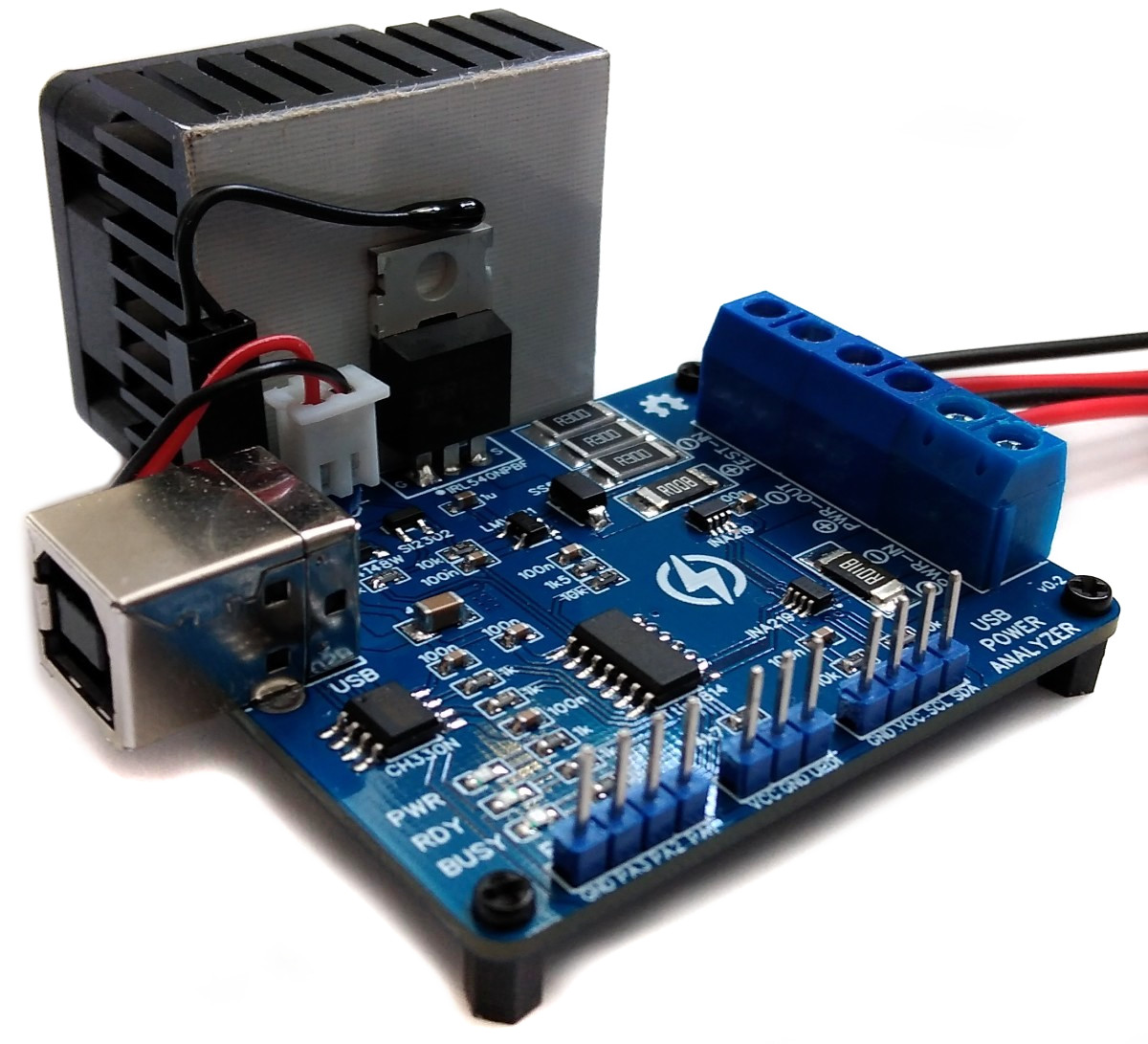

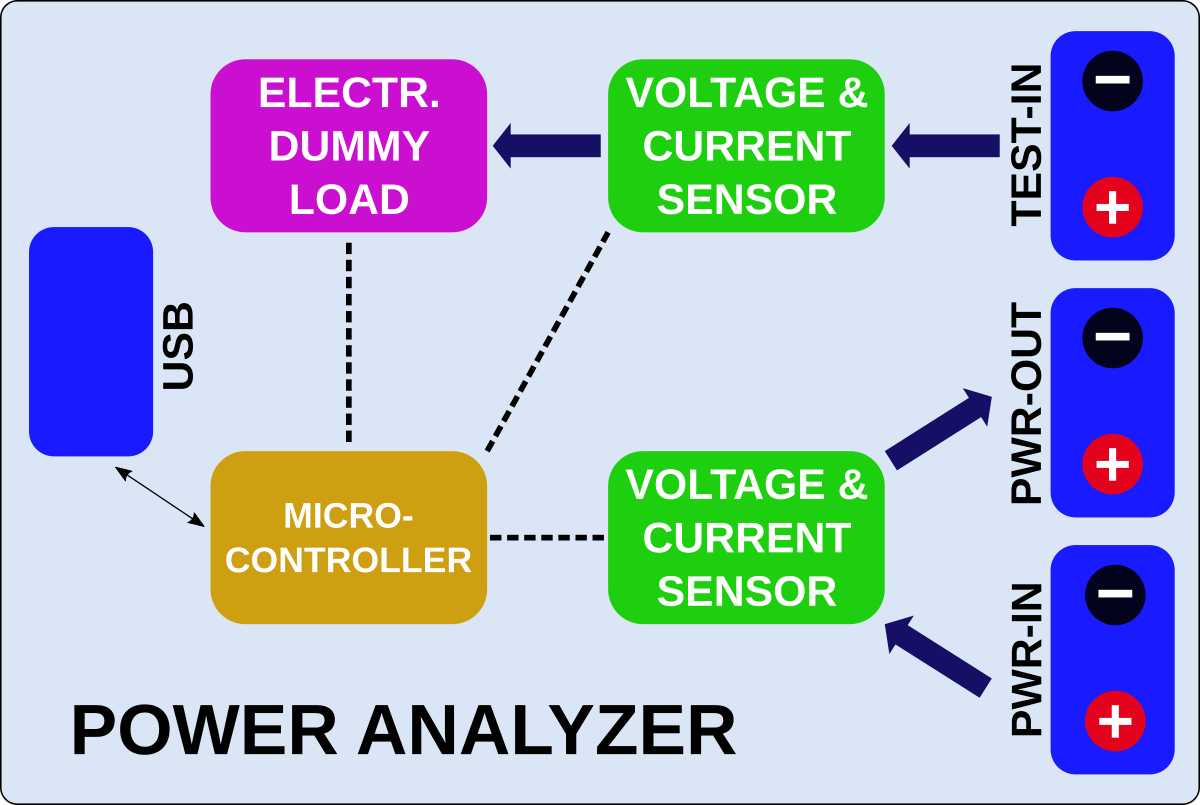

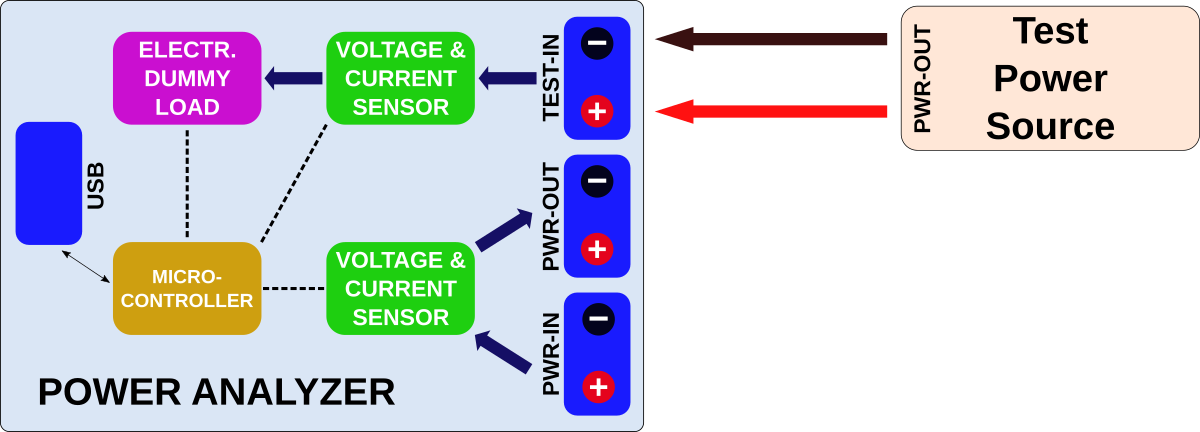

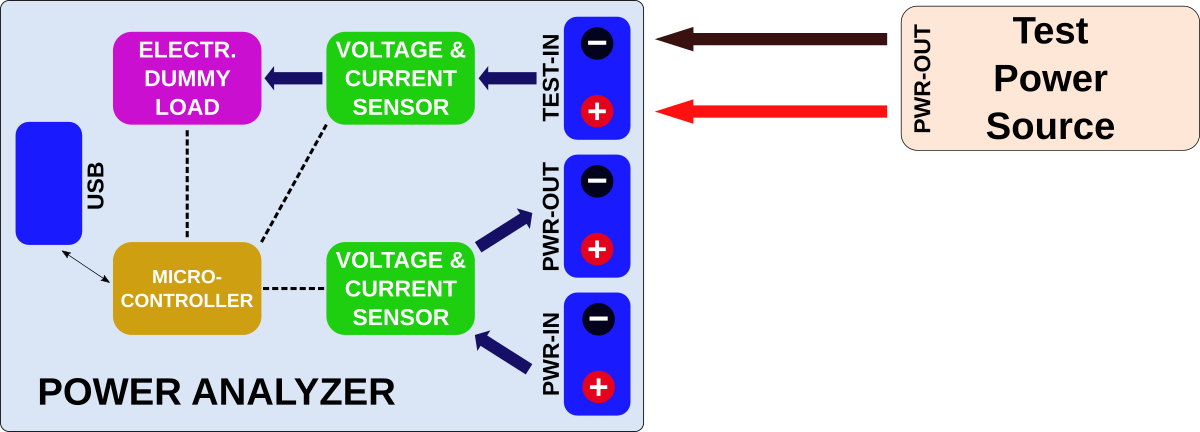

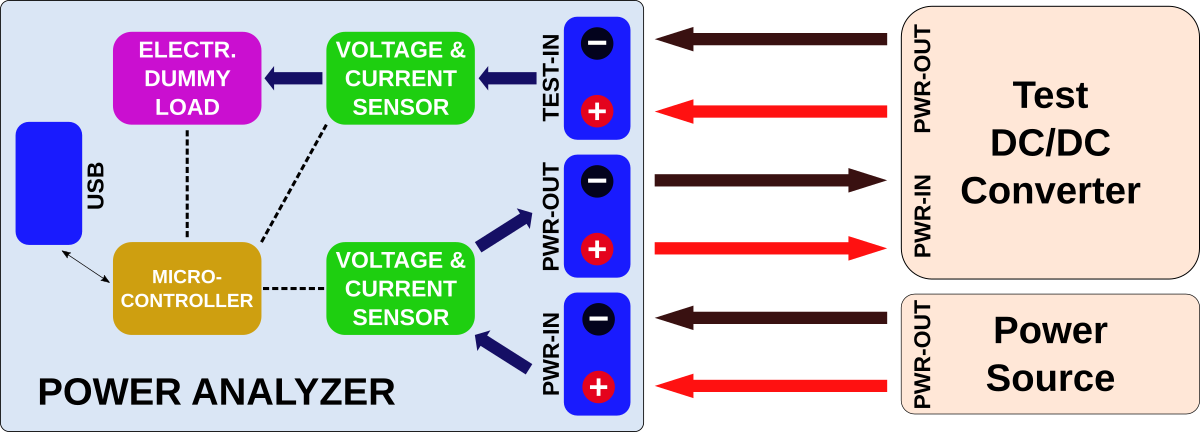

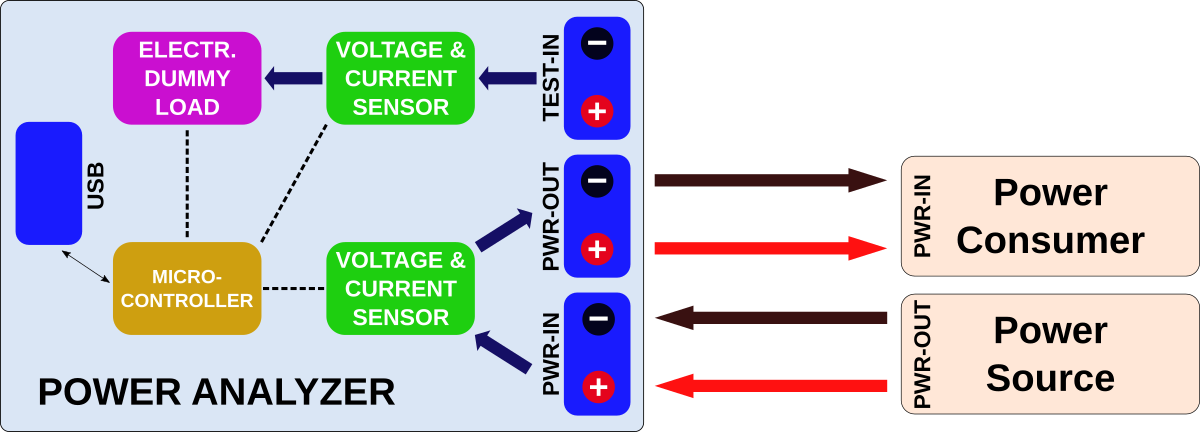

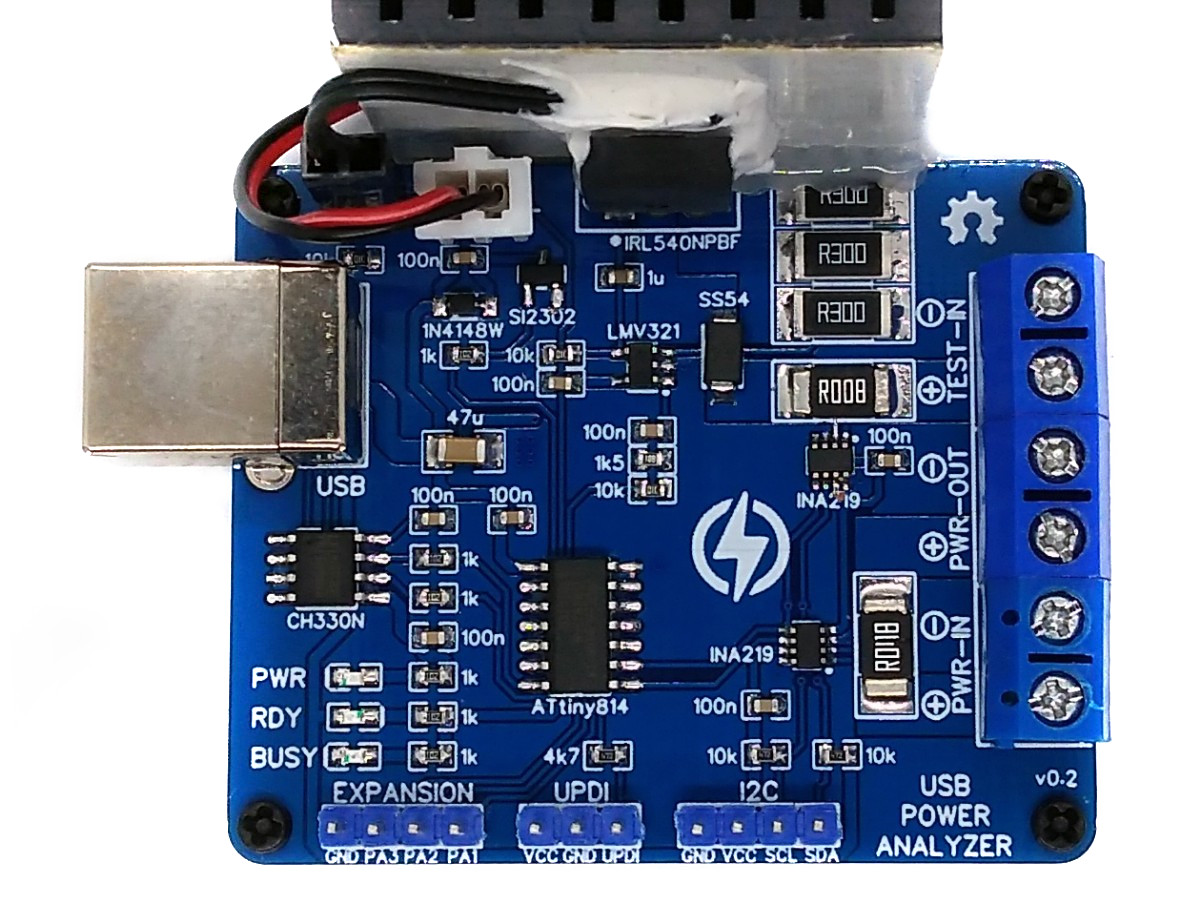

The Power Analyzer is a programmable electronic constant current dummy load with two high side voltage and current sensors for an automatic analysis of power supplys, DC/DC converters, voltage regulators, batteries, chargers, power consumers and others. The device can be controlled via USB serial interface using a serial monitor or the provided Python skripts. Data can be exported to spread sheet programs or directly be analyzed by the Python skript.

- Project Video (YouTube): https://youtu.be/q4-aywmeqHs

- Design Files (EasyEDA): https://easyeda.com/wagiminator/y-attiny814-power-analyzer

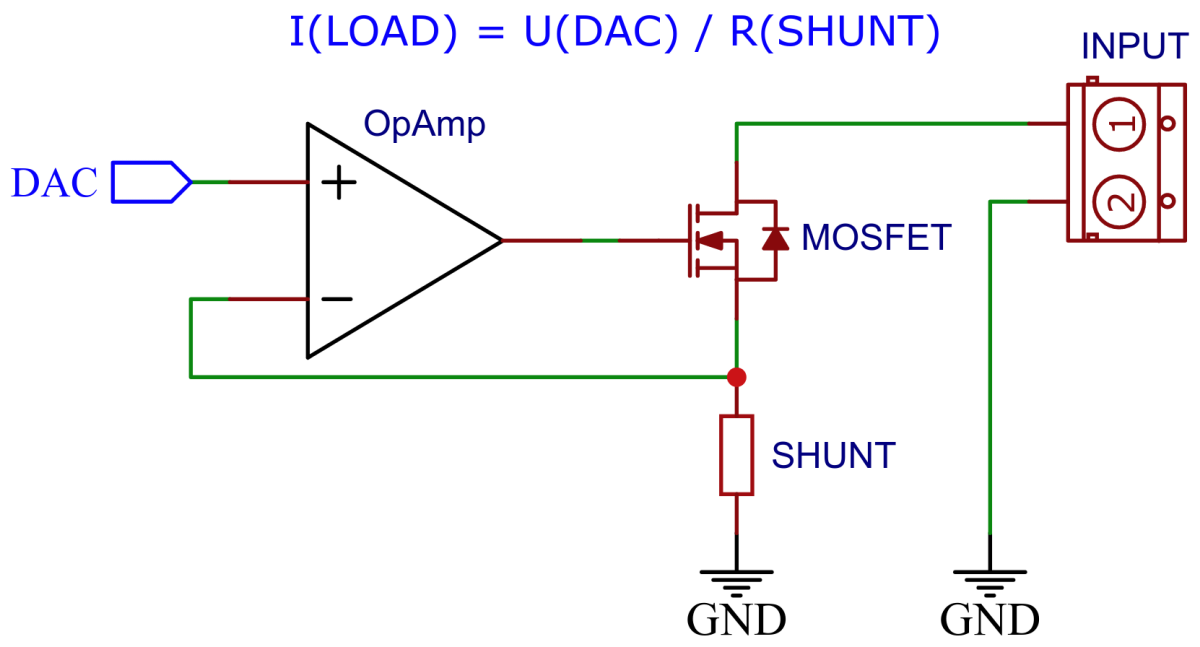

The electronic load control circuit, which essentially consists of an operational amplifier, a MOSFET and a shunt resistor, ensures that the same current flows regardless of the voltage applied.

For this purpose, a 100mΩ shunt consisting of three 300mΩ resistors in parallel for proper heat dissipation is located in the load circuit, via which the current is measured. The LMV321 rail-to-rail OpAmp compares this with the target value, which is specified by the ATtiny's internal digital to analog converter (DAC) via a voltage divider and accordingly controls the gate of an IRL540N logic level power MOSFET, which in turn adjusts the current through its internal resistance set in this way.

Voltage and current are measured via a high side 8mΩ shunt resistor connected to an INA219 with a resolution of 4mV/1mA. A second INA219 is connected to another 8mΩ shunt resistor between the PWR-IN and PWR-OUT terminal. The INA219 is a current shunt and power monitor with an I²C-compatible interface. The device monitors both shunt voltage drop and bus supply voltage, with programmable conversion times and filtering. A programmable calibration value, combined with an internal multiplier, enables direct readouts of current in amperes. The selected shunt resistance of 8mΩ enables both a very small influence on the circuit and a measurement with a resolution of 1mA. For an accurate measurement, a shunt resistor with a low tolerance (1% or better) should be selected.

The Power Analyzer is connected via USB to a PC or a RaspberryPi. Commands to the Analyzer can be sent via a serial monitor or by the GUI-based Python skript. The Analyzer has different built-in automatic test algorithms. The collected data is sent back via the serial interface/USB to the PC/RaspberryPi. The ATtiny814 constantly measures power and temperature of the heatsink. It controls the fan and cuts off the load when the temperature gets too hot.

The ATtiny814 controls the electronic dummy load with its internal digital to analog converter (DAC). All of its 5 internal reference voltages are being used in order to get the maximum accuracy and resolution of the DAC. The DAC is connected to an OpAmp which acts as a unity gain amplifier controlling the resistance of the MOSFET.

// DAC reference voltages (load current = DAC voltage * R16 / (R15 + R16) / R_SHUNT)

// Reference voltages: 0.55V, 1.1V, 1.5V, 2.5V, 4.3V

const uint8_t DACREF[] = {0x00, 0x01, 0x04, 0x02, 0x03}; // CTRLA.DAC0REFSEL values

const uint16_t DACCUR[] = { 717, 1434, 1956, 3260, 5608}; // max current in mA

uint8_t DACreference = 0; // start with 0.55V reference

// Setup the digital to analog converter (DAC)

void DAC_init(void) {

VREF_CTRLB |= VREF_DAC0REFEN_bm; // enable DAC reference

_delay_us(25); // wait for Vref to start up

pinDisable(DAC_PIN); // disable digital input buffer

DAC0.CTRLA = DAC_ENABLE_bm // enable DAC

| DAC_OUTEN_bm; // enable output buffer

}

// Set the lowest reference voltage possible for the DAC to meet the load current

void DAC_setReference(uint16_t current) {

DACreference = 0;

if(current > DACCUR[4]) current = DACCUR[4];

while(current > DACCUR[DACreference]) DACreference++;

DAC0.DATA = 0;

VREF_CTRLA &= 0xf8;

VREF_CTRLA |= DACREF[DACreference];

_delay_us(25);

}

// Set the DAC within the selected reference to the specified load current

void DAC_set(uint16_t current) {

if(current > 5000) current = 5000;

if(current > DACCUR[DACreference]) DAC0.DATA = 255;

else DAC0.DATA = (uint32_t)255 * current / DACCUR[DACreference];

}

// Set the DAC and its reference to the specified load current

void DAC_setLoad(uint16_t current) {

DAC_setReference(current); // set suitable voltage reference

DAC_set(current); // set DAC according to desired load

}

// Reset the load to minimum

void DAC_resetLoad(void) {

DAC_setLoad(0); // reset the load to minimum

}Commands sent via the USB-to-serial converter are stored in a 16-byte command buffer. This is done via interrupts so that load and fan control, for example, can continue to run in parallel. As soon as a command has been completely received, the CMD_compl flag is set. The parser then extracts the command and the arguments.

// UART definitions and macros

#define UART_BAUD 115200

#define UART_BAUD_RATE 4.0 * F_CPU / UART_BAUD + 0.5

#define UART_ready() (USART0.STATUS & USART_DREIF_bm)

// UART command buffer and pointer

#define CMD_BUF_LEN 16 // command buffer length

volatile uint8_t CMD_buffer[CMD_BUF_LEN]; // command buffer

volatile uint8_t CMD_ptr = 0; // buffer pointer for writing

volatile uint8_t CMD_compl = 0; // command completely received flag

// UART init

void UART_init(void) {

pinOutput(TXD_PIN); // set TX pin as output

USART0.BAUD = UART_BAUD_RATE; // set BAUD

USART0.CTRLA = USART_RXCIE_bm; // enable RX interrupt

USART0.CTRLB = USART_RXEN_bm // enable RX

| USART_TXEN_bm; // enable TX

}

// UART transmit data byte

void UART_write(uint8_t data) {

while(!UART_ready()); // wait until ready for next data

USART0.TXDATAL = data; // send data byte

}

// UART RXC interrupt service routine (read command via UART)

ISR(USART0_RXC_vect) {

uint8_t data = USART0.RXDATAL; // read received data byte

if(!CMD_compl) { // command still incomplete?

if(data != '\n') { // not command end?

CMD_buffer[CMD_ptr] = data; // write received byte to buffer

if(CMD_ptr < (CMD_BUF_LEN-1)) CMD_ptr++; // increase and limit pointer

} else if(CMD_ptr) { // received at least one byte?

CMD_compl = 1; // set command complete flag

CMD_buffer[CMD_ptr] = 0; // write string terminator

CMD_ptr = 0; // reset pointer

}

}

}

// Wait for, read and parse command string

void CMD_read(void) {

while(!CMD_compl) updateLoadSensors(); // maintain fan control

uint8_t i = 0;

cmd = CMD_buffer[0];

argument1 = 0; argument2 = 0;

while(CMD_buffer[++i] == ' ');

while(CMD_buffer[i] > ' ') argument1 = argument1 * 10 + CMD_buffer[i++] - '0';

while(CMD_buffer[i] == ' ') i++;

while(CMD_buffer[i] != 0) argument2 = argument2 * 10 + CMD_buffer[i++] - '0';

CMD_compl = 0;

}- Open your Arduino IDE.

- Make sure you have installed megaTinyCore.

- Go to Tools -> Board -> megaTinyCore and select ATtiny1614/1604/814/804/414/404/214/204.

- Go to Tools and choose the following board options:

- Chip: ATtiny1614 or ATtiny814

- Clock: 20 MHz internal

- Leave the rest at the default settings.

- Connect your programmer to your PC and to the UPDI header on the board.

- Go to Tools -> Programmer and select your UPDI programmer.

- Go to Tools -> Burn Bootloader to burn the fuses.

- Open the sketch and click Upload.

- Connect your programmer (jtag2updi or SerialUPDI) to your PC and to the UPDI header on the board.

- Make sure you have installed the latest avr-gcc toolchain.

- Open a terminal.

- Navigate to the folder with the makefile and the sketch.

- Run

DEVICE=attiny814 PROGRMR=serialupdi PORT=/dev/ttyUSB0 make installto compile, burn the fuses and upload the firmware (change DEVICE, PROGRMR and PORT accordingly).

Python needs to be installed on your PC in order to use the GUI-based Python application. Most Linux distributions already include this. Windows users can follow these instructions. In addition PySerial and Tkinter (8.6 or newer) must be installed. However, these are already included in most Python installations.

Windows users may also need to install a driver for the CH330N/CH340N USB to serial adapter. This is not necessary for Linux or Mac users.

The device can be operated in two ways:

- Using a serial monitor: Test algorithms can be started by sending the corresponding command via a serial monitor. The collected data will be displayed in the serial monitor and can be exported to a spread sheet program for further analysis.

- Using the GUI-based Python application: This is the easy way. Everything should be self-explanatory. All following example pictures are created by this application.

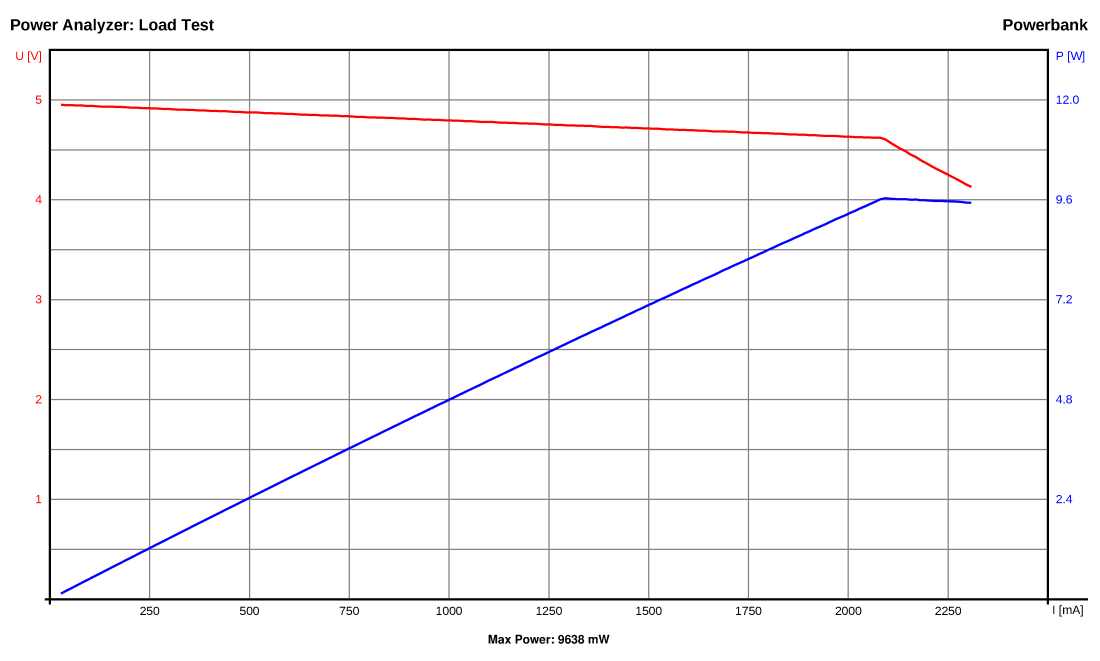

- Command: "l maxloadcurrent[mA: 17..5000] minloadvoltage[mV: 0..26000]"

- Example: "l 2500 4200"

- The Power Analyzer continuously increases the load from 17 mA up to maxloadcurrent. It stops automatically if the voltage drops below minloadvoltage. It continuously transmits the measured values via the serial interface in the format: current[mA] voltage[mV] power[mW] (seperated by the SEPERATOR string).

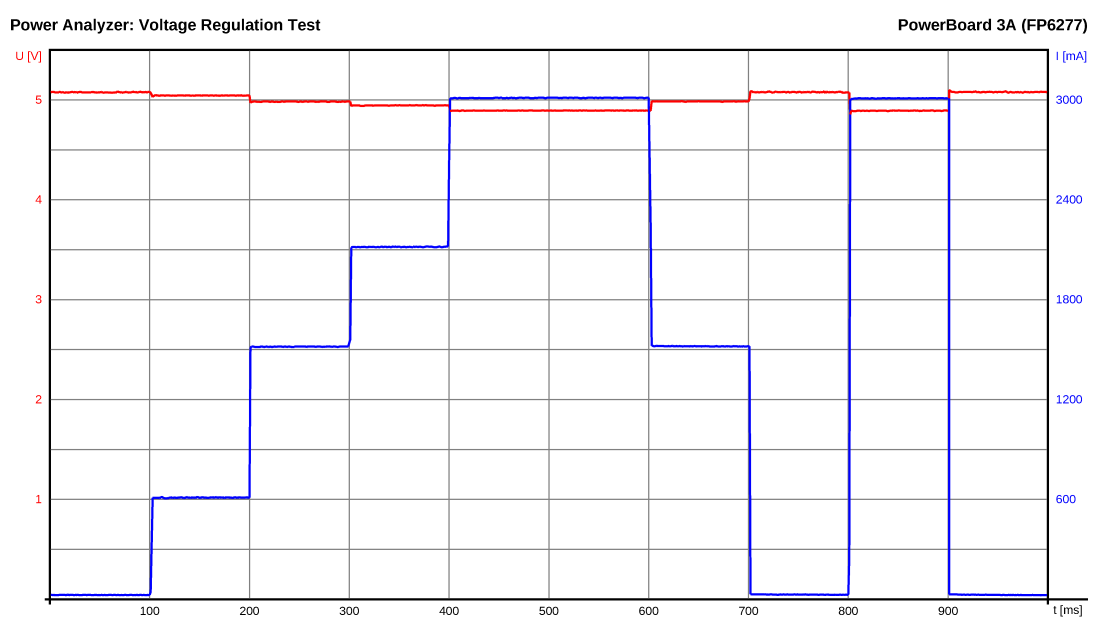

- Command: "g maxloadcurrent[mA: 17..5000]"

- Example: "g 3000"

- The Power Analyzer changes rapidly the load between 17 mA and maxloadcurrent. It continuously transmits the measured values via the serial interface in the format: time[ms] current[mA] voltage[mV] (seperated by the SEPERATOR string).

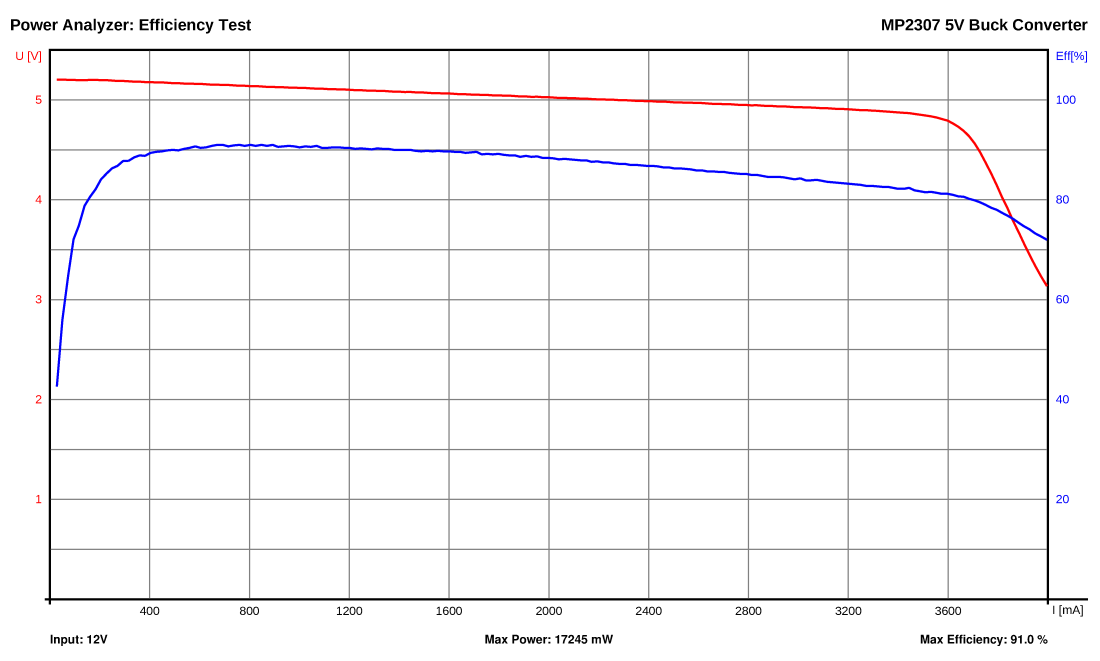

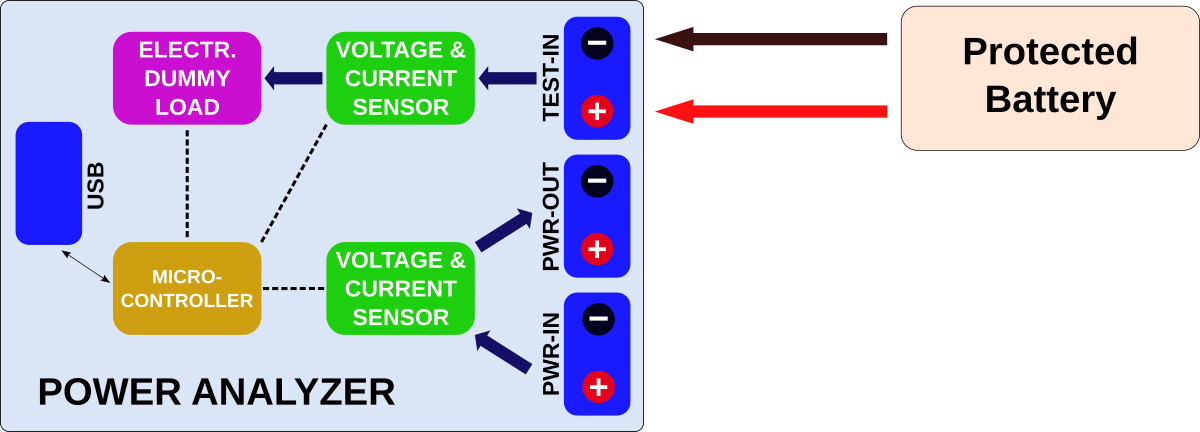

- Command: "e maxloadcurrent[mA: 17..5000] minloadvoltage[mV: 0..26000]"

- Example: "e 4000 2500"

- The Power Analyzer continuously increases the load from 17 mA up to maxloadcurrent. It stops automatically if the voltage at TEST-IN drops below minloadvoltage. It continuously transmits the measured values via the serial interface in the format: current[mA] voltage[mV] efficiency[% * 10] (seperated by the SEPERATOR string).

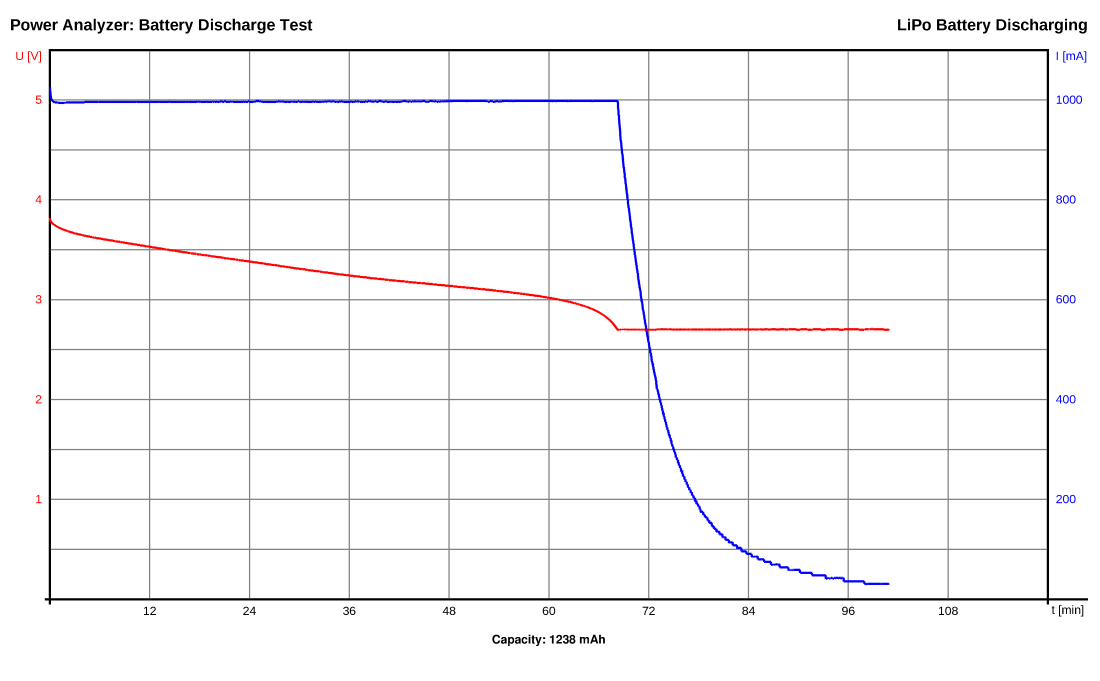

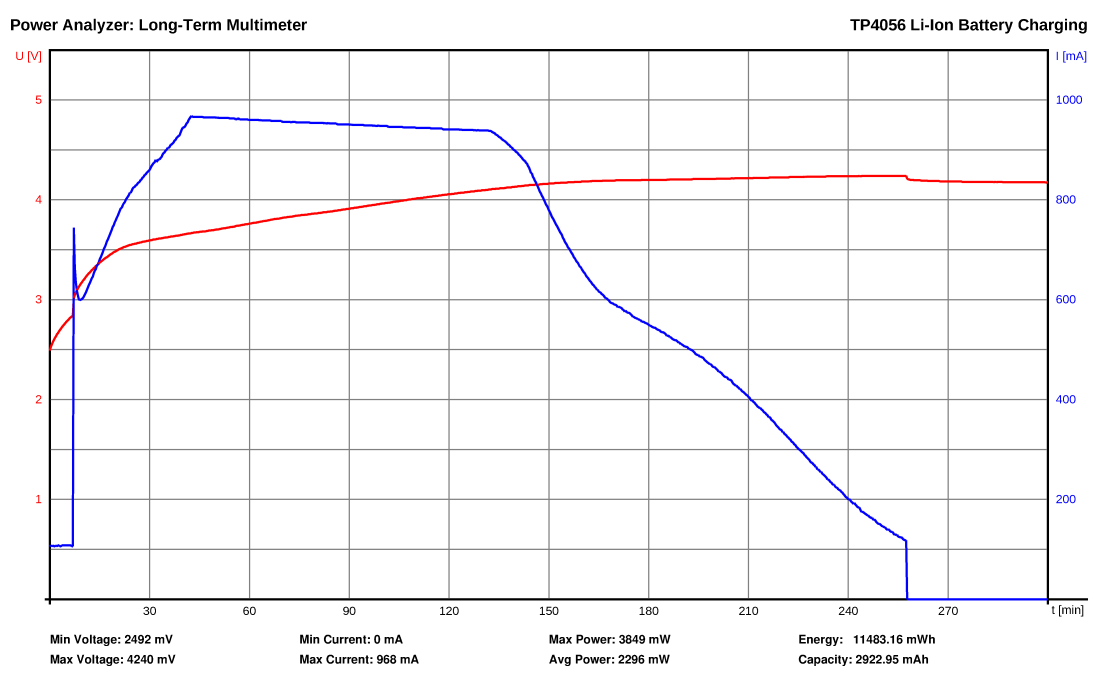

- Command: "b maxloadcurrent[mA: 17..5000] minloadvoltage[mV: 0..26000]"

- Example: "l 1000 2700"

- The Power Analyzer sets a constant current load of maxloadcurrent. If the voltage drops below minloadvoltage it constantly decreases the load to maintain minloadvoltage. It stops automatically if the load current drops to 0mA. It continuously transmits the measured values via the serial interface in the format: time[s] current[mA] voltage[mV] capacity[mAh] (seperated by the SEPERATOR string).

- Command: "m interval[ms: 2..65535] duration[s: 1..65535]"

- Example: "m 18000 18000"

- The Power Analyzer measures voltage, current and power delivered to the test device at every interval for a total of duration. It continuously transmits the measured values via the serial interface in the format: time[ms] current[mA] voltage[mV] (seperated by the SEPERATOR string).

| Command | Function |

|---|---|

| "i" | transmits indentification string ("Power Analyzer") |

| "v" | transmits firmware version number |

| "x" | terminate current test program |

| "s loadcurrent[mA]" | set load to a constant current of loadcurrent |

| "r" | reset the load to minimum |

| "t" | read current and voltage of both sensors and transmit them |

- Use a good heatsink with a 5V fan for the MOSFET! Attach a 10K 3950B NTC thermistor to the heatsink close to the MOSFET!

- Be careful with high power loads! Make some tests to figure out what can be achieved with your cooling solution!

- Due to the limitations of the cheap OpAmp and the internal DAC the minimum load current is around 17mA. You can choose a better OpAmp if you like (must have same pinout, must be rail-to-rail and unity gain stable), but for most cases this is not necessary.

- The maximum load current is 5A, however for small voltages it might be less.

- The maximum PWR-IN/PWR-OUT current is 8A.

- Do not exceed the maximum voltage of 26V on all connectors !

- In order to make the design much simpler all connectors including USB share a common ground. Keep this in mind when making your test setup in order to avoid ground loops or shorts. Using a USB isolator between the Analyzer and your PC is not a bad idea!

- The CH330N can be replaced with a CH340N. Windows users may need to install a driver. This is not necessary for linux users.

- You need a UPDI programmer for uploading the firmware. You can find one in my projects or you can easily build one following this guide.

- The Python skript was only tested on Linux, but it should also work on other operating systems.

This work is licensed under Creative Commons Attribution-ShareAlike 3.0 Unported License. (http://creativecommons.org/licenses/by-sa/3.0/)