DCC multifunction decoder for H0 locomotives

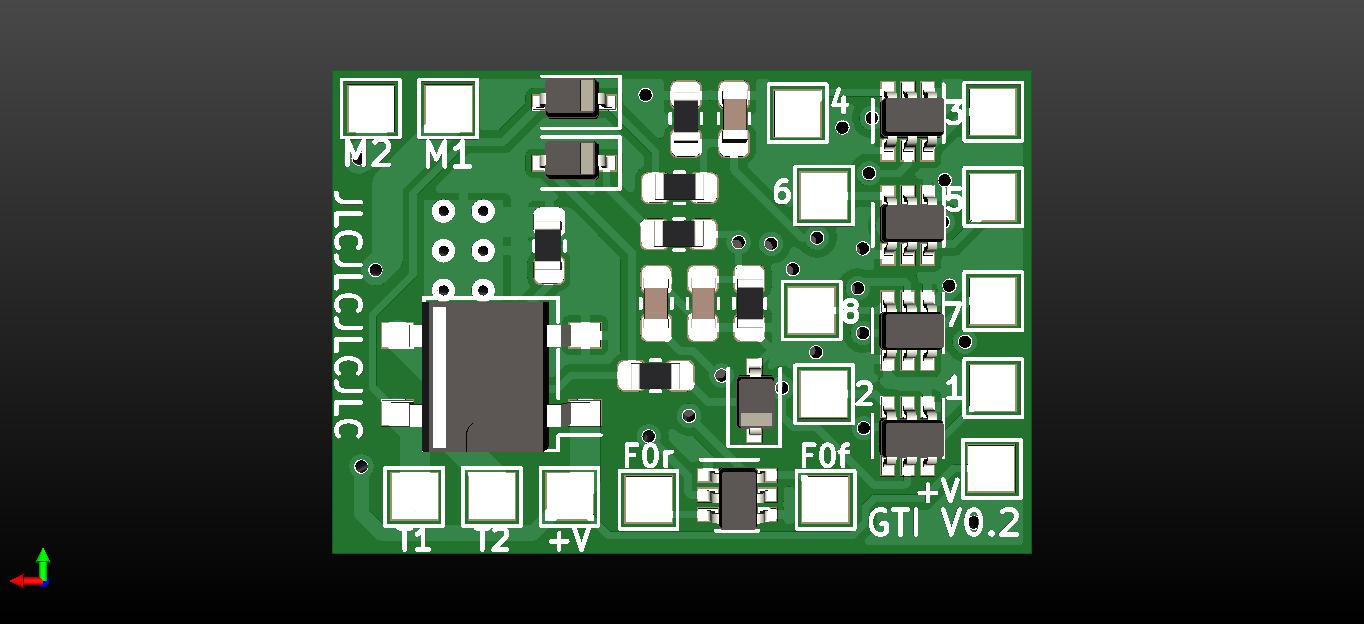

- 1 motor H-bridge output

- 3.6 A peak current

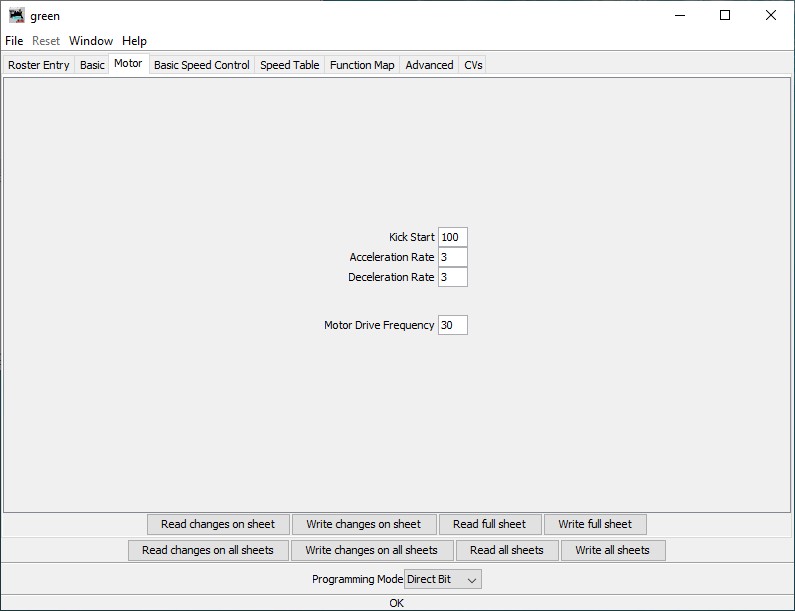

- PWM frequency configurable (1-40 kHz)

- overcurrent and temperature protected

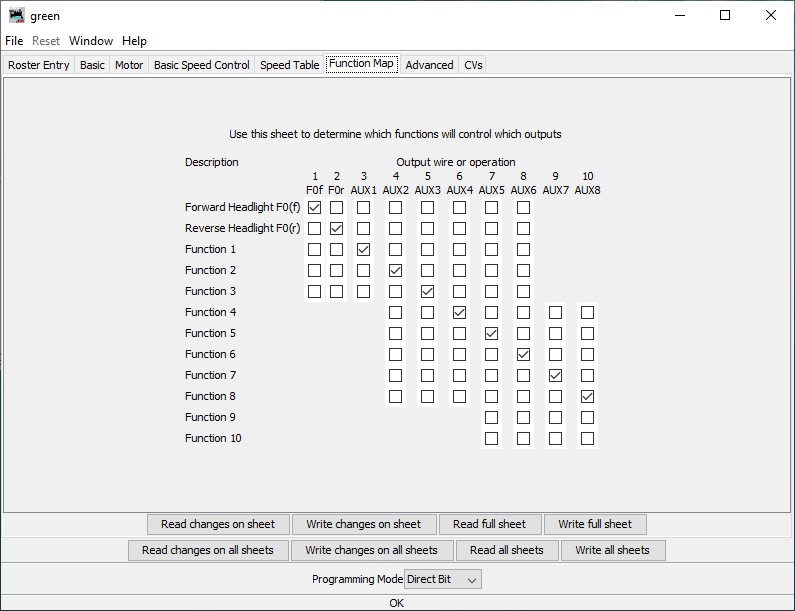

- 10 function outputs

- 115 mA per output

- F0f, F0r, AUX1 and AUX2 are dimmable todo

- mappable to F0-F12 function keys

- DCC asymmetry can be detected (for automatic brake control) todo

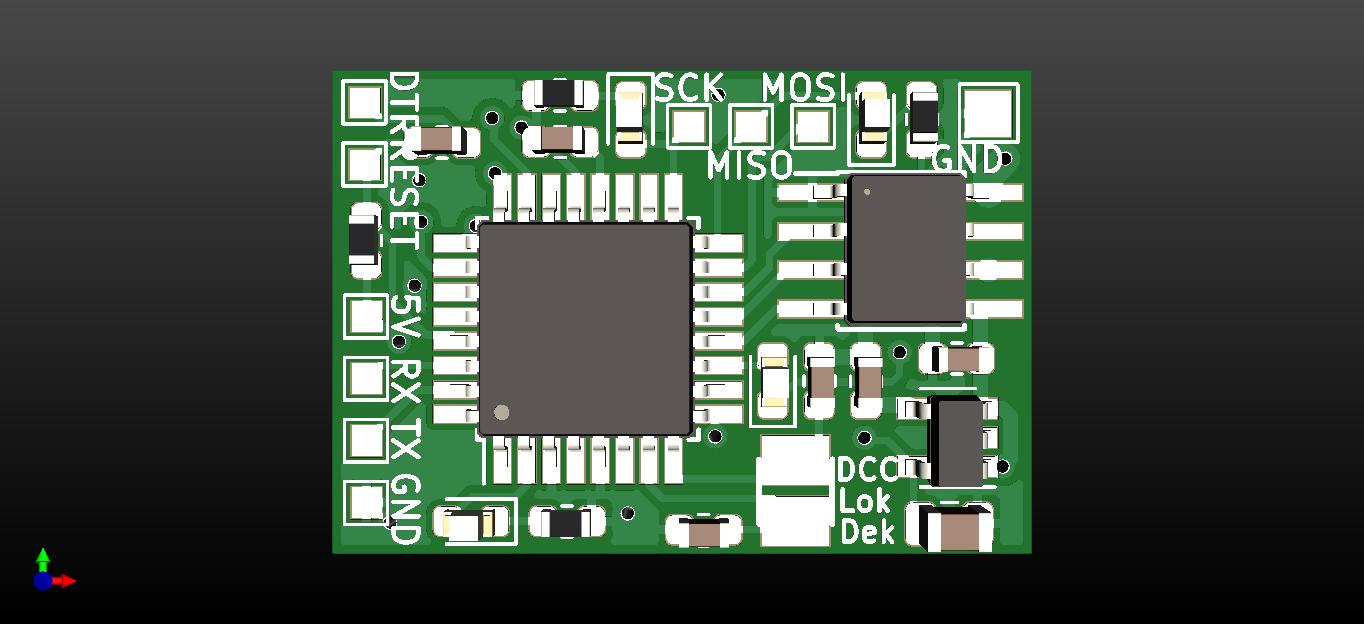

- 4-layer PCB esigned in KiCAD

- fairly standard components (available from Digi-Key, Farnell, Mouser, etc...)

- hand solderable (I did it too)

- 4 debug LEDs (red, yellow, green and blue)

|

|

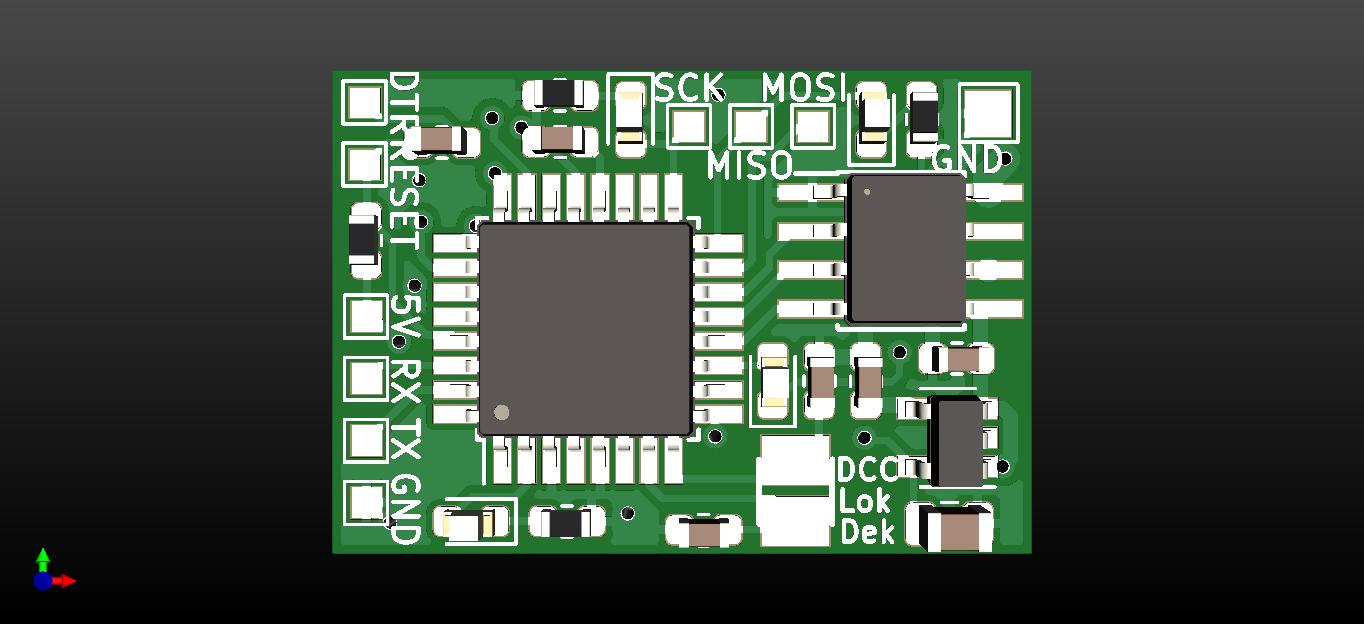

| top side |

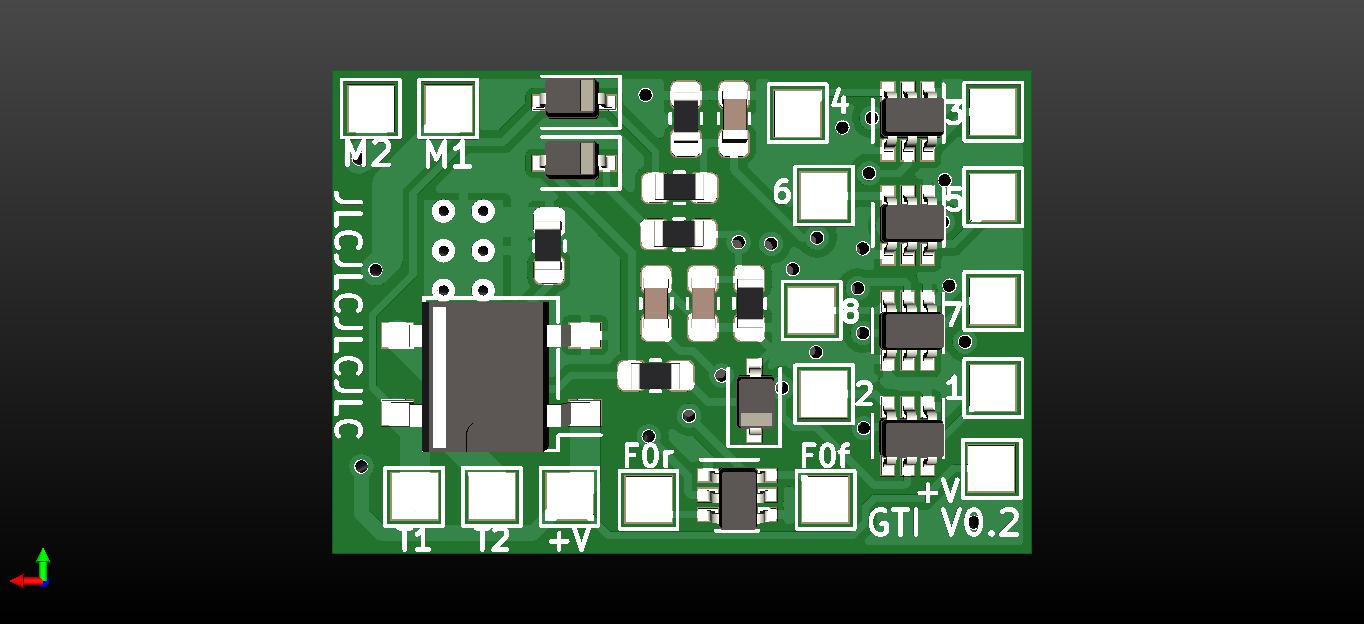

bottom side |

- Arduino compatible programming (behaves like an UNO)

- DCC decoding by NmraDcc library

|

|

|

|

|

|

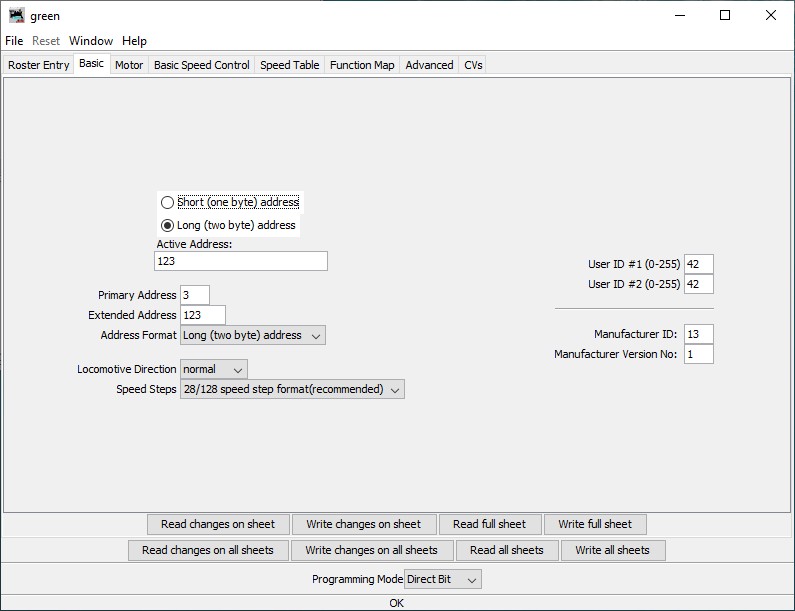

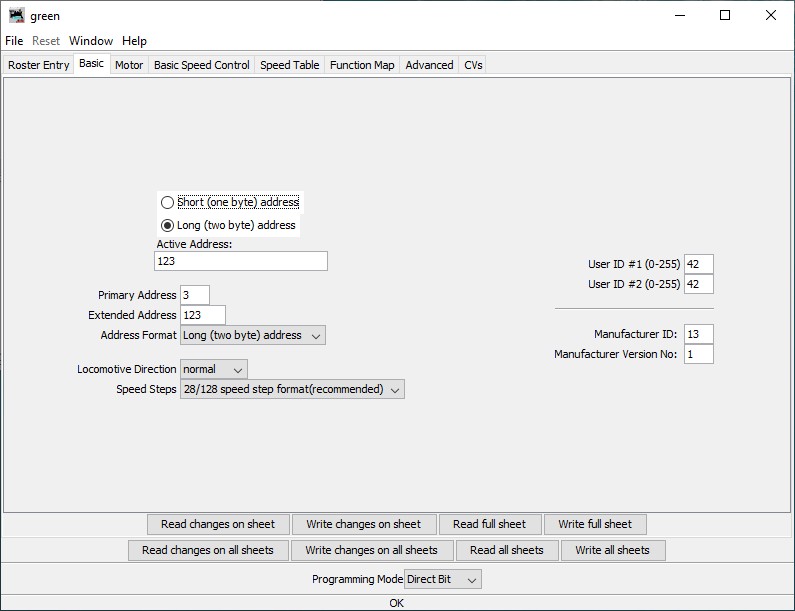

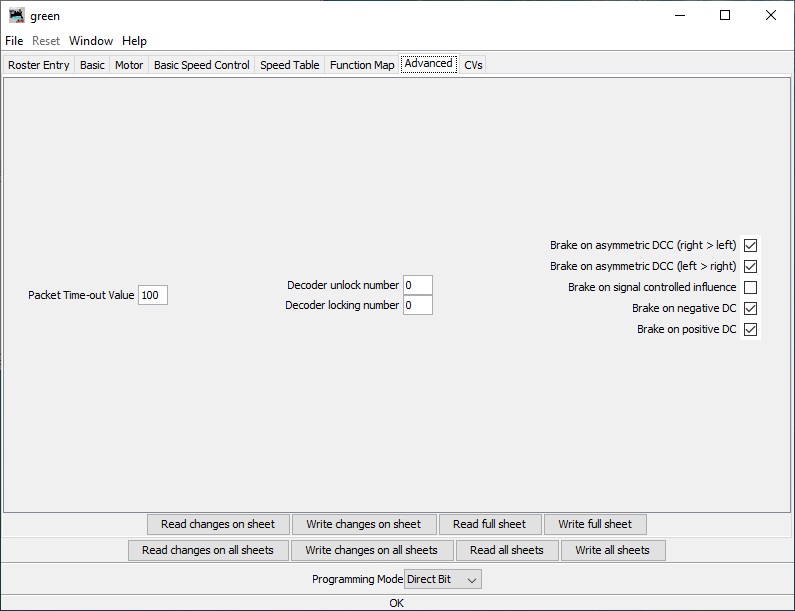

| Basic |

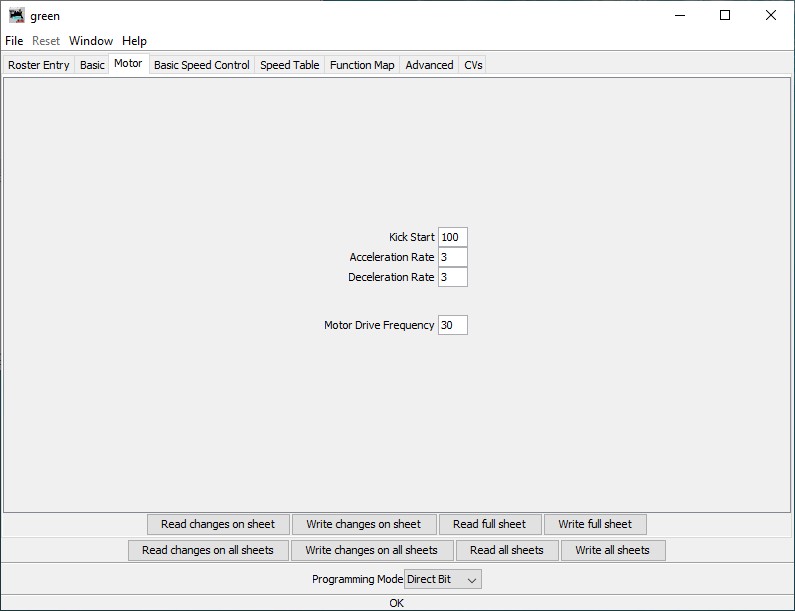

Motor |

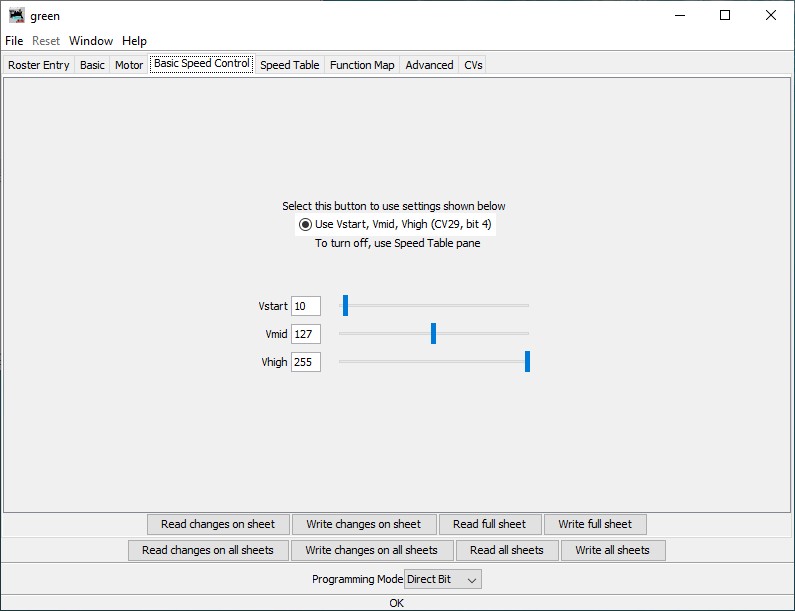

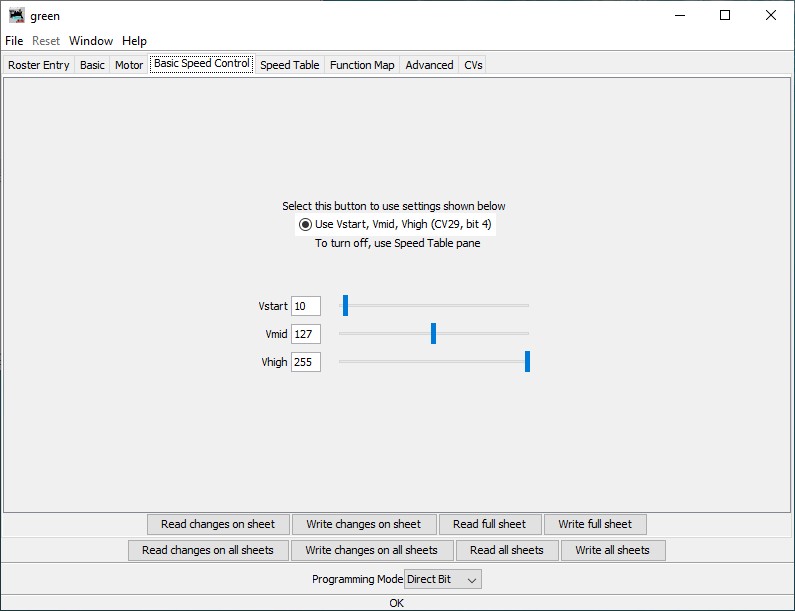

Basic speed control |

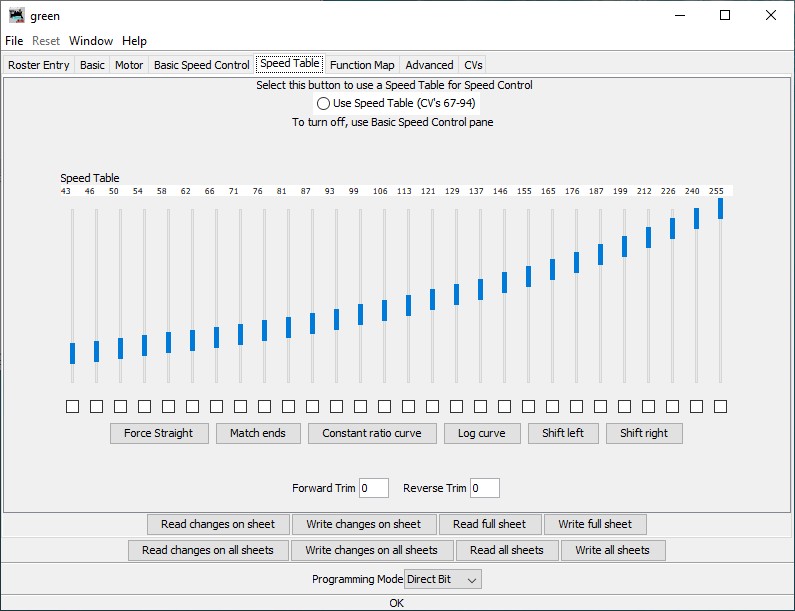

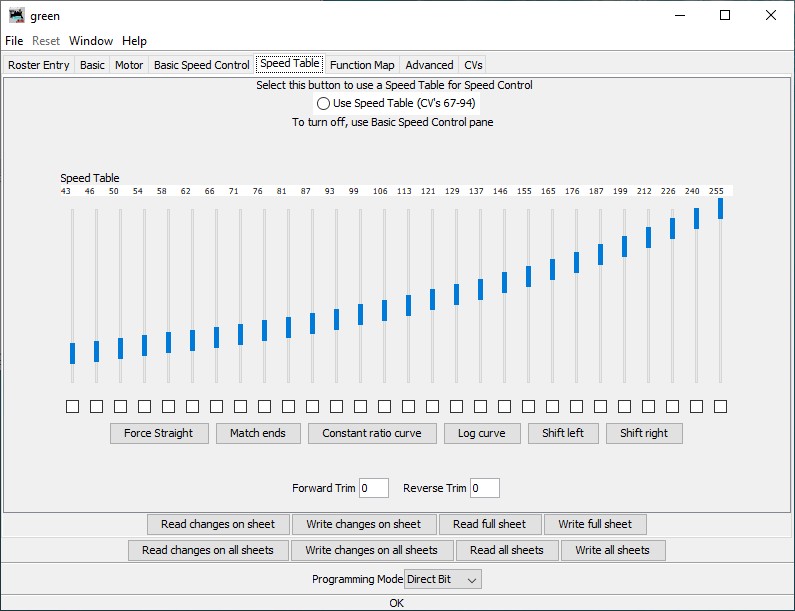

Speed table |

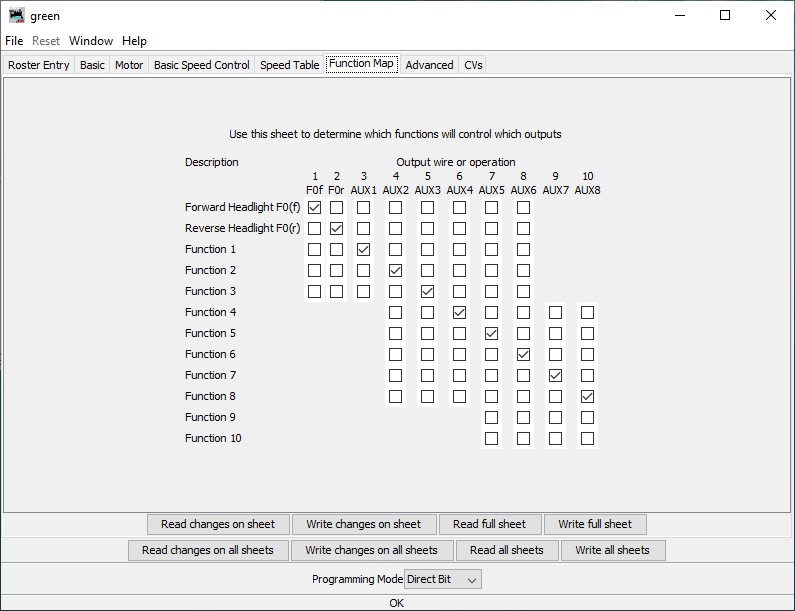

Function map |

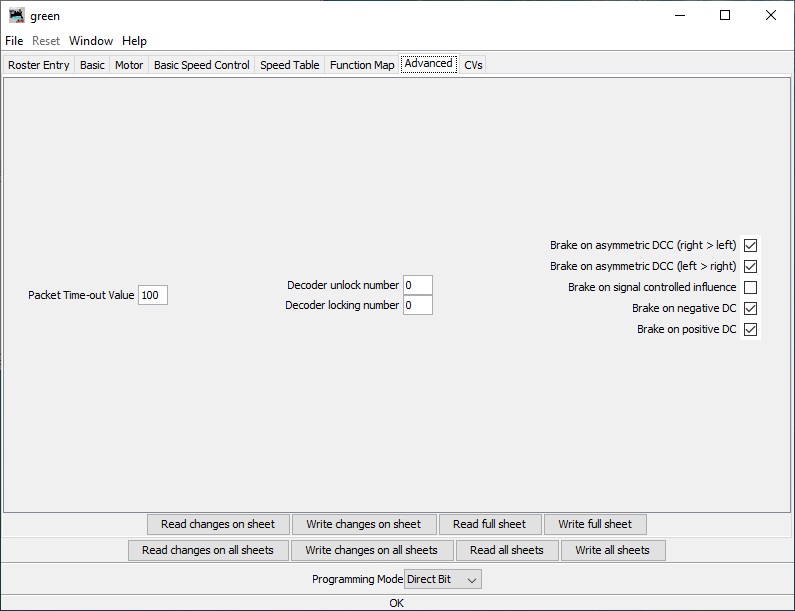

Advanced |

- Get the PCB (e.g. JLCPCB) and the components (e.g. mouser, digikey)

- Solder the components. The SOIC with exposed pad is a bit tricky, it can be soldered from the other side with a big tip and a lot of flux.

- Install the Arduino bootloader using the pads 5V, GND, SCK, MISO, MOSI, RST and an Arduino. Arduino as ISP

- Uncomment the line

#define RESET_FACTORY_DEFAULTS to fill the EEPROM with the default CV values

- Upload the code using the pads 5V, GND, RX, TX, DTR and a USB TTL UART cable like this

- Re-comment the line

#define RESET_FACTORY_DEFAULTS to avoid resetting to factory defaults every time.

- Upload the code again.

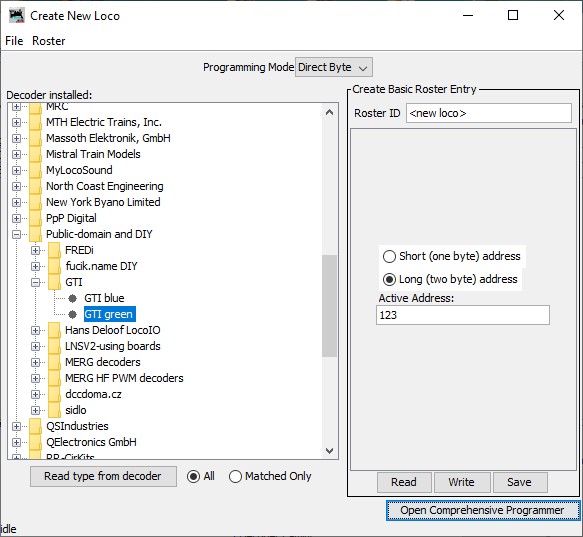

- Add the decoder XML file to JMRI. In DecoderPro select "File-> Import Decoder File..." and browse to the decoder XML. It will take some time, then adds the decoder definition to the database.

- Connect the T1 and T2 pads to the programming track of your DCC system.

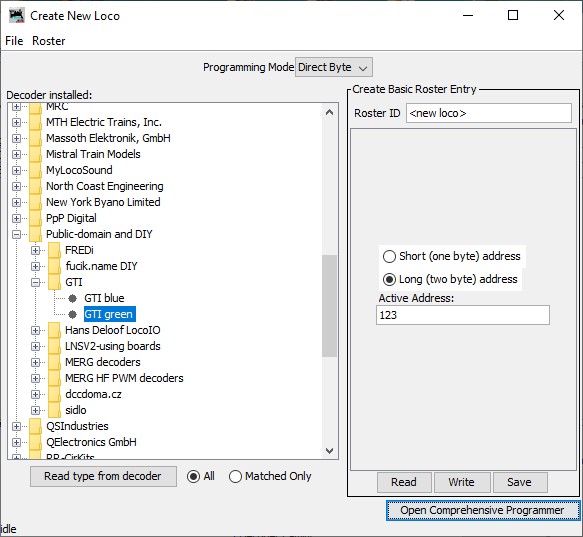

- Add new locomotive with the "New Loco" button and then "Read type from decoder". It should detect the correct type:

- If everything is fine, you can install the decoder into your locomotive!

| Pad |

Function |

| M1 |

Motor 1 |

| M2 |

Motor 2 |

| T1 |

Track 1 |

| T2 |

Track 2 |

| V+ |

Positive common for function outputs (keep-alive capacitor positive) |

| F0f |

F0 function output forward (open drain) |

| F0r |

F0 function output reverse (open drain) |

| 1-8 |

AUX function output n (open drain) |

| 5V |

internal microcontroller +5V supply |

| GND |

ground (keep alive capacitor negative) |

| SCK |

ISP programming clock (connect to ISP SCK) |

| MISO |

ISP programming read (connect to ISP MISO) |

| MOSI |

ISP programming write (connect to ISP MOSI) |

| RST |

ISP programming reset (connect to ISP reset output) |

| RX |

serial programming receive (connect to TTL UART TX) |

| TX |

serial programming transmit (connect to TTL UART RX) |

| DTR |

serial programming reset through a 100 nF capacitor (connect to TTL UART DTR) |