The controller presented in this lab works by means of repeatedly calling

the function run(desired, actual) on the instantiated motor controller object.

This function computes the difference between the desired and actual angular

displacements of the motor, then multiplies this value by a user defined gain,

Kp, to obtain a PWM value. This value may then be fed into a Motor Driver object,

as defined in the motor_driver.py class file. The desired position is user

defined, while the actual position is returned by means of an Encoder Reader

object, as defined in the encoder_reader.py file.

The motor driver class is responsible for instantiating the driving pins used to

operate the motor, and for updating the PWM signal used to drive the motor by

means of the set_duty_cycle(level) function. When updated adequately quickly

by the closed loop controller, it is possible to drive the motor to a given

angular displacement by means of varying the velocity alone.

The encoder reader class is responsible for instantiating the input pins used to

detect changes in motor position. The board's onboard counter is able to detect

and store up to 4000 unique positions (corresponding to one half revolution of

the motor), while the absolute displacement is managed by the class. The read()

function is able to track changes in angular displacement and compare them to

the previously stored value, and updates the displacement accordingly. The

function prevents against auto-reload related counter errors by comparing the

change in position to (AR + 1)/2. As long as the function is run adequately

quickly (100 times per second or more), this comparatively large displacement

will catch overflow/underflow in the counter.

The step response plotter recieves data transmitted from the MCU over the serial port to the PC. The MCU sends both time and positioning data read by the internal clock and the encoder from the encoder_reader.py over the ST-Link. The PC opens the serial port off COM11 and reads the time and positioning data sent from the MCU. The program reads from the serial port until given a command to stop, which it then transitions to plotting the recieved data.

As written in the provided documentation: "Tasks are created as generators,

functions which have infinite loops and call yield() at least once in the

loop. References to all the tasks to be run in the system are kept in a list

maintained by class CoTaskList; the system scheduler then runs the tasks'

run() methods according to a chosen scheduling algorithm such as round-robin

or highest-priority-first."

As stated in the provided documentation: "This file contains classes which allow tasks to share data without the risk of data corruption by interrupts."

The main function sets up two motors, encoders and closed-loop controllers for use in two tasks (implemented as generator functions) that run continuously in the main loop. By providing a Kp value to the main.py, the program uses the encoder_reader.py to determine respective positions and uses a simple proportional gain model to control the motors.

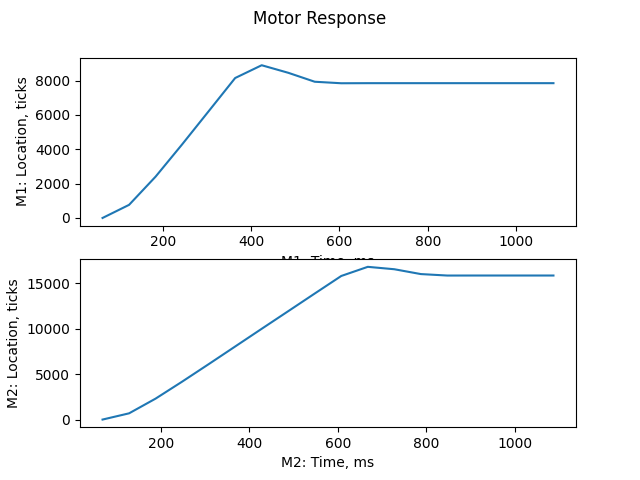

When the motor controller tasks are run too slowly, the response of the system

becomes discretized and jagged. Through repeated trials of the flywheel system,

we found a period of 60 ms to be the point at which the system was running too

slow to function properly. The results of this test are provided in

Figure 1.

Figure 1: Long period response of flywheel to a 1 revolution and 2 revolution

input position, respectively.

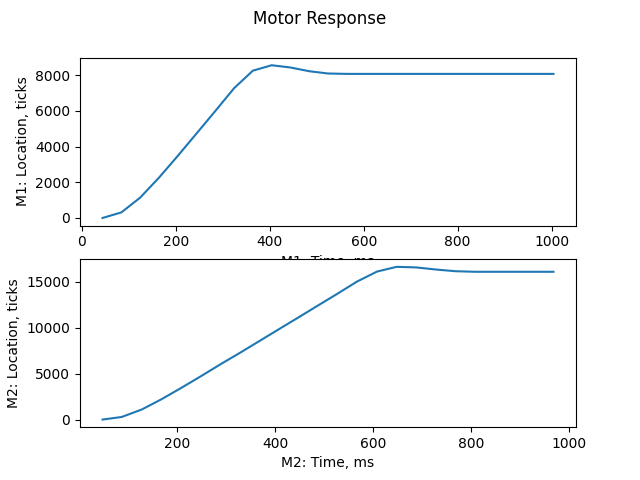

Based on these trials, we recommend a maximum period of 50 ms for good data plotting

as can be seen in Figure 2.

Figure 2: General response of the flywheel systems to a 1 revolution and 2

revolution input position, respectively.