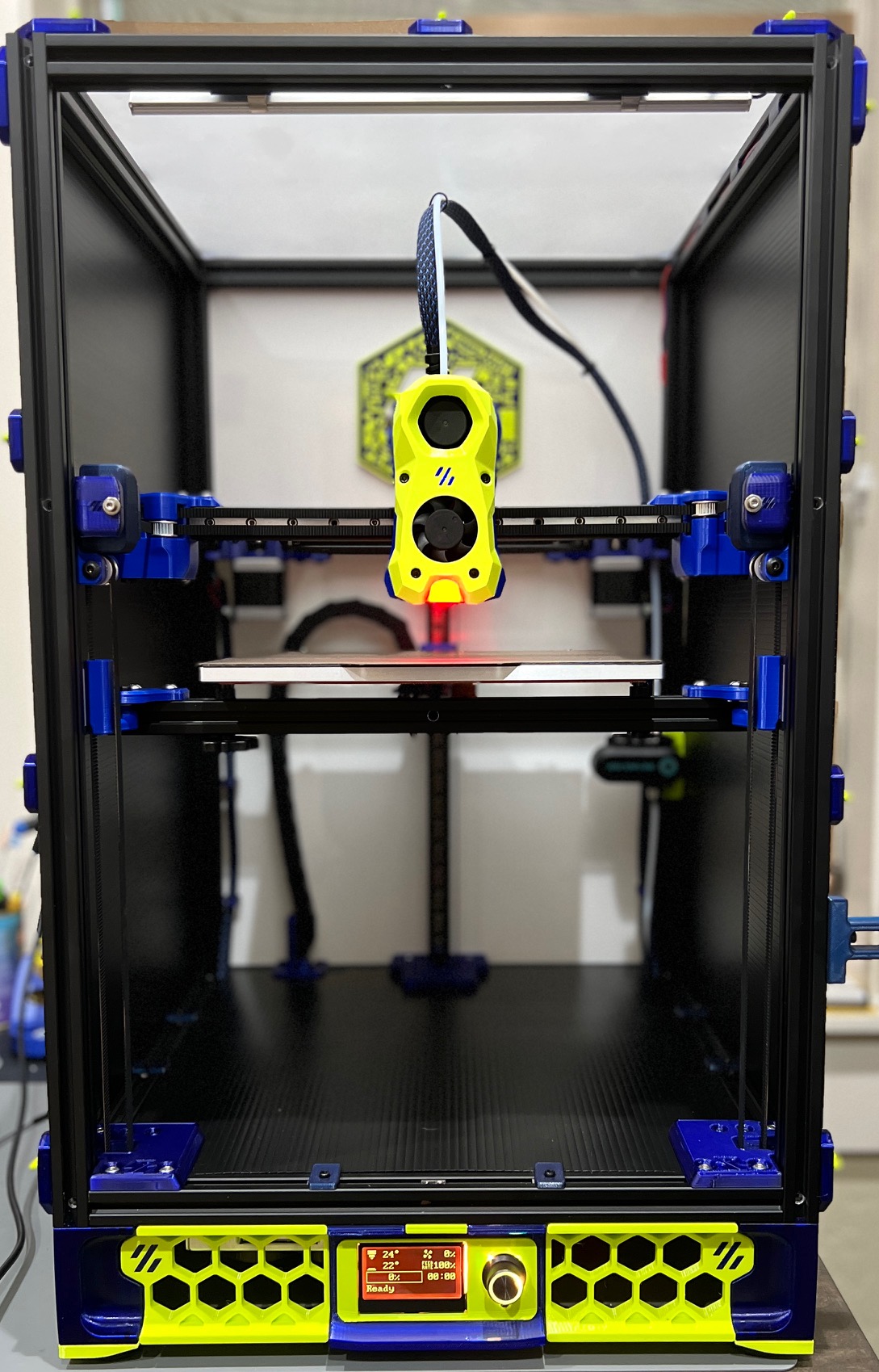

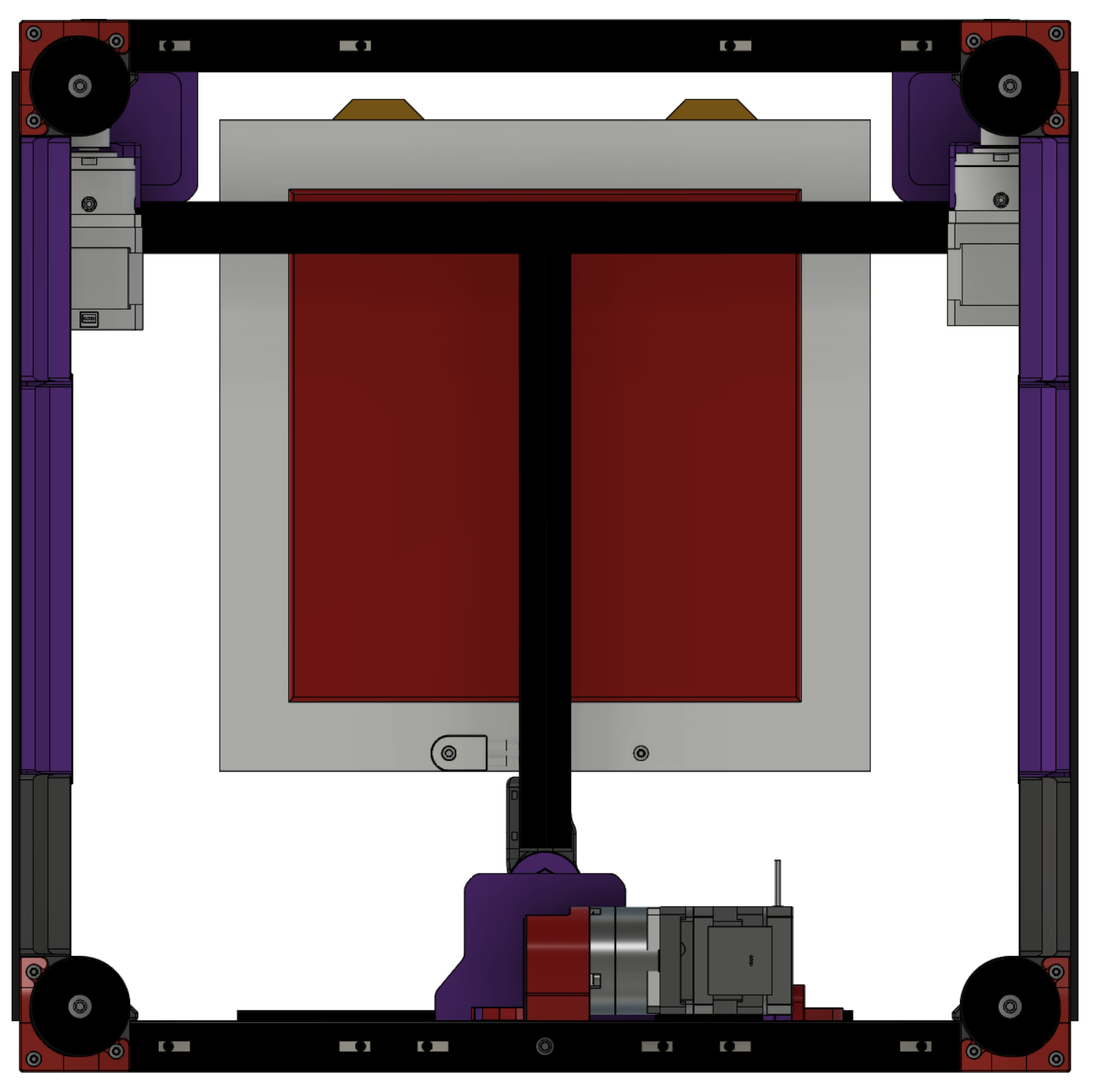

Belt all the things.

This mod is the combination of multiple ideas for belted system for the Trident Z motion. Most of the inspiration came from X0, which uses NEMA 17 gearboxes. The main goal was to use 9mm belts for Z motion while keeping most of the original Trident skirts and not relocating Z steppers to the top of the printer. We give credit to bythorsthunder for his Orion belted mod, which has also been proven efficient and easy to assemble (the same applies to the belted z motion mod introduced by MathematicalPotato).

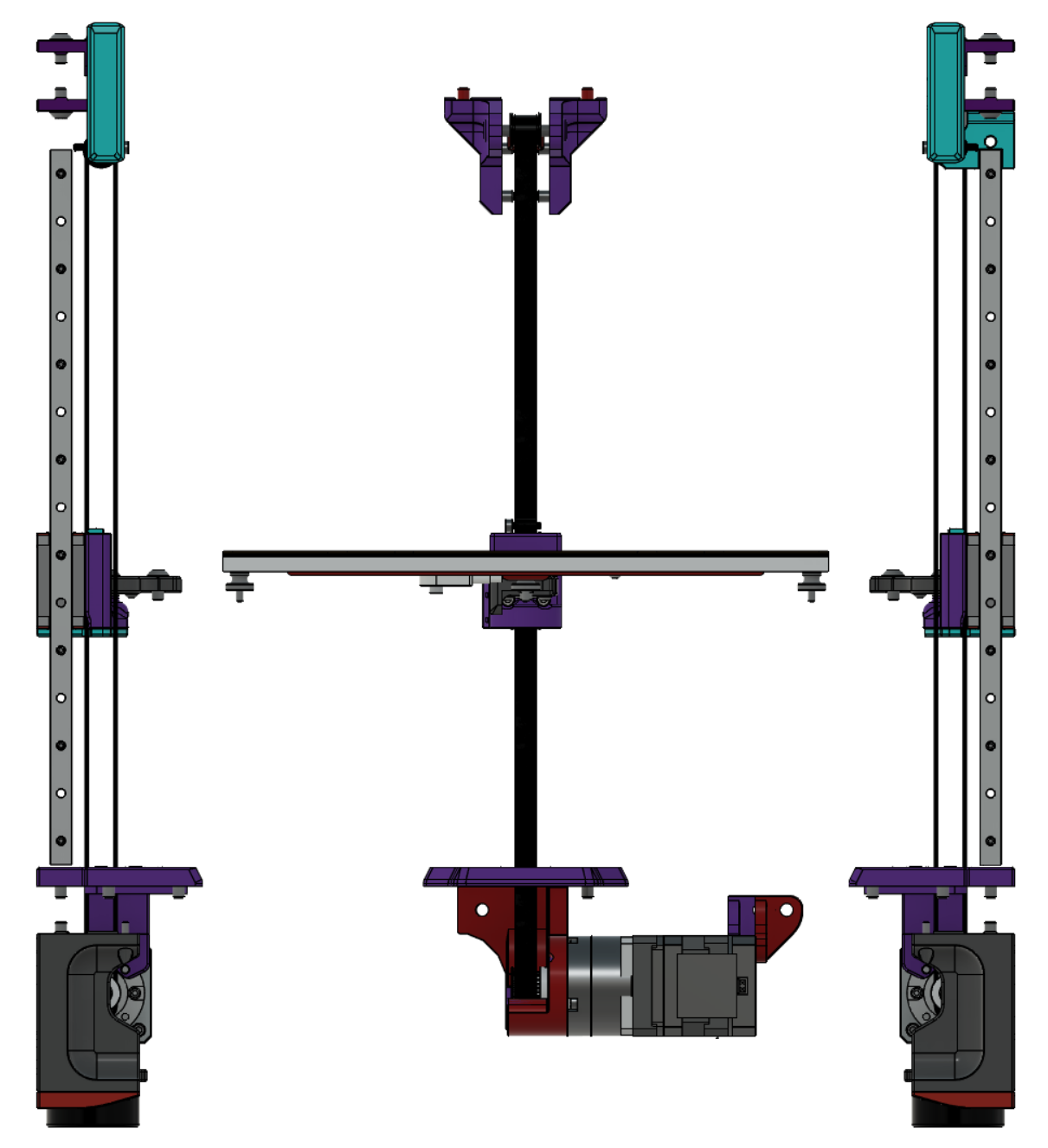

The design offers two different options for the Z idlers:

MathmaticalPotato Idlers:

- Uses existing XY front idlers

- Limited to ONLY 9mm wide pulleys (12mm overall width)

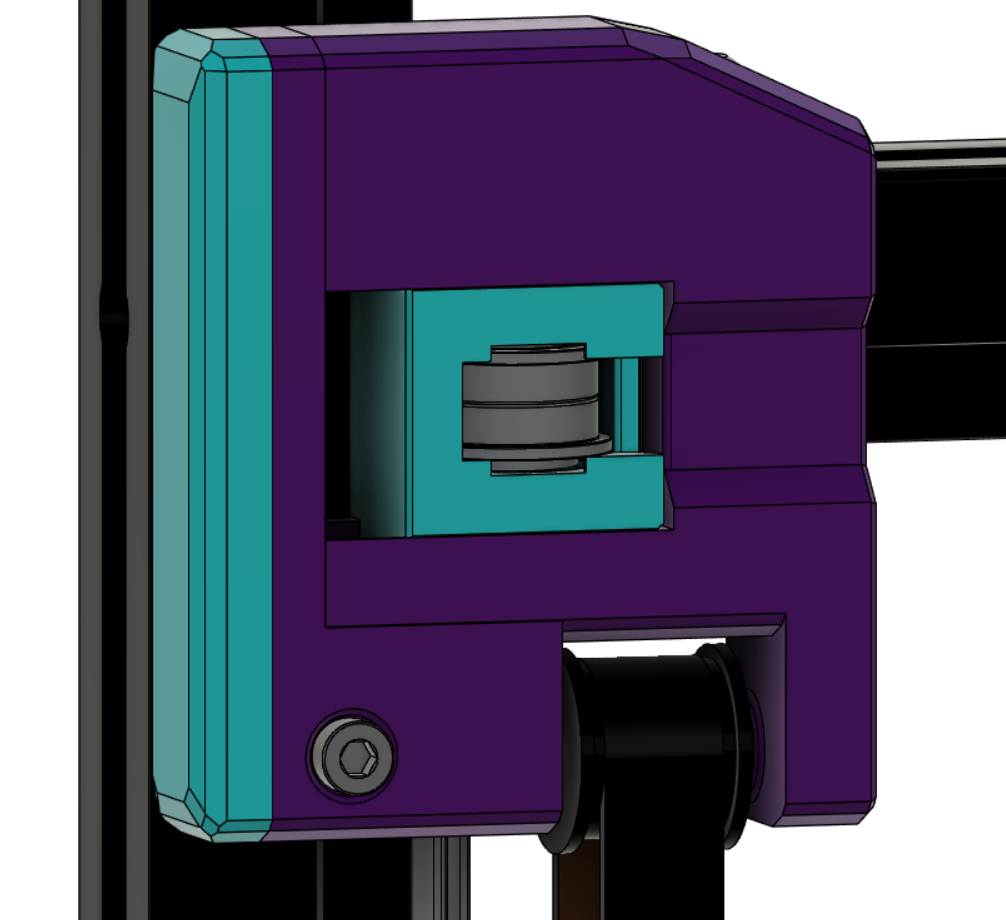

DoubleT XYZ Idlers:

- Modified version of the Ramalama2 idler design

- Z idler pully integrated into XY idler

- More flexibility in Z pulley width

Refer to the CAD drawing for detail on both Idlers. BOM contains sections for both.

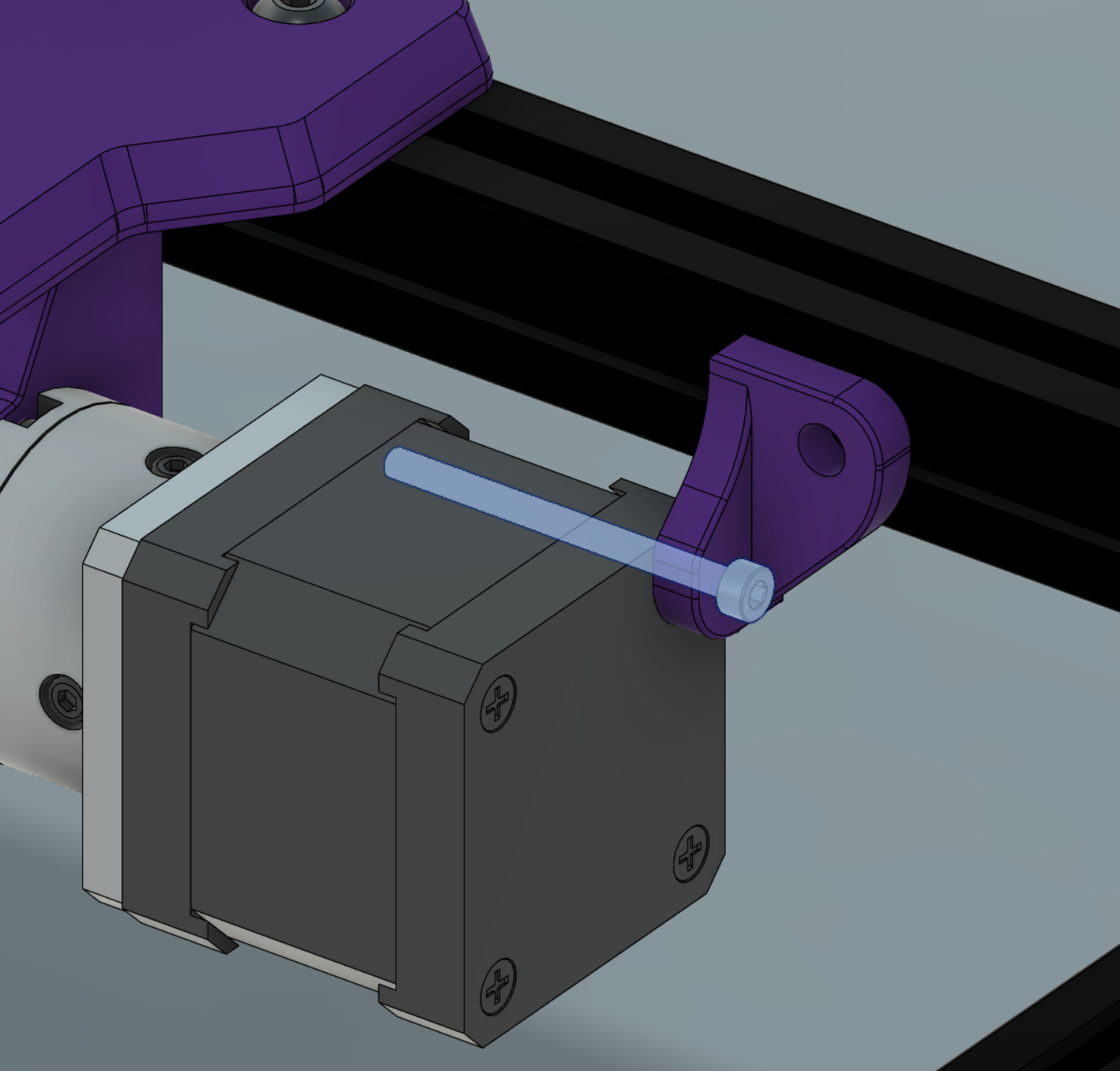

- Revised rear motor mount and idler. Orientation of the motor turned 90 degrees. New idler replaces the rear bracing from Z extrusion to A/B drive extrusion

- New front idler option added. Integrated the Z idler pulley into DoubleT's modified Rama idlers.

- Cleaned up the CAD

- Added motor skirts for 350mm build size

Required parts:

- 3 NEMA 17 Economy planetary steppers

- 9mm GT2 belts

- 3 9mm 20T GT2 drive pulleys, 8mm ID

- 3 9mm 20T toothed idlers, 5mm ID - Gates/Runice recommended. (Overall width of less than 14mm, Flange diameter less than 16mm)

- 9 M3x12 Button head screws (mounting gearmotors)

- 8 M3x30 Socket head screws (Front Motor Bracing, Rear Z carriage mounting)

- 2 M3x35 screws (Front Z belt tensioners)

- 1 M3x40 screw (Rear Z belt tensioner)

- 7 M3 heatset inserts (Front motor bracing, Z belt tensioners)

- 2 M5x35 screws and nuts (front idlers)

- 1 M5x25 screw and nut (rear idler)

- 1 5mmx30mm dowel (Rear Z Idler Shaft)

- 20 M5x10 screws and hammerhead nuts for mounting motor mounts and idlers

- 1 M3 x ? length screw - Length determined by motor chosen. Remove one screw from the nema17 motor housing and replace with longer screw for the rear motor stabilizer.

Mathematical Potato Idlers:

- 2 M4x20 Socket head screws and hammerhead nuts

- 2 M5x40 Button head screws

- 2 M5 nuts

- 2 M5x15 Button Head Screws

DoubleT XYZ Idlers

- Reuses existing fasteners for securing idler to Y extrusion

- 4 M3 heatset inserts

- 4 M3x30 Button head screws

- 2 M3x12 Socket head screws

- 2 M3x20 Socket head screws and hammerhead nuts

- 2 5mm x 25mm dowel

- 2 5mm x 20mm dowel

- 4 6mm x 3mm magnets

- genevamotion - ** - genevamotion - CAD design/ Modeling / Testing

- thiagolocatelli - ** - thiagolocatelli - CAD design / Modeling / Project Management

#####################################################################

# Z Stepper Settings

#####################################################################

## Z0 Stepper - Front Left

## Connected to MOTOR_3

## Endstop connected to M3-STOP

[stepper_z]

step_pin: PD7

dir_pin: !PD6

enable_pin: !PF10

# Rotation Distance for TR8x8 = 8, TR8x4 = 4, TR8x2 = 2

rotation_distance: 7.75

microsteps: 32

endstop_pin: PF5

## Z-position of nozzle (in mm) to z-endstop trigger point relative to print surface (Z0)

## (+) value = endstop above Z0, (-) value = endstop below

## Increasing position_endstop brings nozzle closer to the bed

## After you run Z_ENDSTOP_CALIBRATE, position_endstop will be stored at the very end of your config

#position_endstop: -0.5

## All builds use same Max Z

position_max: 250

position_min: -2.5

homing_speed: 8.0 # Leadscrews are slower than 2.4, 10 is a recommended max.

second_homing_speed: 3

homing_retract_dist: 3

## Make sure to update below for your relevant driver (2208 or 2209)

[tmc2209 stepper_z]

uart_pin: PF9

interpolate: False

run_current: 1.0

sense_resistor: 0.110

stealthchop_threshold: 0

07/23 - Added belt/stepper covers for inverted electronics by Panzarkatten