notes from building and setting up a DIY pen plotter

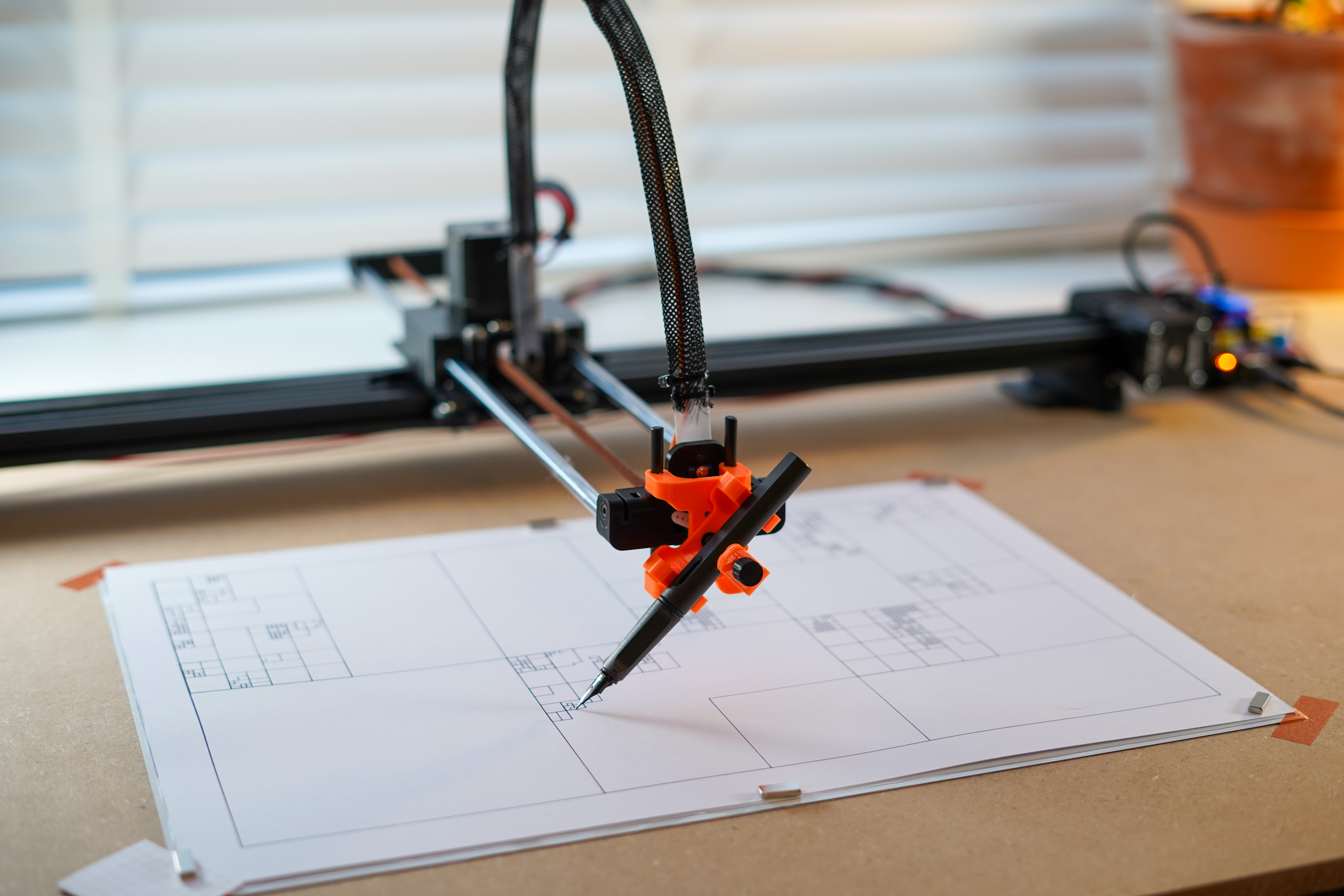

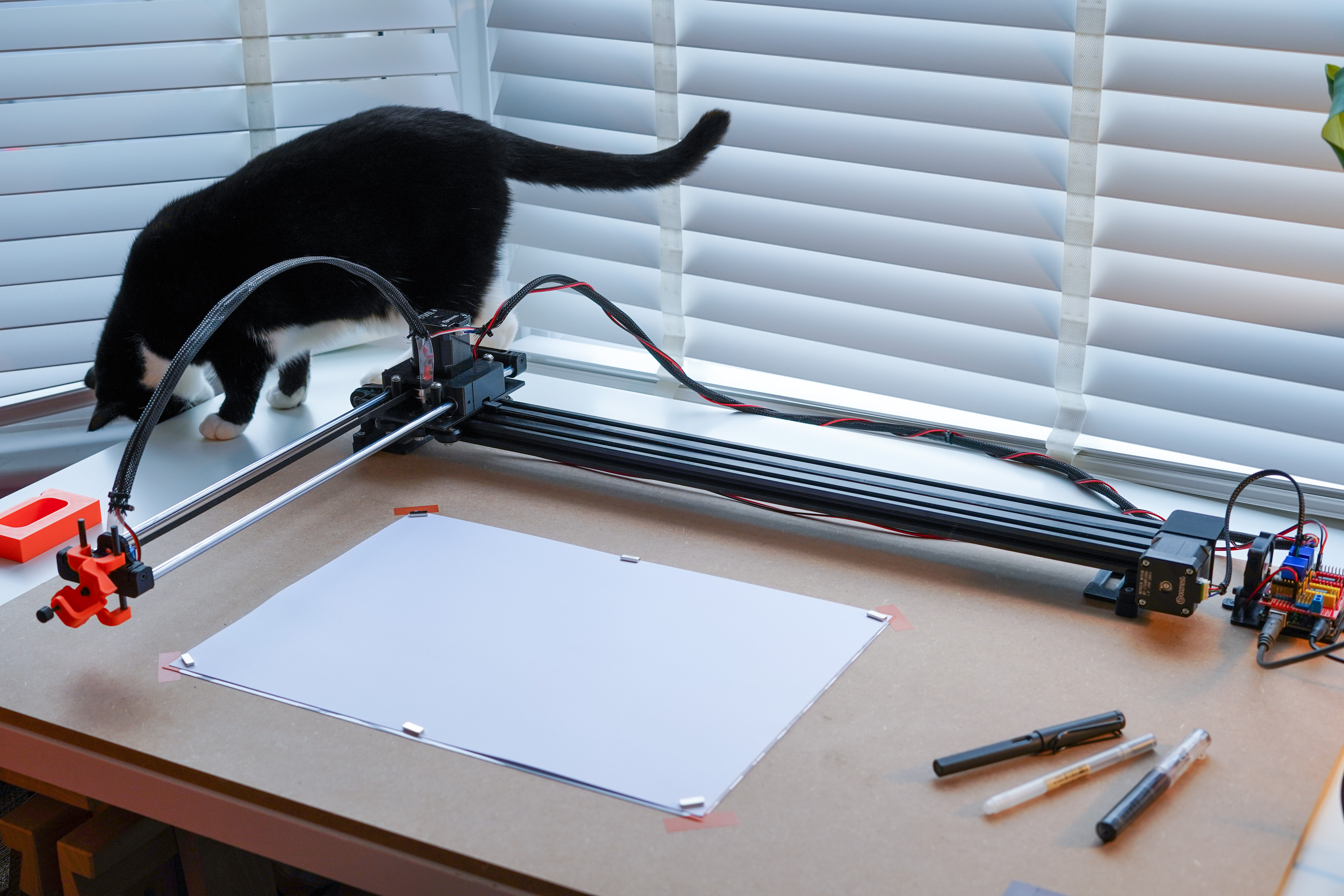

I've used the X-Y plotter (like the Axidraw/Next draw) designed by Andrew Sleigh (v3). The design is simple, and the build was easy enough to work out. Andrew's design and guide is excellent. There isn't more I need to add really, go and build it!

-

I 3D printed the parts (PLA seems fine)

and opted for a 700mm v-slot X-axis, and a 500mm linear rails Y-axis. This gives me a working plotting area of about 420mm x 300 mm, which is frustratingly way too big for A3, and just a bit short to print A2 sized-plots.[EDIT: I have now rebuilt this with an 800 mm v-slot for the X-axis, and 600 mm linear rods for the Y-axis. This now accomodates A2-sized paper (420 x 594 mm). The Y-axis droop isn't as bad as I had feared.] -

I have noticed some slight 'drooping' on the Y-axis arm, so going beyond the current size might cause problems there. If I do need to scale up, I might look at an H-system design, as seen in the ACRO, Unatek, and more recently, the Bantam ArtFrame designs.

-

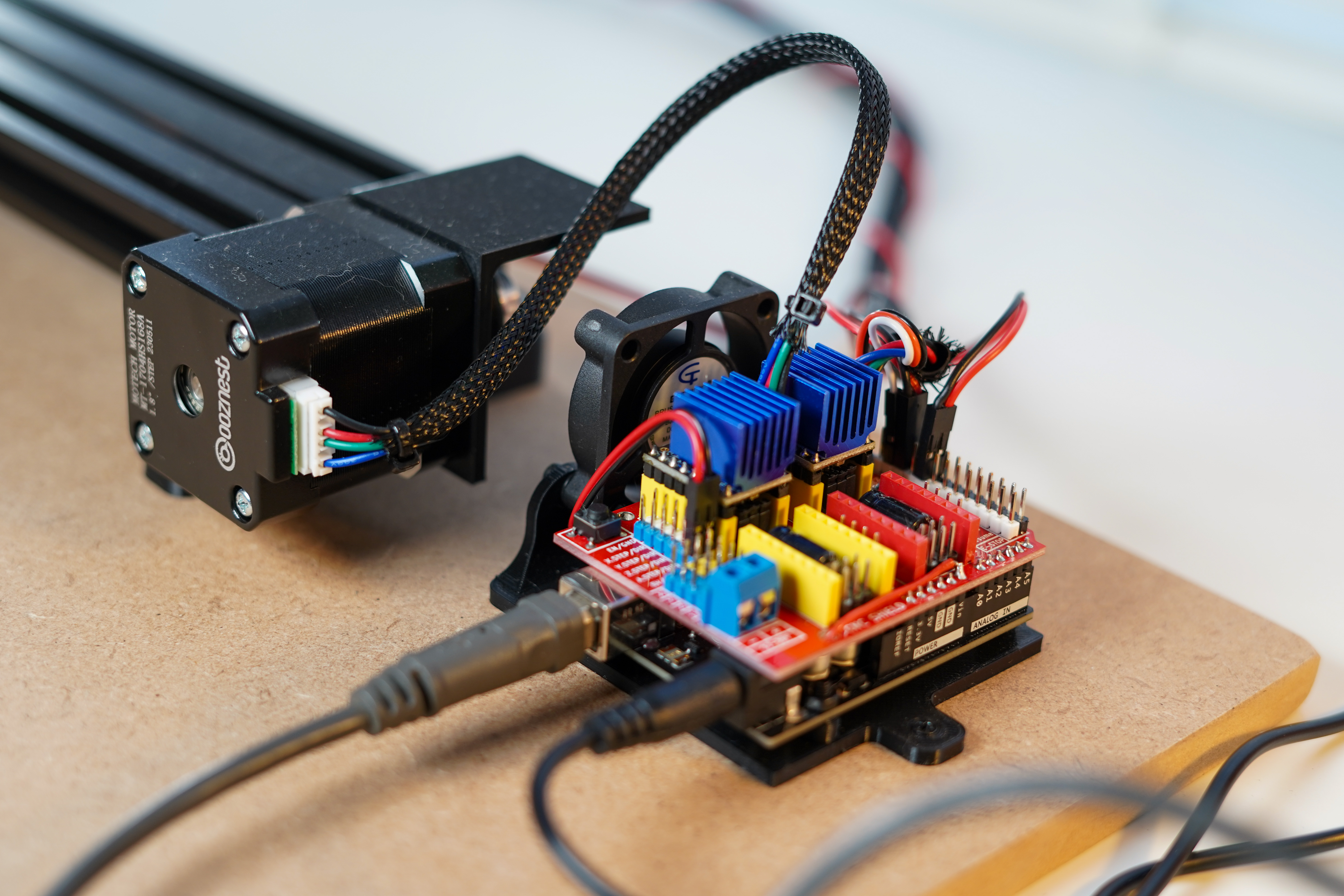

The BOM on Sleigh's post is good. In the UK, I purchased most parts from https://ooznest.co.uk. I would guess that the whole build cost me under £150 (2024)?

-

Don't underestimate the amount/type/colour bolts you need.

-

I hate doing Dupont crimps by hand, but I hate the idea of buying a tool more.

The plotter runs off an Arduino (Elegoo R3) with a CNC shield (protoneer clone). It's running GRBL, controlled with G-code, like a CNC machine. On the CNC shield, I opted for TMC2208 motor drivers with NEMA17 Stepper Motors (1.8° 77oz - probably overkill), and I'm really happy with the lower noise and performance so far. I dialled the Vref down to about 0.8V on each driver (ymmv) and with the fan and heatsinks it seems happy. Before that, the drivers and motors got a bit warm during a plot.

For the CNC shield, note that you'll need to make a small modification in order to draw 12V power from the Arduino to power the motors, rather than use a second power supply. Sleigh mentions it in the guide, but don't overlook it.

Sleigh's design worked brilliantly for me (apart from the Arduino box fit/print time), but I've made a few small modifications to the 3D printer parts:

- A new mounting bracket for the Arduino and CNC shield. (STL file) - I found the original box didn't account for heat sinks, was fiddly to install and took a long time to print. I've opted for an open mount, with a bracket to hold a 40 mm fan pointed at the heat sinks which works well.

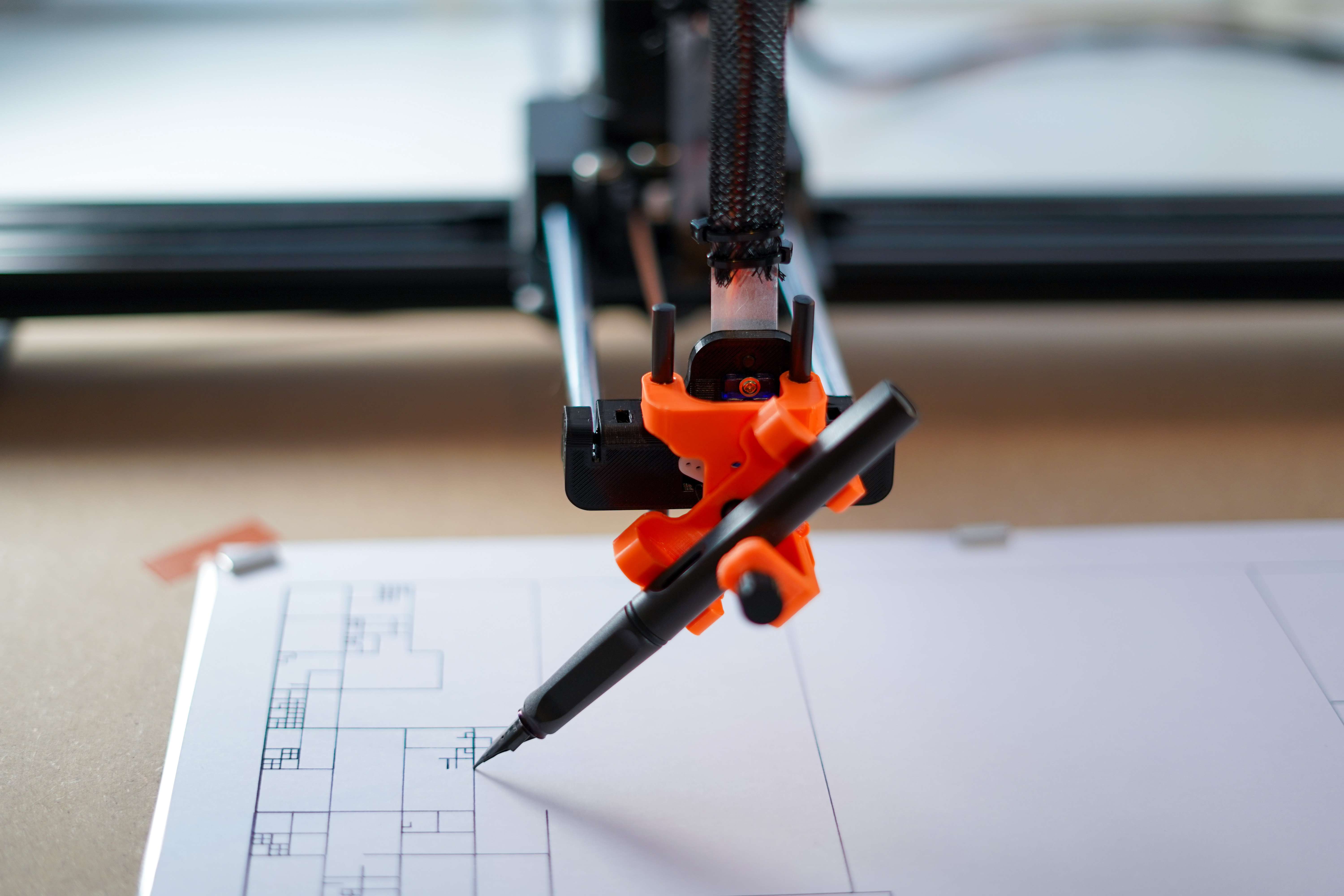

- Remixed Sleigh's pen holder design for fountain pens. (STL files) - I've split this into two parts, allowing the pen-holder to rotate to 45 degrees. This allows it to be used with fountain pens, like the Axi/Next Draw. It's not perfect, I'll probably keep tweaking this. If you just want normal vertically mounted pens, use the Sleigh design.

- Foot risers. This was to give more space for vertically mounted pens when I was printing on a seperate board. Now that I've mounted the plotter on a large MDF sheet, the risers are probably unneccessary. Also, with 45 degree fountain pens, the gap is actually a bit big... so I'll probably remove these soon.

Not essential, but I've recently added (x2) limit switches to the 0 ends of my x and y axes so that I can home the plotter. This isn't essential and I'm not sure how much it helps. There's a bit of a confusion on the CNC shield, even though there's two jumpers (+ and -) for each axis limit switch... connecting both ends doesn't work. You need to wire the switches in series and just connect to one of the jumpers (and ground). The cabling started to get a bit messy with both ends' limit switches, so I've just opted for one switch per axis for now.

Once assesmbled, the plotter needs calibrating. Szymon Kaliski has some useful notes here. I found that UGS offers a helpful GUI wizard for calculating and setting things like travel resolution and limit/end-switches. You can also set these commands individually in the CNCJS console. This is obviously specific to every machine. As a starting point, my settings are here. (TOODO: add settings file)

It isn't vanilla grbl we're using here, instead one of the many pen-servo variants (I think I used this one, but I can't recall now.).

As outlined in the plotter design notes, you need to make a couple of modifications to the grbl library. I had to modify the pen-up/down positions in spindle_control.c before uploading to Arduino. Then in the gcode this equates to Z0 = pen down, and Z>0 = pen up

So the plotter is built, and everything is calibrated and tested. Pen and paper ready! How to plot?

- Create your SVG in Processing/P5js/Inkscape.

- Optimise SVG and convert to GCode with

vpypeandvpype-gcode. - Preview plot with vpype's

showcommand instead of final output. E.g.:vpype read input.svg linemerge linesort linesimplify showto check it looks good - Plot! Send GCode to modified GRBL on Arduino/CNC shield, controlling the plotter (this has to be sent 'live', so make sure your computer doesn't sleep). I'm using cncjs for this control.

P5js doesn't support SVG export natively. Until recently we had to use the p5.js-svg library which has been out of date for a while. Golan Levin has now come to the rescue with P5.PlotSVG - SVG rendering, specifically for pen plotters! For the now depreciated use of exporting SVGs in p5js, see here.

vpype -c config.toml read --no-crop input.svg layout a4 pagerotate occult -i linemerge linesort linesimplify gwrite -p fast-plot output.gcode

This loads the custom config .toml file, in your working directory. This is where I've set my plotter profiles which formats the gcode. You can see an example of my config profile here (my default is 'fast-plot')

Sometimes you'll want to plot in multiple pens, colours, etc. To do that, you can split an SVG into multiple layers, each layer getting its own gcode to plot (be careful to align your pen nib for each layer...)

In vpype, read the svg, splitting layers by stroke (read -a stroke), then delete all layers, keeping the one you want (ldelete --keep 1)

For example:

First, inspect your layers to see which is which (take note of the layer number):

vpype read --no-crop -a stroke circle-packed.svg show

Then run the command to render your gcode for the desired layer:

vpype -c thrly-config.toml read --no-crop -a stroke circle-packed.svg layout -m 3cm 282x210mm pagerotate ldelete --keep 1 linemerge reloop linesort gwrite -p fast-plot circle-pack-layer-1.gcode

Ensure that you delete the layers after setting your layout/scale/position, otherwise the layers will be out of alignment with each other. Then repeat for each layer.

[EDIT, Nov '24: that said, I think I've had some problems recently with alignment between layers, so maybe something is off here?]

- the plotter - https://github.com/andrewsleigh/plotter/tree/master

- my fountain pen holder - https://www.thingiverse.com/thing:6845438

- grbl pen servo, running on the arduin + cnc shield - download and install instead of vanilla GRBL (install in the same way) https://github.com/bdring/Grbl_Pen_Servo/tree/master

- Processing or p5js for designing generative stuff.

- Inkscape -- I'm not using it for design/layout, but its occasionally useful for debugging a weird SVG file.

- P5.PlotSVG - SVG rendering, specifically for pen plotters - https://github.com/golanlevin/p5.plotSvg

P5.js-SVG library, because P5js doesn't actually support SVGs (only working with P5js v. 1.6.0)- https://github.com/zenozeng/p5.js-svg(depreciated in my recent workflow)- vpype for optimising svg for plotting - https://github.com/abey79/vpype

- vpype-gcode (plugin) for converting svg to gcode - https://github.com/plottertools/vpype-gcode

- vpype occult (plugin) for hidden line removal

- cncjs - https://cnc.js.org/

See here for a list of useful pen-plotting / generative art writing, talks, blogs, etc.

- Redesign pen holder to make servo more easily replaceable

- Hook up a raspberry pi to run cncjs headless, so I can free up my computer and send plots over the network.

I've been logging some of my plots on instagram: https://www.instagram.com/ot.x.y/

If you found any of this useful, please drop me a comment! 👋

Oliver