Non-intrusive IoT actuated door handle opener.

Because an in-door smart lock was out of the question in our rented apartment, and of course for the fun of it, I built this door handle opener. It straps to the door handle and can easily be removed without leaving a trace (just like the space heater I smartified).

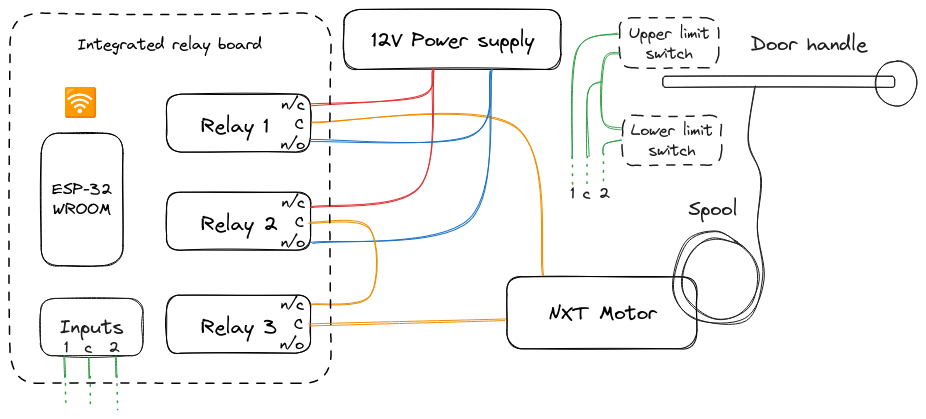

The actuator that pulls on the door handle is a brushed Lego Mindstorms NXT motor. This motor is powered by a generic 12V power supply I had lying around. And it is switched by an H-bridge-y circuit with three relays. Two of the relays switch the motor direction, and the third one cuts the motor power completely (see Motor Braking below).

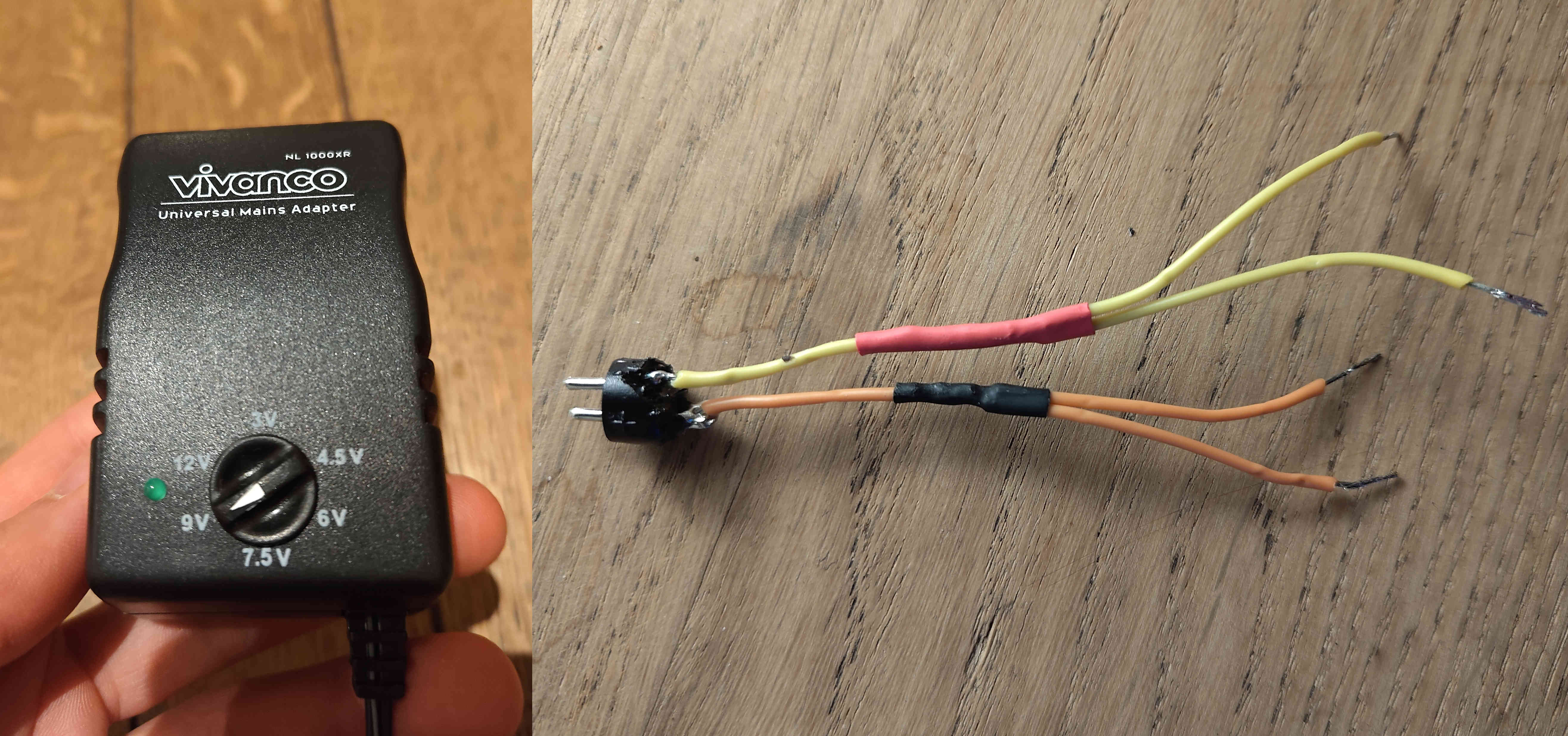

The generic 12V power supply and modified power connector for the relay terminals:

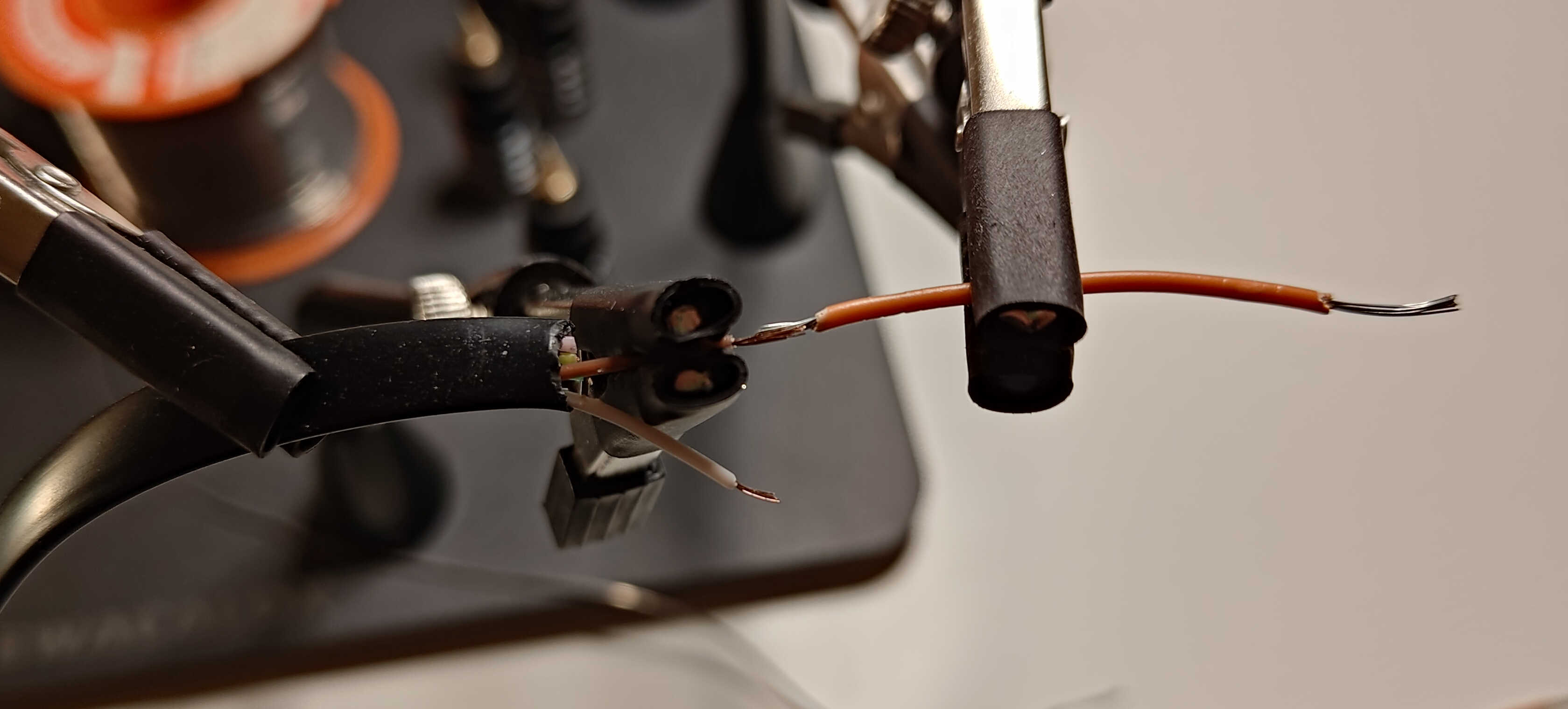

The modified RJ12-terminated telephone cable I used to connect the NXT motor to the relay board:

This video shows the first proof of concept I built. I used the Tasmota web UI over WiFi to activate the control script. The mess of aluminum foil on the left acts as the top and bottom limit switches (see Diagram below).

poc-demo.webm

This diagram shows the motor and relay board, as well as the two limit switches

that detect the end positions of the door handle:

Taking a brake from implementing my own embedded IoT software in C++ or Rust, I decided to try the Berry scripting built into the popular Tasmota IoT firmware. Berry is a simple dynamically typed embedded language with some hints of Lua and JavaScript. The entire control code is contained in door_handle_opener.be.

On demand, this script uses a small state machine to, first spool the string in to pull the door handle down, brake for a bit, and finally unspool the string again to release the handle again.

A big advantage of using Tasmota is that it comes with easy Home Assistant

integration. In the dashboard that looks like this:

FYI: I trigger the common apartment buzzer ('Benedendeur') with a Shelly Uni.

Before looking for the right motor, I calculated the torque it would need to

apply to the door handle. For this I first determined the weight required to

overcome the static friction of the handle and daytime latch (at

Measuring the force required to open the door handle:

This little experiment showed that I'd need a weight of at least

Looking though my parts bin, I didn't find any loose motors that could provide this kind of torque. At least not without gearing. Instead, I went with a Lego Mindstorms NXT motor, which makes gearing with Lego Technic parts easy.

From Philo's amazingly detailed NXT® motor

internals page, I learned

that the motor can handle a maximum of just over

If you exclusively want to switch the direction of a brushed DC motor, you really only need two relays. By switching the relays so that both leads of the motor are connected to the same polarity, the motor will brake (resisting approximately its own maximum torque). While this setup is fine, I didn't like the idea of the motor potentially damaging itself or the power supply when being turned. To add a fourth 'free spinning' mode besides, 'clockwise', 'counter-clockwise', and 'braking', I connected a third relay to one of the motor leads.

Video demonstrating free spin after hitting the top limit switch:

free-spin.webm

Soon...

(maybe)