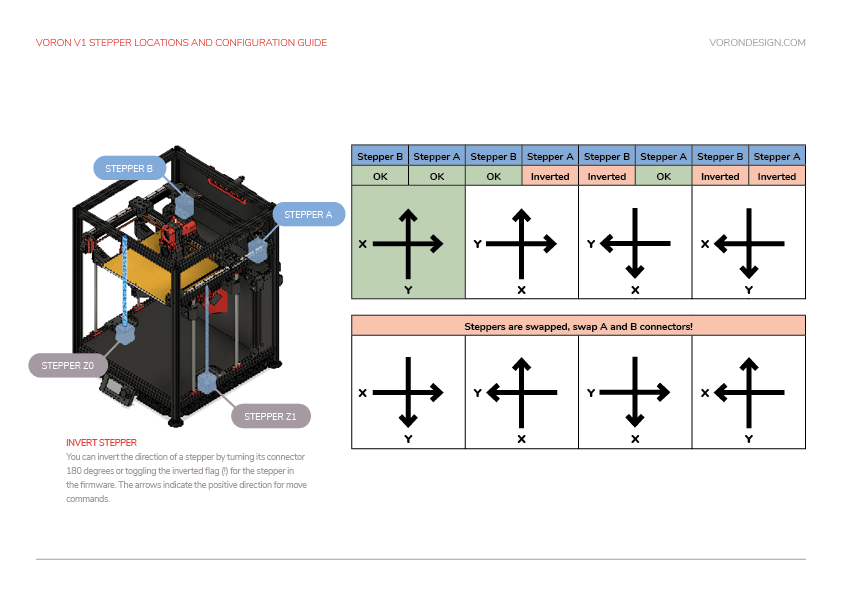

Regarding how you cable the motors wires in a discussion with @jaeger (github id mhoush) he mentioned:

The only reason for that is that's what color order MY stepper motors had Apparently there's no real standard for it. So with that said the colors aren't as important as the windings. If you're not sure or don't have data from the stepper manufacturer, you can identify windings by shorting two of the wires together (with the stepper unplugged) If it gets harder to turn by hand, those two wires are a winding (winding = πηνίο)

check [(LDO-42STH20-1004ASHVRN-RevA-technical-datasheet.pdf]((LDO-42STH20-1004ASHVRN-RevA-technical-datasheet.pdf) which states that fot he exrtruder motor we have the windings pairs are Black/A-Green/C and Red/B-Blue/D These are wired into the After Burner PCB:

| Type | Winding 1 | Winding 1 | Winding 2 | Winding 2 |

|---|---|---|---|---|

| Cable | Black | Green | Red | Blue |

| PCB | S1B | S1A | S2A | S2B |

| Spider | A2 | A1 | B1 | B2 |

Regarding the motor wiring I did:

- M1 - X-MOT - Z-LEFT

- M2 - Y-MOT - A

- M3 - Z-MOT - Empty

- M4 - E0-MOT - E

- M5 - E1-MOT - Z-RIGHT

- M6 - E2-MOT - Z-REAR

- M7 - E3-MOT - B

- M8 - E4-MOT - Empty

My current configuration is this printer.cfg

- sample_firmwares/trident-spider-1.1.majarspeed.cfg from github

- sample_firmwares/trident-spider-1.1.mhoush.cfg from github

- sample_firmwares/trident-spider-1.1.nkalogerinis.cfg from nick

start here

we currently have:

- X/Y: LDO-42STH40-2004MAC(VRN) datasheet of hi temp equivalent 0.9° Step Angle/400 Steps/2 Amp/350mN-m Holding Torque/130C

- Ex1: LDO-42STH20-1004ASH-MM(VRN) datasheet 1.8° Step Angle/200 Steps/1.0A/18Ncm Holding Torque/180C

- Zx3: LDO-42STH40-1684L300E(VRN) datasheet 1.8° Step Angle/200 Steps/1.68A/450Nm Holding Torque/130C

calculate currents based on Calculating Driver Current Settings . And avoid specifying hold current because klipeer says so

- X/Y:

run_current = 2 * 0.707 = 1.414,hold_current = run_current * 0.6 = 0.8484 - Zx3:

run_current = 1.68 * 0.707 = 1.1877,hold_current = run_current * 0.6 = 0.712 - Ex1:

run_current = 1 * 0.707 = 0.7,hold_current = run_current * 0.6 = 0.42

Go with conservative configs, microsteps 32 and interpolation off. Do not setup hold_current. Mainly use the settings in octopus config. run currents are calculated based on 70% of the run_rurrent

[stepper_x]

microsteps: 32

full_steps_per_rotation: 400 # 200 for 1.8 degree motors, 400 for 0.9 degree

[tmc2209 stepper_x]

uart_pin: PA15

interpolate: False

run_current: 1.0

sense_resistor: 0.110

stealthchop_threshold: 0

[stepper_y]

microsteps: 32

full_steps_per_rotation: 400 # 200 for 1.8 degree motors, 400 for 0.9 degree

[tmc2209 stepper_y]

uart_pin: PE15

interpolate: False

run_current: 1.0

sense_resistor: 0.110

stealthchop_threshold: 0[stepper_z1]

microsteps: 32

[tmc2209 stepper_z1]

uart_pin: PC15

interpolate: False

run_current: 0.7

sense_resistor: 0.110

stealthchop_threshold: 0[extruder]

microsteps: 32

[tmc2209 extruder]

uart_pin: PD7

interpolate: False

run_current: 0.5

sense_resistor: 0.110

stealthchop_threshold: 0Thermistor used in the Keenovo is a 'NTC 100K thermistor (Beta 25/50 3950K-1%)' based on the fermio site

from klipper config

sensor_type:

# Type of sensor - common thermistors are "EPCOS 100K B57560G104F",

# "ATC Semitec 104GT-2", "ATC Semitec 104NT-4-R025H42G", "Generic

# 3950","Honeywell 100K 135-104LAG-J01", "NTC 100K MGB18-104F39050L32",

# "SliceEngineering 450", and "TDK NTCG104LH104JT1". See the

# "Temperature sensors" section for other sensors. This parameter

# must be provided.

sensor_type: Generic 3950got (vonwange) ATC Semitec 104GT-2

[extruder]

sensor_type: ATC Semitec 104GT-2STEPPER_BUZZ STEPPER=stepper_x

STEPPER_BUZZ STEPPER=stepper_y

STEPPER_BUZZ STEPPER=stepper_z

STEPPER_BUZZ STEPPER=stepper_z1

STEPPER_BUZZ STEPPER=stepper_z2

STEPPER_BUZZ STEPPER=extruder

QUERY_ENDSTOPScheck this try to do a home x and y and invert pins if required

dir_pin: PD6G90

G28 X Y

G1 X300.00 Y300.00 F7800

G1 X0.00 Y0.00 F7800

M114 # get current location

G1 X300.00 Y0.00 F7800

G1 X0.00 Y300.00 F7800

G90

G1 X170.00 Y300.00 F7800Figure out where Z-Endstop is update [homing_override] or [safe_z_home] with those values. For me it is 170

G28 X Y Z

QUERY_PROBE

# move bed close to nozzle

QUERY_PROBE

// probe: TRIGGERED

// PROBE_ACCURACY at X:150.000 Y:149.000 Z:35.000 (samples=10 retract=3.000 speed=5.0 lift_speed=5.0)

08:21:06 // probe at 150.000,149.000 is z=8.280000

08:21:08 // probe at 150.000,149.000 is z=8.281250

08:21:10 // probe at 150.000,149.000 is z=8.281250

08:21:11 // probe at 150.000,149.000 is z=8.281250

08:21:13 // probe at 150.000,149.000 is z=8.281250

08:21:15 // probe at 150.000,149.000 is z=8.281250

08:21:16 // probe at 150.000,149.000 is z=8.281250

08:21:18 // probe at 150.000,149.000 is z=8.281250

08:21:19 // probe at 150.000,149.000 is z=8.281250

08:21:21 // probe at 150.000,149.000 is z=8.281250

08:21:21 // probe accuracy results: maximum 8.281250, minimum 8.280000, range 0.001250, average 8.281125, median 8.281250, standard deviation 0.000375

G28 X Y Z

G90

G1 Z7.00 F7800

PID_CALIBRATE HEATER=heater_bed TARGET=60

// PID parameters: pid_Kp=40.922 pid_Ki=1.057 pid_Kd=395.922

M106 S100

PID_CALIBRATE HEATER=extruder TARGET=210

// PID parameters: pid_Kp=25.246 pid_Ki=1.476 pid_Kd=107.925

verify that the following are under the probe:

points:

30, 5

150, 245

270, 5For this process NEVER have the part fan on

G28 X Y

G90

G1 X30.00 Y5.00 F7800

G1 X150.00 Y245.00 F7800

G1 X270.00 Y5.00 F7800

SET_HEATER_TEMPERATURE HEATER=extruder TARGET=210

SET_HEATER_TEMPERATURE HEATER=heater_bed TARGET=60

G28 X Y Z

G90

G1 Z10.00 F7800

# allow some time needed for the probe to stabilize ~ 5 min

# wait until standard deviation < 0.003

PROBE_ACCURACY

G1 Z10.00 F7800

Z_TILT_ADJUST

G28

BED_MESH_CLEAR

Z_ENDSTOP_CALIBRATE

TESTZ Z=-30.0

TESTZ Z=-2.0

TESTZ Z=-0.3

ACCEPT

The Z offset can be adjusted during a print using the Tune menu on the display, and the printer configuration can be updated with this new value. Remember that higher values for the position_endstop means that the nozzle will be closer to the bed.

Important: Klipper assumes that this process is being done cold. If being performed hot, do an additional TESTZ Z=-0.1 before accepting.

M117 Homing...

G28 Y0 X0 Z0

Z_TILT_ADJUST

BED_MESH_CALIBRATE

SET_HEATER_TEMPERATURE HEATER=extruder TARGET=210

# measure 120mm and tie a tie wrap

extrude twice 50mm and measure

measured 21mm

New Config Value = Old Config Value * (Actual Extruded Amount/Target Extruded Amount)

22.4899598 = 22.6789511 * (119/120)

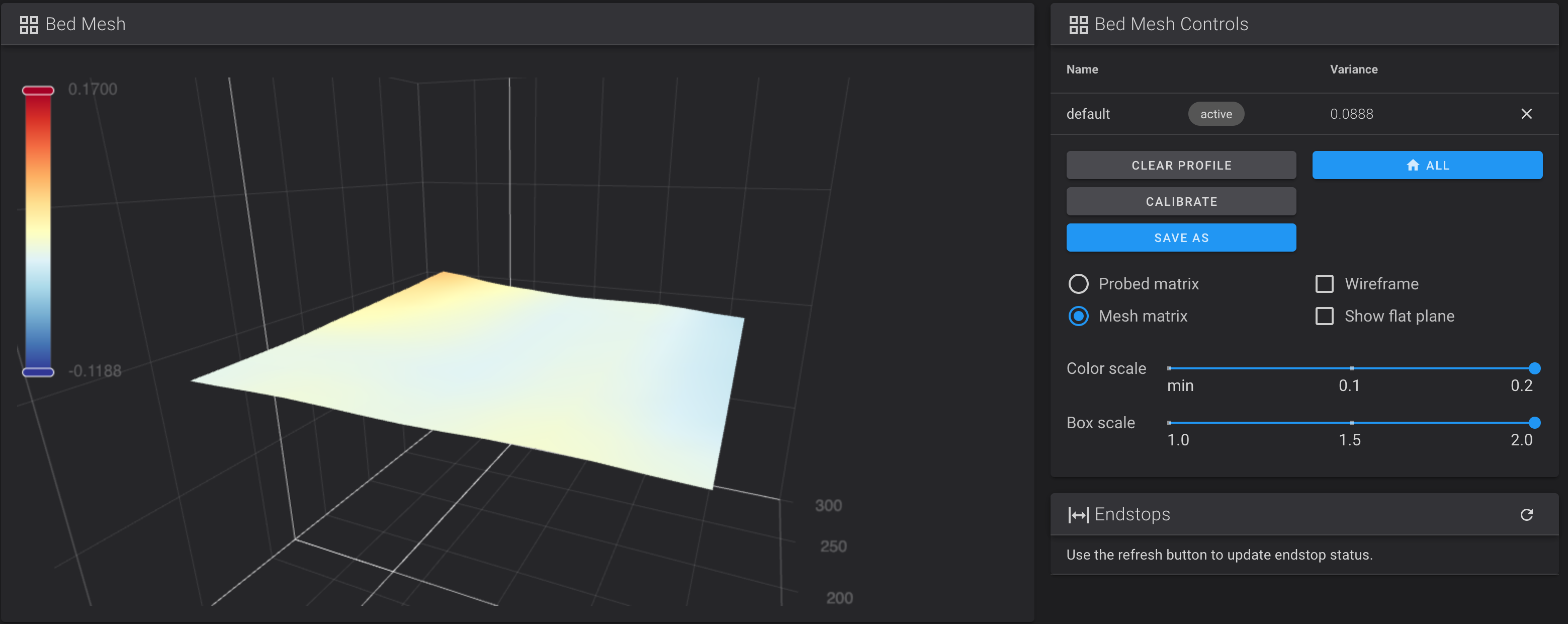

I tried a bed mesh with cold bed and got the following results:

#*# [bed_mesh default]

#*# version = 1

#*# points =

#*# 0.002500, 0.011250, 0.006250, 0.016250, 0.005000

#*# 0.007500, 0.003750, -0.001250, 0.007500, -0.011250

#*# 0.027500, 0.013750, 0.000000, 0.003750, -0.015000

#*# 0.046250, 0.018750, -0.000000, 0.002500, -0.015000

#*# 0.070000, 0.025000, 0.002500, 0.005000, -0.018750

#*# tension = 0.2

#*# min_x = 40.0

#*# algo = bicubic

#*# y_count = 5

#*# mesh_y_pps = 2

#*# min_y = 40.0

#*# x_count = 5

#*# max_y = 260.0

#*# mesh_x_pps = 2

#*# max_x = 260.0

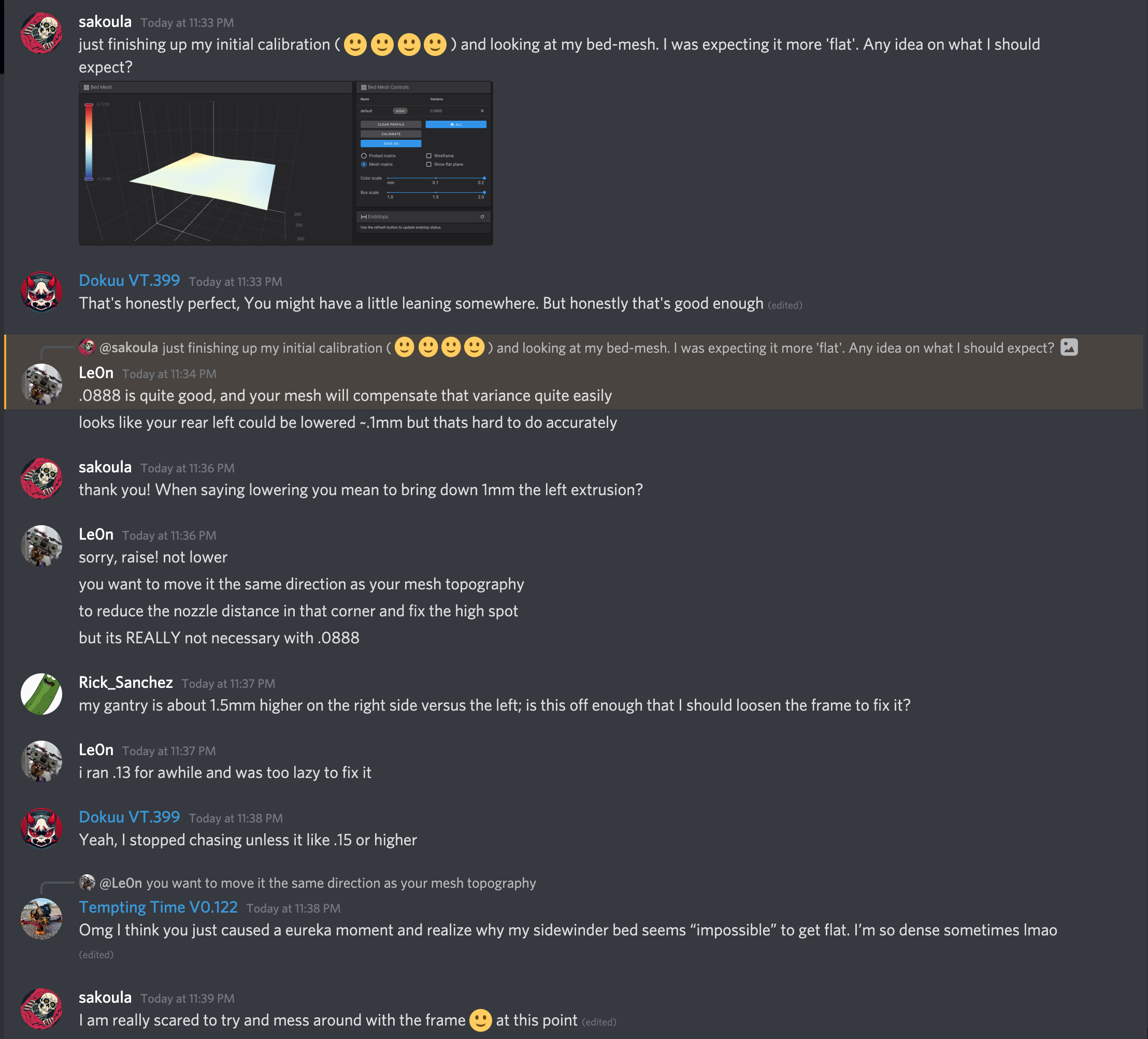

I posted on discord and it is good:

- nozzle to probe is about 2-3mm. I got it to 4mm

- igus chains 18 links

- washer ground/bed

- x igus chain fixed end on the toolhead to be as horizontal as possible

- y igus chain fixed end on front on the accent piece to be as horizontal as possible

- end stop octapus for probe

- probe uses 24V

- 2209 use UART

- connected pi to spider over pins

- power use 20AWG

- tx/rx use 24AWG

Before putting the drivers follow this procedure and according to this

- Power off the motherboard completely (remove the wiring completely), and wait for the 24v, 5v and 3.3v LEDs to be completely off.

- Connect a 100K resistor (or a cable) to the +/- pole of MAIN_PWR. Wait 10 minutes and disconnect it

- Connect a 100K resistor (or a cable) to the +/- pole of VMOT. Wait 10 minutes and disconnect it

- Wait for 5-10 minutes, plug in the driver, and perform firmware and other operations.

This is the procedure. You really do not need to do this part. According to FYSETC every board that leaves the factory has already a bootloader on. However since there have been two versions of bootloaders lets put the latest 32k one.

Power off board, remove SD Card, and

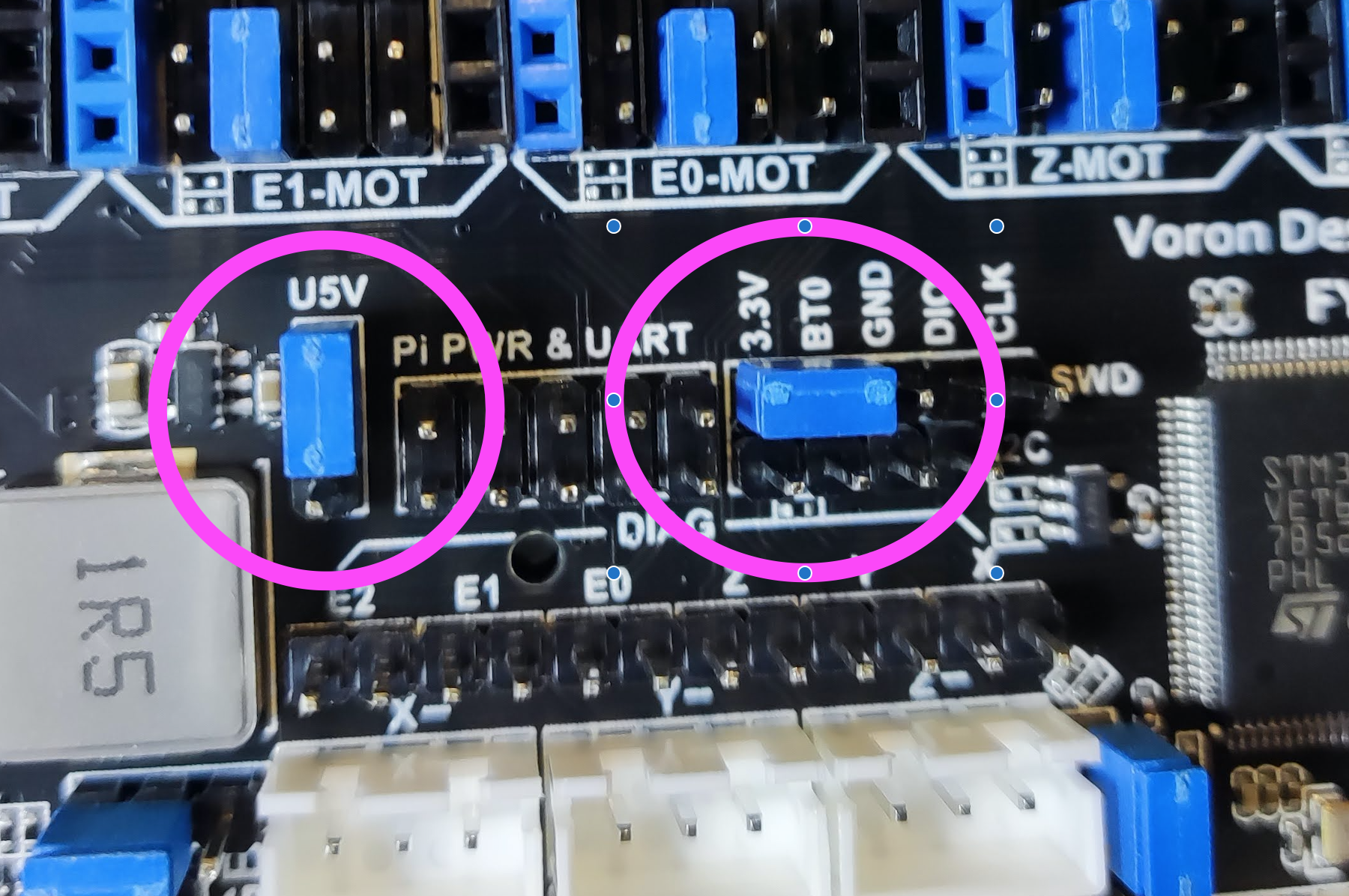

- place jumper on BT0 and 3.3V. (Between Z- endstop and E0 driver). This is on the right of the PI PWR & UART in the middle of the board. Place one jumper horizontally

- Connect Spider to Pi with USB cable with jumper in place.

- Set U5V jumper closest to stepper driver modules to power Spider from the Pi USB (you can power it with 24V I preferred this way). The U5V jumper left of the PI PWR & UART in the middle of the board

on the pi type:

$ apt-get install dfu-util

$ dfu-util --list

dfu-util 0.9

Copyright 2005-2009 Weston Schmidt, Harald Welte and OpenMoko Inc.

Copyright 2010-2016 Tormod Volden and Stefan Schmidt

This program is Free Software and has ABSOLUTELY NO WARRANTY

Please report bugs to http://sourceforge.net/p/dfu-util/tickets/

Found DFU: [0483:df11] ver=2200, devnum=3, cfg=1, intf=0, path="1-1.2", alt=3, name="@Device Feature/0xFFFF0000/01*004 e", serial="STM32FxSTM32"

Found DFU: [0483:df11] ver=2200, devnum=3, cfg=1, intf=0, path="1-1.2", alt=2, name="@OTP Memory /0x1FFF7800/01*512 e,01*016 e", serial="STM32FxSTM32"

Found DFU: [0483:df11] ver=2200, devnum=3, cfg=1, intf=0, path="1-1.2", alt=1, name="@Option Bytes /0x1FFFC000/01*016 e", serial="STM32FxSTM32"

Found DFU: [0483:df11] ver=2200, devnum=3, cfg=1, intf=0, path="1-1.2", alt=0, name="@Internal Flash /0x08000000/04*016Kg,01*064Kg,03*128Kg", serial="STM32FxSTM32"

$ wget https://github.com/FYSETC/FYSETC-SPIDER/raw/main/bootloader/Bootloader_FYSETC_SPIDER.hex

$ objcopy --input-target=ihex --output-target=binary Bootloader_FYSETC_SPIDER.hex Bootloader_FYSETC_SPIDER.bin && dfu-util -a 0 -s 0x08000000:mass-erase:force -D Bootloader_FYSETC_SPIDER.bin

Copyright 2005-2009 Weston Schmidt, Harald Welte and OpenMoko Inc.

Copyright 2010-2016 Tormod Volden and Stefan Schmidt

This program is Free Software and has ABSOLUTELY NO WARRANTY

Please report bugs to http://sourceforge.net/p/dfu-util/tickets/

dfu-util: Invalid DFU suffix signature

dfu-util: A valid DFU suffix will be required in a future dfu-util release!!!

Opening DFU capable USB device...

ID 0483:df11

Run-time device DFU version 011a

Claiming USB DFU Interface...

Setting Alternate Setting #0 ...

Determining device status: state = dfuERROR, status = 10

dfuERROR, clearing status

Determining device status: state = dfuIDLE, status = 0

dfuIDLE, continuing

DFU mode device DFU version 011a

Device returned transfer size 2048

DfuSe interface name: "Internal Flash "

Performing mass erase, this can take a moment

Setting timeout to 35 seconds

Downloading to address = 0x08000000, size = 20260

Download [=========================] 100% 20260 bytes

Download done.

File downloaded successfullykeep U5V on powering by USB (closest to stepper driver modules) do not power from 24V yet.

use kiauh

install everything as pi

pi@thor ~$ cd /home/pi/kiauh

./kiauh.sh

install klipper

install moonraker 1 instance

install fluidd (install MJPG-Streamer)$ cd klipper

$ make menuconfig

enable extra low-level configuration options

Micro-controller Architecture `STMicroelectronics STM32`

Processor model `STM32F446`

Clock reference `12 MHz crystal`

Boot address 32k

Communication interface USB (on PA11/PA12)

makecopy out/klipper.bin to an sdcard as FAT32 and place it on the root directory with the name firmware.bin.

$ cd klipper

$ make menuconfig

enable extra low-level configuration options

Micro-controller Architecture `STMicroelectronics STM32`

Processor model `STM32F446`

Bootloader offset (32KiB bootloader)

Clock reference `12 MHz crystal`

Communication interface (Serial (on USART1 PA10/PA9))

makecopy out/klipper.bin to an sdcard as FAT32 and place it on the root directory with the name firmware.bin.

pi@thor ~$ sudo raspi-config

3 Interface Options Configure connections to peripherals

P6 Serial Port Enable/disable shell messages on the serial connection

Would you like a login shell to be accessible over serial? <No>

Would you like the serial port hardware to be enabled? <Yes>

add at /boot/config.txt

dtoverlay=pi3-disable-bt

remove from /boot/cmdline.txt any instance of "console=serial0,115200" or "console=ttyAMA0,115200"make sure that you have shutdown everything. place the SDCARD on spider and connect pi via usb. Power on pi and let everything boot.

goto pi and type:

$ ls -l /dev/serial/by-id/

total 0

lrwxrwxrwx 1 root root 13 Oct 10 17:45 usb-Klipper_stm32f446xx_1D0032000250563046353420-if00 -> ../../ttyACM0edit the klipper printer.cfg and enter the following (from klipper config repository ):

# This file contains common pin mappings for the Fysetc Spider board.

# To use this config, the firmware should be compiled for the STM32F446.

# When calling "menuconfig", enable "extra low-level configuration setup"

# and select the "12MHz crystal" as clock reference.

# For flashing, write the compiled klipper.bin to memory location 0x08000000

# See docs/Config_Reference.md for a description of parameters.

[stepper_x]

step_pin: PE11

dir_pin: PE10

enable_pin: !PE9

microsteps: 16

rotation_distance: 40

endstop_pin: PB14 # PA1 for X-max

position_endstop: 0

position_max: 200

[stepper_y]

step_pin: PD8

dir_pin: PB12

enable_pin: !PD9

microsteps: 16

rotation_distance: 40

endstop_pin: ^PB13 # PA2 for Y-max

position_endstop: 0

position_max: 200

[stepper_z]

step_pin: PD14

dir_pin: PD13

enable_pin: !PD15

microsteps: 16

rotation_distance: 8

endstop_pin: PA0 # PA3 for Z-max

position_endstop: 0

position_max: 400

[extruder]

step_pin: PD5

dir_pin: !PD6

enable_pin: !PD4

microsteps: 16

rotation_distance: 33.500

nozzle_diameter: 0.400

filament_diameter: 1.750

heater_pin: PB15

sensor_type: EPCOS 100K B57560G104F

sensor_pin: PC0

control: pid

pid_Kp: 22

pid_Ki: 1.08

pid_Kd: 114

min_temp: 0

max_temp: 260

#[extruder1]

#step_pin: PE6

#dir_pin: !PC13

#enable_pin: !PE5

#heater_pin: PC8

#sensor_pin: PC1

#[extruder2]

#step_pin: PE2

#dir_pin: !PE4

#enable_pin: !PE3

#heater_pin: PB3

#sensor_pin: PC2

#[extruder3]

#step_pin: PD12

#dir_pin: PC4

#enable_pin: !PE8

#[extruder4]

#step_pin: PE1

#dir_pin: !PE0

#enable_pin: !PC5

[heater_bed]

heater_pin: PB4

sensor_type: EPCOS 100K B57560G104F

sensor_pin: PC3

control: watermark

min_temp: 0

max_temp: 130

#fan for printed model FAN0

[fan]

pin: PB0

#fan for hotend FAN1

#[heater_fan my_nozzle_fan]

#pin: PB1

#shutdown_speed: 1

#fan for control board FAN2

#[heater_fan my_control_fan]

#pin: PB2

#####################################################################

# LED Control

#####################################################################

#[output_pin caselight ]

## Chamber Lighting - In 5V-RGB Position

#pin: PD3

#pwm: true

#shutdown_value: 0

#value:100

#cycle_time: 0.01

[mcu]

## Obtain definition by "ls -l /dev/serial/by-id/" then unplug to verify

serial: /dev/serial/by-id/usb-Klipper_Klipper_firmware_12345-if00

[printer]

kinematics: cartesian

max_velocity: 300

max_accel: 3000

max_z_velocity: 5

max_z_accel: 100

########################################

# TMC UART configuration

########################################

#[tmc2208 stepper_x]

#uart_pin: PE7

#run_current: 0.8

#hold_current: 0.5

#stealthchop_threshold: 999999

#[tmc2208 stepper_y]

#uart_pin: PE15

#run_current: 0.8

#hold_current: 0.5

#stealthchop_threshold: 999999

#[tmc2208 stepper_z]

#uart_pin: PD10

#run_current: 0.8

#hold_current: 0.5

#stealthchop_threshold: 999999

#[tmc2208 extruder]

#uart_pin: PD7

#run_current: 0.8

#hold_current: 0.5

#sense_resistor: 0.110

#stealthchop_threshold: 999999

#[tmc2208 extruder1]

#uart_pin: PC14

#run_current: 0.8

#hold_current: 0.5

#stealthchop_threshold: 999999

#[tmc2208 extruder2]

#uart_pin: PC15

#run_current: 0.8

#hold_current: 0.5

#stealthchop_threshold: 999999

#[tmc2208 extruder3]

#uart_pin: PA15

#run_current: 0.8

#hold_current: 0.5

#stealthchop_threshold: 999999

#[tmc2208 extruder4]

#uart_pin: PD11

#run_current: 0.8

#hold_current: 0.5

#stealthchop_threshold: 999999

########################################

# TMC SPI configuration

########################################

#[tmc2130 stepper_x]

#spi_bus: spi4

#cs_pin: PE7

#diag1_pin: PB14

#run_current: 0.800

#hold_current: 0.500

#stealthchop_threshold: 999999

#[tmc2130 stepper_y]

#spi_bus: spi4

#cs_pin: PE15

#diag1_pin: PB13

#run_current: 0.800

#hold_current: 0.500

#stealthchop_threshold: 999999

#[tmc2130 stepper_z]

#spi_bus: spi4

#cs_pin: PD10

#diag1_pin: PA0

#run_current: 0.800

#hold_current: 0.500

#stealthchop_threshold: 999999

#[tmc2130 extruder]

#spi_bus: spi4

#cs_pin: PD7

#diag1_pin: PA3

#run_current: 0.800

#hold_current: 0.500

#stealthchop_threshold: 999999

#[tmc2130 extruder1]

#spi_bus: spi4

#cs_pin: PC14

#diag1_pin: PA2

#run_current: 0.800

#hold_current: 0.500

#stealthchop_threshold: 999999

#[tmc2130 extruder2]

#spi_bus: spi4

#cs_pin: PC15

#diag1_pin: PA1

#run_current: 0.800

#hold_current: 0.500

#stealthchop_threshold: 999999

#[tmc2130 extruder3]

#spi_bus: spi4

#cs_pin: PA15

#run_current: 0.800

#hold_current: 0.500

#stealthchop_threshold: 999999

#[tmc2130 extruder4]

#spi_bus: spi4

#cs_pin: PD11

#run_current: 0.800

#hold_current: 0.500

#stealthchop_threshold: 999999

########################################

# EXP1 / EXP2 (display) pins

########################################

[board_pins]

aliases:

# EXP2 header

EXP1_10=<5V>, EXP1_9=<GND>,

EXP1_8=PD1, EXP1_7=PD0,

EXP1_6=PC12, EXP1_5=PC10, # Slot in the socket on the other side

EXP1_4=PD2, EXP1_3=PC11,

EXP1_2=PA8, EXP1_1=PC9,

# EXP1 header

EXP2_10=<5V>, EXP2_9=<GND>,

EXP2_8=<RST>, EXP2_7=PB10,

EXP2_6=PA7, EXP2_5=PC7, # Slot in the socket on the other side

EXP2_4=PA4, EXP2_3=PC6,

EXP2_2=PA5, EXP2_1=PA6

# See the sample-lcd.cfg file for definitions of common LCD displays.make sure you edit [mcu] part

type as root: systemctl restart klipper

go to the logs and verify that spider is detected:

mcu 'mcu': Starting serial connect

Loaded MCU 'mcu' 91 commands (v0.10.0-39-g5f184e3f / gcc: (15:7-2018-q2-6) 7.3.1 20180622 (release) [ARM/embedded-7-branch revision 261907] binutils: (2.31.1-11+rpi1+11) 2.31.1)

MCU 'mcu' config: BUS_PINS_i2c1=PB6,PB7 BUS_PINS_i2c2=PB10,PB11 BUS_PINS_spi3a=PC11,PC12,PC10 BUS_PINS_spi2a=PC2,PC3,PB10 BUS_PINS_i2c1a=PB8,PB9 RESERVE_PINS_USB=PA11,PA12 CLOCK_FREQ=180000000 BUS_PINS_spi1a=PB4,PB5,PB3 STATS_SUMSQ_BASE=256 STEP_DELAY=2 ADC_MAX=4095 BUS_PINS_spi4=PE13,PE14,PE12 RESERVE_PINS_crystal=PH0,PH1 BUS_PINS_spi2=PB14,PB15,PB13 BUS_PINS_spi1=PA6,PA7,PA5 BUS_PINS_spi3=PB4,PB5,PB3 MCU=stm32f446xx

Sending MCU 'mcu' printer configuration...

Configured MCU 'mcu' (1024 moves)

Starting heater checks for heater_bed

Starting heater checks for extruder

...

shutdown everything, remove sdcard and verify that the firmware.bin is not there anymore.

when you want to upgrade the firmware you will always do it with the sdcard.