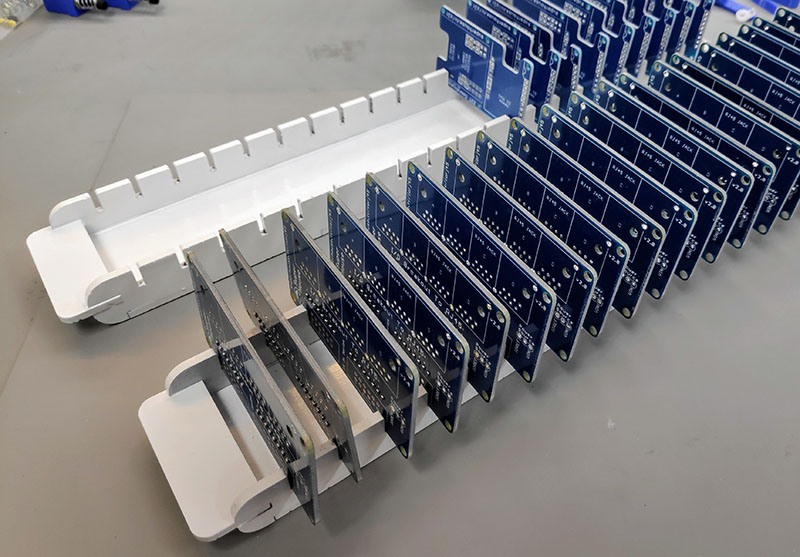

Simple tray design that can be used to safely store PCBs vertically during the production process.

The trays used by professional PCB assemblers are usually made from static-dissipative material that can also withstand immersion in an ultrasonic bath. My design isn't intended as a replacement for those, but just as a handy way for hobbyists to keep small batches of boards organised on the workbench or shelves.

This is much better than stacking populated PCBs on top of each other because it saves the parts and boards being scratched or damaged.

More information: https://www.superhouse.tv/vlog-69-easy-laser-cut-pcb-tray/

The Fusion360 project includes parameters so that you can tune the material thickness and the slot size to suit your own requirements. There is also a parameter for board width, but it's broken at the moment.

DXFs have also been included, for 3mm MDF and 2mm PCB slots.

For each tray, cut:

- 1 x base

- 2 x sides

- 2 x handles

Glue together as shown in the photo.

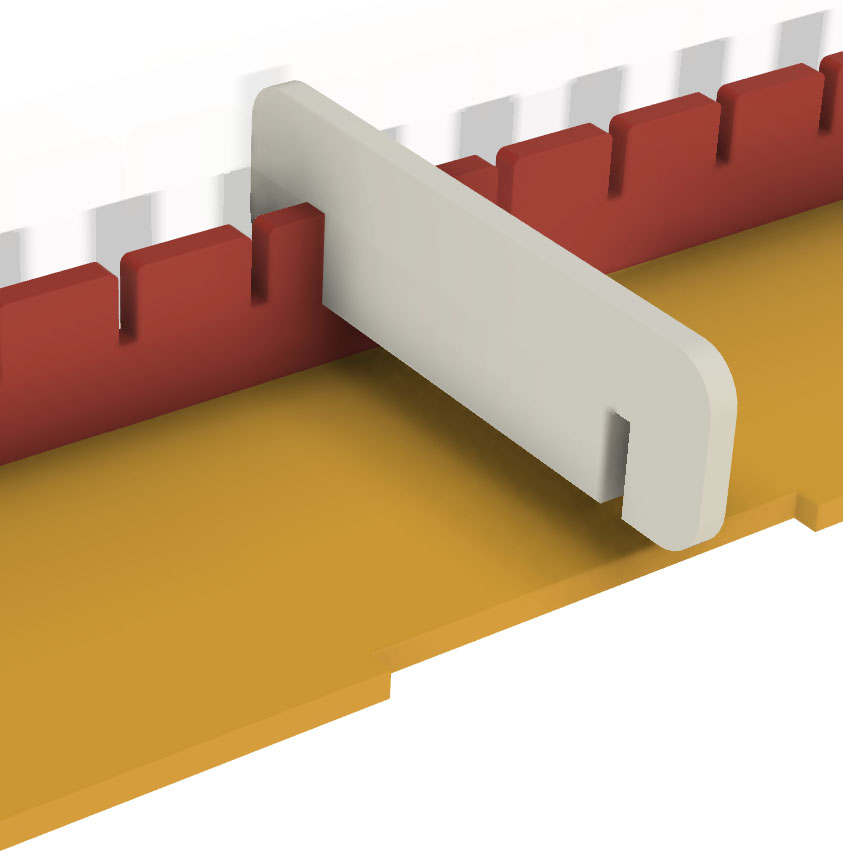

There is also a piece called "Assembly Jig" included in the design. This is not part of the tray: it's to hold the sides in the correct position while the glue is drying. Cut a few of the assembly jigs and slide them down onto the tray without glue. This prevents the sides from deforming. You can then either put rubber bands around the whole assembly, or sit weights on the assembly jigs to keep the parts sitting flat while the glue dries: